Magnetic covalent bond type chitosan-based modified flocculant and preparation method and application thereof

A technology of chitosan and covalent bond, which is applied in the field of magnetic covalent bond chitosan-based modified flocculant and its preparation, can solve the problem of high price of graphene oxide, unfavorable large-scale application, poor flocculation effect, etc. problems, to achieve good chemical stability, broaden the applicable range of pH, and improve the demulsification ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The invention provides a method for preparing a magnetic covalent bond type chitosan-based modified flocculant, comprising the following steps:

[0041] (1) The magnetic Fe 3 o 4 The nanoparticles were dispersed in a mixed solvent of ethanol and water to obtain Fe 3 o 4 Dispersions;

[0042] (2) the Fe 3 o 4 The dispersion liquid is mixed with ammonia water to obtain basic Fe 3 o 4 Dispersions;

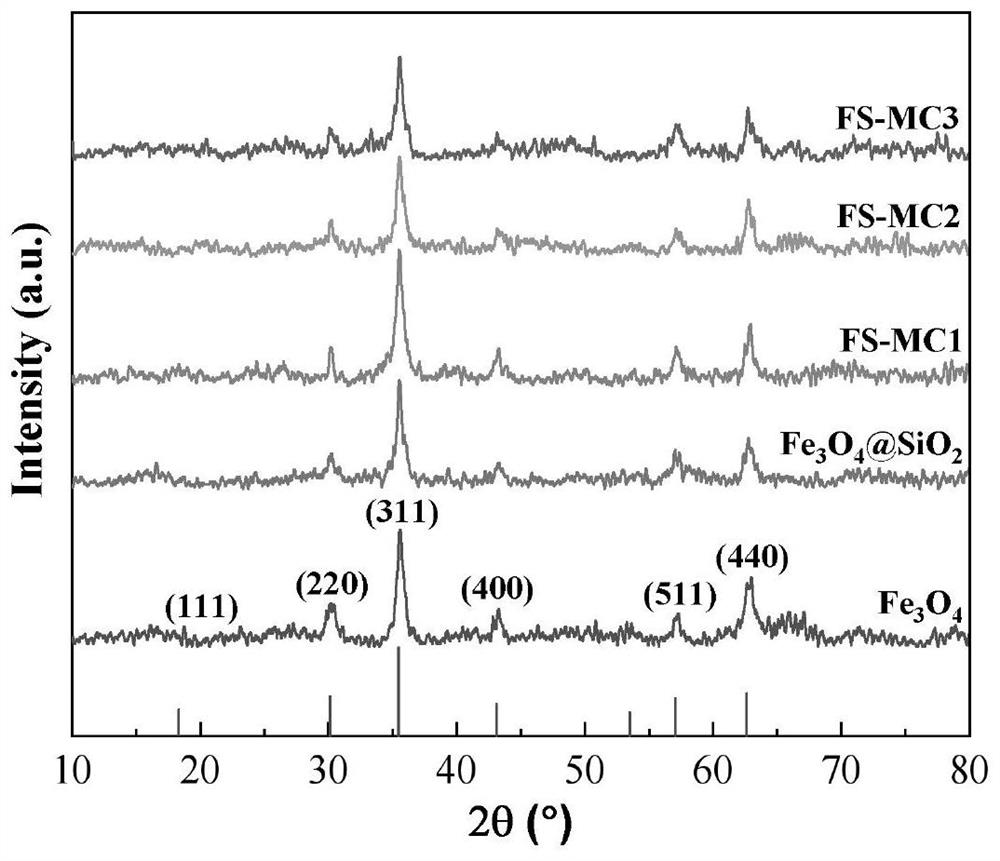

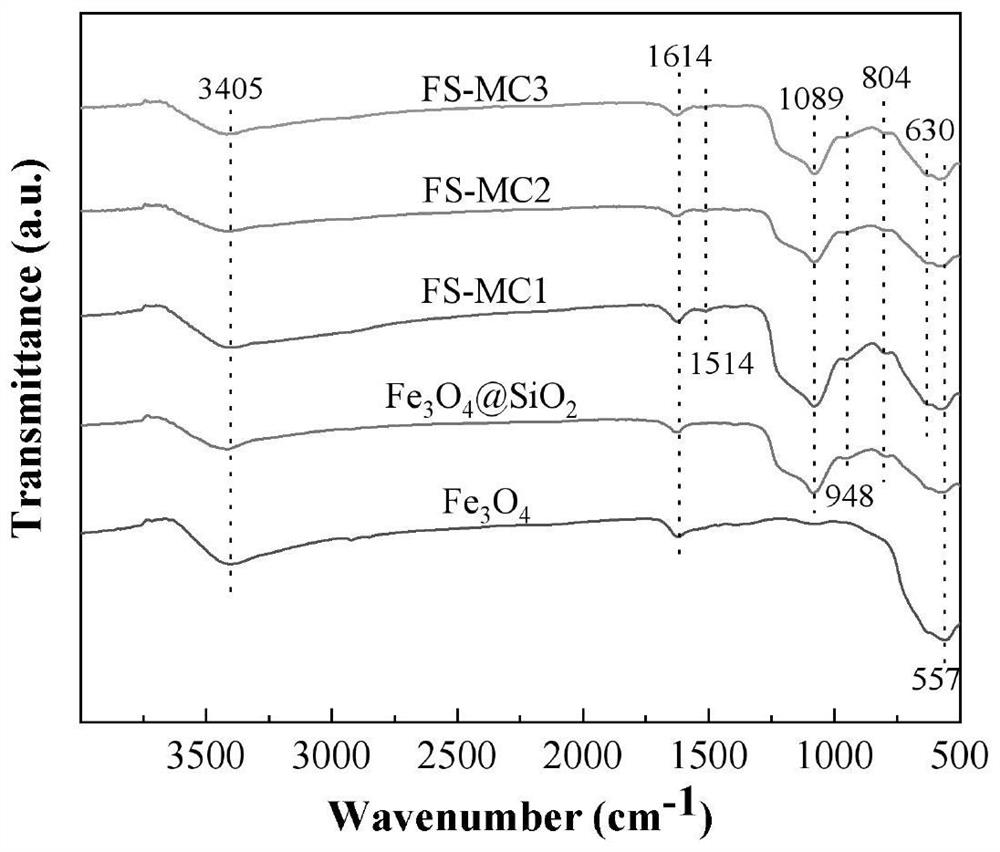

[0043] (3) the basic Fe 3 o 4 The dispersion is mixed with tetraethyl orthosilicate reaction to obtain Fe 3 o 4 @SiO 2 Material;

[0044] (4) the Fe 3 o 4 @SiO 2 Materials, ethanol and silane coupling agent are mixed for the first graft copolymerization reaction to obtain silane coupling agent grafted Fe 3 o 4 @SiO 2 ;

[0045] (5) the silane coupling agent grafted Fe 3 o 4 @SiO 2 , water, modified chitosan (MCS) and initiator are mixed to carry out the second graft copolymerization reaction, obtain magnetic covalent bond type chitosan-based modified fl...

Embodiment 1

[0061] (1) 2g magnetic Fe 3 o 4 Nanoparticles were added to a mixed solution of 200mL absolute ethanol and 50mL deionized water, and ultrasonicated for 20min until the magnetic nuclei were uniformly dispersed to obtain Fe 3 o 4 Dispersions;

