Patents

Literature

40results about How to "Good action consistency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

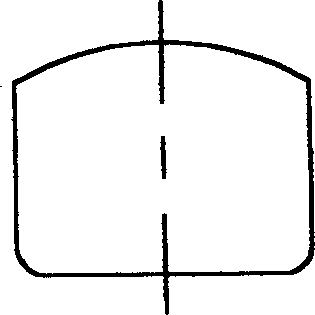

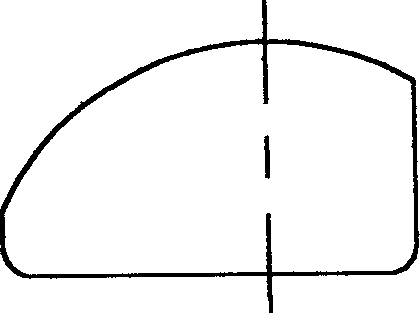

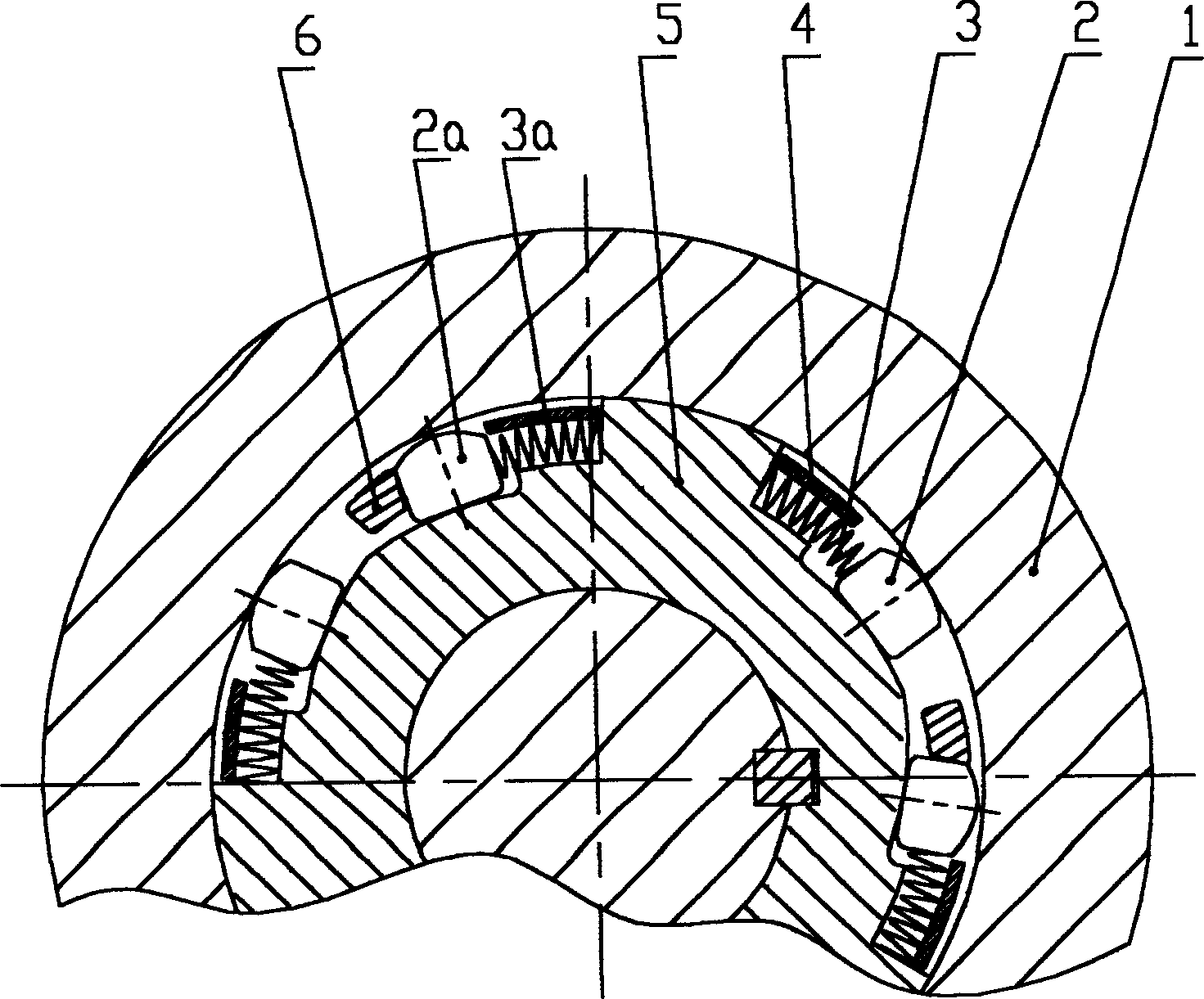

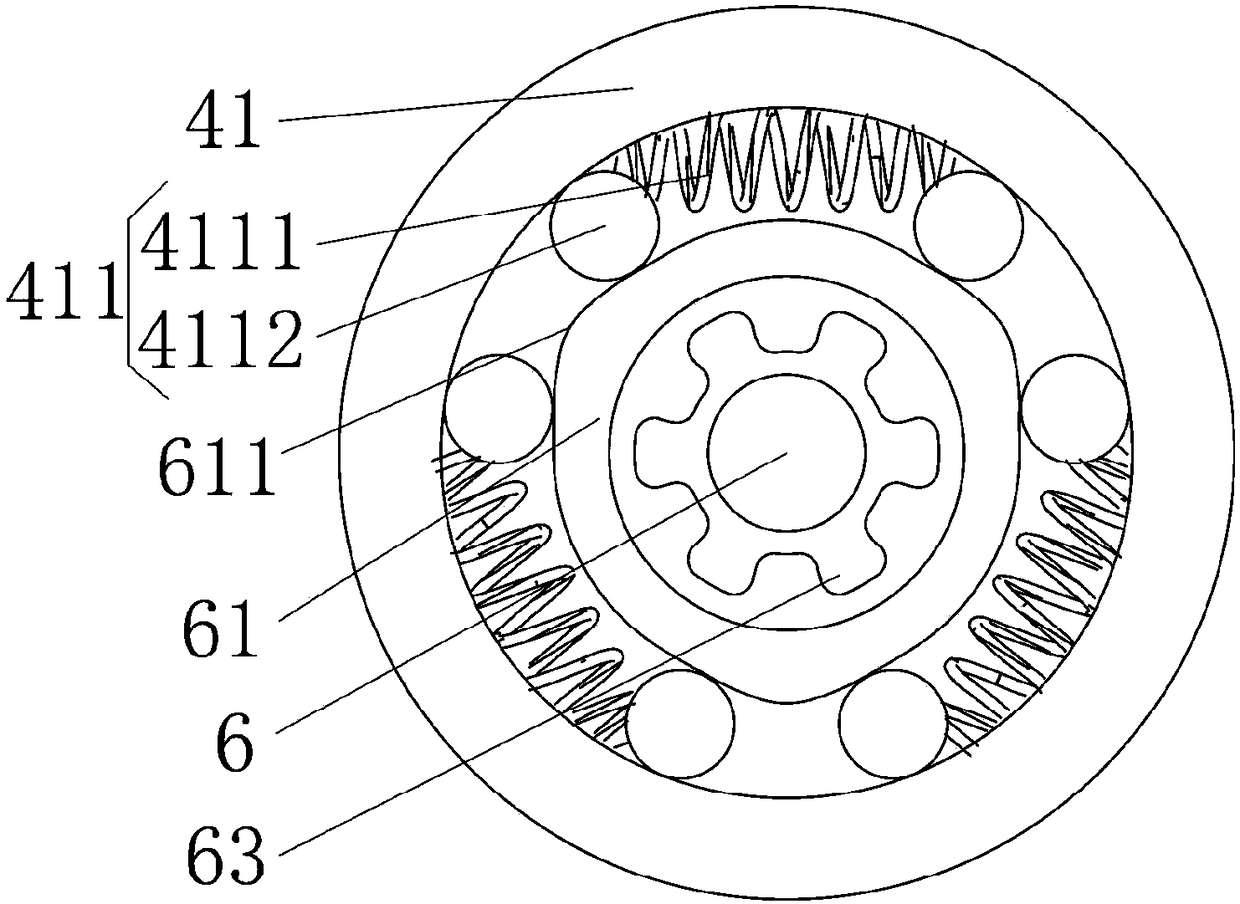

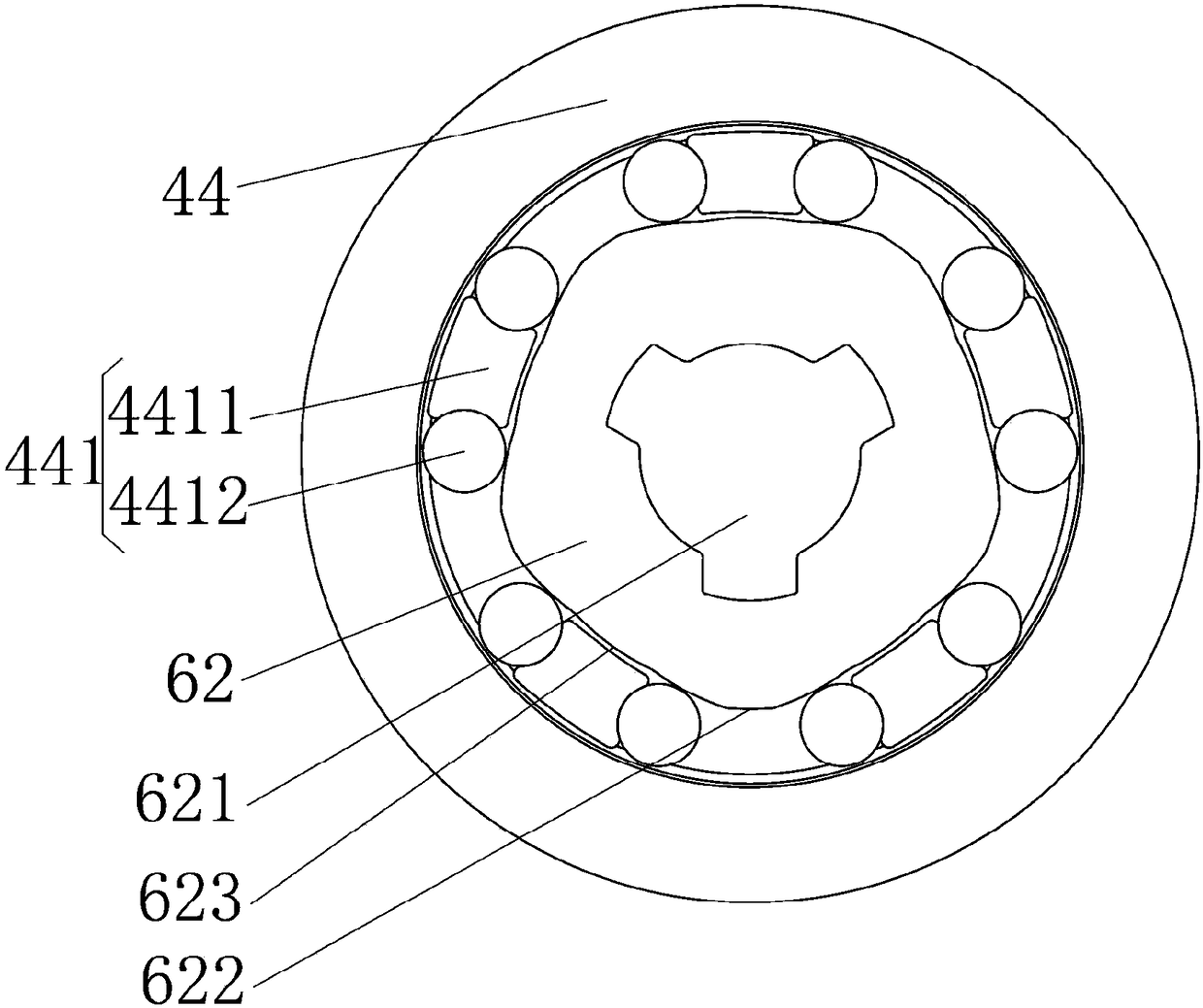

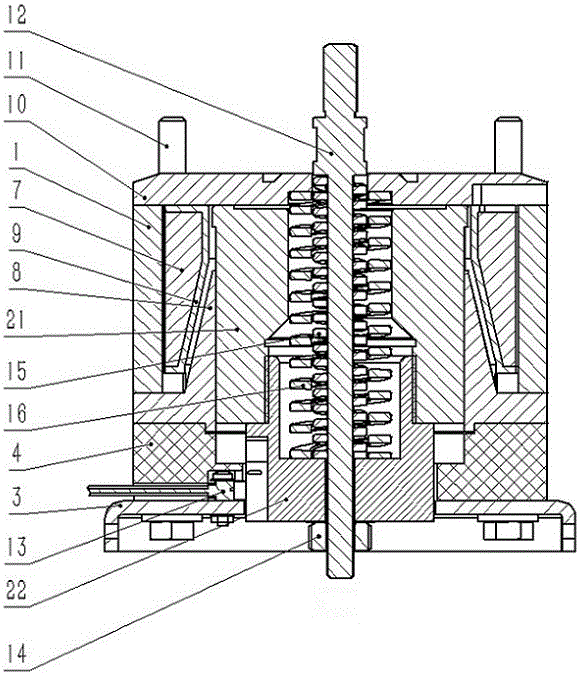

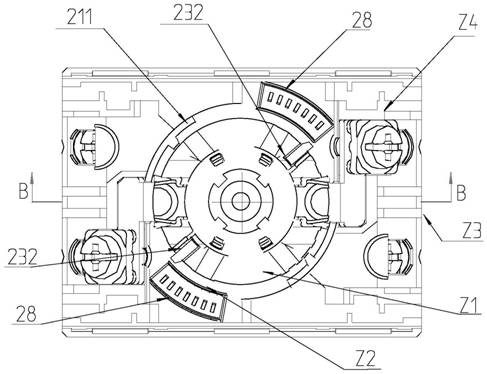

Wedge type freewheeling clutch apparatus

A wedge type freewheeling clutch apparatus wherein the working surface where the wedge contacts with the inner hole cylinder face of the outer ring of the free wheel device is a portion of the cylinder whose diameter is greater than the operational height of the wedge, the working surface on the wedge witch contacts with the star-wheel is a plane surface. Compared with the prior art wedge type freewheeling clutch apparatus, the advantages of the present invention are better movement consistency, higher reliability, more even load-bearing, greater load-bearing capacity and longer operating life.

