Six-guide-wheel multi-line cutter

A multi-wire cutting machine and guide wheel technology, applied in the direction of grinding machines, fine working devices, working accessories, etc., can solve the problems of inability to cut, long time, high economic cost, etc., to achieve reduced time cost, good action consistency, winding Line mode simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings. It should be noted that this embodiment is based on the technical solution, and provides detailed implementation and specific operation process, but the protection scope of the present invention is not limited to the present invention. Example.

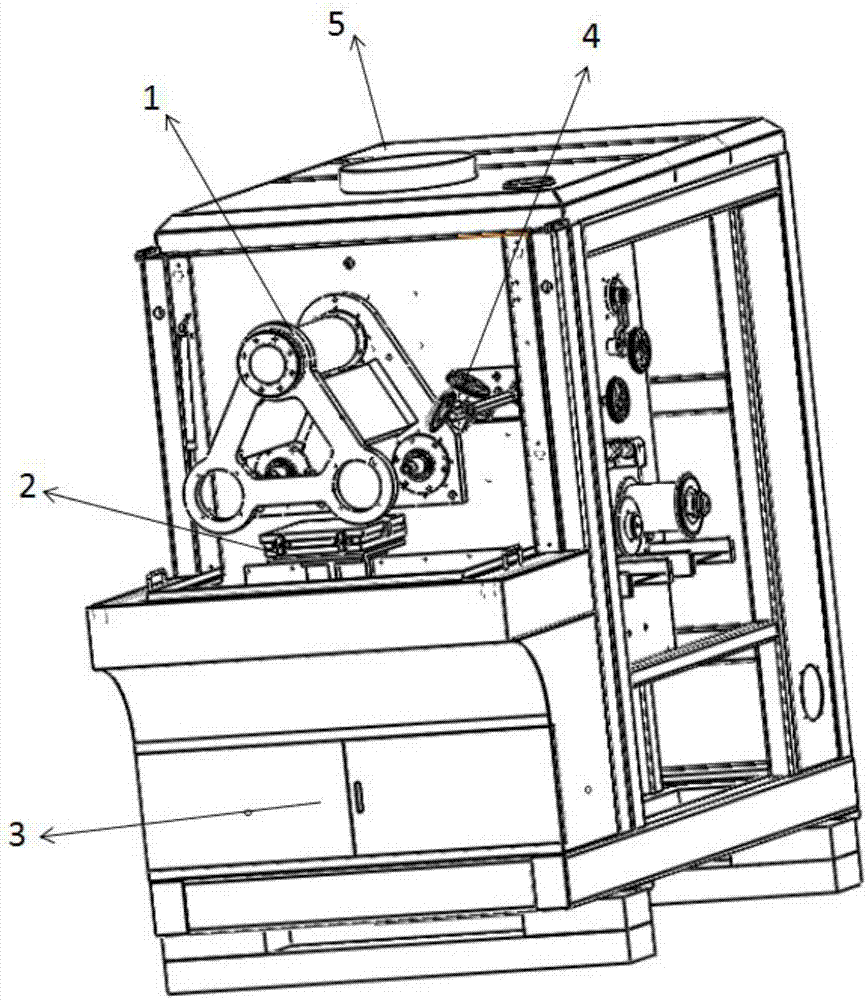

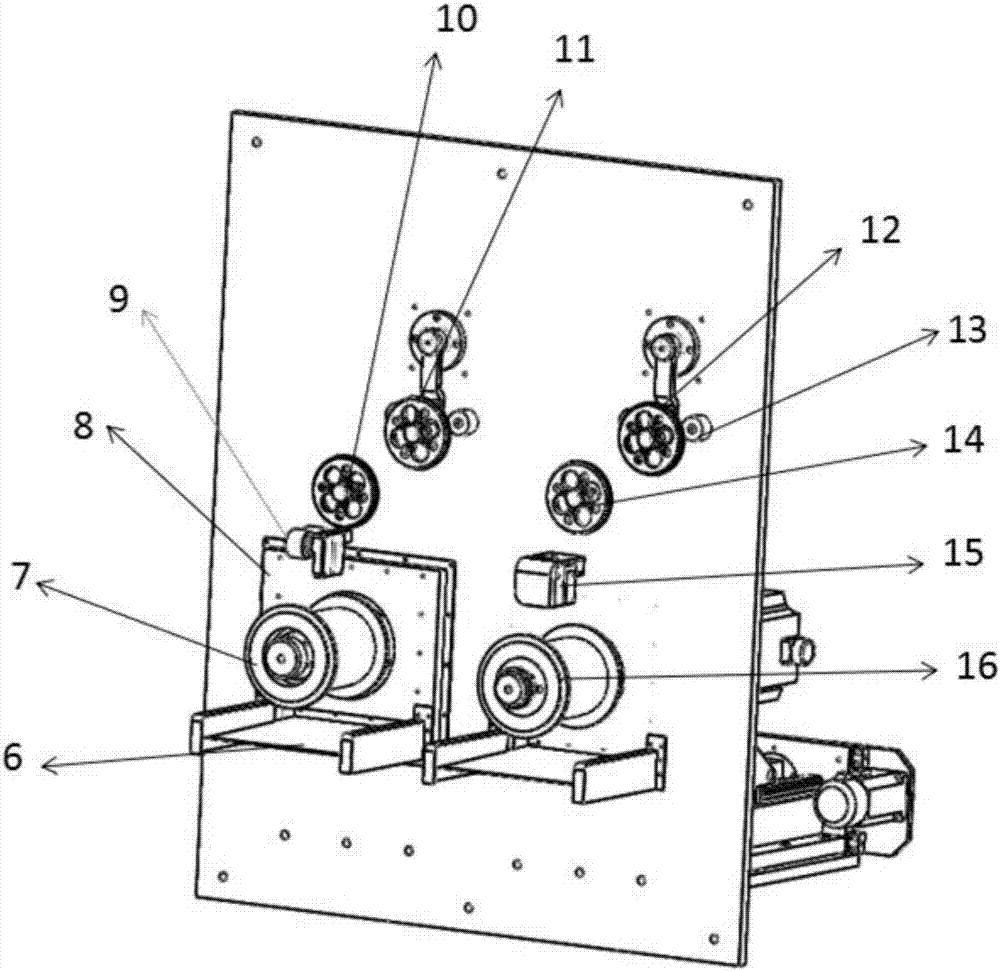

