Modular filter

A filter device, modular technology, applied in harmonic reduction devices, AC networks to reduce harmonics/ripples, etc., can solve the problem of no treatment equipment, increased energy consumption grid pollution, power factor compensation cabinet compensation capacitor loss, etc. problems, to achieve the effect of simple winding method, prevention of harmonics, and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

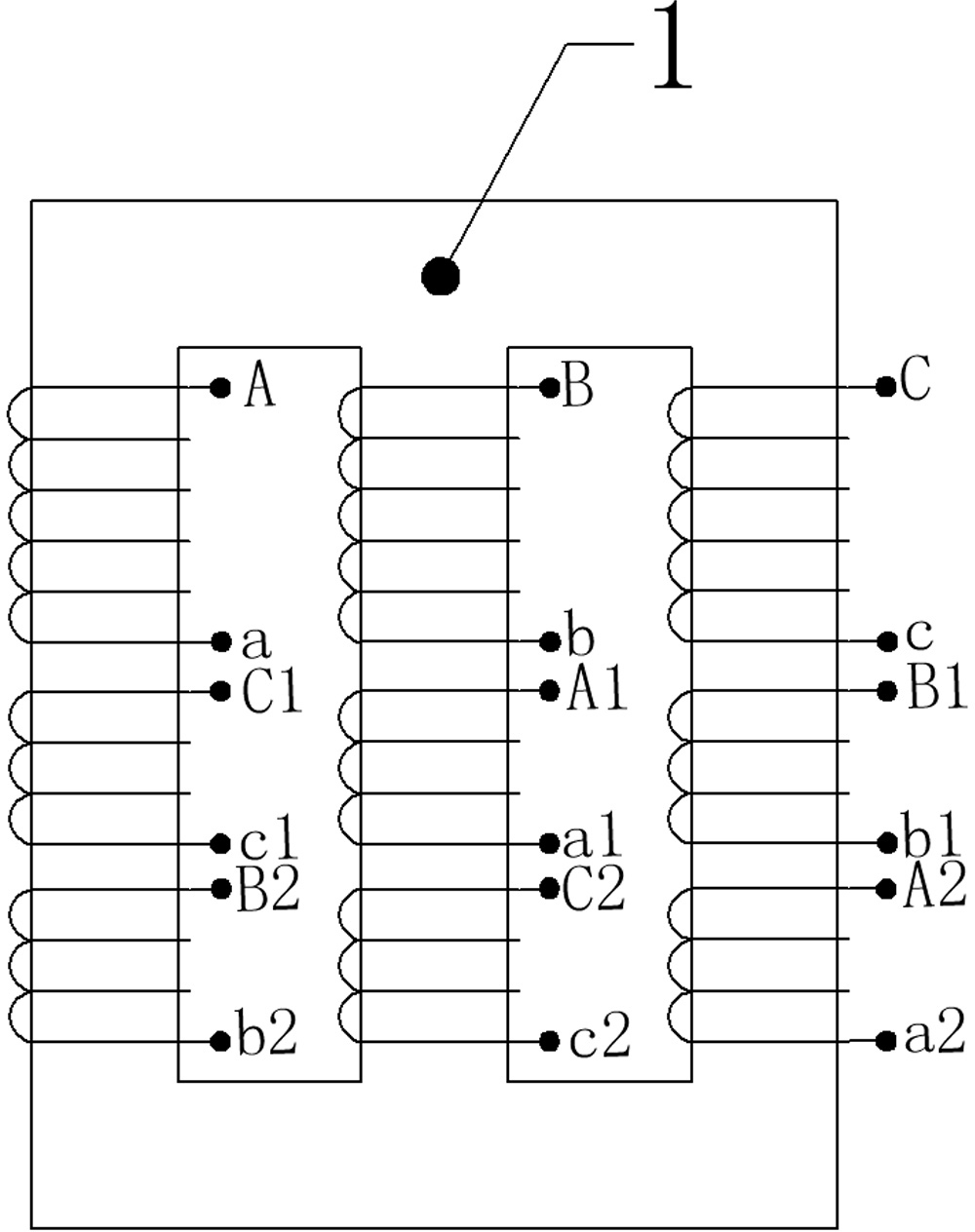

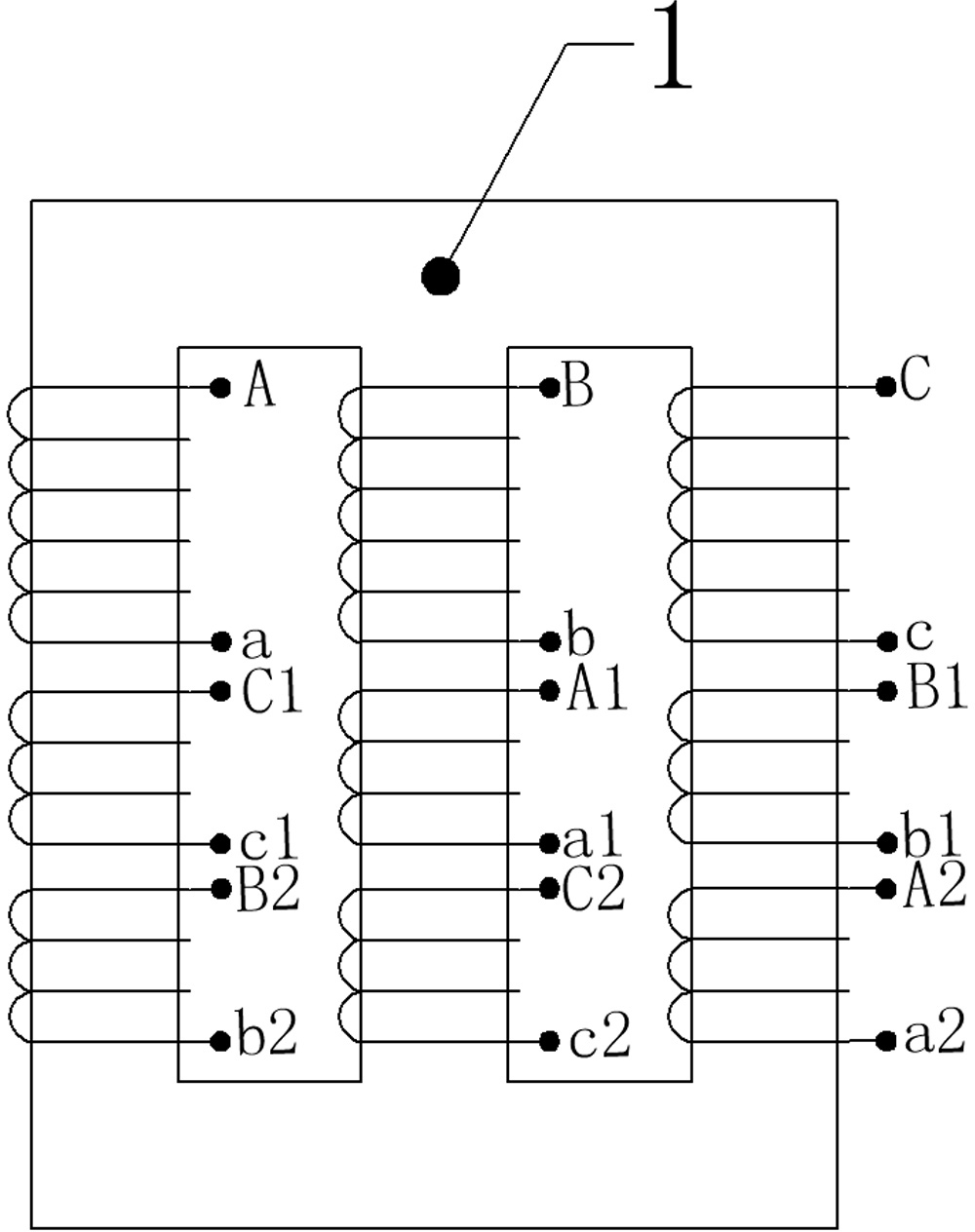

[0012] Such as figure 1 As shown, the modular filtering device of the present invention is composed of a winding core 1 and a three-phase winding ABC. The winding core 1 is formed by stacking multiple steel sheets. The winding core 1 has three winding columns. The third phase of the three-phase line The first winding is respectively wound on the three winding columns in sequence. The second winding of the three-phase line is that the A phase is wound under the B phase, the B phase is wound under the C phase, and the C phase is wound under the A phase. The third winding of the line is that phase A is wound under phase C, phase B is wound under phase A, and phase C is wound under phase B; generally, the first, second and third windings of phase A are wound first, and then The first, second and third windings of phase B, and then the first, second and thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com