Owner:夏明崙

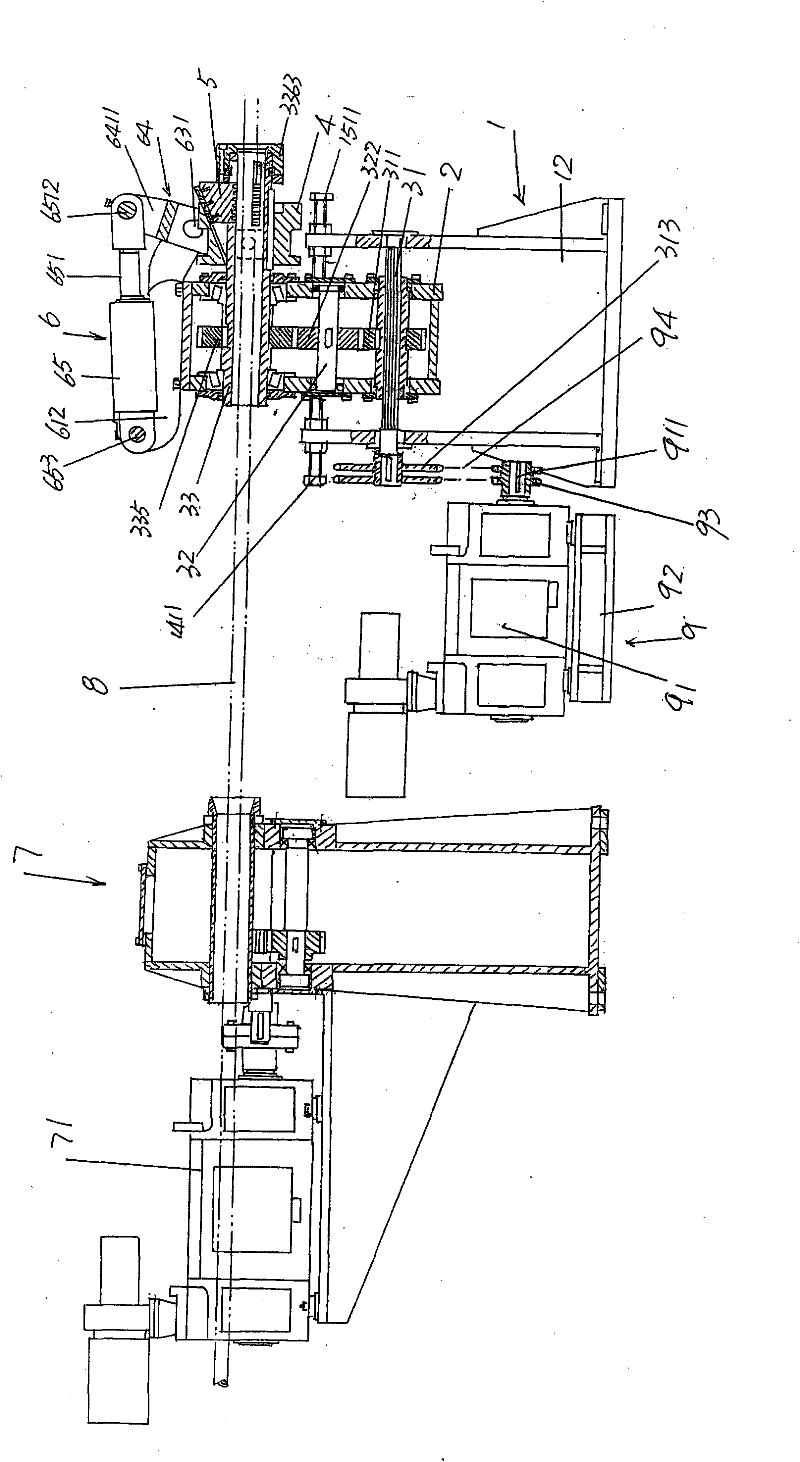

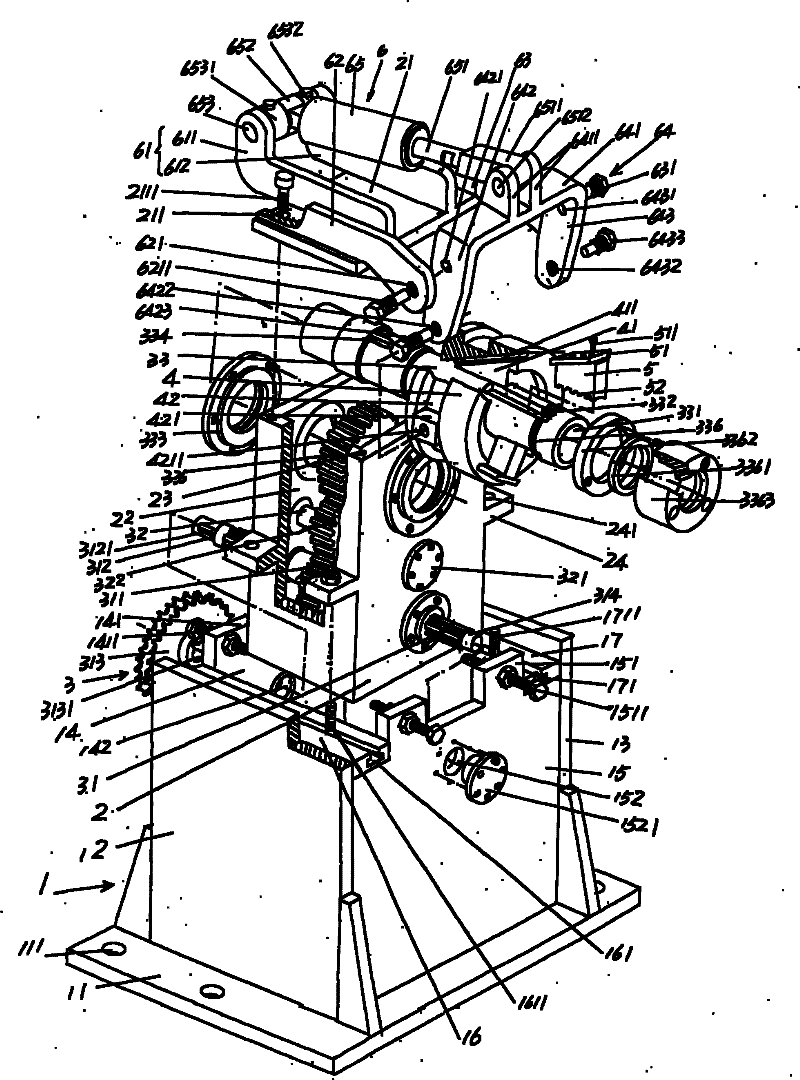

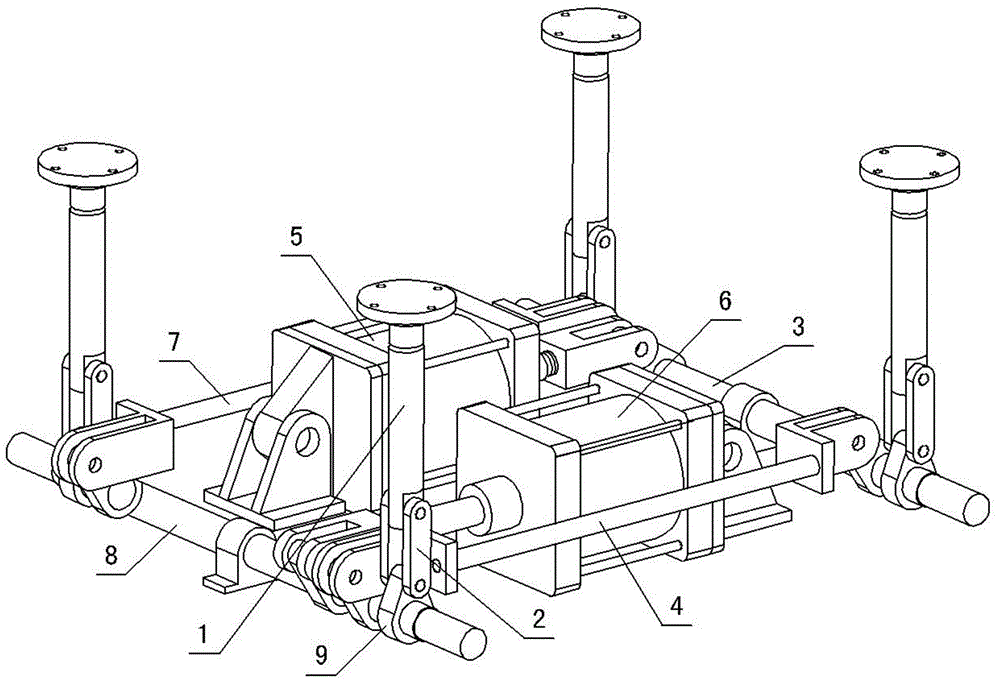

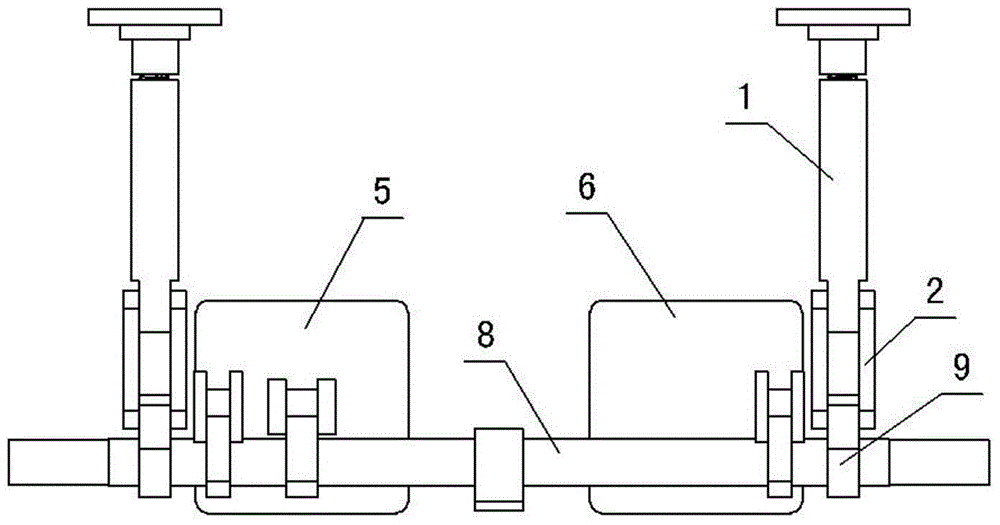

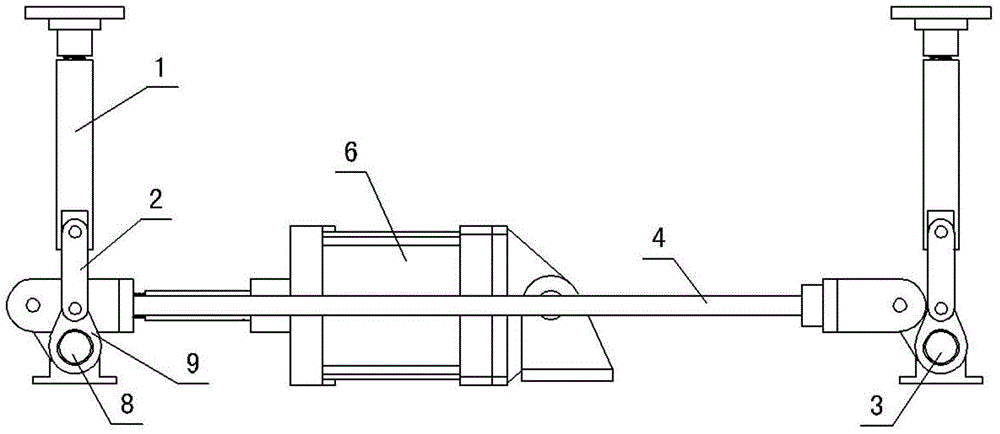

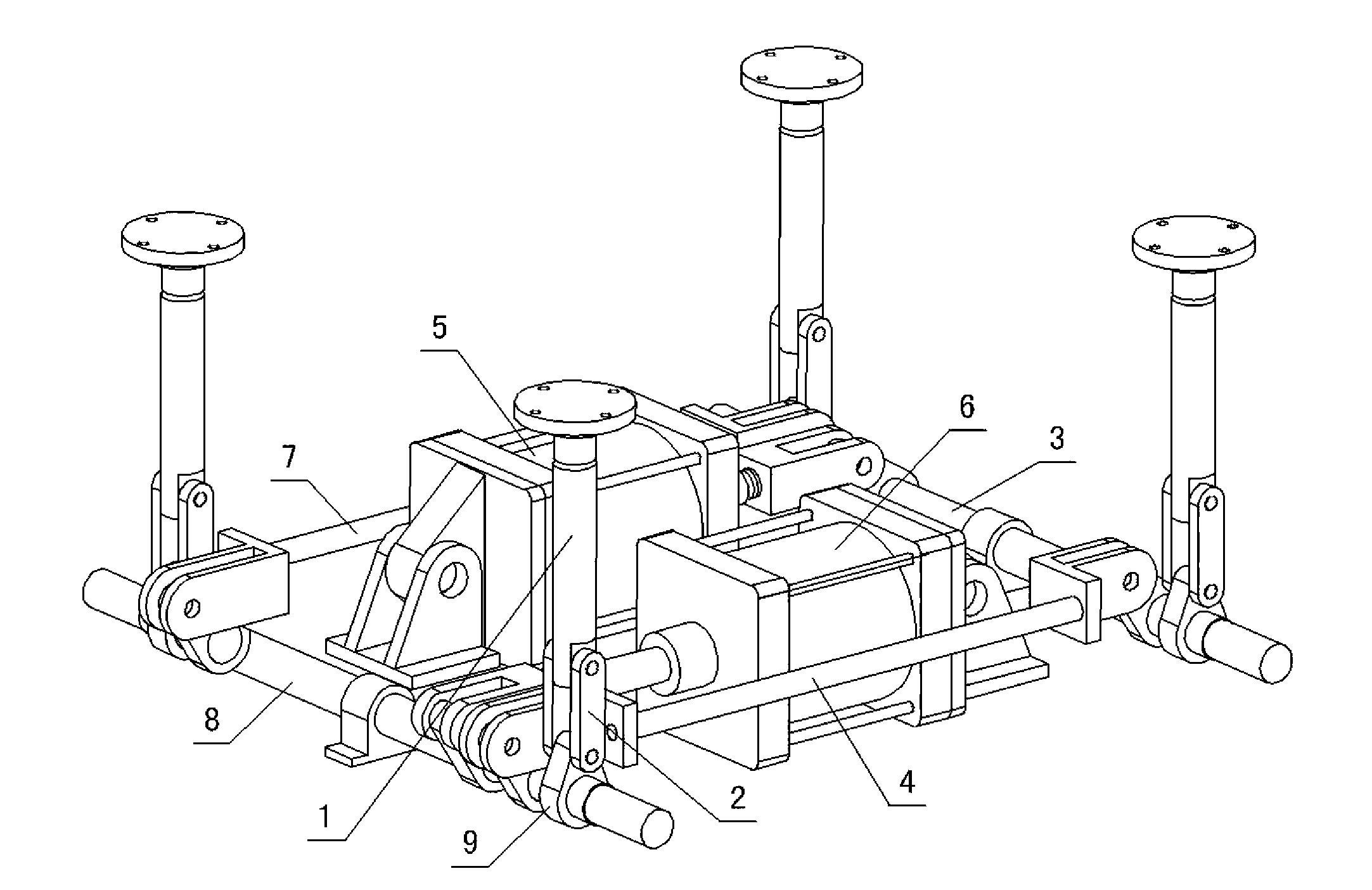

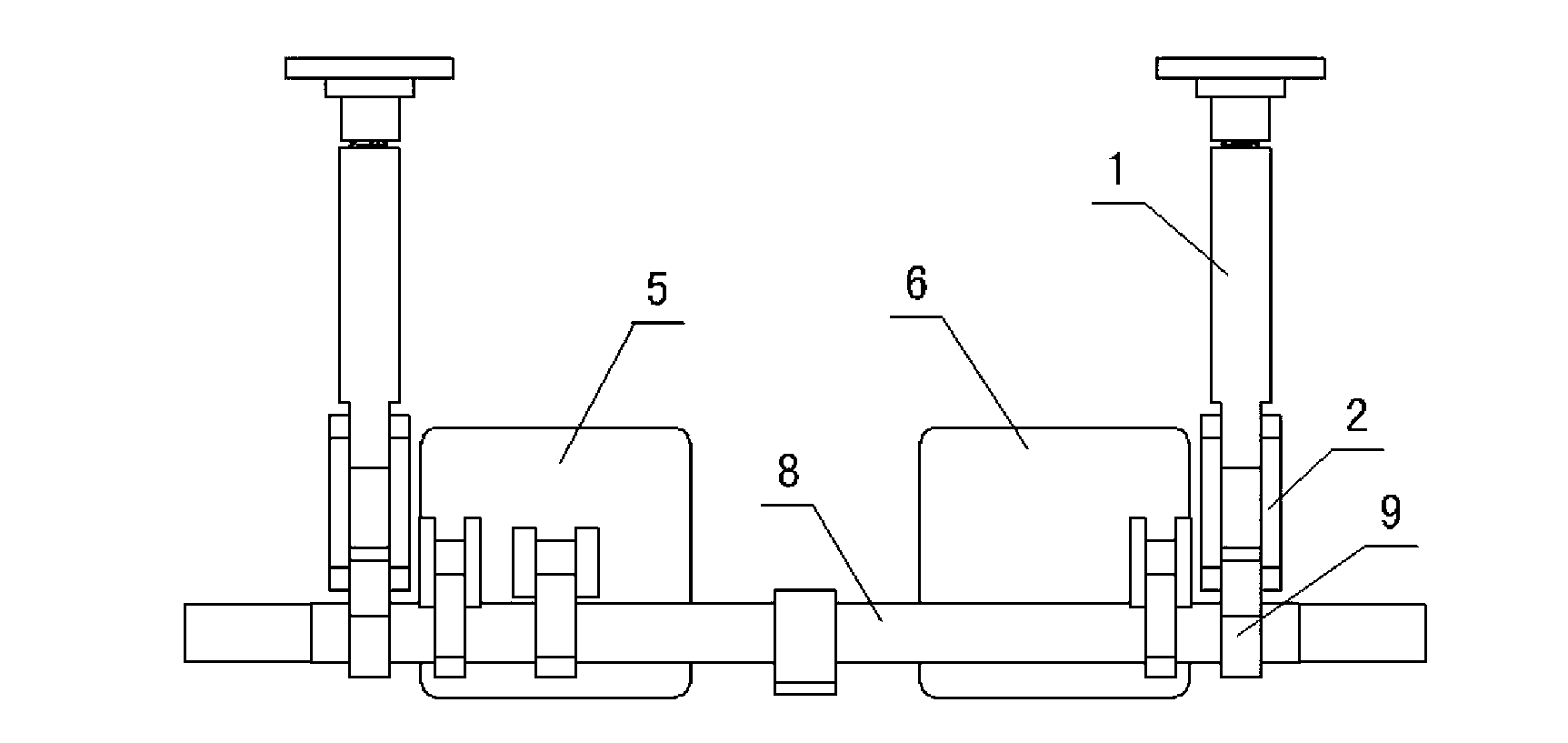

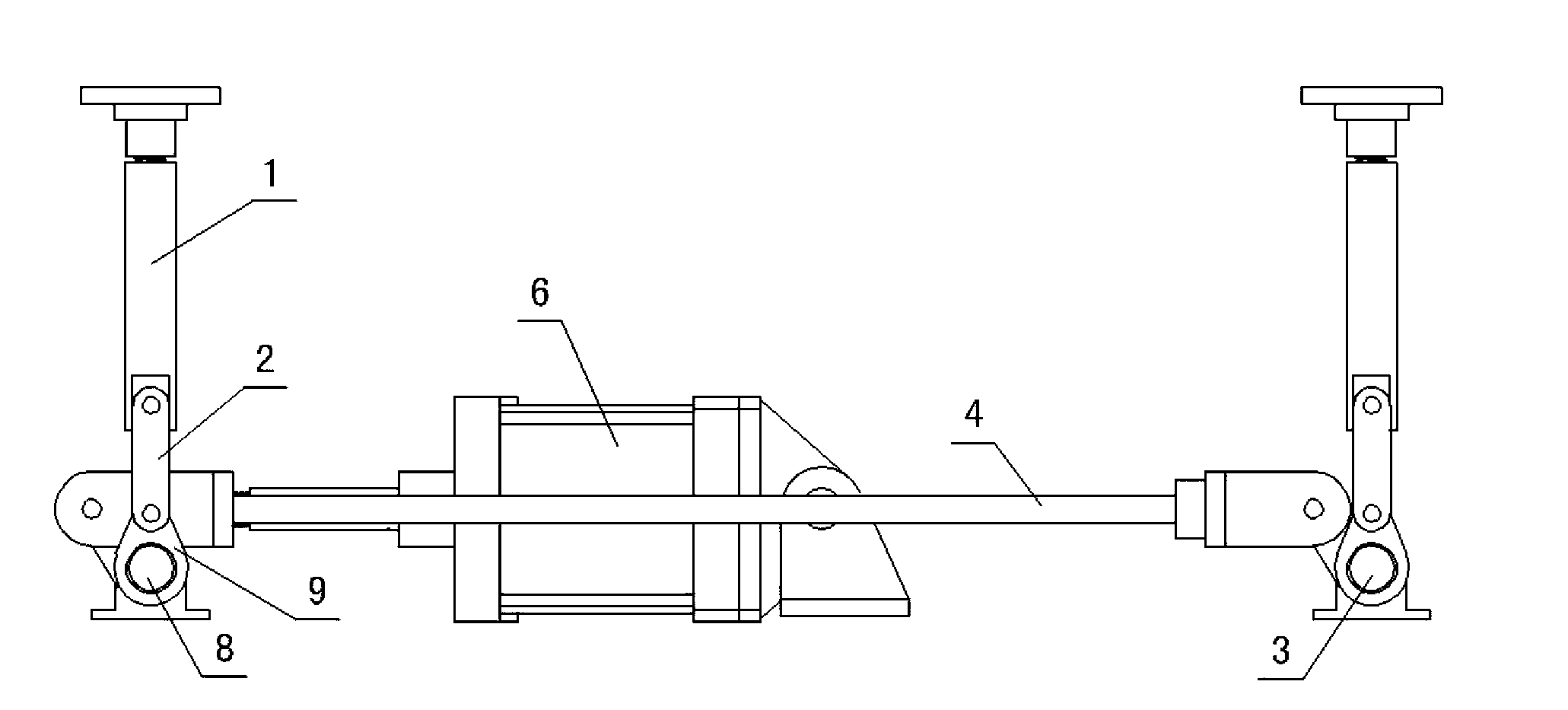

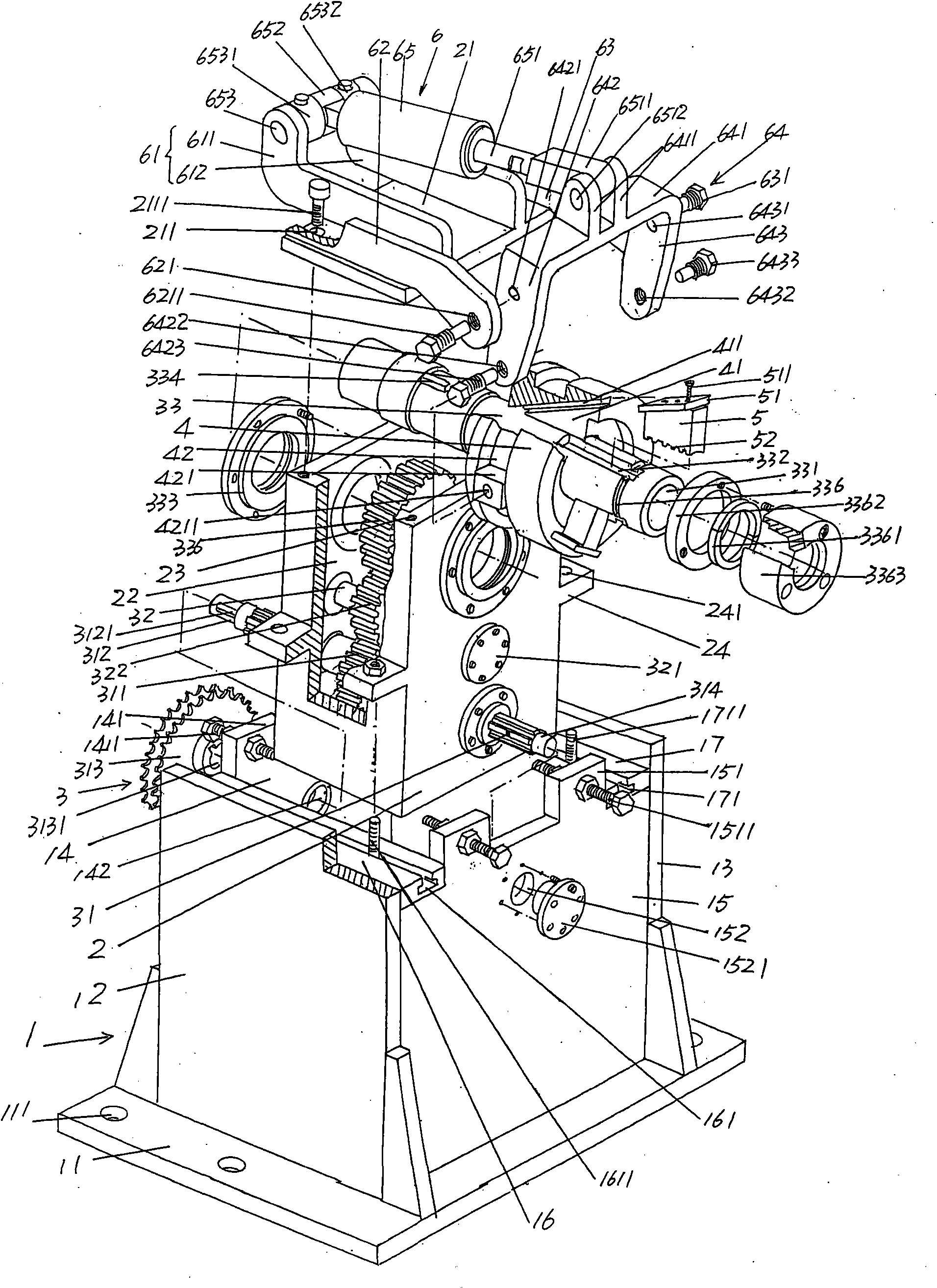

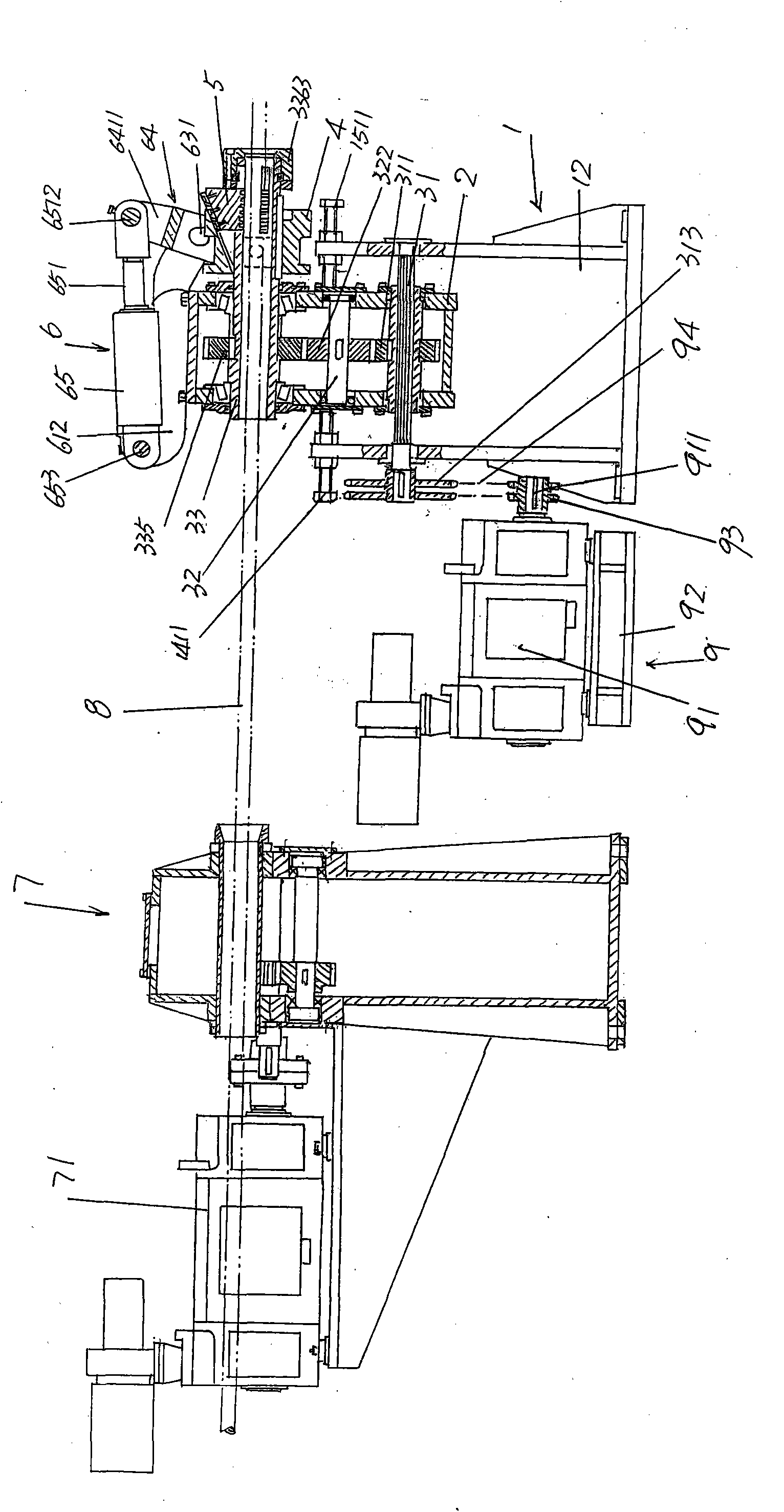

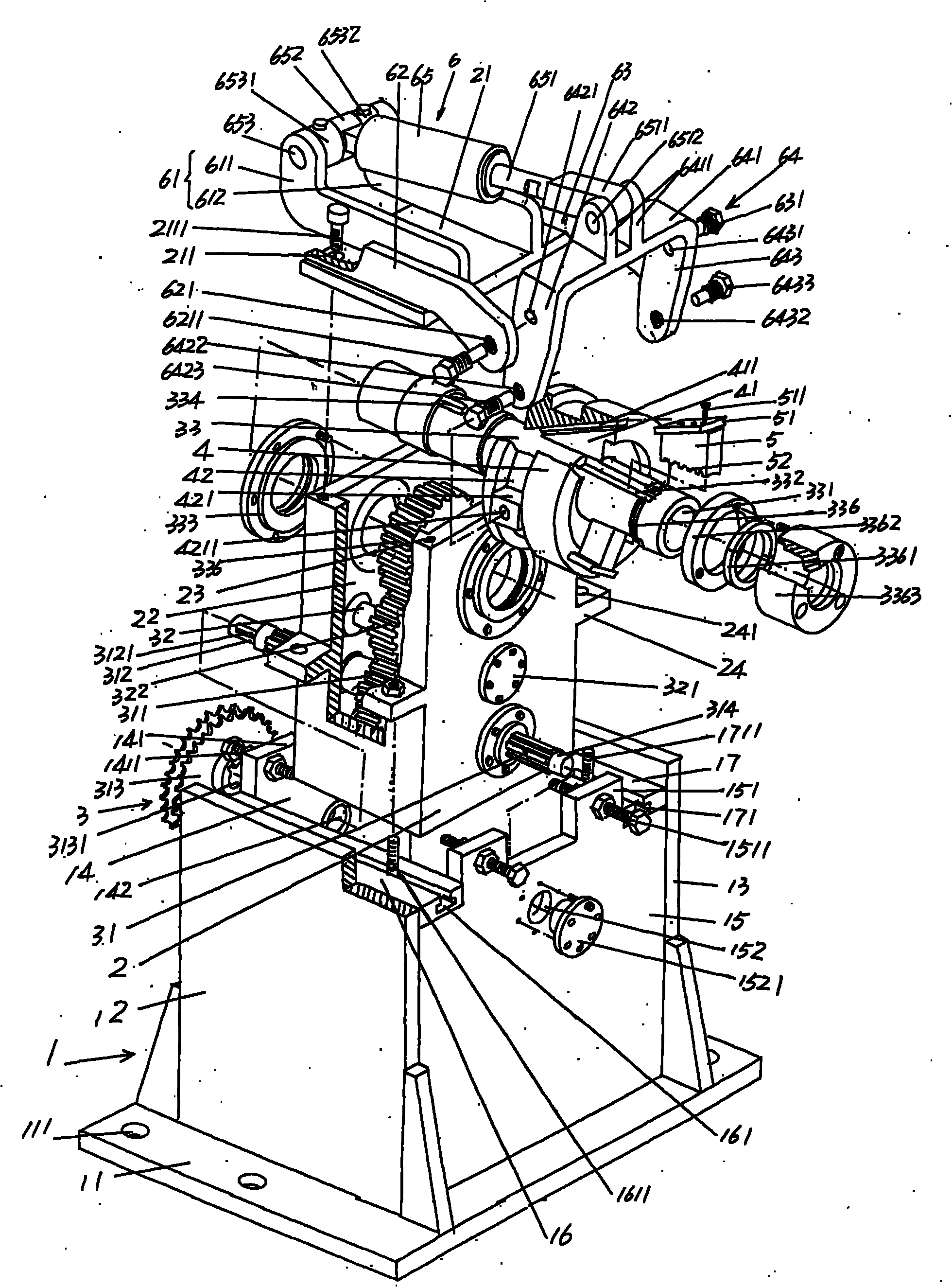

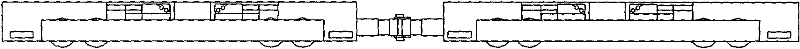

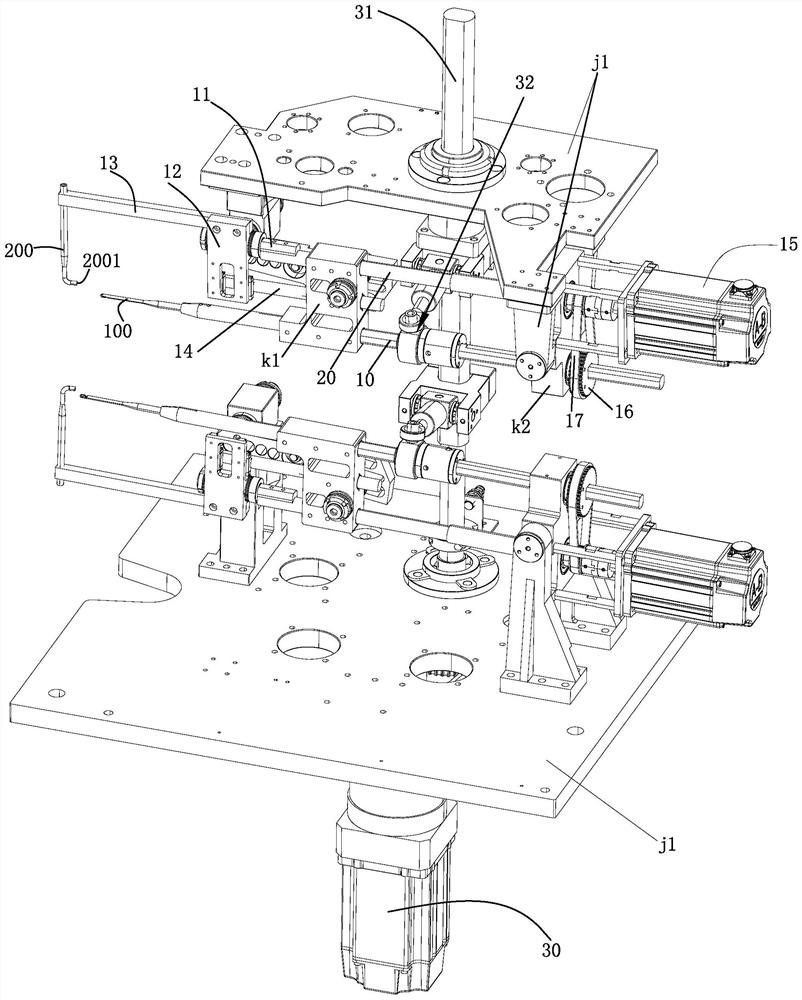

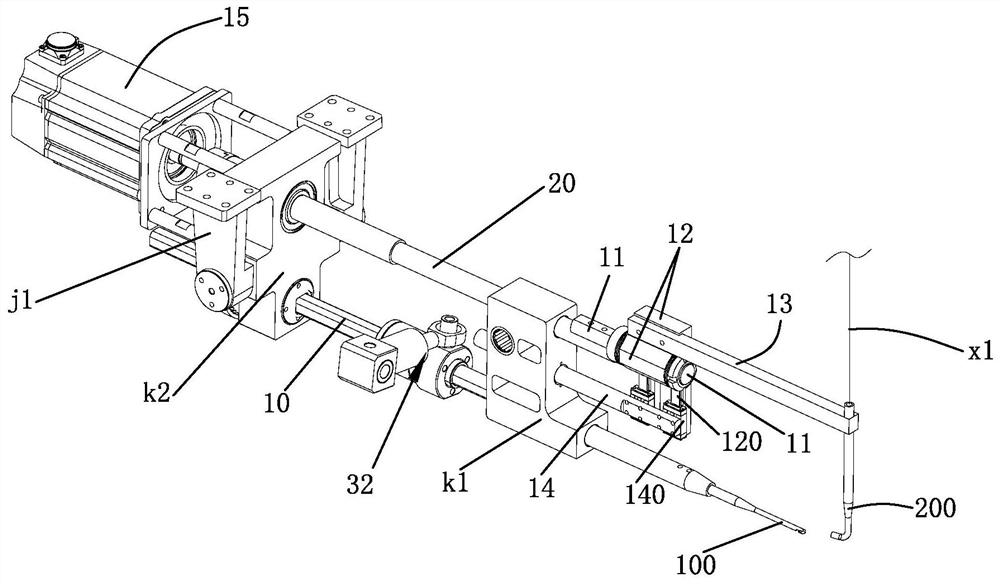

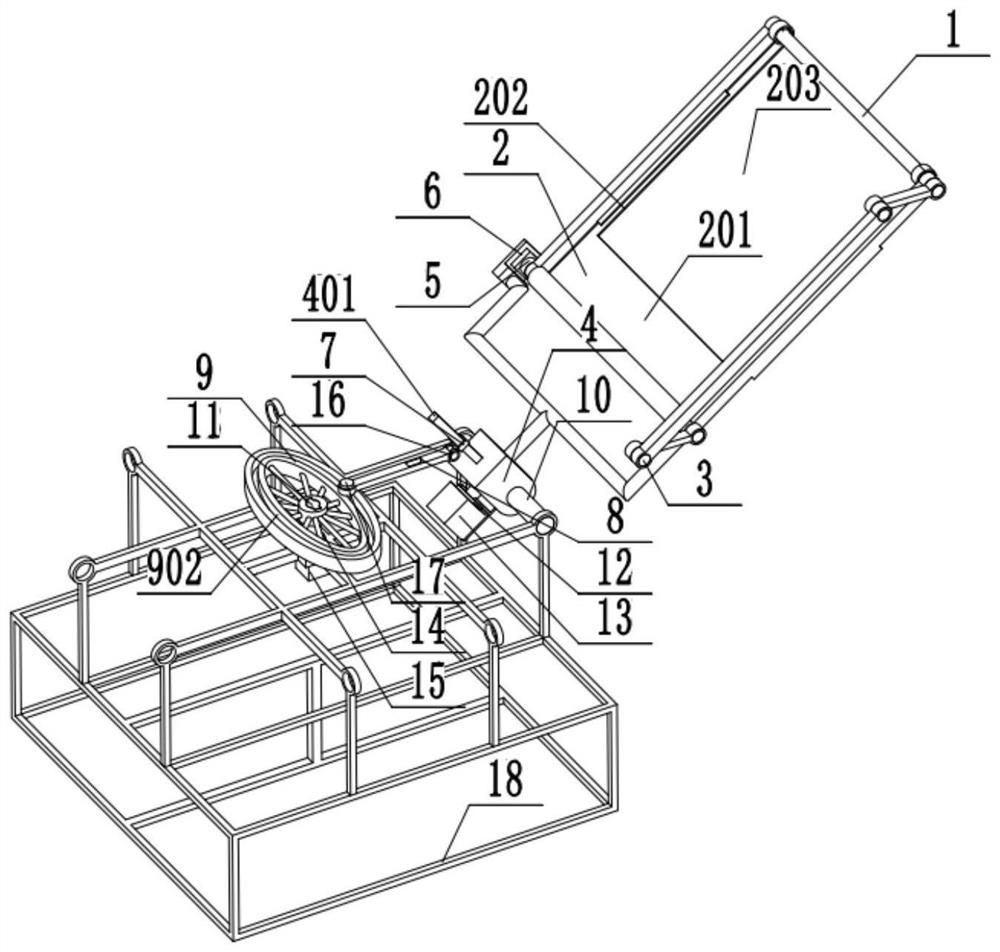

Swing mechanism of cold-rolling pipe mill

InactiveCN102059252BNo damageGood action consistencyWork manipulationMandrelsEngineeringUltimate tensile strength

Owner:CHANGSHU MEILI MACHINERY MFG

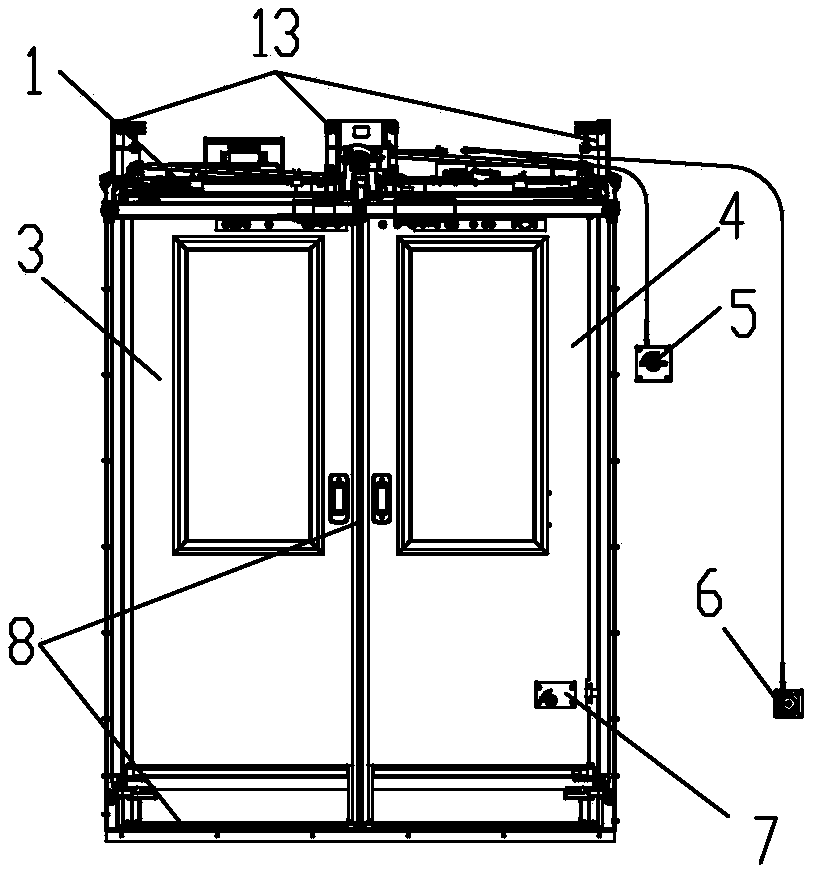

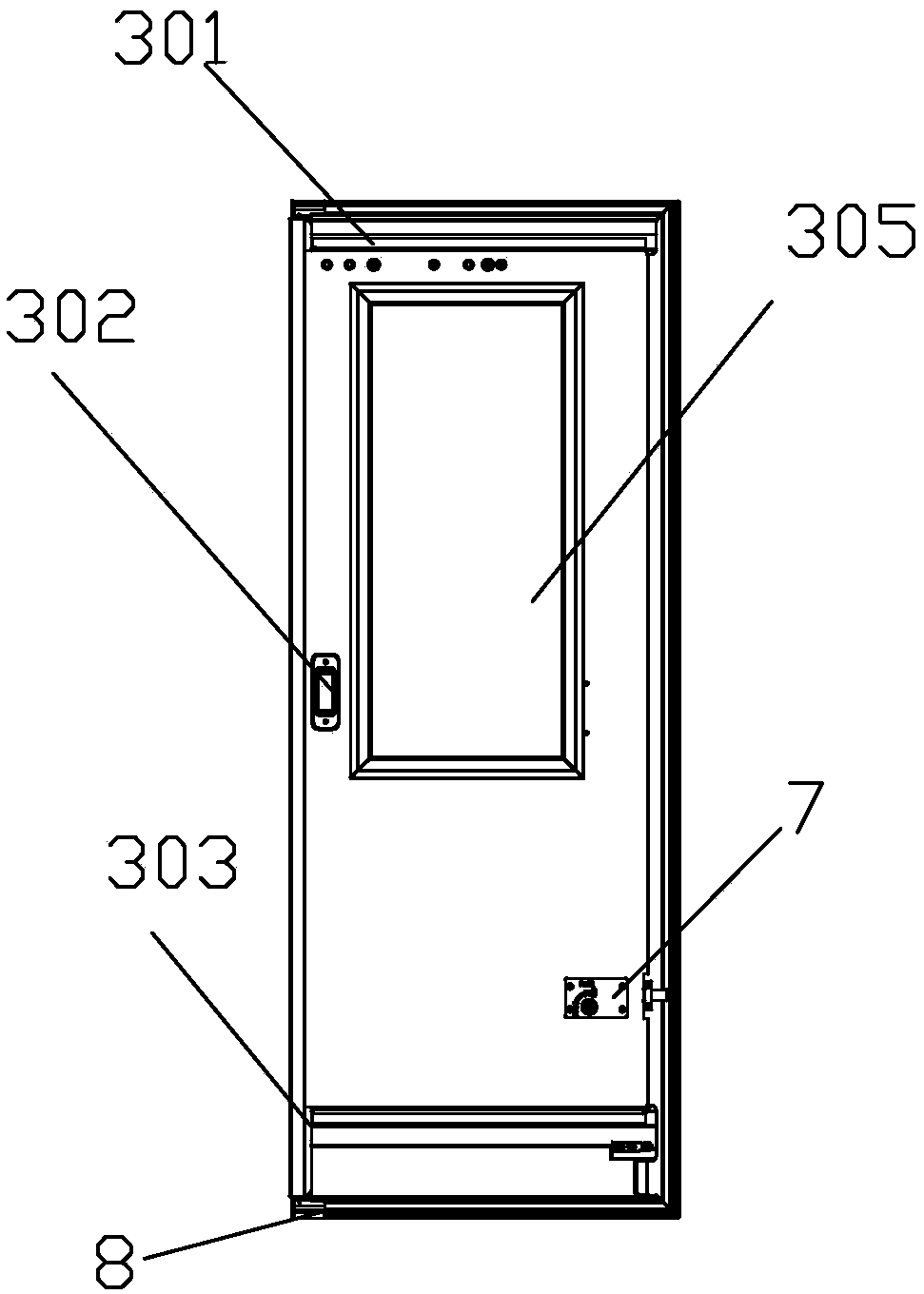

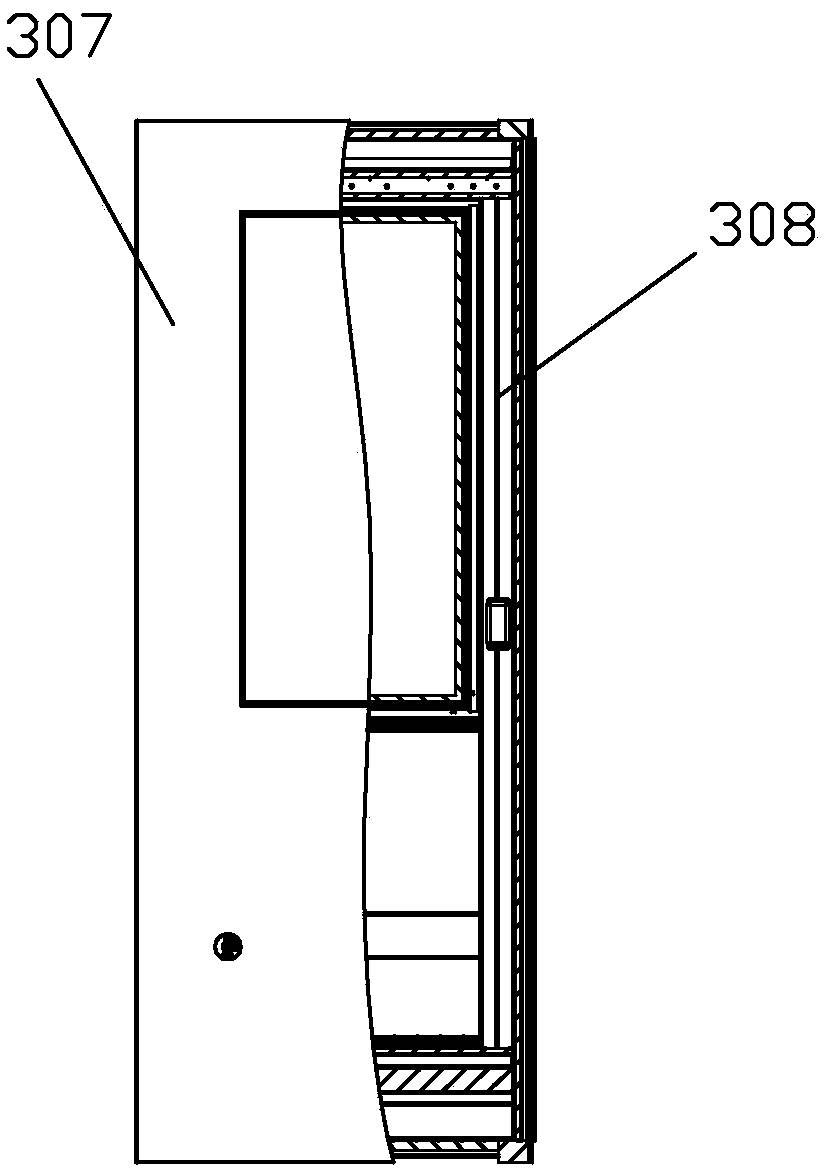

Sliding-plug door

PendingCN110552592AOvercome the defect of uneven forceImprove coordinationWing operation mechanismsSealing arrangementsEngineeringElectrical and Electronics engineering