[0062] (2) Add 8mL ammonia water to the Fe in step (1) 3 o 4 In the dispersion liquid, ultrasonic 10min to make it fully mixed, so that the pH of the mixed solution = 9 ~ 10, to obtain basic Fe 3 o 4 Dispersions;

[0063] (3) the obtained basic Fe in step (2) 3 o 4 Place the dispersion in a water bath, keep the temperature at 40°C, add 3 mL of tetraethylorthosilicate dropwise using a peristaltic pump, and stir electrically at 400 rpm for 6 hours. After the reaction is complete, magnetically separate the mixture. After washing with water, ethanol and deionized water for 3 times, vacuum drying at 60 °C for 12 h, Fe 3 o 4 @SiO 2 Material;

[0064] (4) the obtained Fe in step (3) 3 o 4 @SiO 2 Add 50mL of absolute ethanol, plac...

Embodiment 2

[0068] (1) 2g magnetic Fe 3 o 4 Nanoparticles were added to a mixed solution of 200mL absolute ethanol and 50mL deionized water, and ultrasonicated for 20min until the magnetic nuclei were uniformly dispersed to obtain Fe 3 o 4 Dispersions;

[0069] (2) Add 8mL ammonia water to the Fe in step (1) 3 o4 In the dispersion liquid, ultrasonic 10min to make it fully mixed, so that the pH of the mixed solution = 9 ~ 10, to obtain basic Fe 3 o 4 Dispersions;

[0070] (3) the obtained basic Fe in step (2) 3 o 4 Place the dispersion in a water bath, keep the temperature at 40°C, add 3 mL of tetraethylorthosilicate dropwise using a peristaltic pump, and stir electrically at 400 rpm for 6 hours. After the reaction is complete, magnetically separate the mixture. After washing with water, ethanol and deionized water for 3 times, vacuum drying at 60 °C for 12 h, Fe 3 o 4 @SiO 2 Material;

[0071] (4) the obtained Fe in step (3) 3 o 4 @SiO 2 Add 50mL of absolute ethanol, place ...

PUM

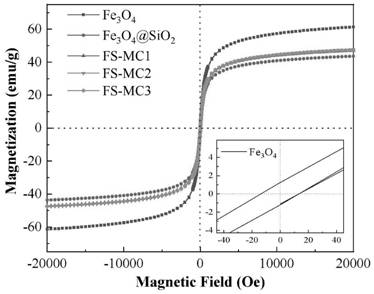

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com