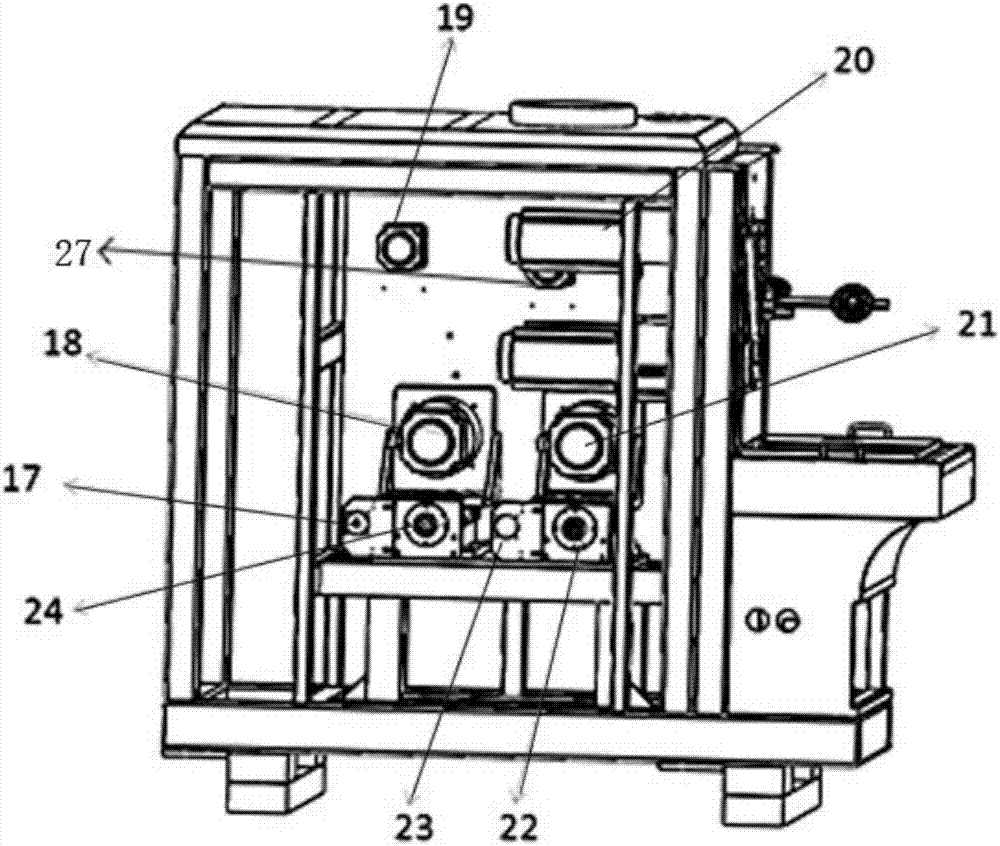

[0023] Such as figure 1 As shown, a six-guide wheel multi-wire cutting machine includes a frame and a working line roller 1, a workbench 2 and a workbench driving device 3 arranged on the front of the frame. The table driving device 3 drives the table 2 to move vertically upwards or downwards. The workbench driving device is mainly composed of a servo motor, a ball screw pair and a reduction device. The servo motor drives the ball screw pair to move through the reduction device, and the ball screw pair drives the worktable to make a linear motion. When cutting the workpiece, place the workpiece on the workbench, and the workbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com