Owner:北京天乐泰力科技发展有限公司

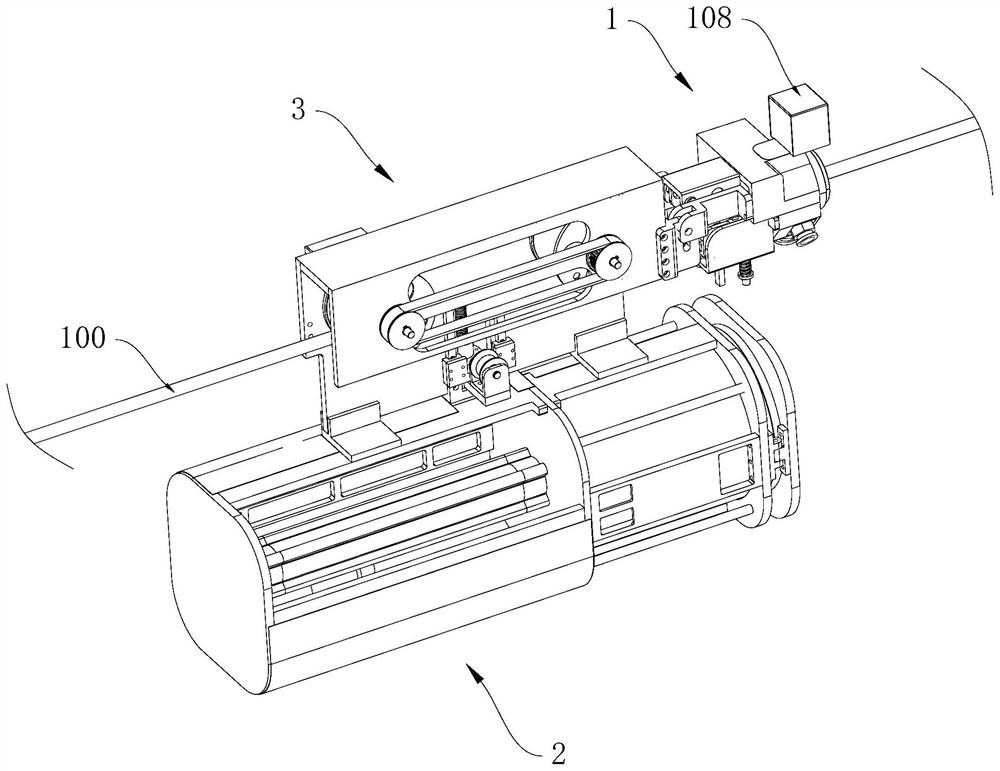

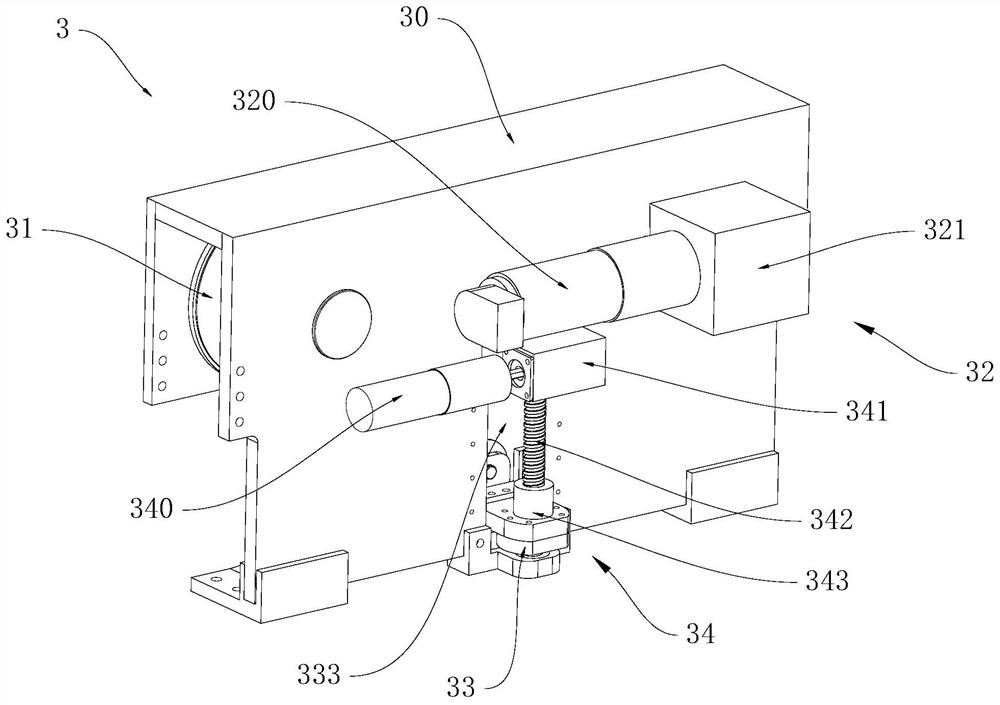

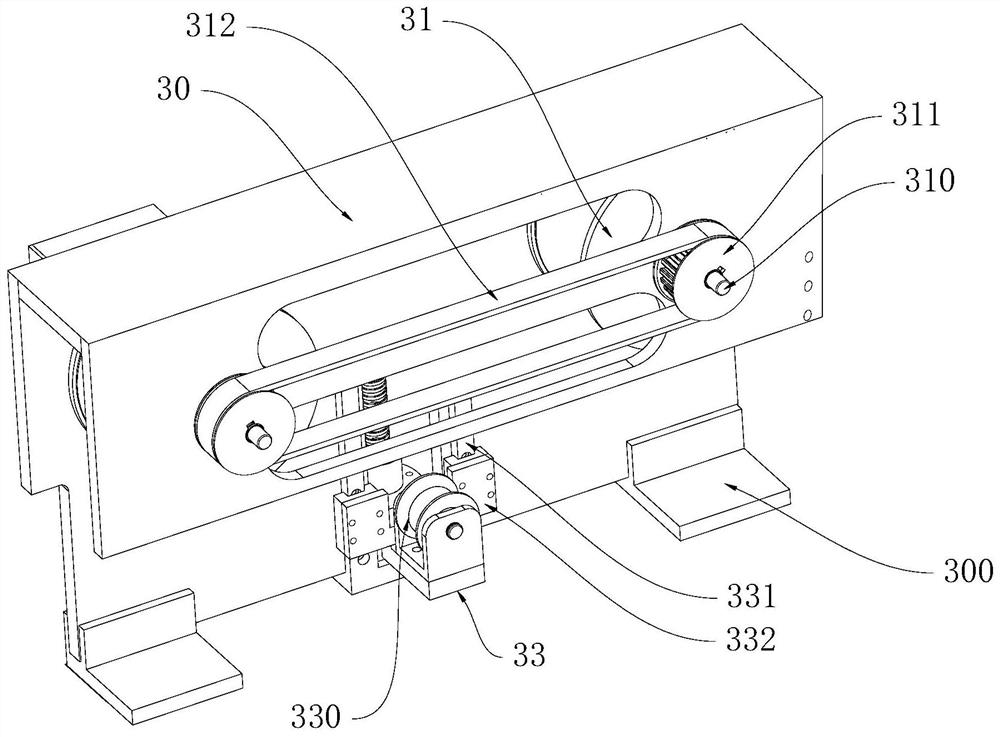

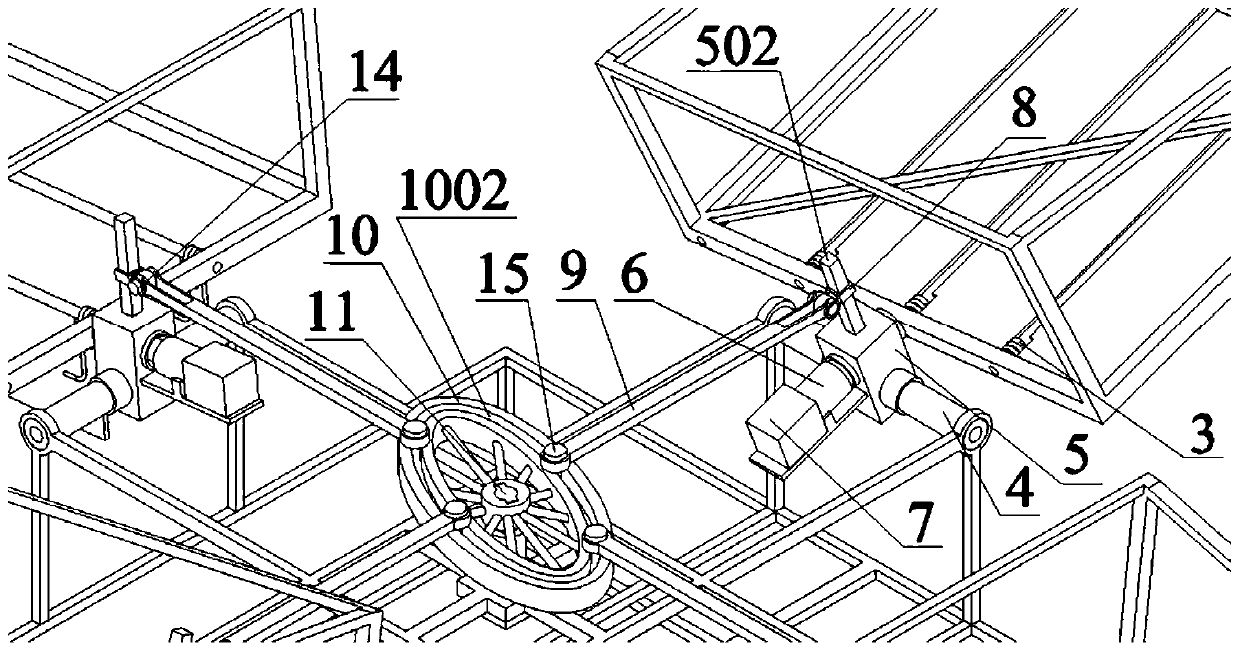

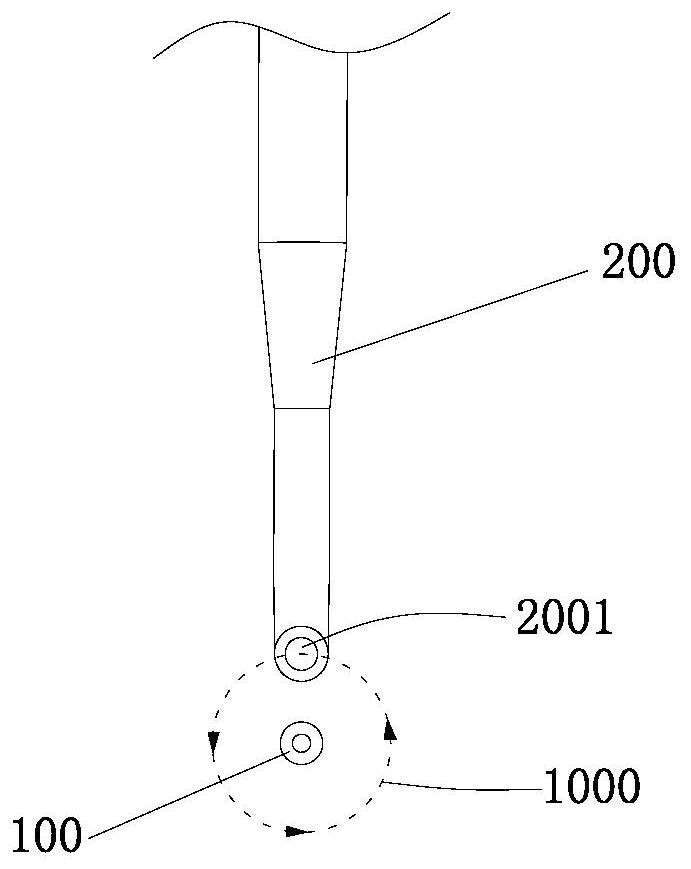

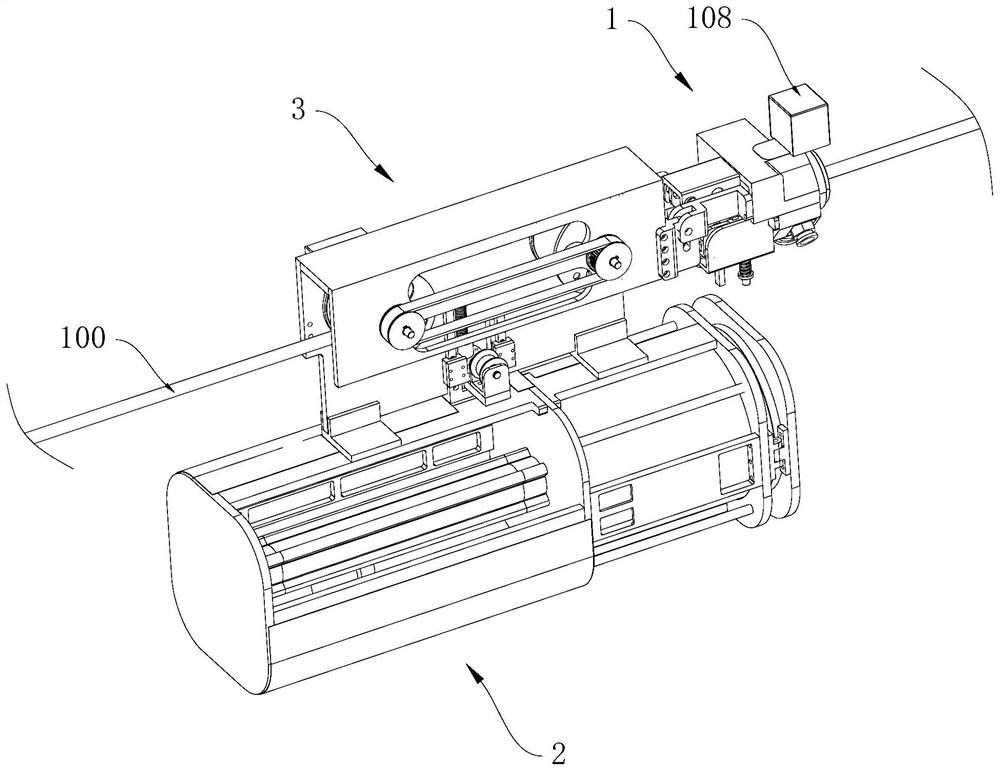

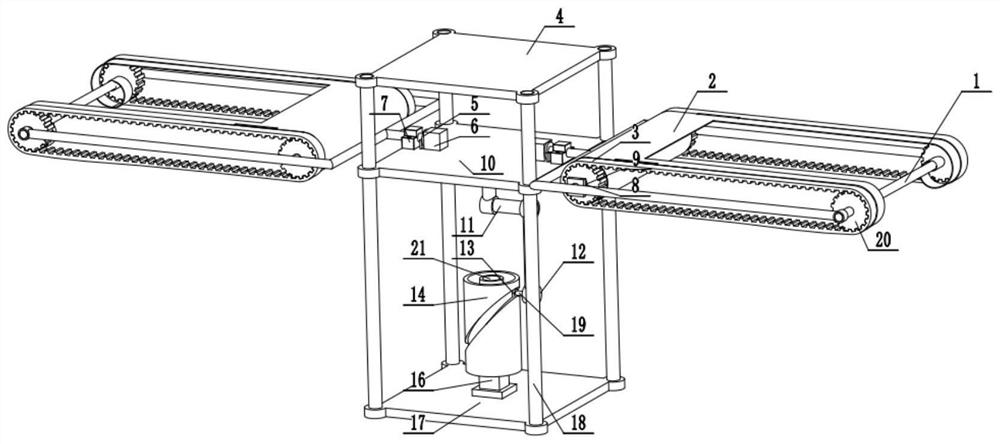

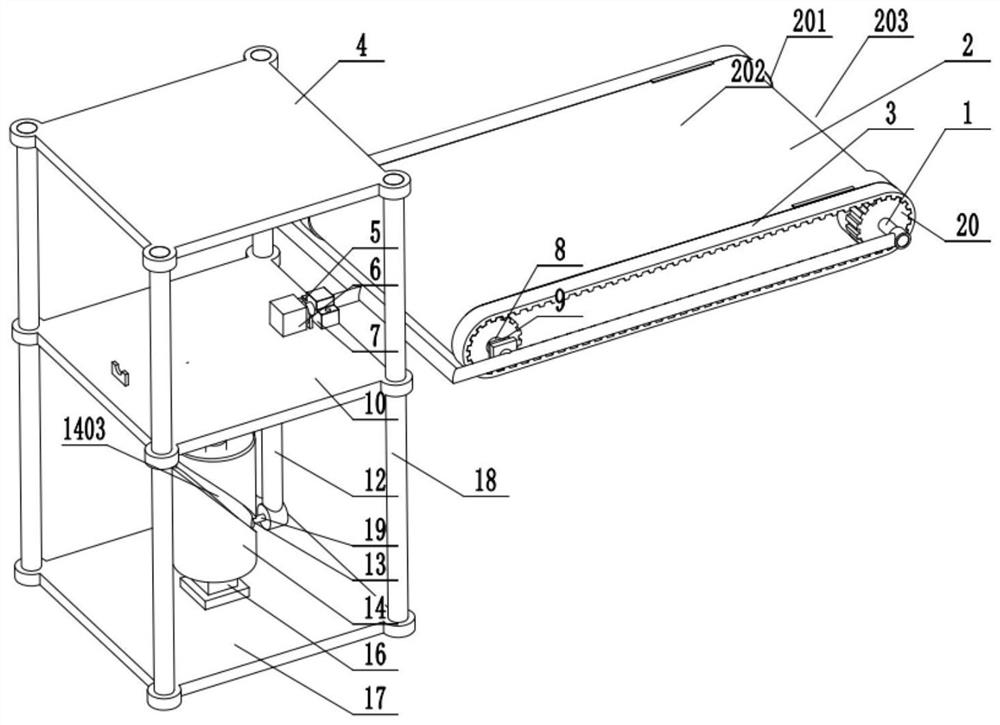

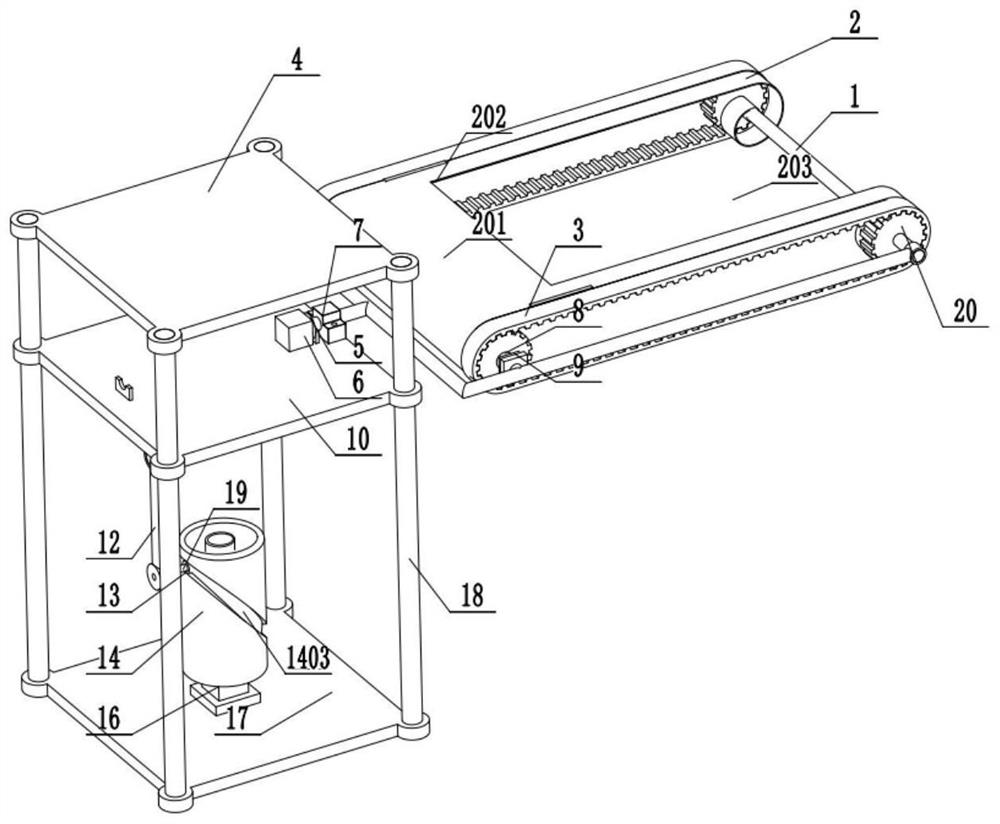

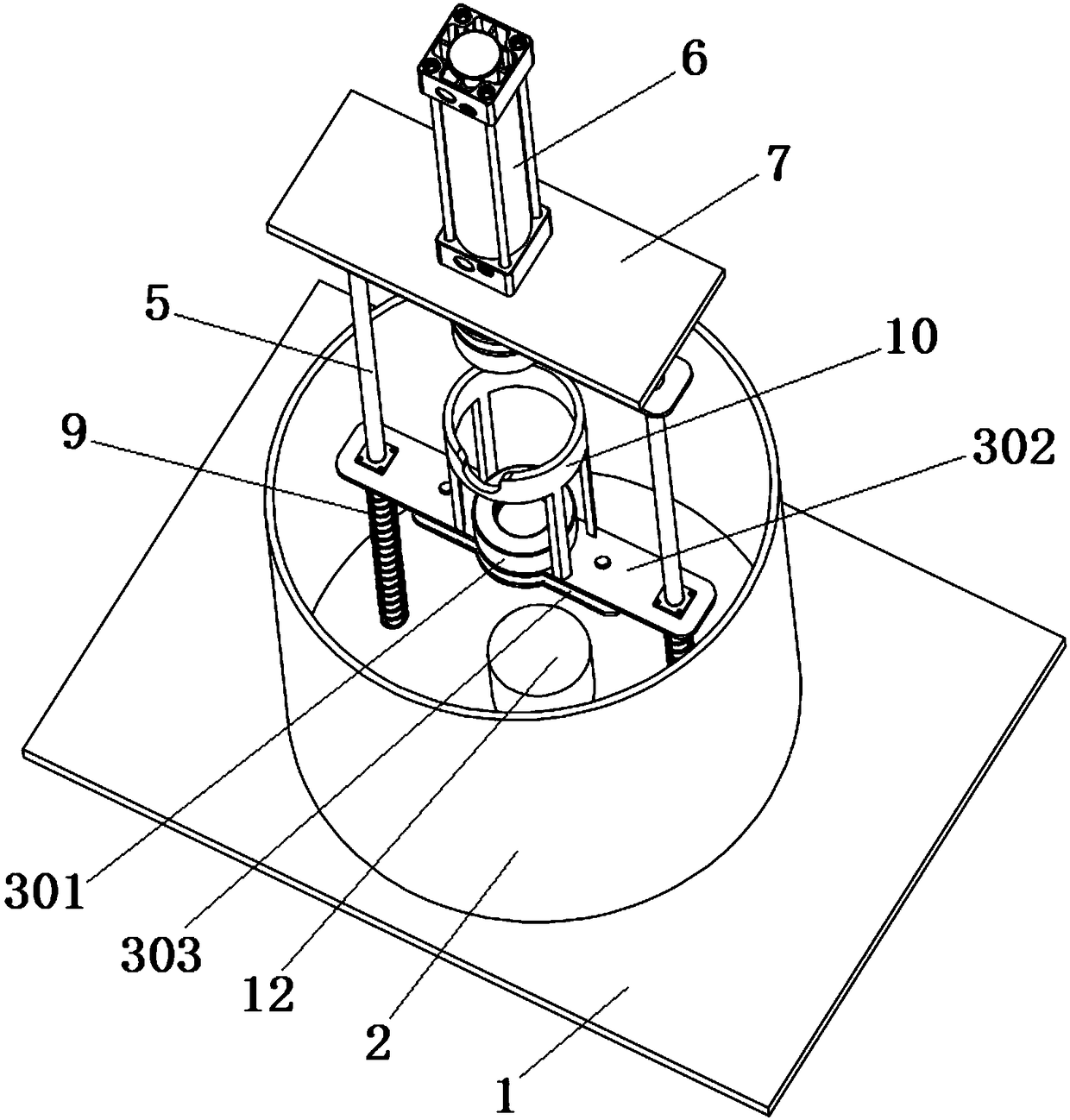

Hot-line work type overhead bare conductor insulating material automatic coating equipment

ActiveCN112570220ARealize automatic coating operationEasy to installLiquid surface applicatorsCoatingsEngineeringMaterial supply

The invention discloses hot-line work type overhead bare conductor insulating material automatic coating equipment. The equipment comprises a coating device, a material supply device and a traction device, wherein the coating device is used for coating the surface of a bare conductor with an insulating material; the material supply device is used for conveying the insulating material to the coating device; and the traction device is arranged on the bare conductor, the coating device and the material supply device are separately connected to the traction device, and the traction device is usedfor walking on the bare conductor and driving the coating device and the material supply device to move relative to the bare conductor. The equipment is compact in structure, good in action consistency, convenient to install and higher in automation performance.

Owner:天津恩泰智能装备有限公司

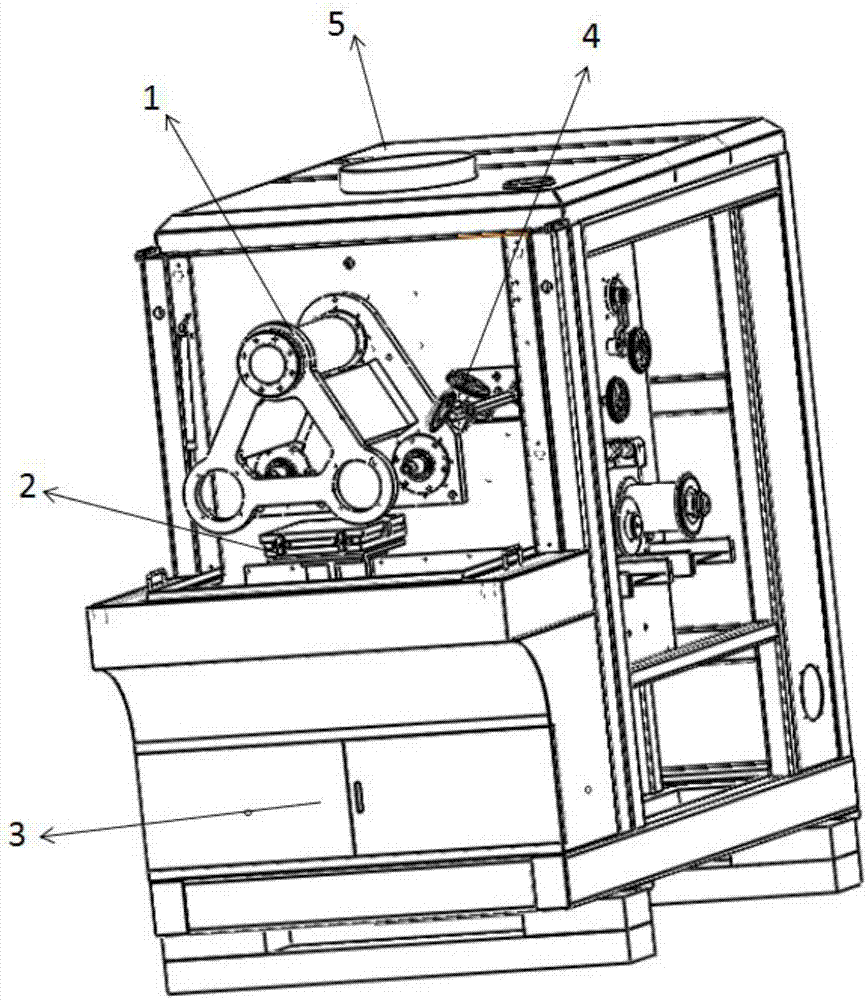

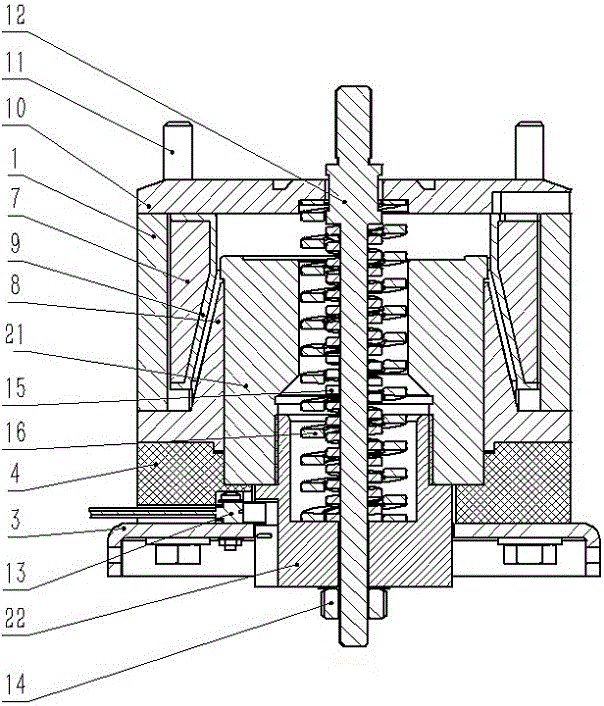

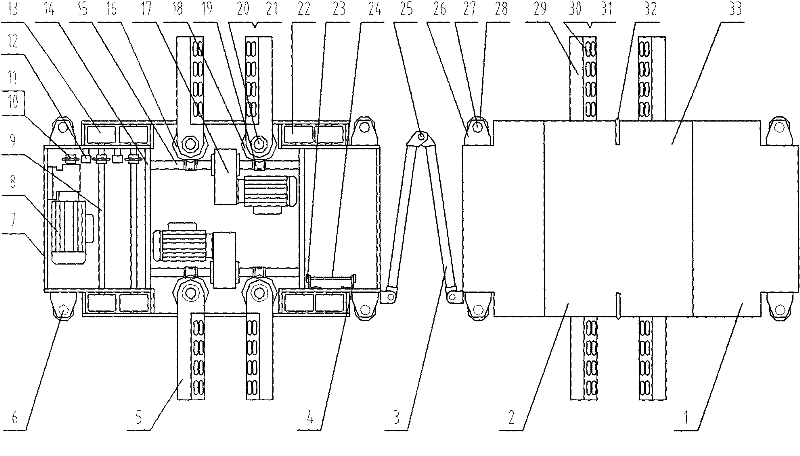

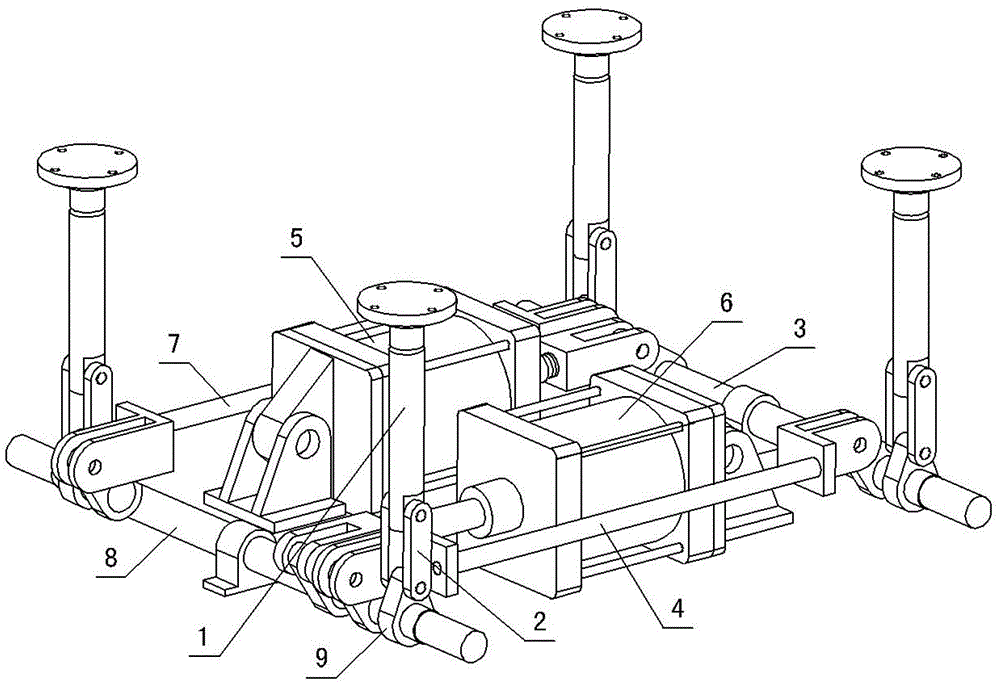

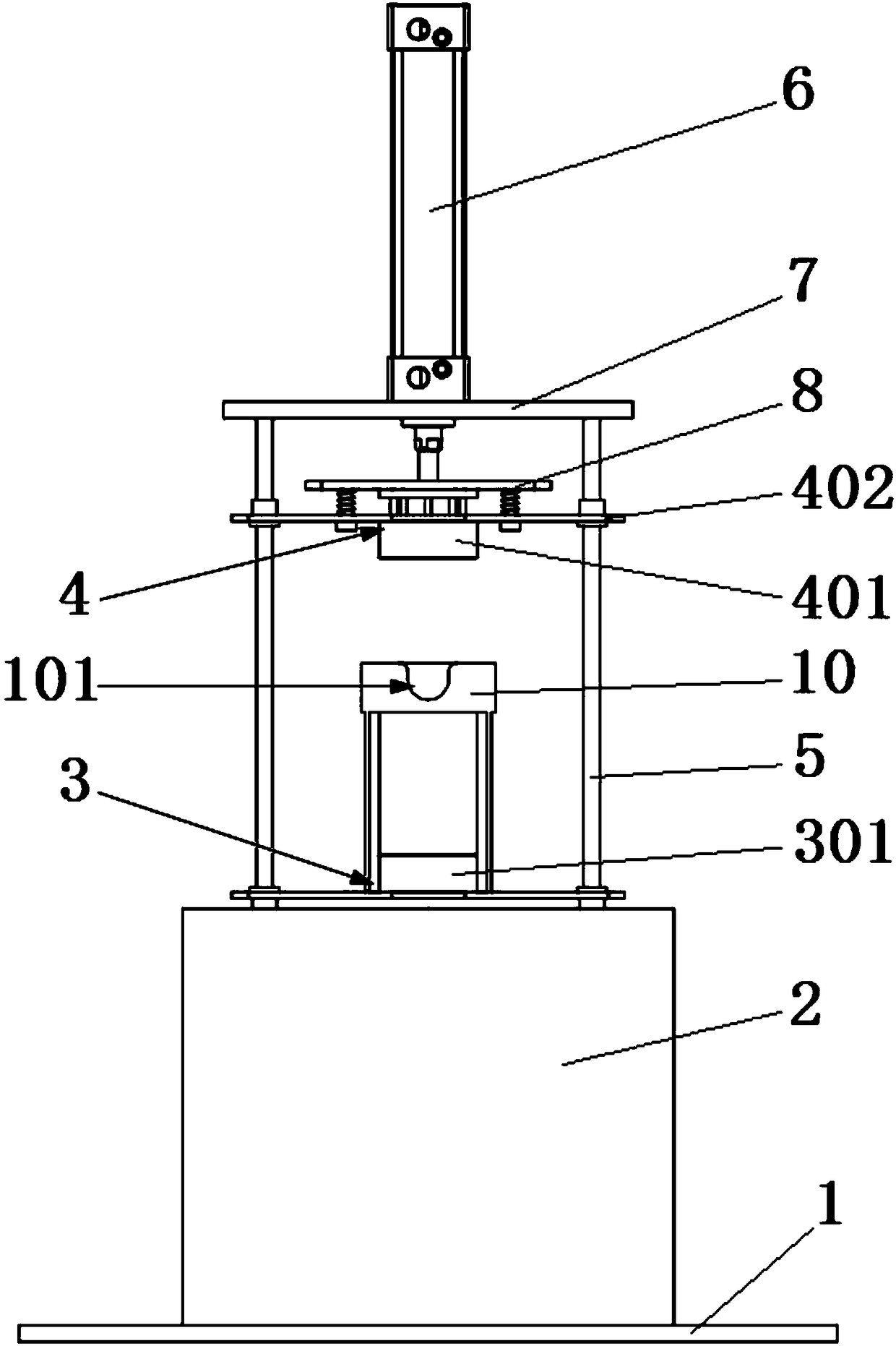

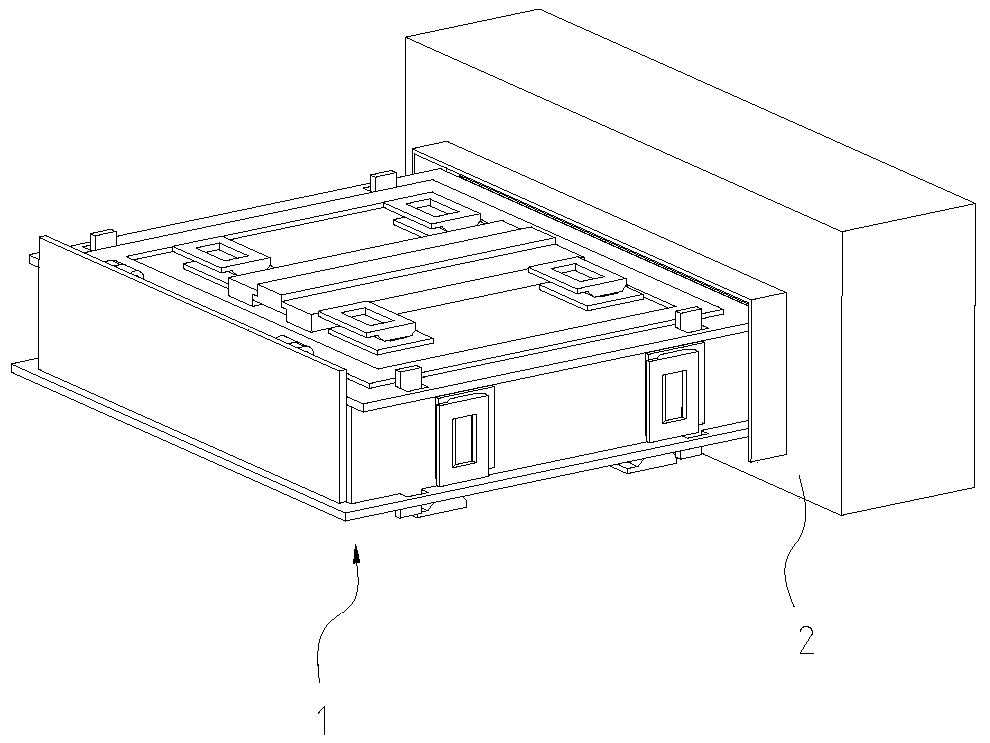

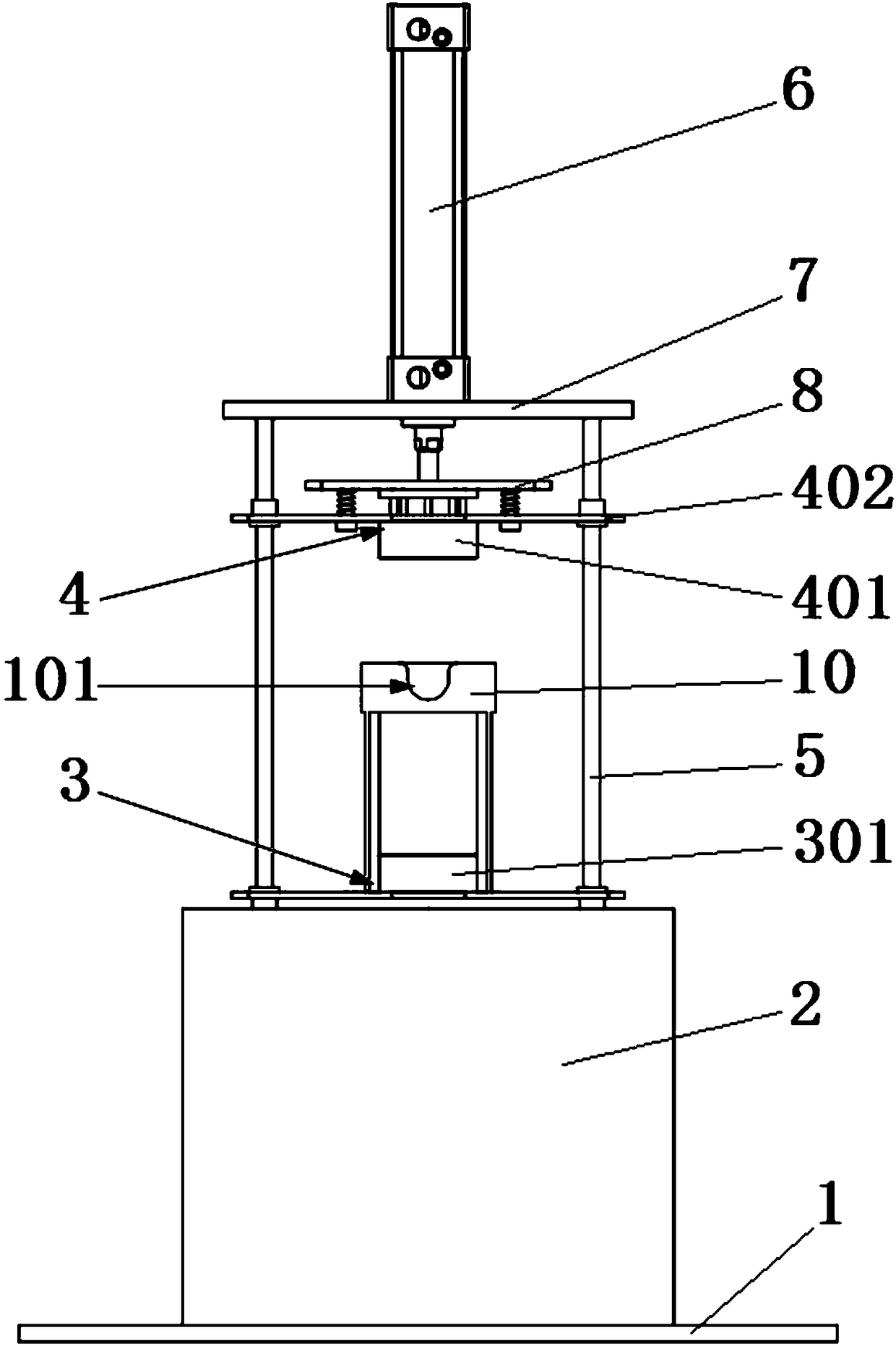

Control method of ejection mechanism of special single-station foaming machine for refrigerators

The invention discloses an ejector mechanism of a single-trip foaming special machine of a refrigerator and a control method of the ejector mechanism. The ejector mechanism is characterized in that a parallel four-bar mechanism is formed by articulating a front connecting rod frame, a rear connecting rod frame, a left camshaft and a right camshaft which are distributed as a rectangular frame on a plane, wherein cams are respectively arranged on the left camshaft and the right camshaft front and back, a slider-crank mechanism consists of the cams, connecting rods connected with the cams, ejector rods connected with the connecting rods, and foaming special machine bottom plates fixedly arranged on the ejector rods, a pre-positioned air cylinder and a post-positioned air cylinder are arranged as a driving mechanism, the left camshaft is driven to rotate by a piston rod of the pre-positioned air cylinder through a pre-positioned crank, and the right camshaft is driven to rotate by a piston rod of the post-positioned air cylinder through a post-positioned crank. According to the ejector mechanism, the foaming can be realized on the single foaming special machine.

Owner:CHUZHOU JINGWEI MOULD MFG CO LTD

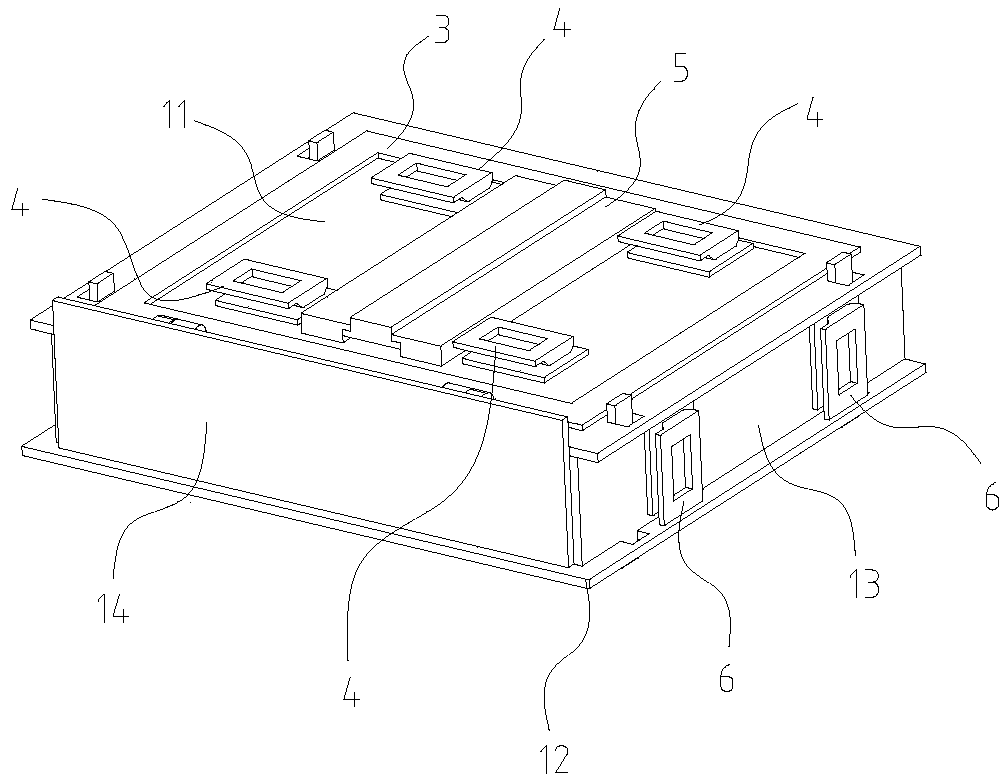

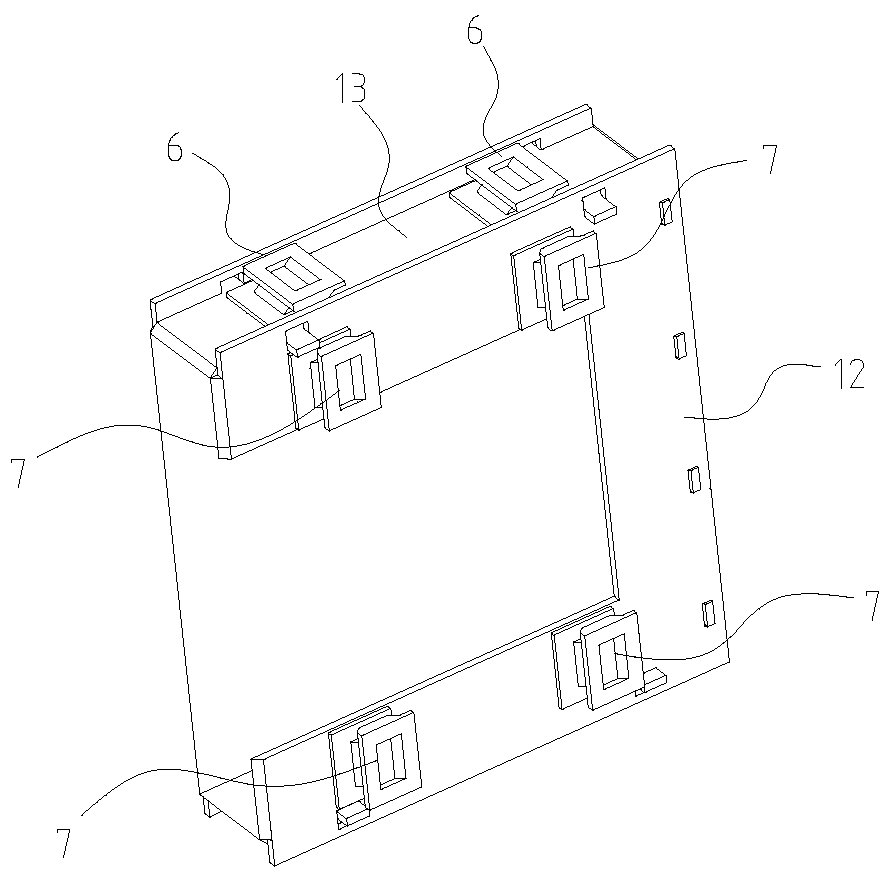

Ejector mechanism of single-trip foaming special machine of refrigerator and control method of ejector mechanism

The invention discloses an ejector mechanism of a single-trip foaming special machine of a refrigerator and a control method of the ejector mechanism. The ejector mechanism is characterized in that a parallel four-bar mechanism is formed by articulating a front connecting rod frame, a rear connecting rod frame, a left camshaft and a right camshaft which are distributed as a rectangular frame on a plane, wherein cams are respectively arranged on the left camshaft and the right camshaft front and back, a slider-crank mechanism consists of the cams, connecting rods connected with the cams, ejector rods connected with the connecting rods, and foaming special machine bottom plates fixedly arranged on the ejector rods, a pre-positioned air cylinder and a post-positioned air cylinder are arranged as a driving mechanism, the left camshaft is driven to rotate by a piston rod of the pre-positioned air cylinder through a pre-positioned crank, and the right camshaft is driven to rotate by a piston rod of the post-positioned air cylinder through a post-positioned crank. According to the ejector mechanism, the foaming can be realized on the single foaming special machine.

Owner:滁州市经纬模具制造有限公司

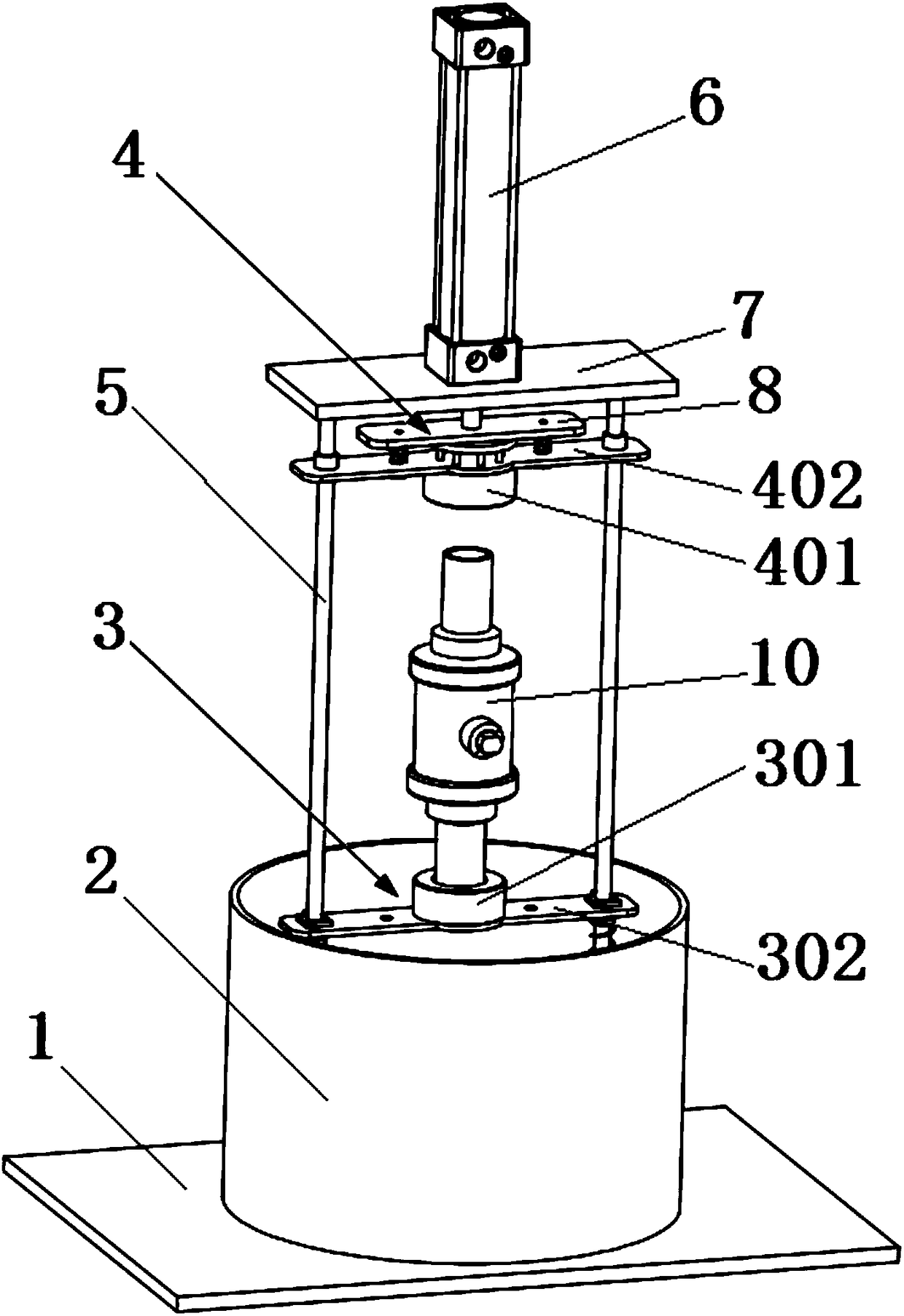

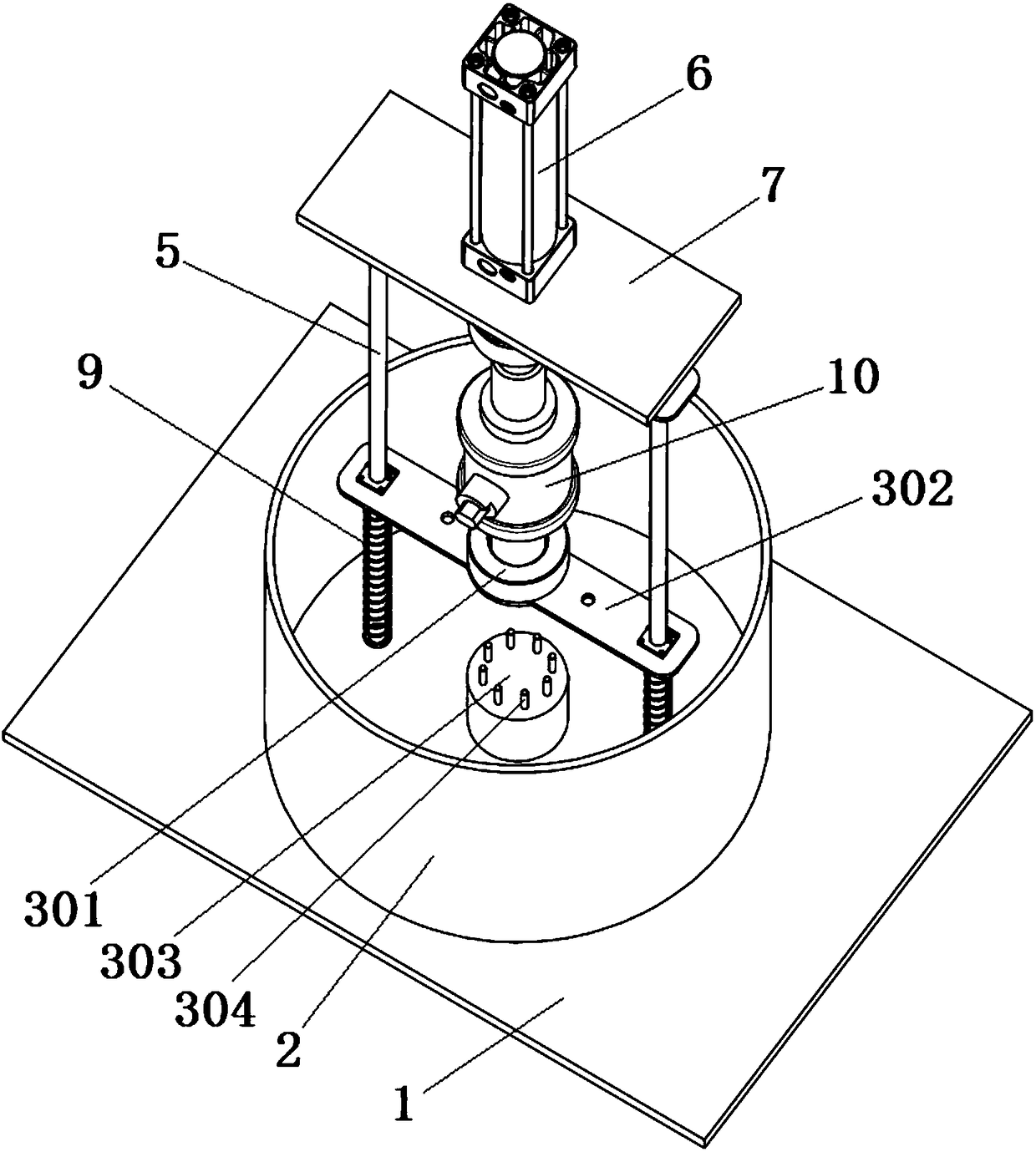

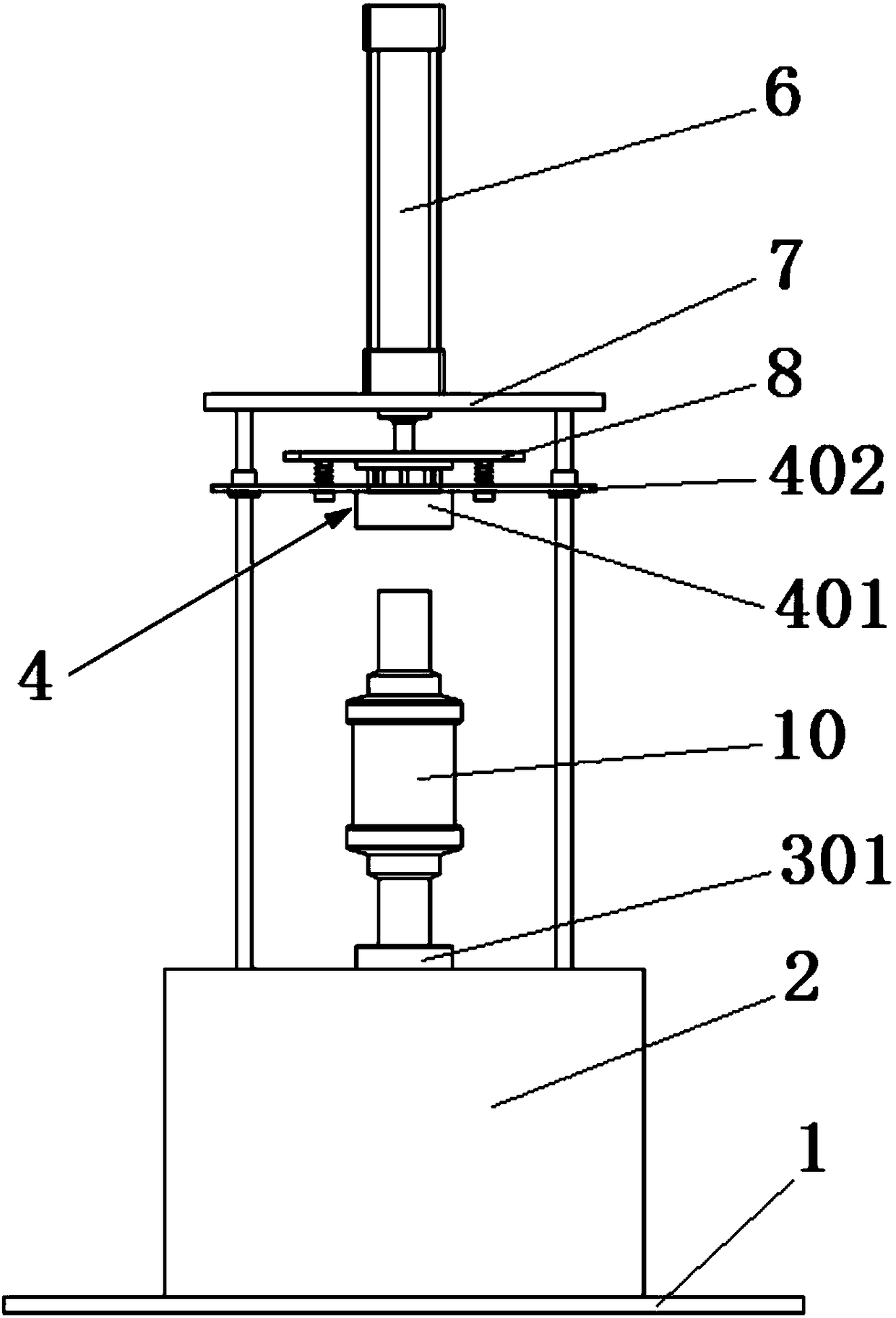

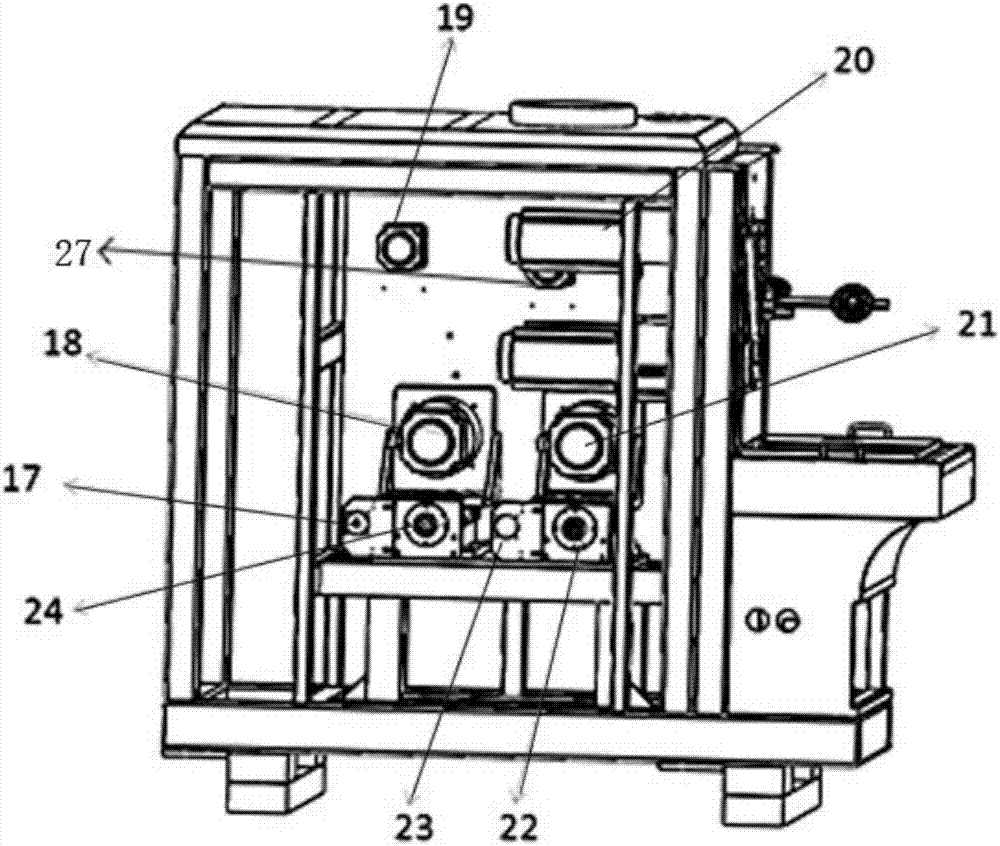

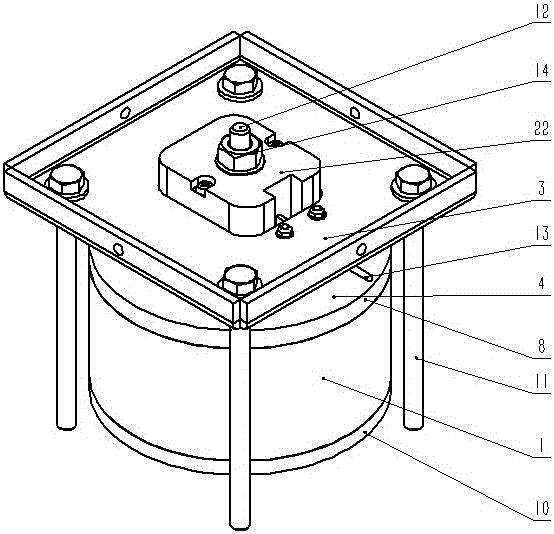

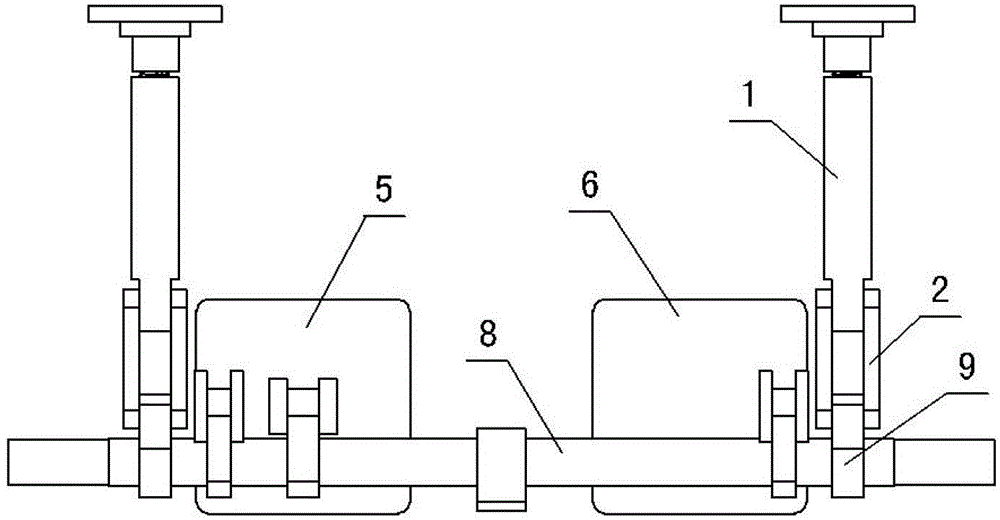

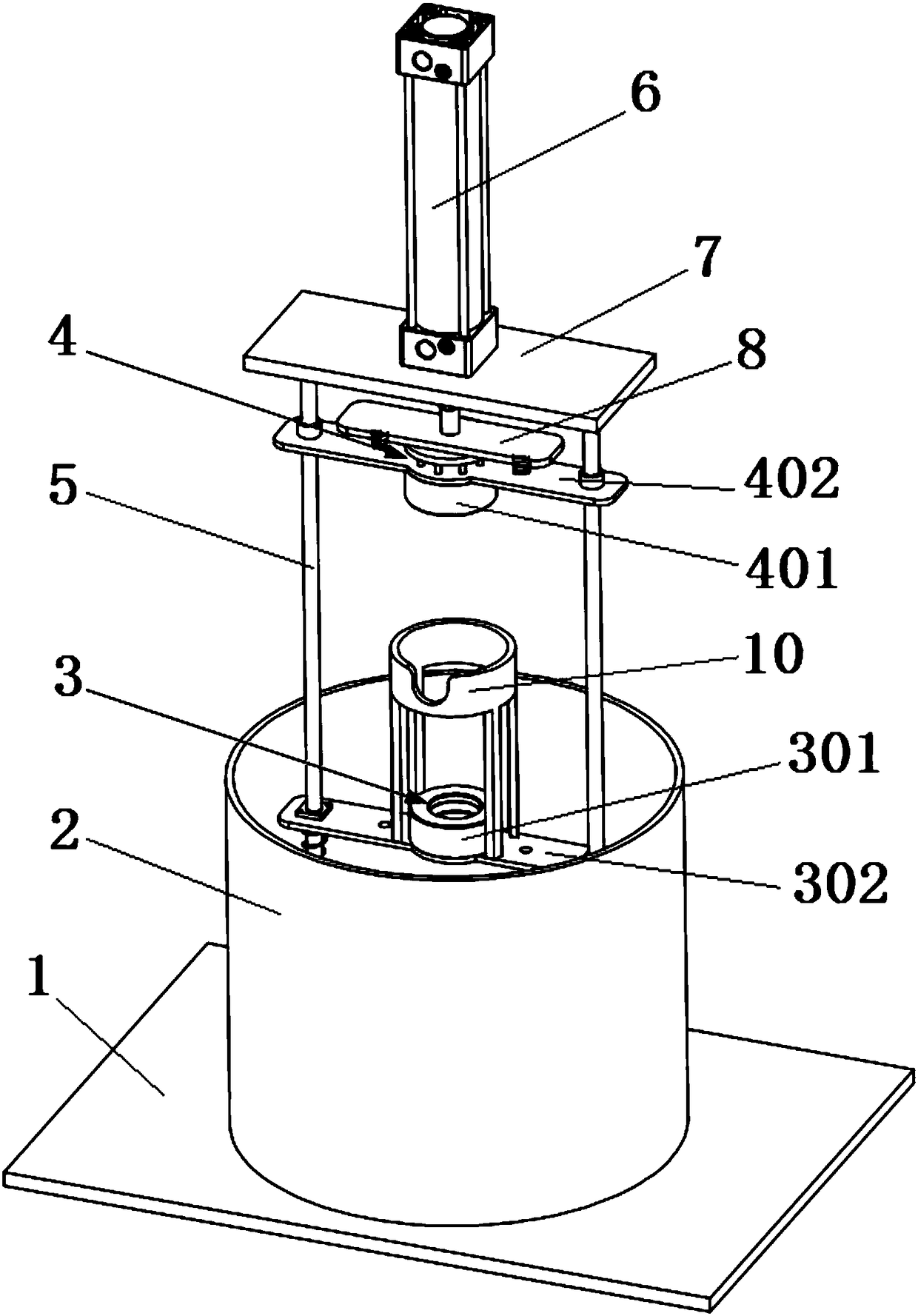

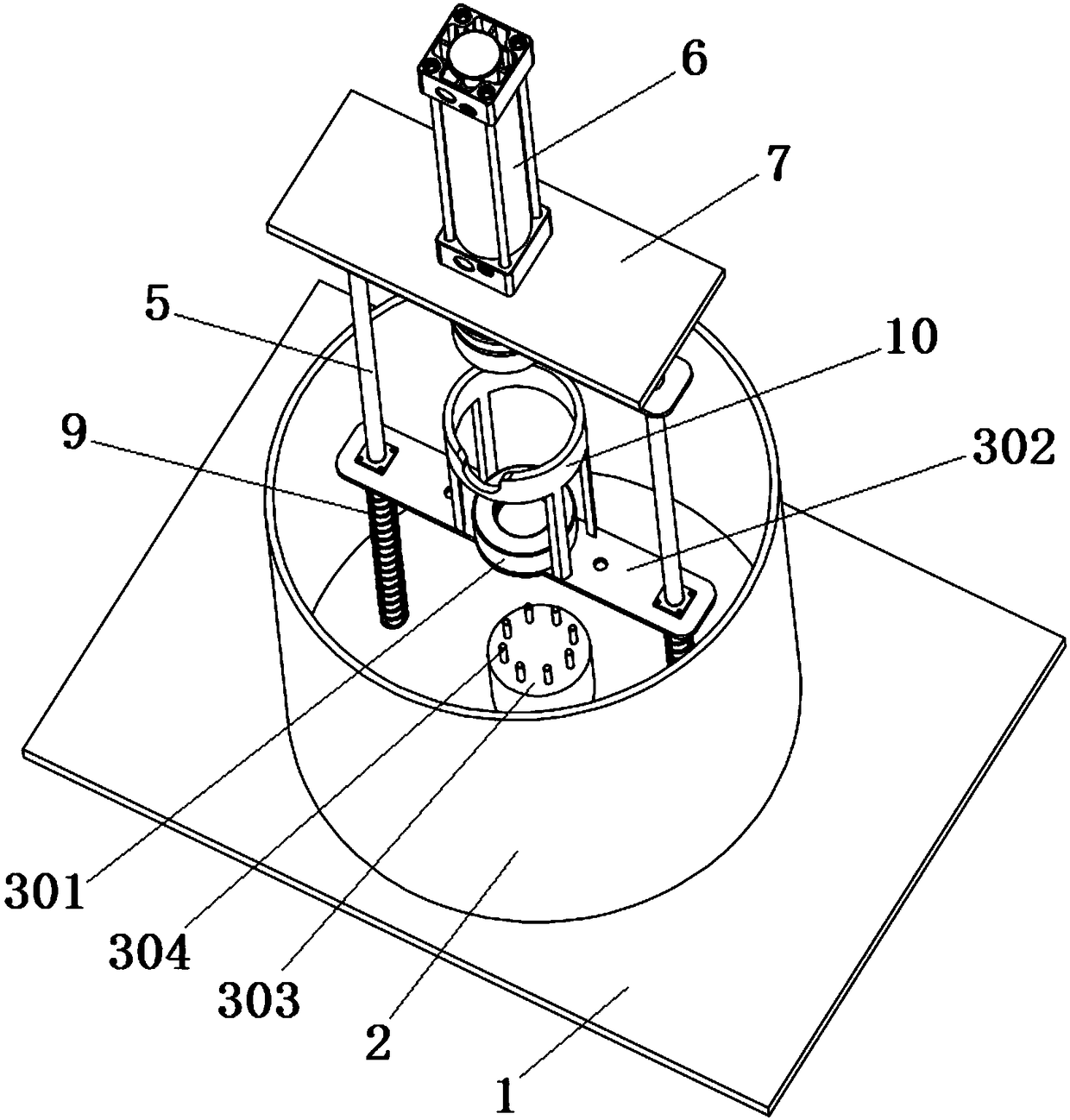

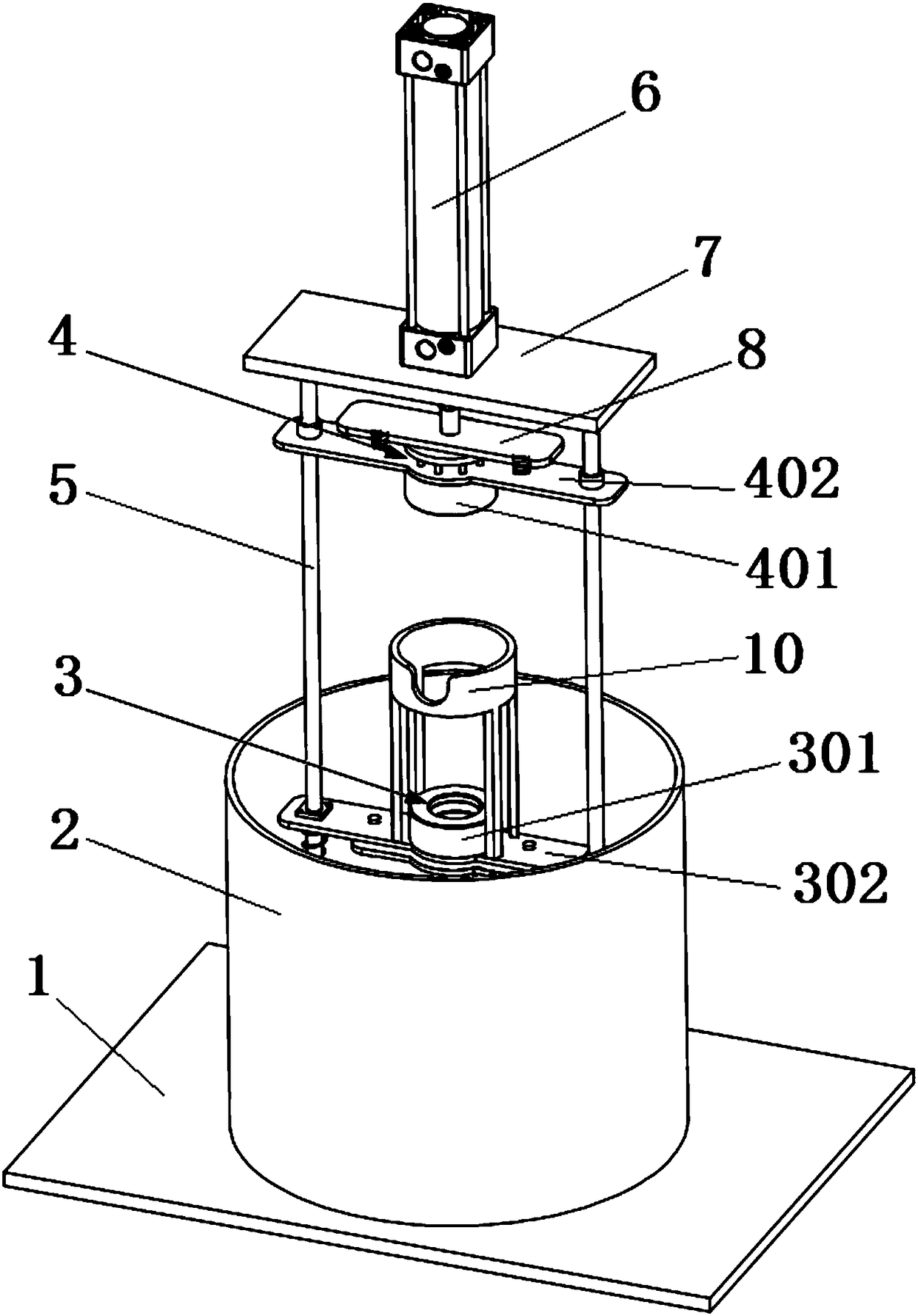

A valve automatic testing equipment

ActiveCN105738041BSave human effortImprove efficiencyDetection of fluid at leakage pointTest efficiencyAutomatic test equipment

The invention discloses automatic valve test equipment, and relates to the field of tests of sealing properties of valves. The automatic valve test equipment comprises a base and a water tank arranged on the base, wherein two polish rods are vertically arranged in the water tank, and the upper ends of the polish rods extend out of the water tank; a fixed plate connected with the two polish rods is arranged above the water tank; an upper sealing mechanism for sealing the upper end of the valve and a lower sealing mechanism for sealing the lower end of the valve are arranged between the fixed plate and the bottom of the water tank; a cylinder for driving the upper sealing mechanism is arranged on the fixed plate. The valve sealing property test equipment aims at solving the problems that an existing valve sealing property test method is inconvenient for clamping, low in efficiency and low in automation degree and costs much labor, and is high in test efficiency, convenient for clamping and high in automation degree.

Owner:辛集市邑阔天然气有限公司

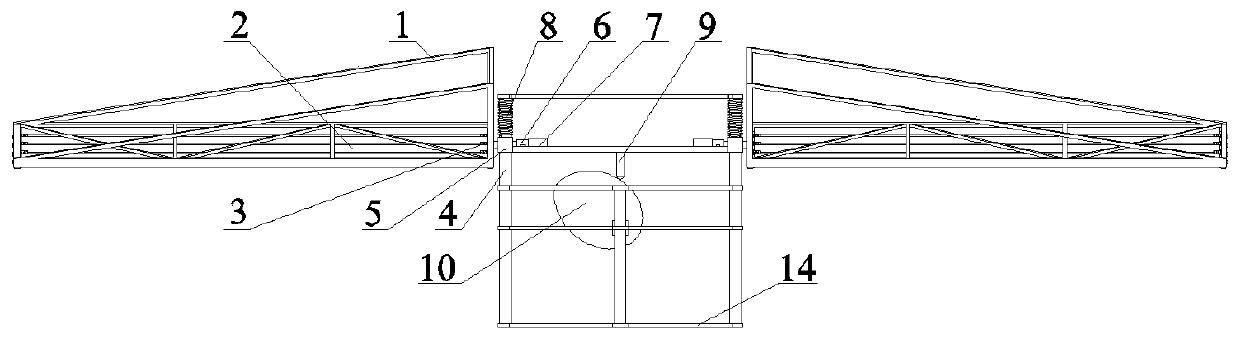

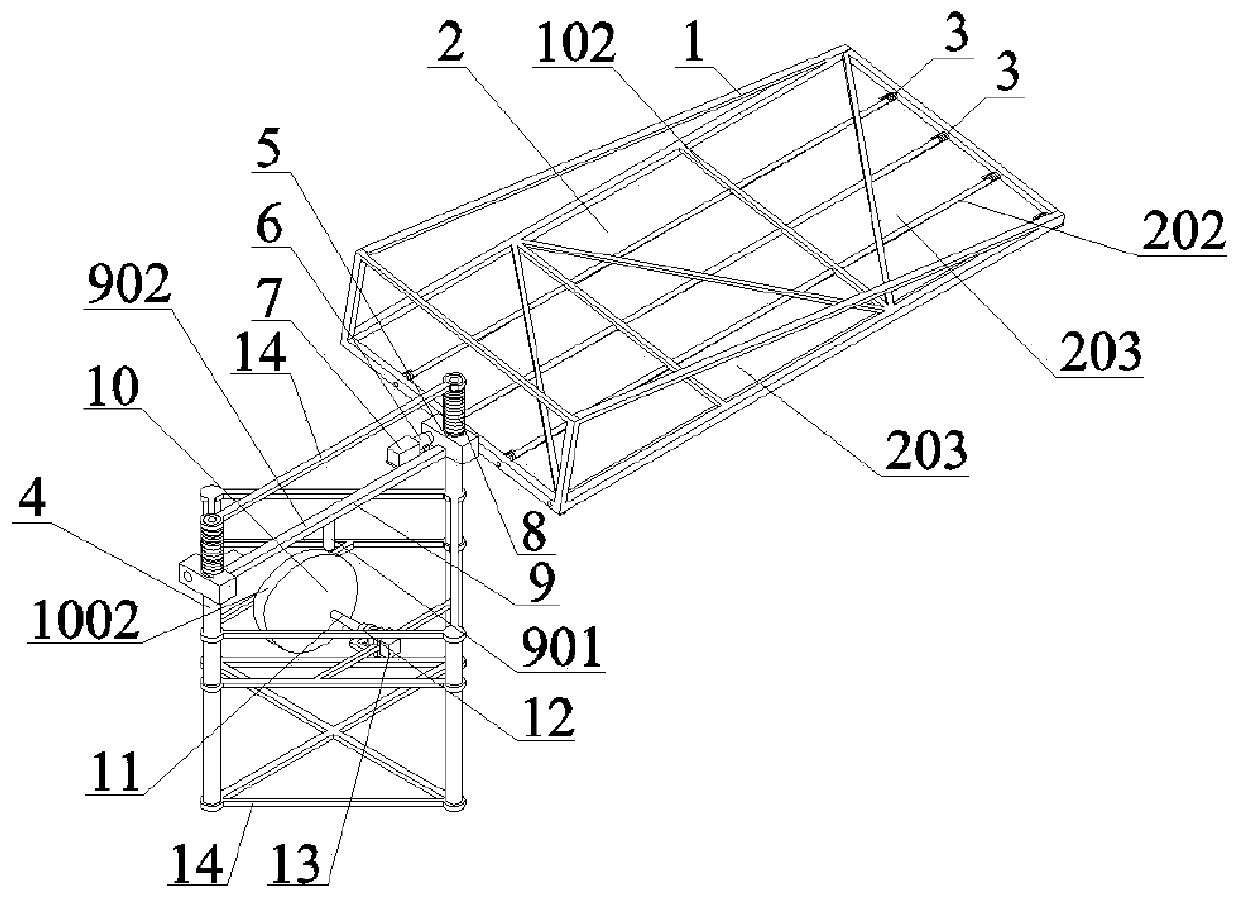

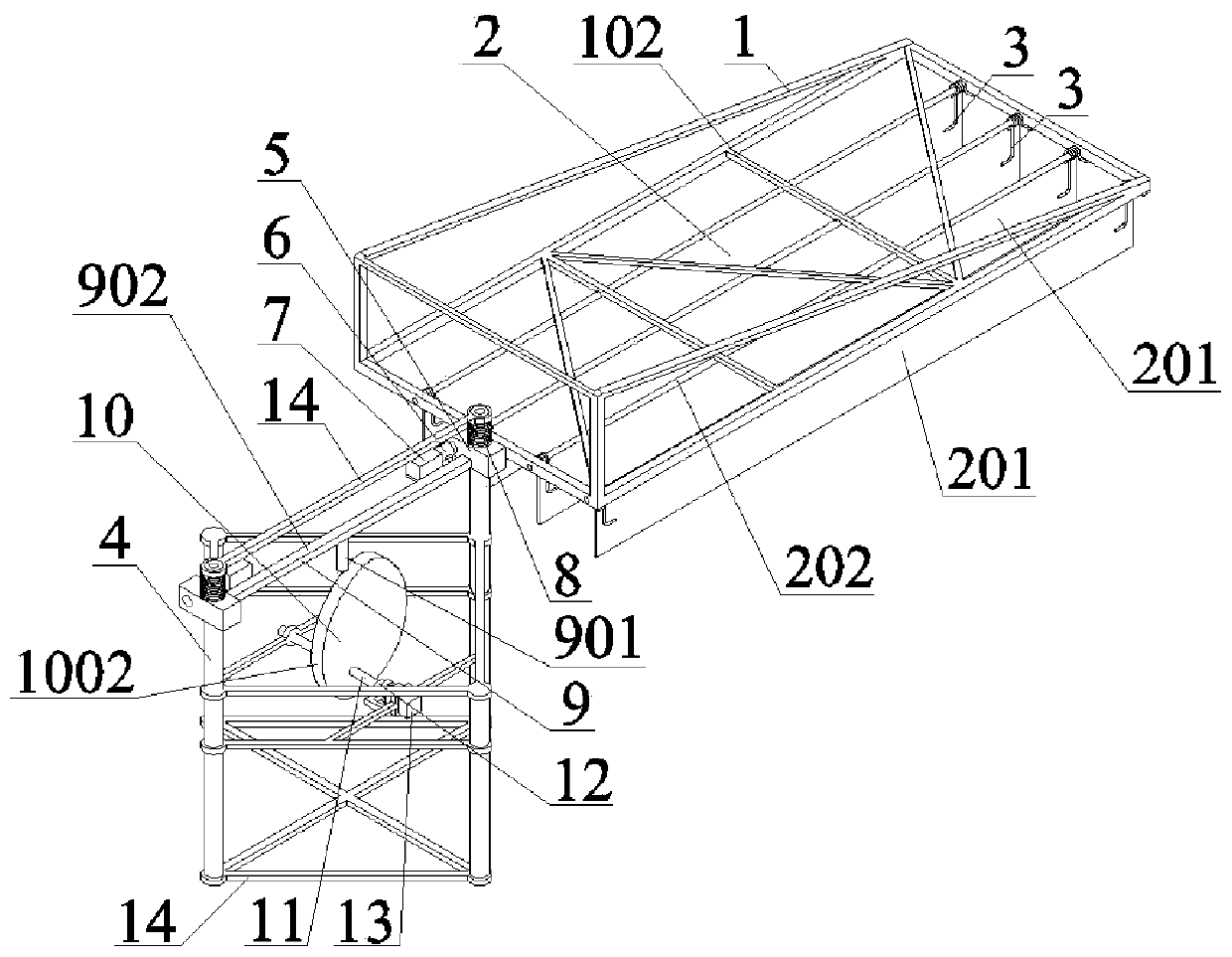

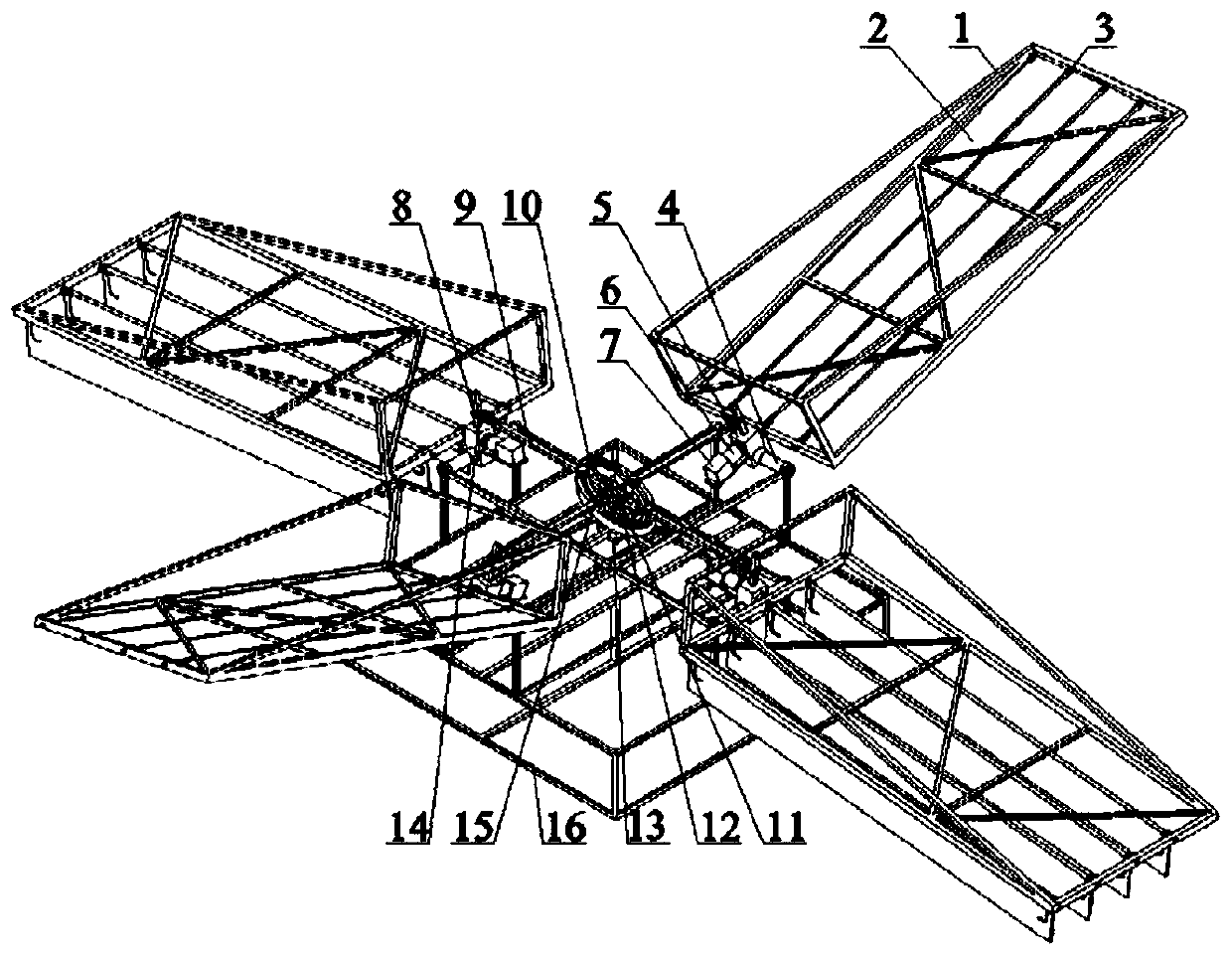

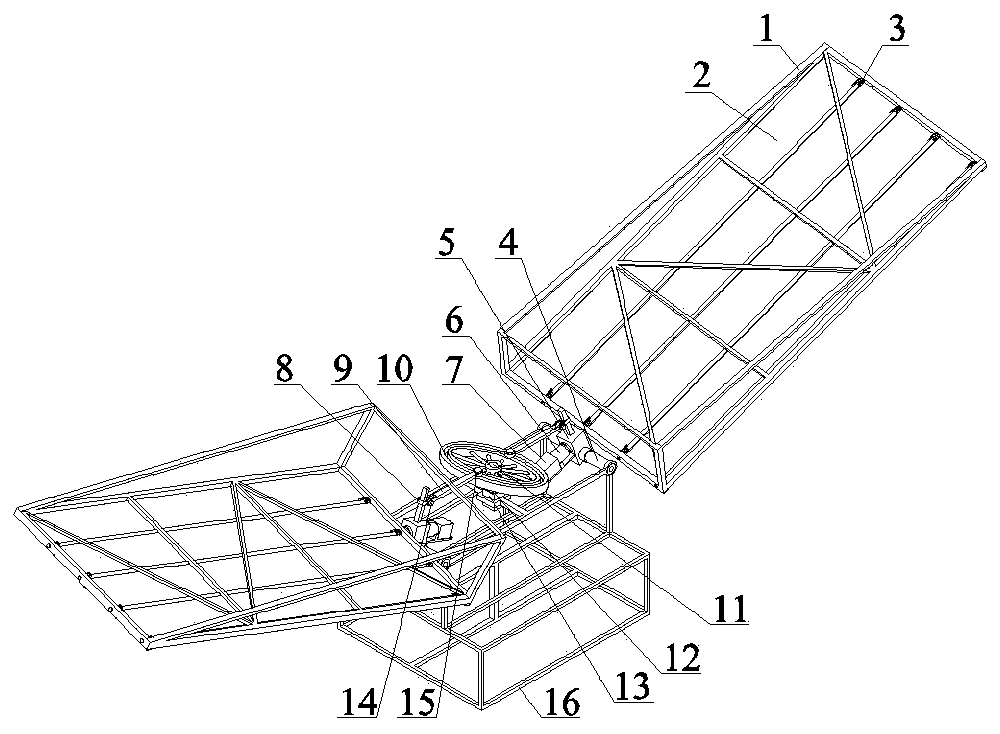

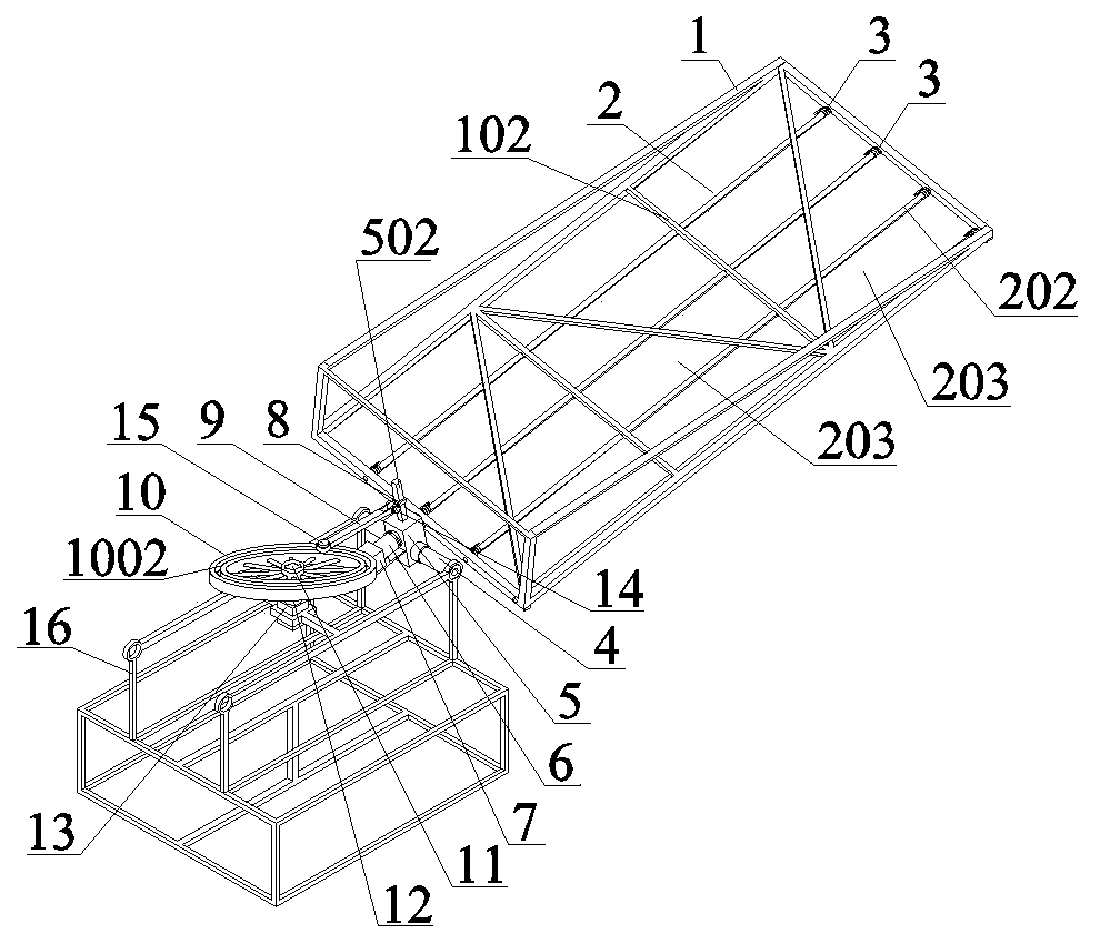

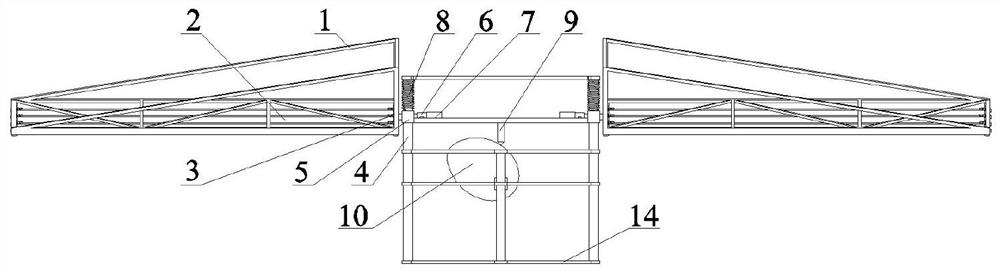

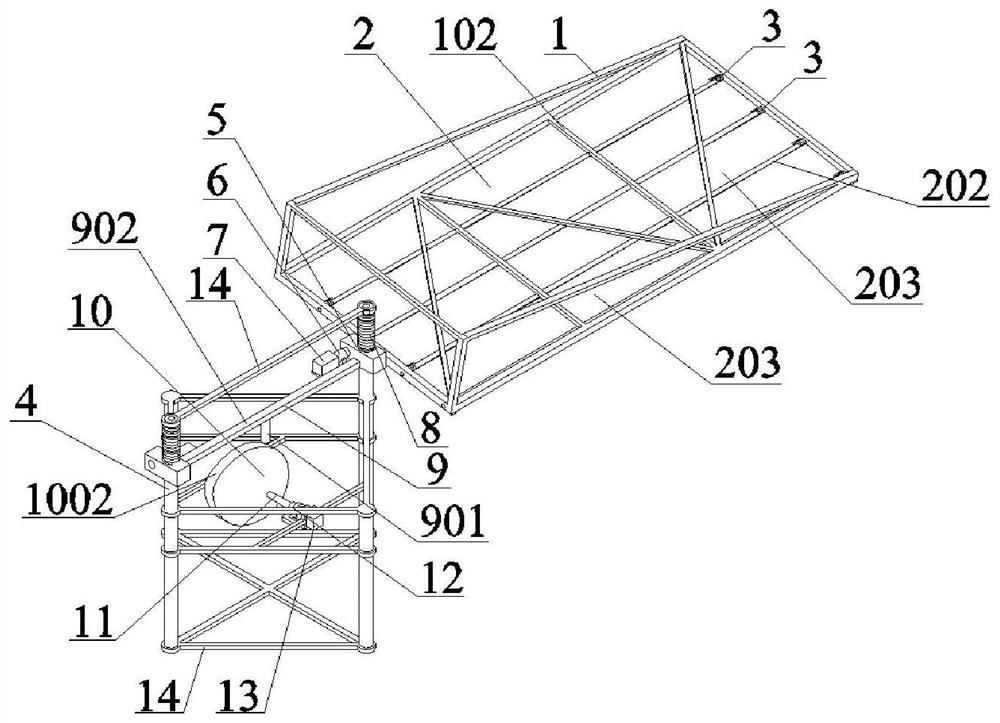

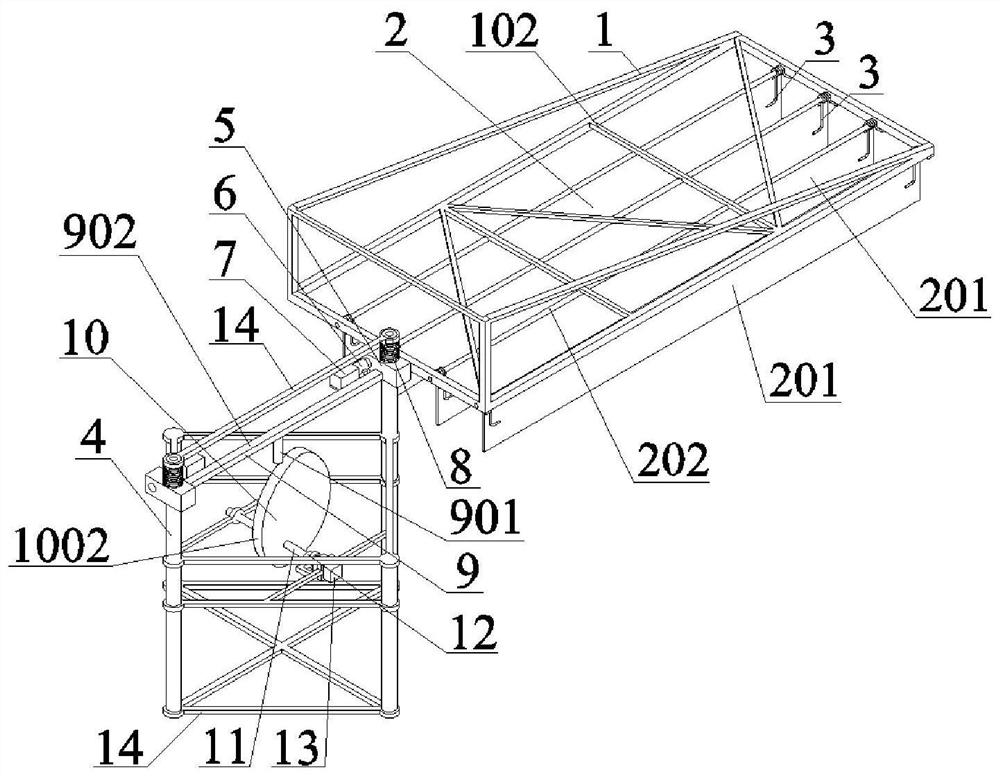

Low-resistance synchronous direct-acting type double-flapping-wing aircraft

ActiveCN110294118AImprove aerodynamic efficiencyReduce resistanceSpars/stringersWing adjustmentsFlapping wingReduction drive

The invention relates to the field of flapping wing type aircrafts and flying robots, in particular to a low-resistance synchronous direct-acting type double-flapping-wing aircraft. The double-flapping-wing aircraft comprises flapping wings, slideways, connecting pieces, a first speed reducer, a stepping motor, a transmission mechanism, a second speed reducer, motors and a machine body frame, wherein the two slideways in the vertical direction are symmetrically installed and fixed on two sides of the machine body frame; the two connecting pieces are respectively connected to the two slidewaysin a sliding manner; the two flapping wings are respectively connected to the two connecting pieces and can rotate relatively; the flapping wing comprises a flapping wing frame and a rotatable blade arranged in the flapping wing frame; a torsional spring is also arranged in the flapping wing frame and is used for resetting the blade; the transmission mechanism is connected to the two connecting pieces; the motors arranged on the machine body frame drive the transmission mechanism to move after being decelerated by the second speed reducer so that the two connecting pieces synchronously slide up and down; and the two stepping motors arranged on the connecting pieces drive the two flapping wings to rotate respectively after being decelerated by the first speed reducer.

Owner:GLOBAL INST OF SOFTWARE TECH +1

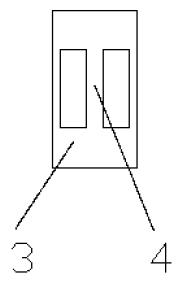

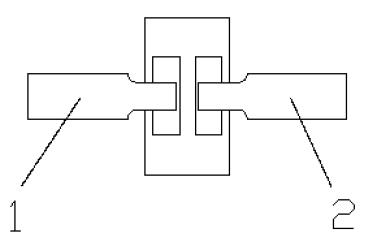

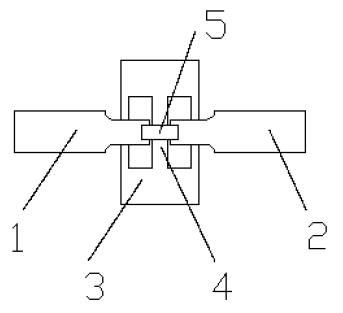

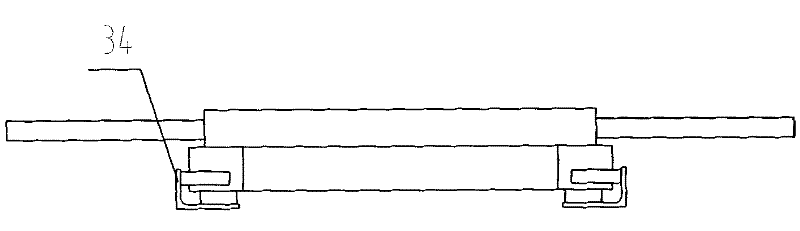

Temperature fuse and manufacturing method thereof

InactiveCN102064060ASmall sizeGood action consistencyFuse device manufacturePower flowTwo temperature

The invention relates to a temperature fuse and a manufacturing method thereof. The temperature fuse comprises metal conductive members, low-temperature fusible alloy and insulating films, wherein the fronts and the backs of the metal conductive members are connected by two layers of low-temperature fusible alloy, the surface of the low-temperature fusible alloy is coated with fluxing resin, the ends of the metal conductive members, the low-temperature fusible alloy and the fluxing resign are covered with the insulating films, an under layer of a middle insulating film separates the two layers of low-temperature fusible alloy and is connected with the metal conductive members. The manufacturing method of the temperature fuse comprises the following steps of: welding the metal conductive members on the middle insulating film and reserving gaps at the ends; welding the two layers of low-temperature fusible alloy on the fronts and the backs of the ends of the metal conductive members; coating the fluxing resin on the surface of the low-temperature fusible alloy; covering two insulating films on the middle insulating film and covering the ends of the metal conductive members, the low-temperature fusible alloy and the fluxing resign with the insulating films. The temperature fuse is suitable to working occasions with small size and large current and has the function approximate to the function of two fuses which are connected in parallel, is superior to two fuses which are connected in parallel in action consistency and has the advantages of small size and space and cost saving.

Owner:SHANGHAI CHANGYUAN WAYON CIRCUIT PROTECTION CO LTD

Height regulating device for automobile chair

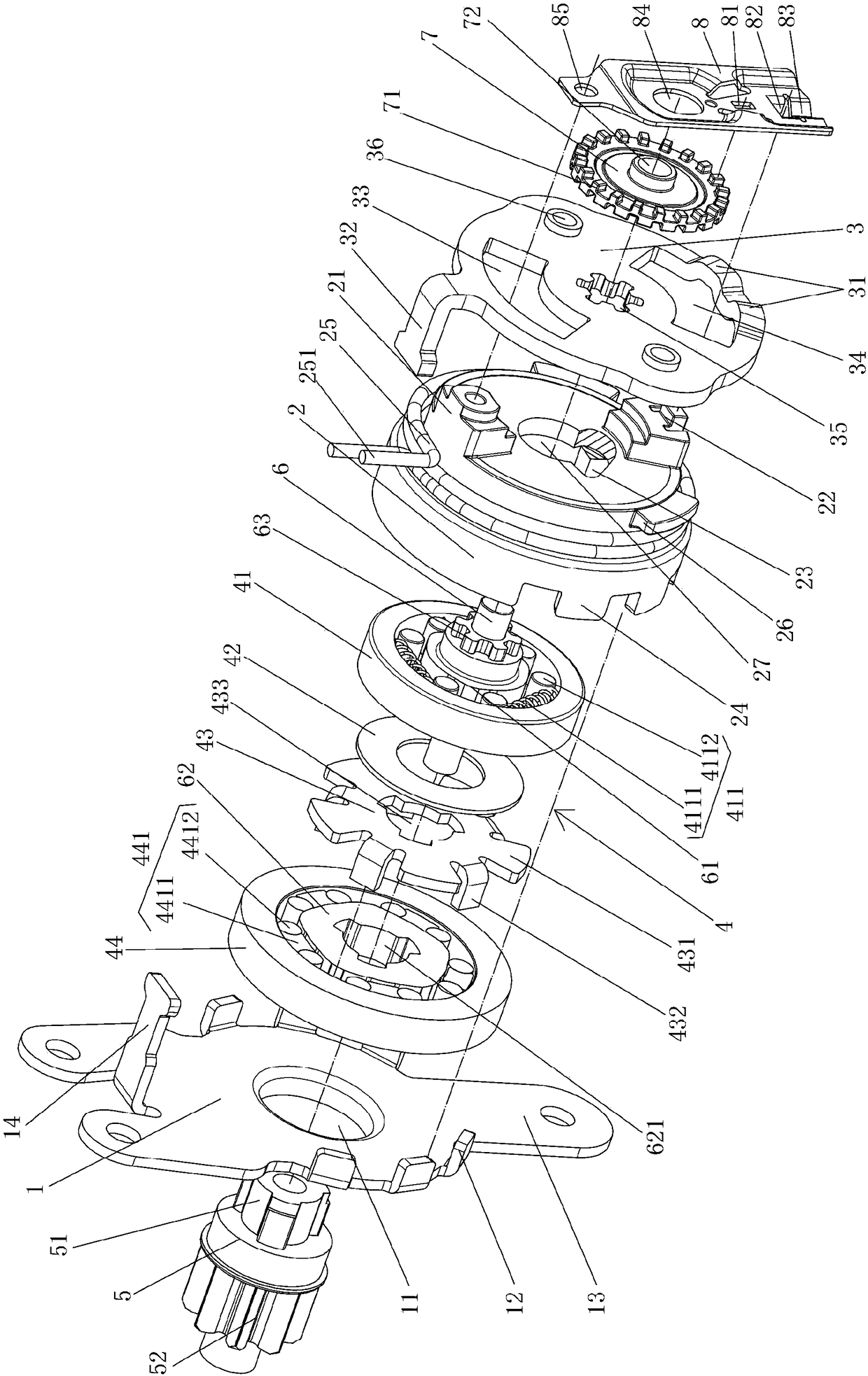

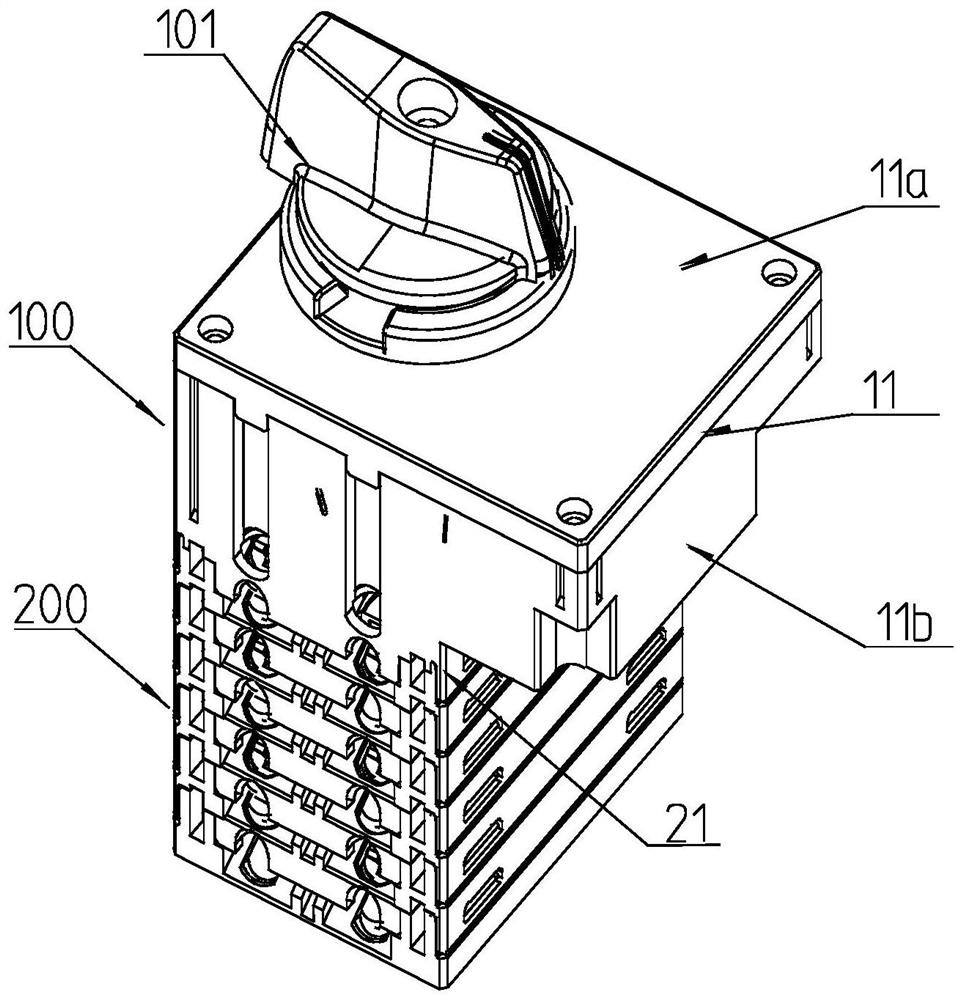

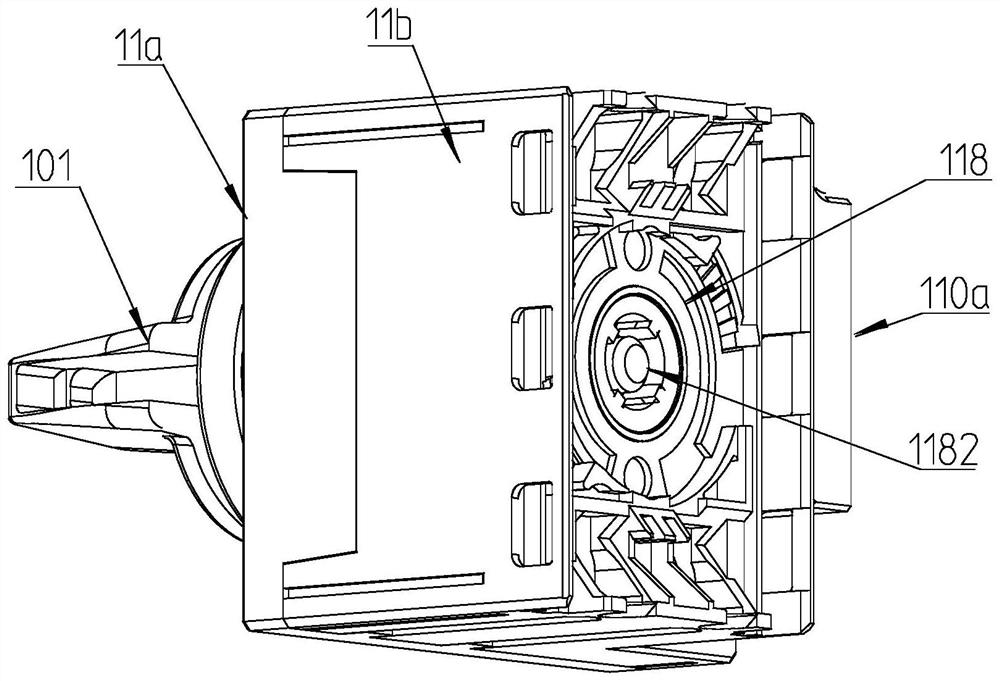

PendingCN108556696APrevent rotationAvoid self-sinking situationsMovable seatsLocking mechanismEngineering

The invention relates to a height regulating device for an automobile chair. The height regulating device for the automobile chair comprises an installing plate, a cover case, an operation plate, a locking mechanism, an output shaft and a center shaft, wherein the cover case is arranged at one side of the installing plate; the operation plate is arranged on the cover case; the locking mechanism isarranged in the cover case; the output shaft is arranged at the other side of the installing plate; the center shaft is respectively connected with the output shaft and the operation plate. The height regulating device has the characteristics that the center shaft is provided with an anti-loosening wheel at one end connected with the operation plate; an anti-loosening plate is arranged on the cover case; a position limiting lug boss is arranged above one side, facing the anti-loosening wheel, of the cover case; the position limiting lug boss passes through the operation plate to be fixed withthe anti-loosening plate; anti-loosening teeth are distributed at intervals in the circumference direction of one side, facing the anti-loosening plate, of the anti-loosening wheel; anti-loosening tooth clamp grooves are formed in the anti-loosening plate; a locking lug boss is arranged under one side, facing the anti-loosening wheel, of the cover case; the locking lug boss penetrates through theoperation plate and is arranged in the locking hole of the anti-loosening plate in a penetrating way; a striping lug boss is arranged at one side, facing the operation plate under the locking hole, of the anti-loosening plate; a pair of unlocking lug bosses is arranged at one side, facing the anti-loosening plate, of the operation plate in a projected way. The automatic sinking of the chair is avoided; the service life is prolonged; the manufacturing cost is low; the action consistency is good; the unlocking idle stroke is small.

Owner:JIANGSU ZHONGMING XIANGHE SEIKO

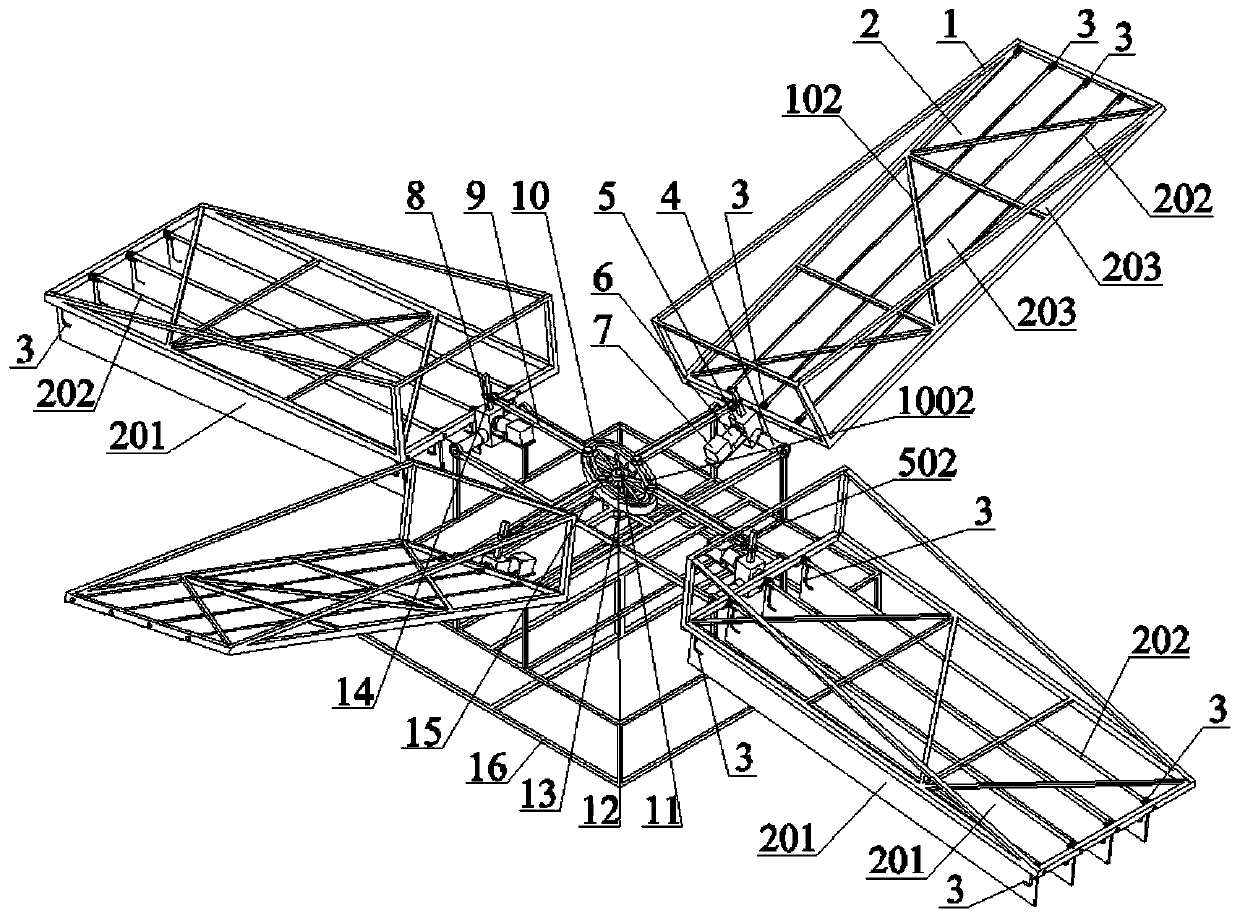

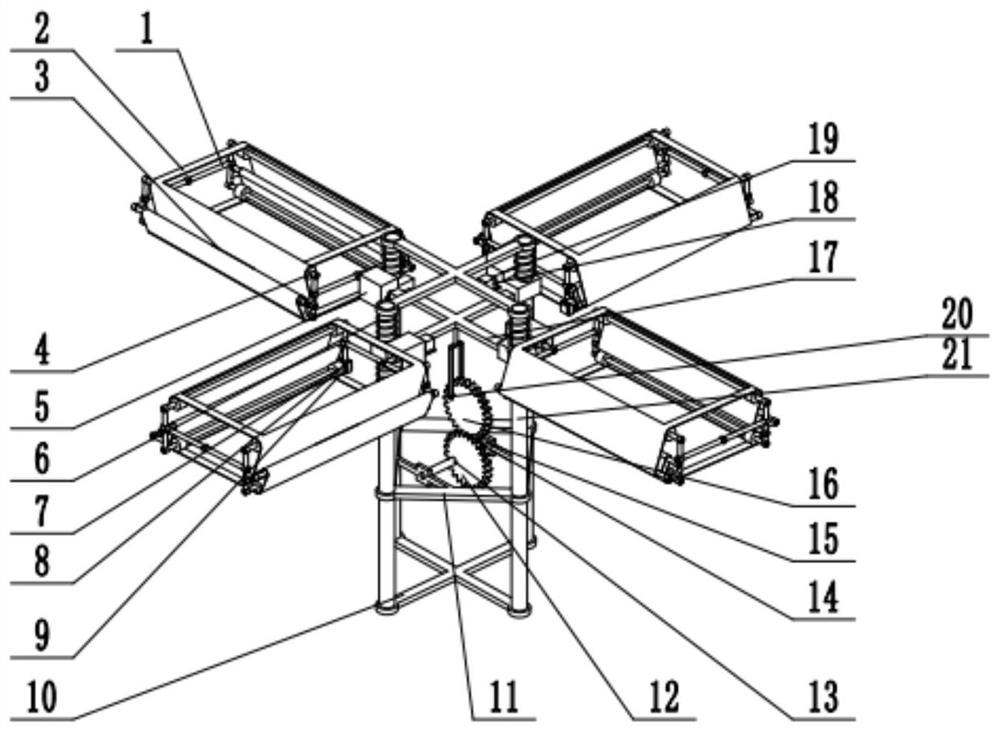

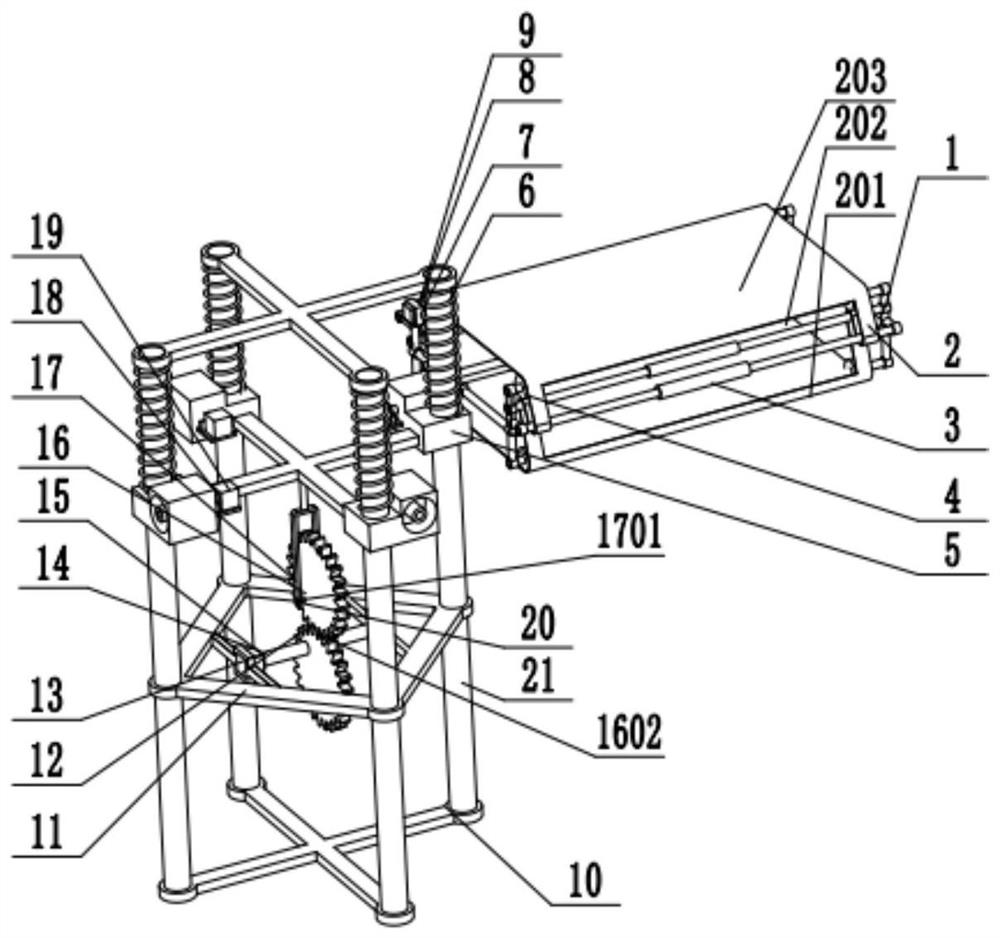

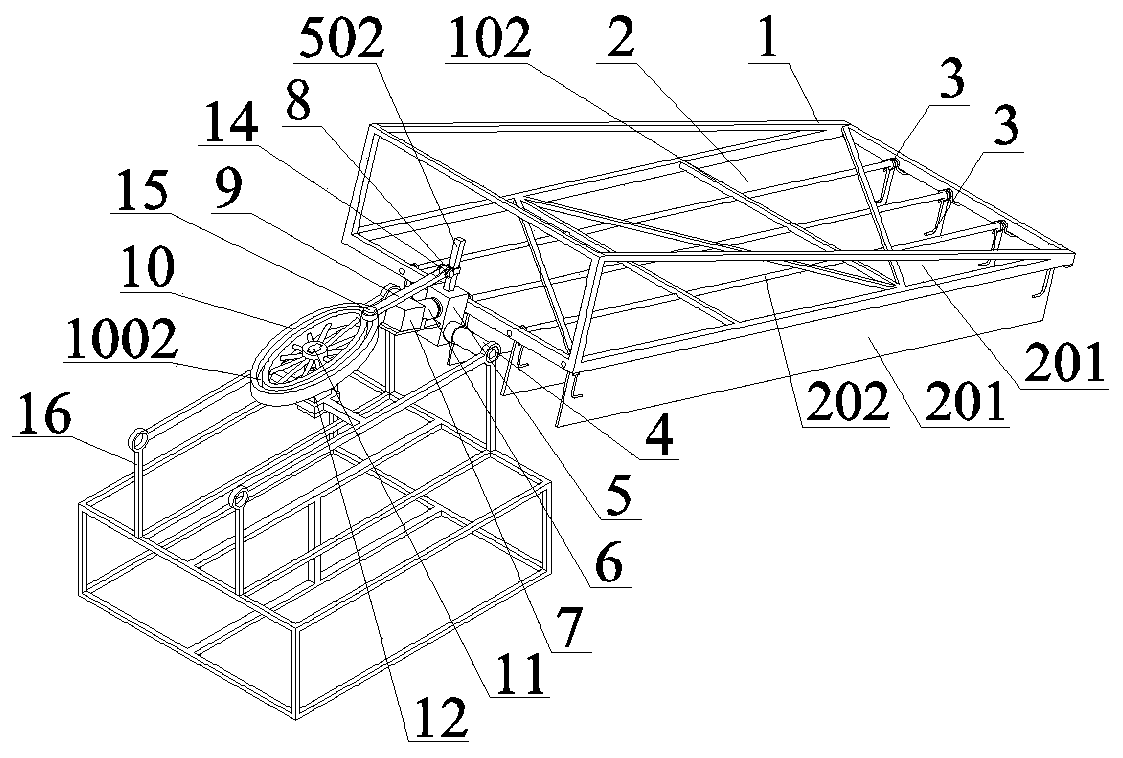

Synchronous swinging type rotary vane four-flapping-wing aircraft

ActiveCN110294120AImprove aerodynamic efficiencyReduce resistanceSpars/stringersWing adjustmentsFlapping wingReducer

The invention relates to the field of flapping wing type aircrafts and flight robots, in particular to a synchronous swinging type rotary vane four-flapping-wing aircraft. The synchronous swinging type rotary vane four-flapping-wing aircraft comprises flapping wings, swinging shafts, connecting pieces, first speed reducers, stepping motors, a transmission mechanism, a second speed reducer, a motorand a machine body frame. The four horizontal-direction swinging shafts are symmetrically installed and fixed to the periphery of the machine body frame. The four connecting pieces are connected to the four swinging shafts and oppositely rotate. The four flapping wings are connected to the four connecting pieces correspondingly and can oppositely rotate. Each flapping wing comprises a flapping wing frame and a rotary vane arranged in the flapping wing frame, wherein a torsion spring is further arranged in the flapping wing frame for vane resetting. The transmission mechanism is connected to the two connecting pieces, and after the motor is decelerated through the second speed reducer, the transmission mechanism is driven to move, the four connecting pieces synchronously swing up and down,and the four stepping motors drive the four flapping wings to rotate after being decelerated through the two first speed reducers.

Owner:GLOBAL INST OF SOFTWARE TECH +1

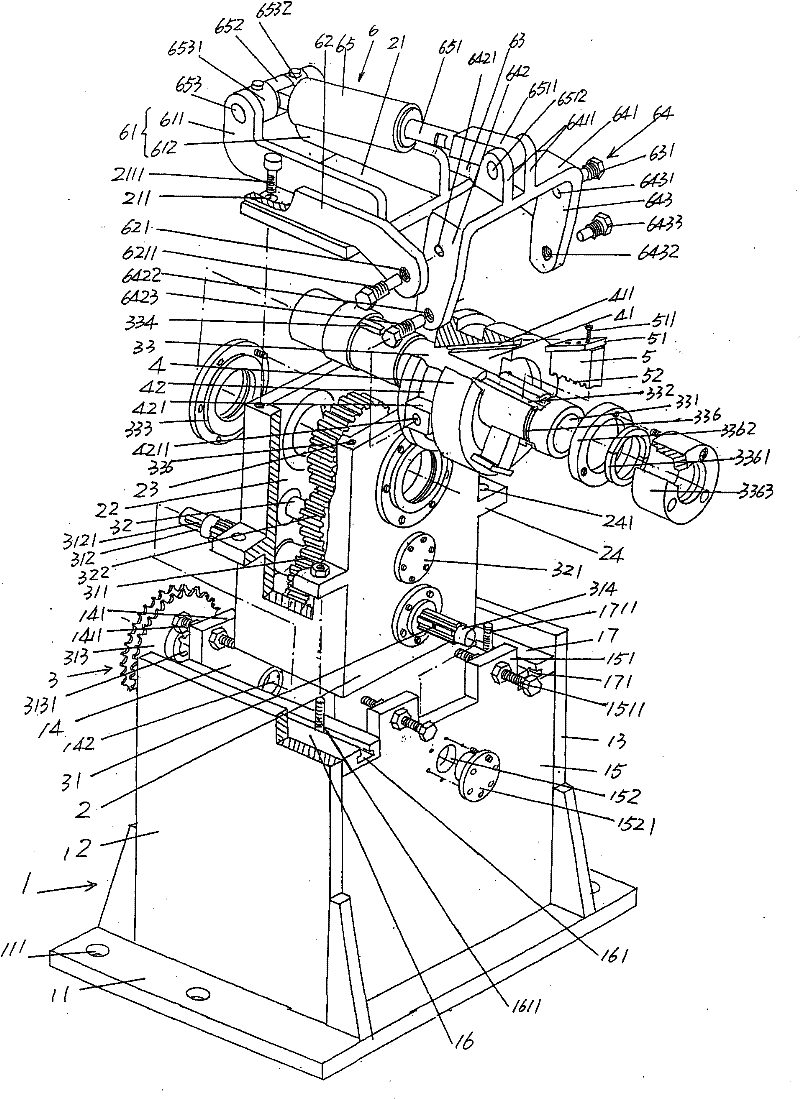

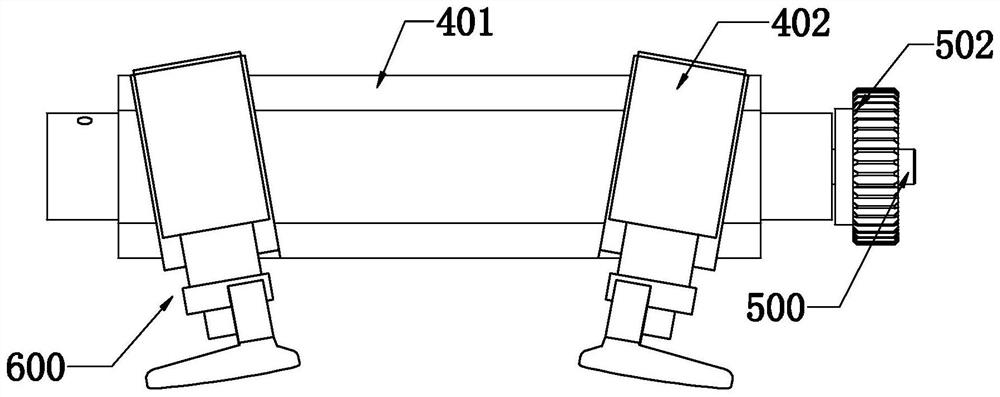

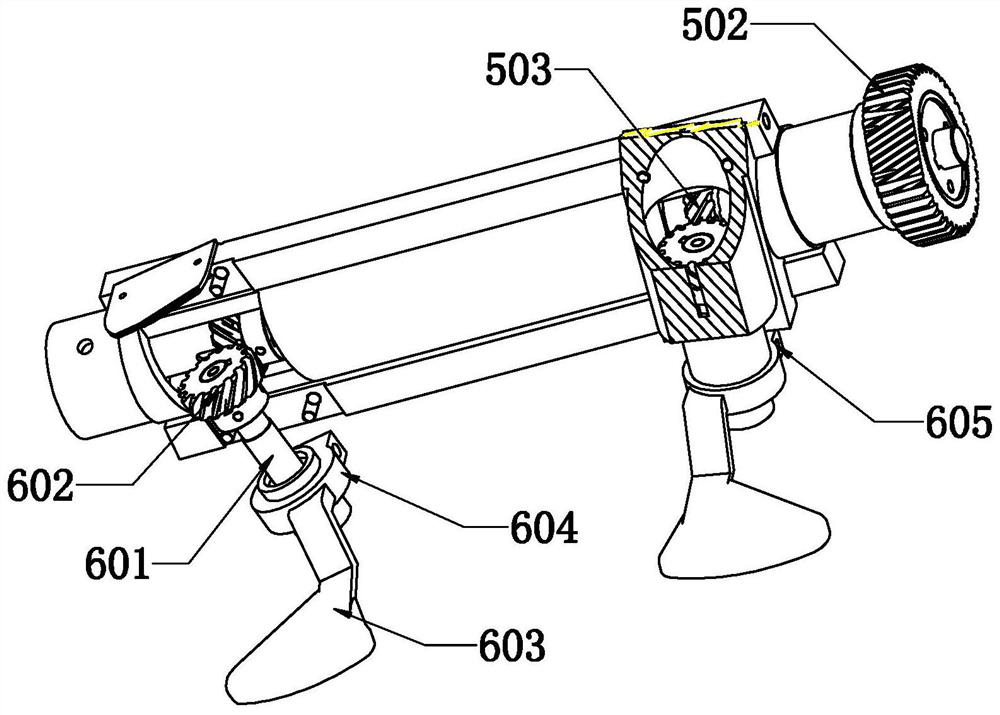

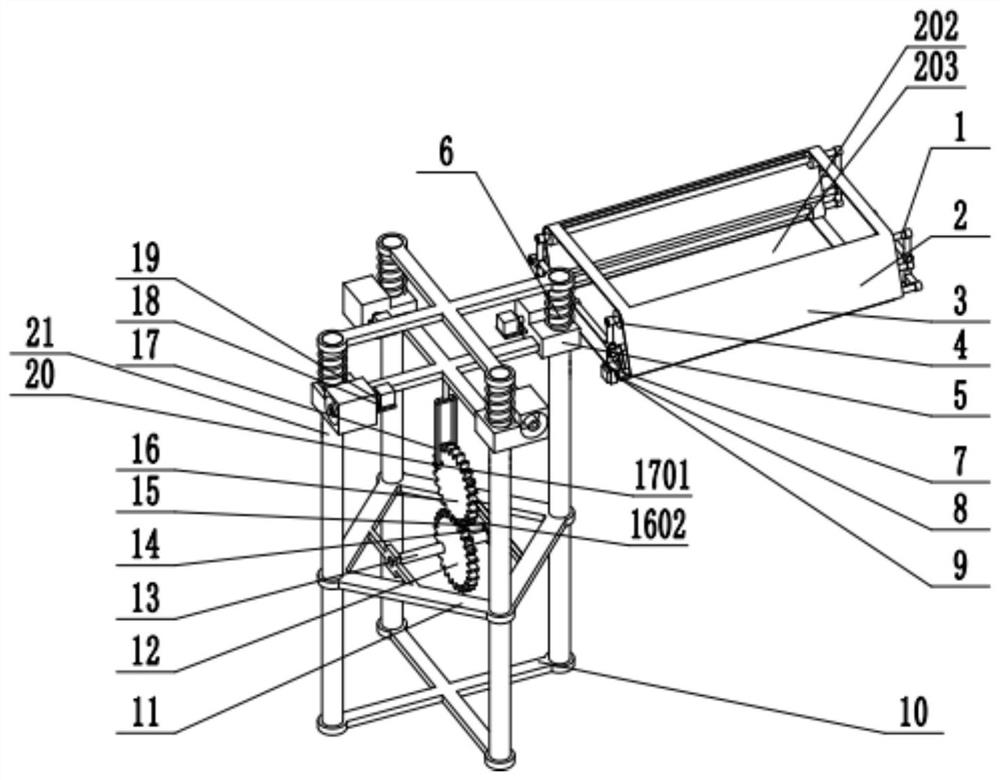

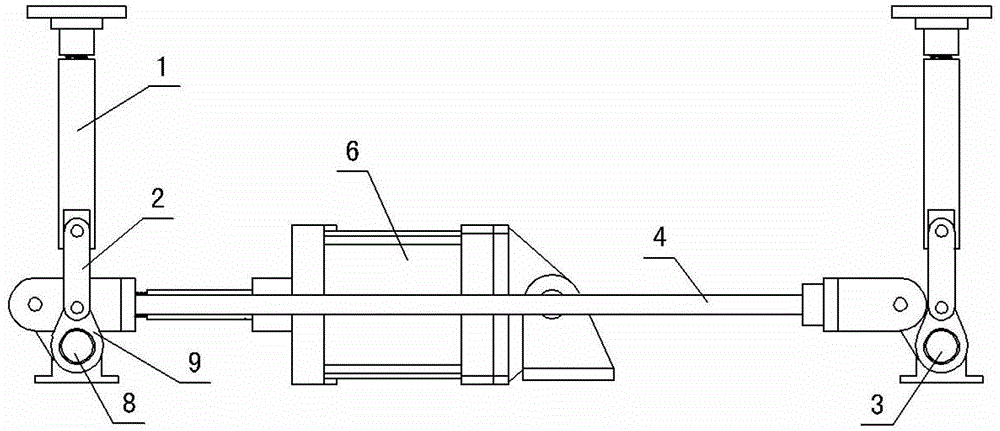

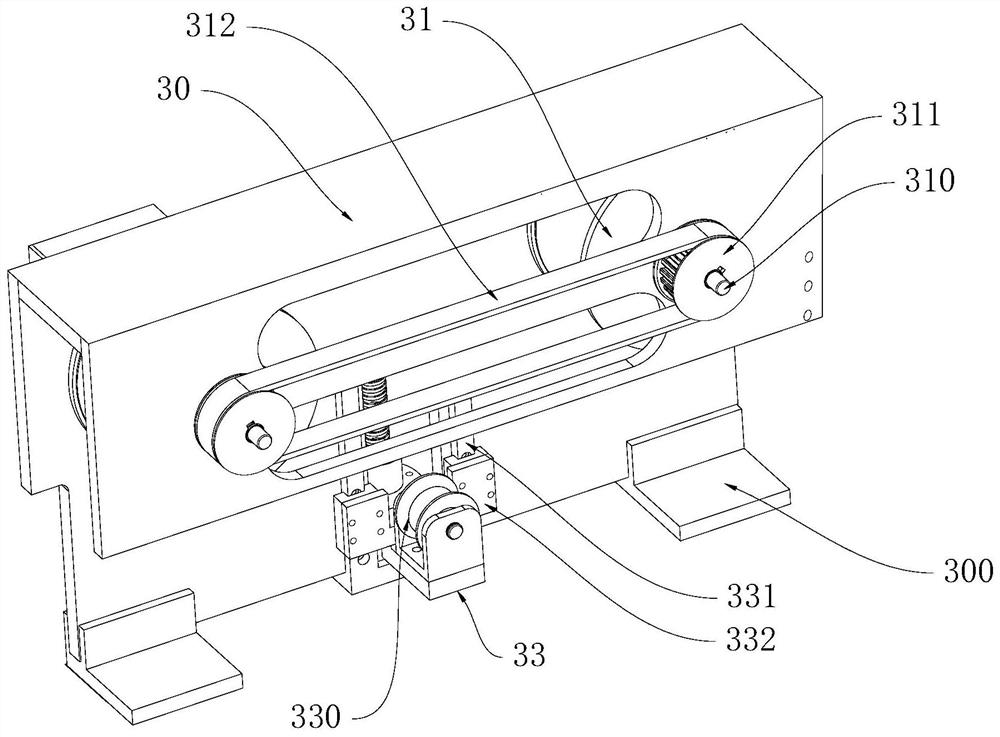

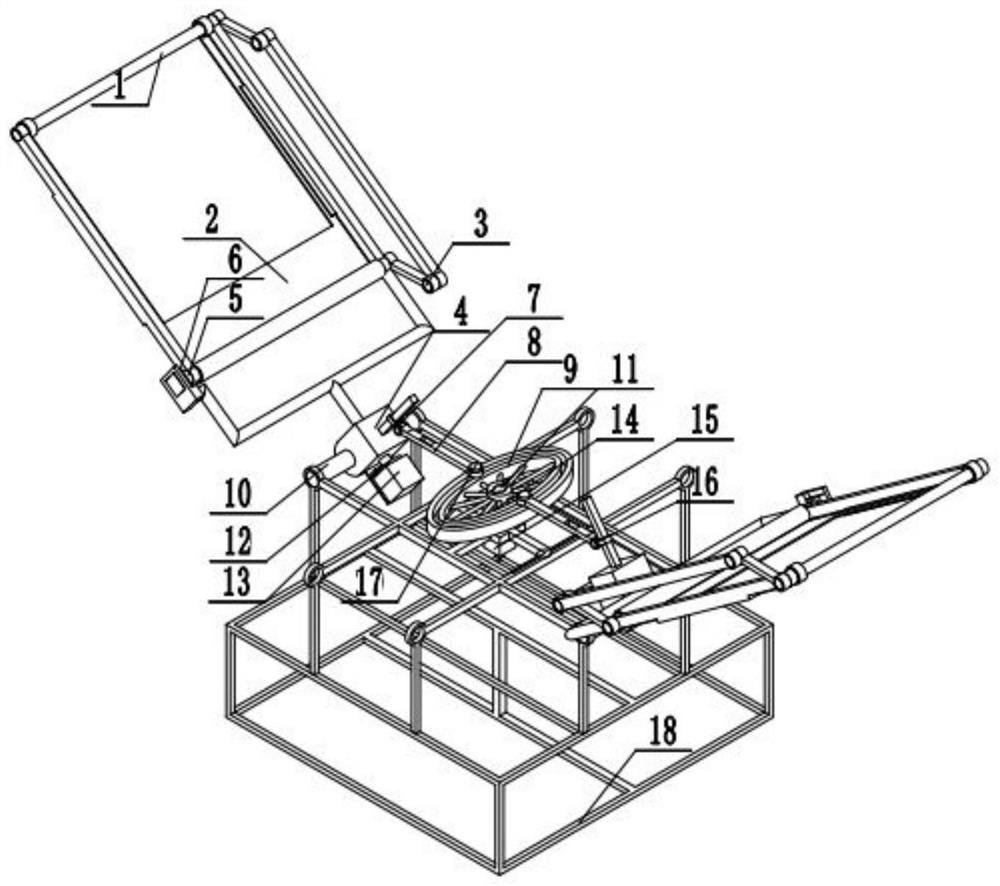

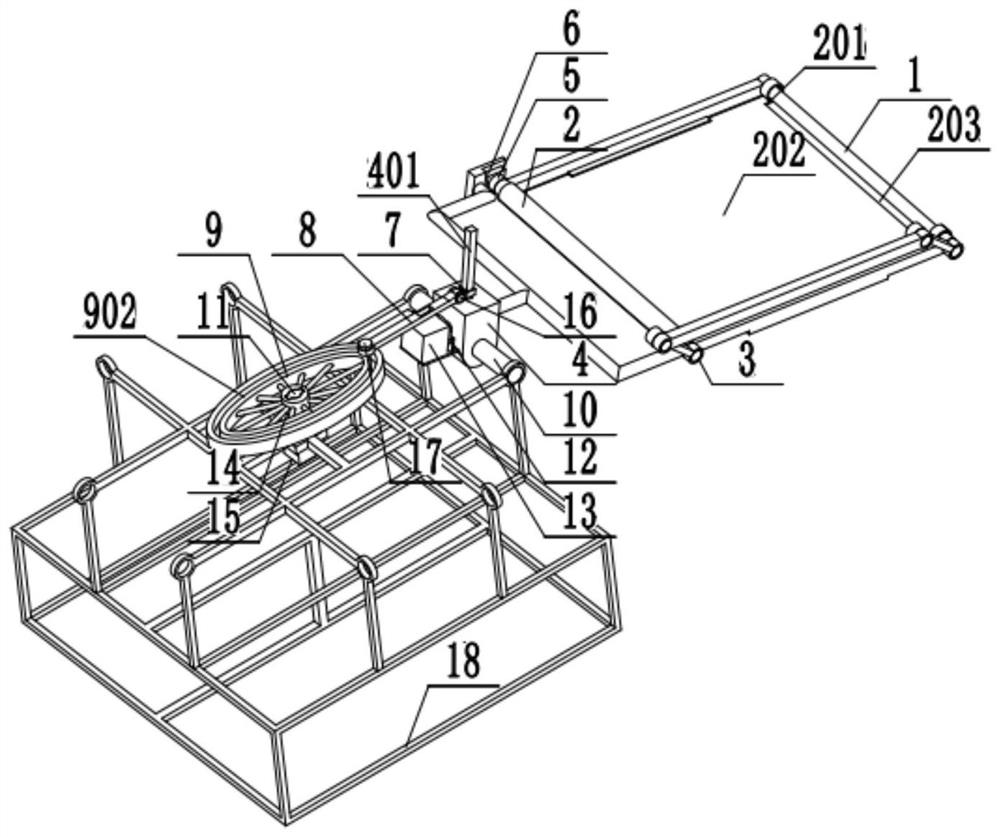

Swing mechanism of cold-rolling pipe mill

InactiveCN102059252ANo damageGood action consistencyWork manipulationMandrelsEngineeringUltimate tensile strength

The invention relates to a swing mechanism of a cold-rolling pipe mill, and belongs to the technical field of metal pipe processing machinery. The swing mechanism comprises a mounting support base, a transmission case which is arranged on the mounting support base and is provided with a cover, a power transmission device which is arranged on the transmission case and comprises a power input shaft, a transition shaft and a power output shaft, a chuck which is arranged on the power output shaft in a sliding way, and a set of jack catches which are arranged on the chunk in a sliding way. The swing mechanism is characterized by further comprising a chunk actuating device which is used to drive the chunk to slide on the power output shaft left and right and further change the position of the set of the jack catches which are arranged on the chunk in a sliding way, wherein the chunk actuating device is fixed on the cover of the transmission box and is connected with the chunk. The swing mechanism has the advantage of fast operation speed and good action consistency of the jack catches, and can lighten the working strength of operators.

Owner:CHANGSHU MEILI MACHINERY MFG

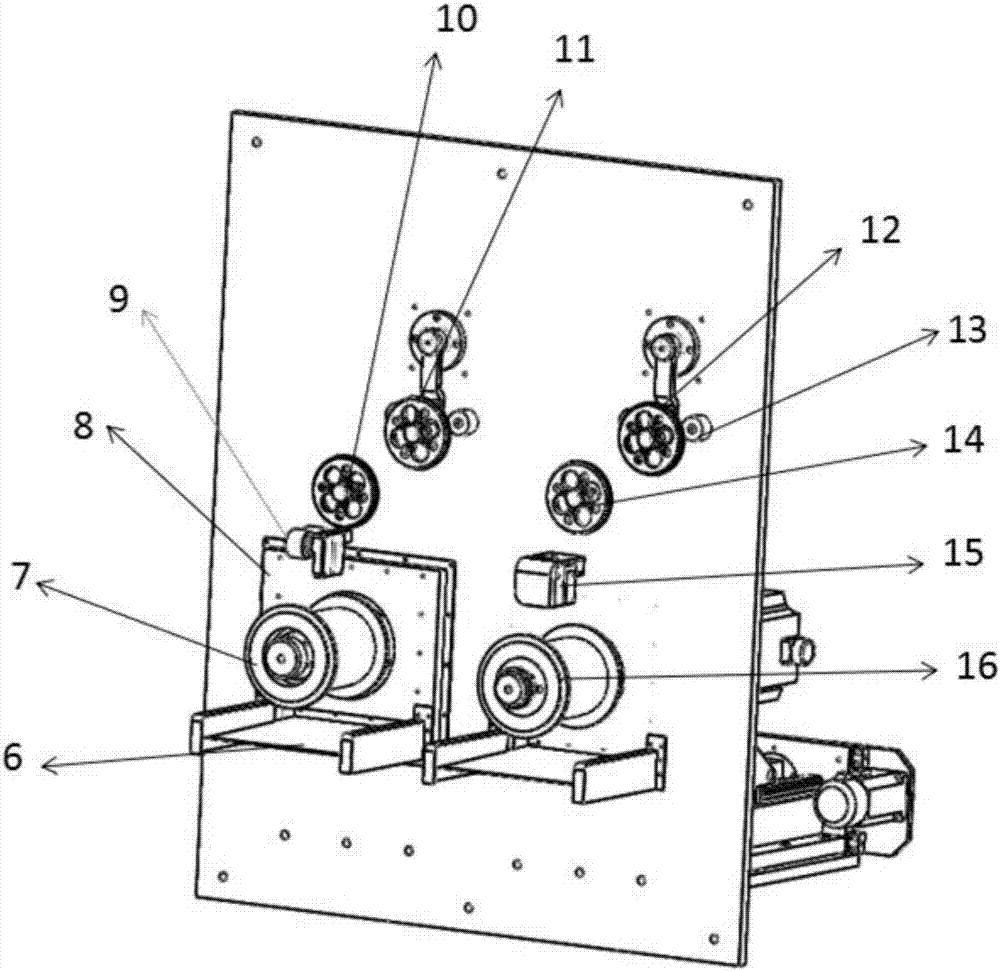

Six-guide-wheel multi-line cutter

InactiveCN107225702AWinding method is simpleShorten the timeWorking accessoriesGrinding machinesWork cycleEngineering

The invention discloses a six-guide-wheel multi-line cutter. The six-guide-wheel multi-line cutter comprises a rack, a work line roller, a worktable, a worktable driving device, a reverse wheel, a first line roller, a first auxiliary wheel, a first adjusting wheel, a first tensioning wheel, a second line roller, a second tensioning wheel, a second adjusting wheel and a second auxiliary wheel. The work line roller comprises three triangularly-arranged work main shafts. The reverse wheel is arranged on one side of the work line roller. The first line roller, the first auxiliary wheel, the first adjusting wheel, the first tensioning wheel, the second line roller, the second tensioning wheel, the second adjusting wheel and the second auxiliary wheel are arranged on the other side of the rack. The first line roller, the first auxiliary wheel, the first adjusting wheel and the first tensioning wheel are arranged in sequence from bottom to top. The second tensioning wheel, the second adjusting wheel, the second auxiliary wheel and the second line roller are arranged on one sides of the first line roller, the first auxiliary wheel, the first adjusting wheel and the first tensioning wheel in sequence from top to bottom. A steel wire is wound through the six guide wheels, the winding mode is simple, under the premise of completing functions, each work cycle time is reduced greatly, and the time cost of the equipment is also reduced to a certain extent.

Owner:玉田县昌通电子有限公司

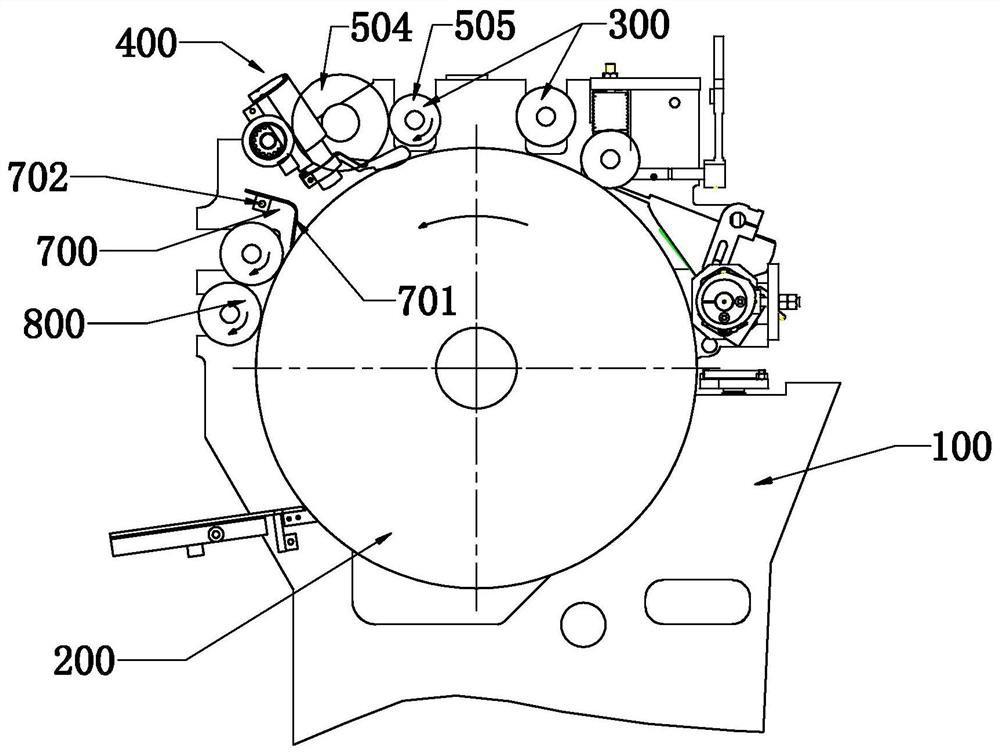

Bag bottom closing device of paper bag making machine

PendingCN112009026AGuaranteed safe and reliable useEasy to useBag making operationsPaper-makingStructural engineeringMechanical engineering

The invention discloses a bag bottom closing device of a paper bag making machine. The bag bottom closing device of the paper bag making machine comprises a drum wheel assembly, two groups of foldingknife assemblies, a rear folding piece closing assembly, a front folding piece closing assembly and a pressing roller assembly. A front folding piece and a rear folding piece are arranged at the bag bottom of a paper bag. One group of folding knife assemblies is in transmission fit with the rear folding piece closing assembly; the two groups of folding knife assemblies can enable the rear foldingpiece at the bag bottom to move to the rear folding piece closing assembly along with the drum wheel assembly and close the rear folding piece under the driving of the folding knife assemblies; afterthe rear folding piece of the bag bottom is closed, the front folding piece of the bag bottom can move to the front folding piece closing assembly along with the drum wheel assembly to close the frontfolding piece, and then the front folding piece is rolled by the pressing roller assembly and output. The bag bottom closing device of the paper bag making machine has the advantages that a rear folding plate group is stable, reliable, free of impact sound, low in noise, small in error and accurate in action in the using process, accordingly, the bag bottom closing quality is guaranteed, the bagmaking speed is greatly increased due to the advantage of synchronous operation, the production efficiency is very high, and therefore the bag making cost is reduced.

Owner:上豪包装机械(镇江)有限公司

Four-drive energy adjustable continuous winged variable dip angle direct-acting aircraft

PendingCN114056564AImprove flight aerodynamic efficiencyReduce resistancePower plant typeAir-flow influencersReduction driveFlight vehicle

The invention relates to a four-drive energy adjustable continuous winged variable dip angle direct-acting aircraft. Four vertical slideways are symmetrically mounted and fixed on the periphery of the fuselage frame, the four connecting pieces are respectively connected to the four slideways in a sliding manner, the four belt wings are respectively connected to the four connecting pieces and can rotate relatively, and each belt wing comprises a belt wing frame and a soft belt mounted on the belt wing frame; a belt wheel, a tensioning wheel and a driving motor are further arranged in the winged frame and used for switching between the working state and the reset state of the winged frame, the transmission mechanism is connected to the four connecting pieces, and the motor arranged on the fuselage frame drives the transmission mechanism to move after being decelerated through a second speed reducer so that the four connecting pieces can synchronously slide up and down. The four stepping motors arranged on the four connecting pieces correspondingly drive the four belt wings to rotate after being decelerated through the four third speed reducers.

Owner:GLOBAL INST OF SOFTWARE TECH

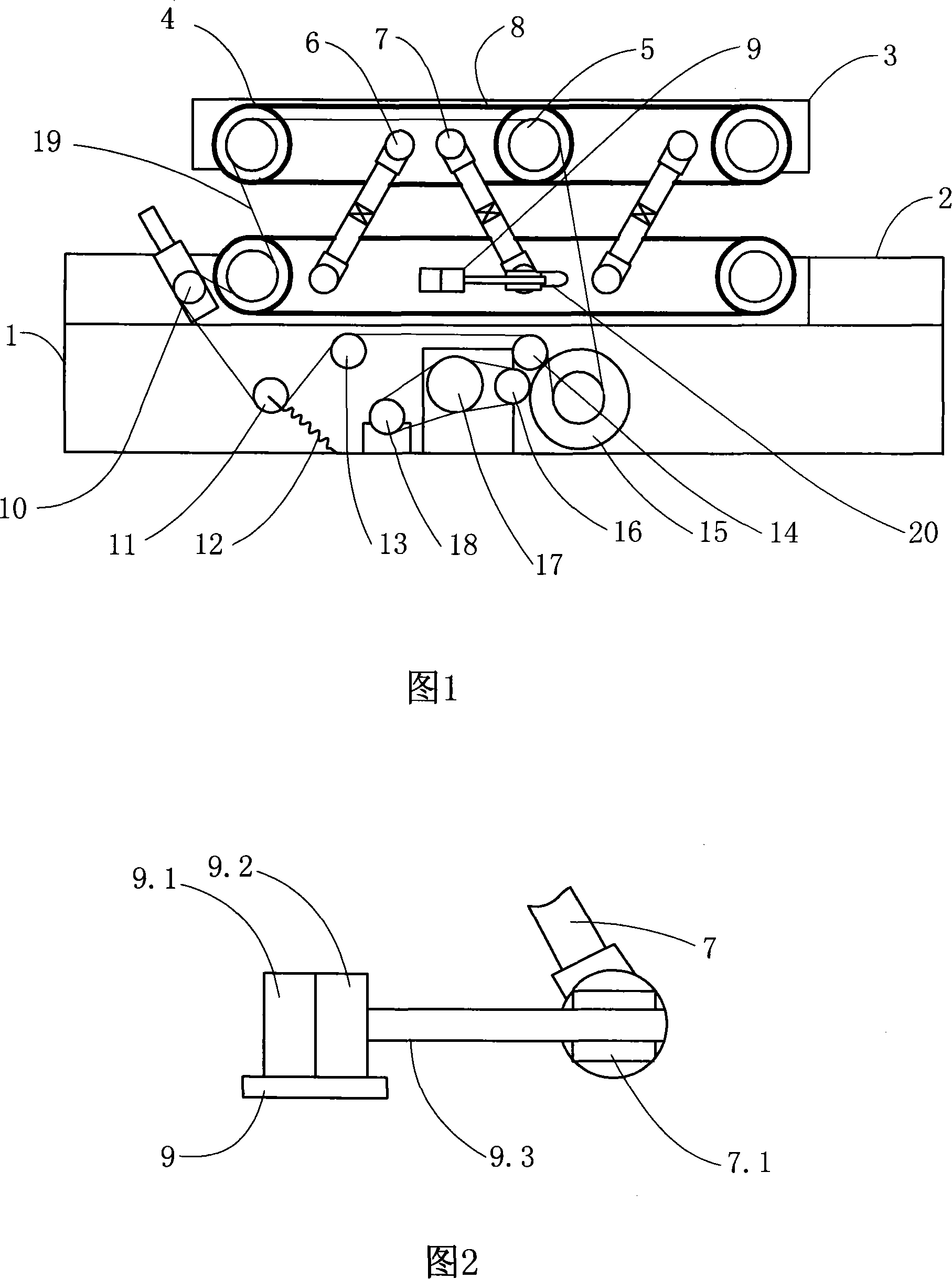

Traction machine for resin basis composite material sectional material

The invention provides a SEMI compound material section tractor, a stand is arranged on a frame and arranges an upper stand by a motor gap adjustment pole and a limiting pole, the two ends of the stand are provided with a clamp transmission belt wheel, a clamp transmission belt is connected on, an upper stand motor transmission wheel is arranged on the upper stand, the lower end of the motor adjustment pole is arranged in a lubrication hole, and connected with a motor gap adjustment pole driving machine, a transmission chain tension adjuster, a transmission chain flexible adjuster, a left and a right transmission guide pulley, a transmission chain main wheel, a transmission chain main wheel power feeding wheel, a slow down wheel, the power transmission wheel of a drive motor, which are all arranged on the frame and the lower stand base wheel and connected with each other by a transmission chain or a gear. The invention has the advantages of little consumption, good movement action, stability, even tractive force, high efficiency and never damaging the structural shape, which is suitable for the traction of the SEMI compound material section production process.

Owner:葫芦岛市鑫一达科技发展有限公司

Single-phase magnetic-keeping operating mechanism

InactiveCN105742085AAvoid chafingReduce material costsSwitch power arrangementsBreak springEngineering

The invention provides a single-phase magnetic-keeping operating mechanism, which comprises an upper magnet yoke, a lower magnet yoke, a magnetic sleeve, a movable iron core assembly, a lower plastic end block and a metal fixed pressure plate, wherein a coil is arranged in the middle of the upper magnet yoke, the lower magnet yoke and the sleeve; the movable iron core assembly comprises a movable iron core and a plastic seal cover; the plastic seal cover is arranged at the lower part of the movable iron core assembly through a thread; an air-gap dustproof bead is arranged at the upper end part of the movable iron core; the middle part of the movable iron core passes through an operating pull rod, a breaking spring and a closing spring; the movable core iron runs between the plastic end block and the upper magnet yoke in a limiting manner, and finishes mechanism operation through the operating pull rod through cooperation of the breaking spring and the closing spring; and a photoelectric sensing element is embedded into the plastic end block. The single-phase magnetic-keeping operating mechanism provided by the invention forms the magnetic sleeve by low-cost alloy structure steel and has an airtight dustproof straight motion structure; friction blockage of mechanism motion is completely avoided through limiting of the end part of the movable iron core and position and speed photoelectric signal transmission; and low cost, high reliability, intelligent monitoring and long-lifetime operation of the operating mechanism are achieved.

Owner:ZHENJIANG SHISHENG ELECTRIC CO LTD

Robot clamping carrier

The invention relates to a robot clamping carrier which comprises two carrying trolleys which are symmetrically distributed, have the same structure and are used for respectively clamping front wheels and rear wheels of a vehicle, wherein each carrying trolley is provided with a synchronous clamper with two pairs of mechanical hands; the two carrying trolleys are connected through a telescopic bending arm; each carrying trolley is internally provided with an electrical positioning system for detecting the positions of the front wheels and the rear wheels of the vehicle and comprises a trolleybody, a walking drive motor speed reducer, a chain wheel, a chain, a driving wheel, a driving wheel shaft, a tensioning wheel, a driven wheel and a guide mechanism; each synchronous clamper comprisesa clamping framework connected with the trolley body, an upper cover plate, a clamping motor speed reducer fixed on the upper cover plate, a worm shaft I, a worm shaft II, a worm gear I, a worm gear II, a spindle and mechanical hands; and each clamping motor speed reducer is simultaneously connected with the worm shaft I and the worm shaft II to drive respective worm gear pairs and mechanical hands to rotate along the spindles. In the invention, the positions of the rotating spindles of the clamping mechanical hands are fixed without moving; a single motor controls a group of mechanical hands, which ensures that the motions are synchronous, and the structure is simple and reliable; meanwhile, the defects of carriers in a carrier plate type and a comb tooth exchange type are overcome; and the robot clamping carrier has the advantages of high vehicle access speed, good rigidity, low civil engineering cost, and the like.

Owner:北京航天汇信科技有限公司

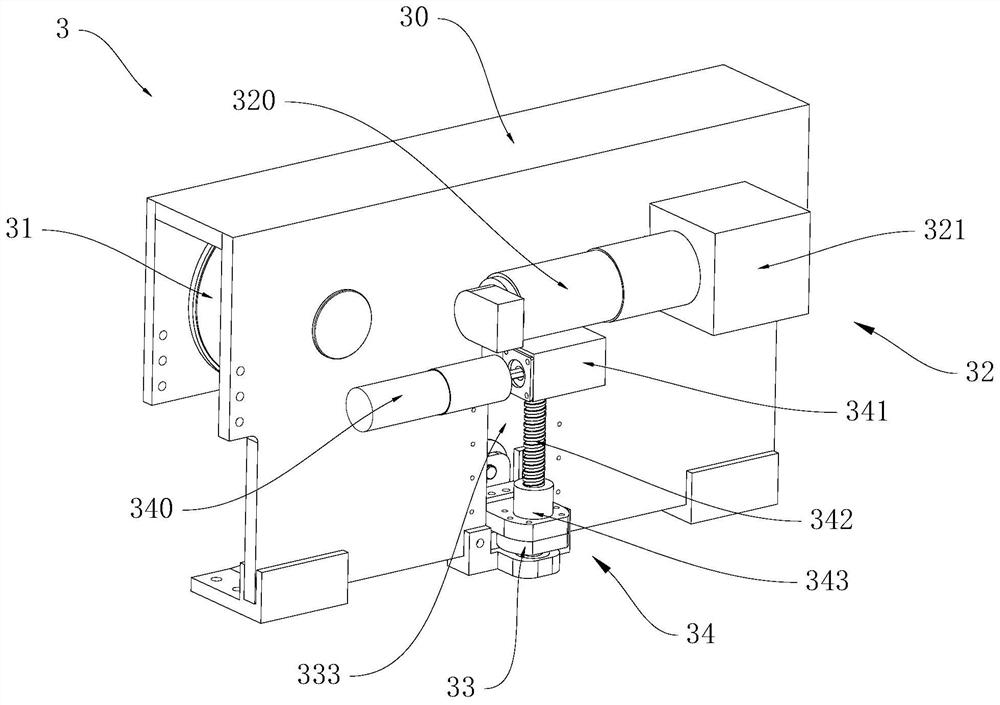

Stator coil binding mechanism

PendingCN111987876AEnhanced binding effectQuality improvementManufacturing dynamo-electric machinesCoil bindStator coil

The invention relates to a stator coil binding mechanism. The binding mechanism comprises an equipment frame and a binding unit rotationally arranged on the equipment frame. The binding unit comprisesa crochet hook, a swing nozzle, a supporting assembly, a first supporting shaft arranged on the supporting assembly and used for supporting the crochet hook, and a second supporting shaft arranged onthe supporting assembly and used for supporting the swing nozzle. The binding mechanism further comprises a first driving mechanism for driving the binding unit to rotate so as to switch the positions of the crochet hook and the swing nozzle in the up-down direction, and a second driving mechanism for driving the crochet hook to do front-back telescopic motion. The binding unit further comprisesa third driving mechanism and a transmission mechanism. Only one driver for providing power for the swing nozzle and the crochet hook is arranged in the binding mechanism. Therefore, the action consistency of the two mechanisms is better, the difficulty of debugging and maintenance work is reduced, the debugging and maintenance cost is greatly reduced, the overall use stability of the binding mechanism is better, the binding efficiency of the binding mechanism is improved, the overall structure of the binding mechanism is more compact, and the manufacturing cost of equipment is reduced.

Owner:ALLIANCE AUTOMATIONSUZHOUCO

Rotary vane based synchronous swing type double-flapping-wing aircraft

ActiveCN110294123AImprove aerodynamic efficiencyReduce resistanceSpars/stringersWing adjustmentsFlapping wingReduction drive

The invention relates to the field of flapping wing type aircrafts and flying robots, in particular to a rotary vane based synchronous swing type double-flapping-wing aircraft which comprises two flapping wings, two swing shafts, two connecting pieces, two first speed reducers, two stepping motors, a transmission mechanism, a second speed reducer, an electromotor and a fuselage ring, wherein the two swing shafts are symmetrically mounted and fixed on the two sides of the fuselage ring in the horizontal direction; the two connecting pieces are connected onto the two swing shafts separately androtate relatively; the two flapping wings are connected onto the two connecting pieces separately and can rotate relatively; each of the flapping wings comprises a flapping wing frame and a rotatablevane mounted in the flapping wing frame; a torsional spring for resetting the vane is further arranged in the flapping wing frame; the transmission mechanism is connected onto the two connecting pieces; after the second speed reducer reduces the speed of the electromotor, the electromotor drives the transmission mechanism to move, so that the two connecting pieces synchronously swing up and down;and after the two first speed reducers reduce the speed of the two stepping motors, the two stepping motors drive the two flapping wings to rotate separately.

Owner:GLOBAL INST OF SOFTWARE TECH +1

Ejector mechanism of single-trip foaming special machine of refrigerator and control method of ejector mechanism

The invention discloses an ejector mechanism of a single-trip foaming special machine of a refrigerator and a control method of the ejector mechanism. The ejector mechanism is characterized in that a parallel four-bar mechanism is formed by articulating a front connecting rod frame, a rear connecting rod frame, a left camshaft and a right camshaft which are distributed as a rectangular frame on a plane, wherein cams are respectively arranged on the left camshaft and the right camshaft front and back, a slider-crank mechanism consists of the cams, connecting rods connected with the cams, ejector rods connected with the connecting rods, and foaming special machine bottom plates fixedly arranged on the ejector rods, a pre-positioned air cylinder and a post-positioned air cylinder are arranged as a driving mechanism, the left camshaft is driven to rotate by a piston rod of the pre-positioned air cylinder through a pre-positioned crank, and the right camshaft is driven to rotate by a piston rod of the post-positioned air cylinder through a post-positioned crank. According to the ejector mechanism, the foaming can be realized on the single foaming special machine.

Owner:滁州市经纬模具制造有限公司

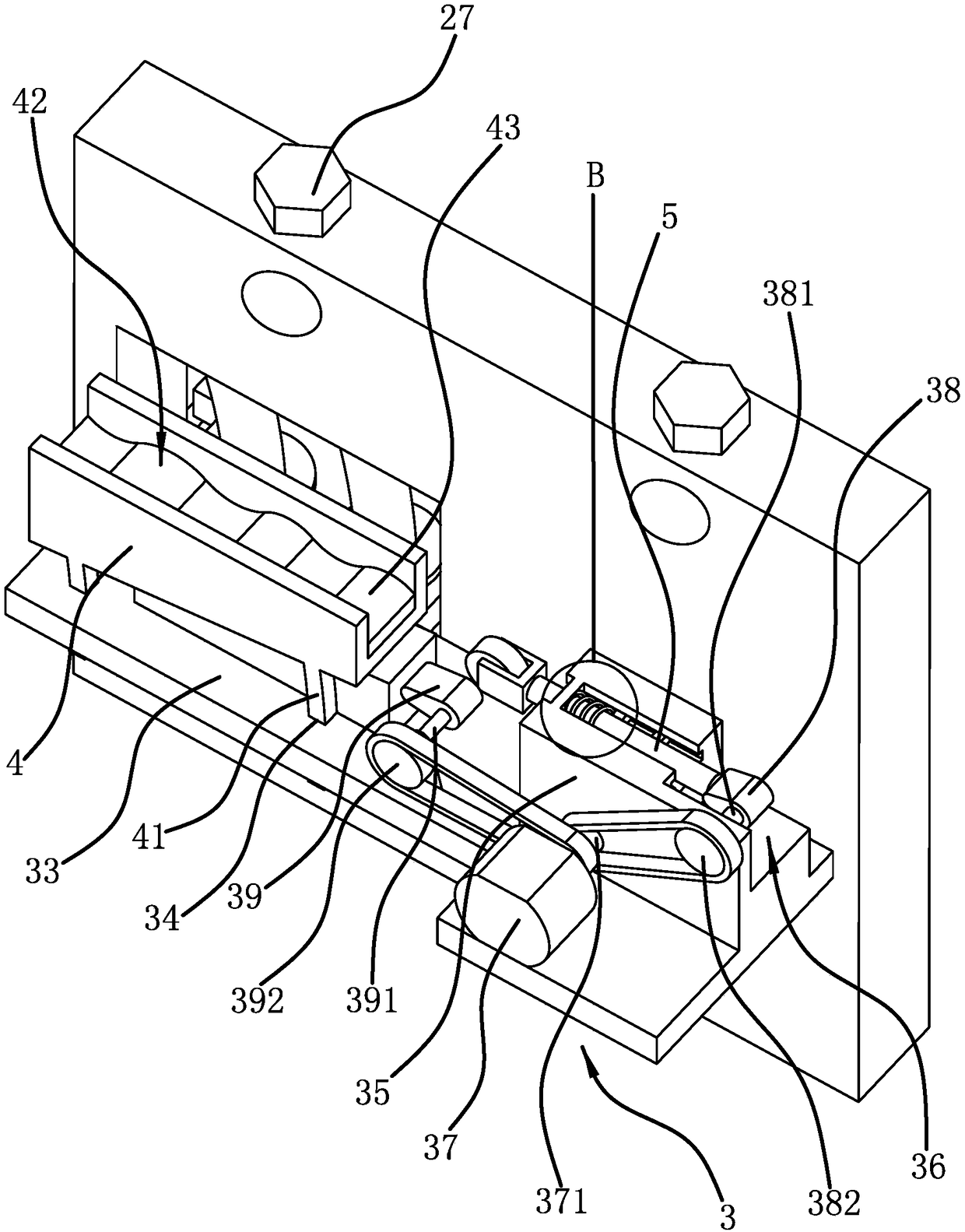

An automobile handbrake fatigue test device

ActiveCN106053065BHigh degree of automationReduce wearMachine gearing/transmission testingCamFatigue testing

The invention provides an automobile hand brake fatigue testing device, and belongs to the technical field of automobile testing equipment. The invention solves a problem that a conventional automobile hand brake fatigue test is higher in difficulty. The device comprises a support, and the support is provided with two supporting shafts. The two supporting shafts are slidingly connected with a substrate, and the substrate is slidingly connected with a drive frame. The drive frame is slidingly connected with a jacking block, and the substrate is rotatingly connected with a drive cam. The drive frame is rotatingly connected with a fine tuning cam. The drive frame is also slidigly connected with an unlocking push rod, and the drive frame is rotatingly connected with an unlocking cam. The drive frame is provided with an unlocking motor which can drive the fine tuning cam and the unlocking cam to rotate synchronously. The device can automatically pull and release an automobile hand brake, and is high in automation degree.

Owner:山东临港汽车制造有限公司

Low drag synchronous direct motion double flapping wing aircraft

ActiveCN110294118BImprove aerodynamic efficiencyReduce resistanceSpars/stringersWing adjustmentsFlapping wingFlight vehicle

The invention relates to the field of flapping-wing aircraft and flying robots, in particular to a low-resistance synchronous direct-acting double flapping-wing aircraft. It includes flapping wings, slides, connectors, first reducer, stepping motor, transmission mechanism, second reducer, electric motor and fuselage frame, and two vertical sliding slides are installed and fixed symmetrically on both sides of the fuselage frame. The two connecting parts are respectively slidably connected to the two slideways, and the two flapping wings are respectively connected to the two connecting parts and can be rotated relatively. The flapping wing frame is also equipped with a torsion spring for the reset of the blade. The transmission mechanism is connected to the two connecting parts. The motor set on the fuselage frame drives the transmission mechanism to move after being decelerated by the second reducer to make the two The two connecting parts slide up and down synchronously, and the two stepping motors on the connecting parts are decelerated by the first reducer to respectively drive the two flapping wings to rotate.

Owner:GLOBAL INST OF SOFTWARE TECH +1

An automatic leak detection device

InactiveCN105910769BSave human effortImprove efficiencyDetection of fluid at leakage pointTest efficiencyEngineering

The invention discloses an automated leakage detection device, which relates to the valve sealing performance testing field. The automated leakage detection device comprises a base and a water tank arranged on the base, wherein two polished rods are arranged in the water tank, the two polished rods are vertically arranged, upper ends of the polished rods extend out of the water tank, a fixed plate connected with the two polished rods is arranged above the water tank, an upper sealing mechanism, a lower sealing mechanism and a positioning bracket are arranged between the fixed plate and the bottom part of the water tank, the upper sealing mechanism is used for sealing an upper end of a valve, the lower sealing mechanism is used for sealing a lower end of the valve, the positioning bracket is used for positioning the valve, and a cylinder used for driving the upper sealing mechanism is arranged on the fixed plate. For solving the problems that an existing valve sealing performance testing method is inconvenient in installation and clamping, low in efficiency, labor-consuming and not high in automation degree, the automated leakage detection device having the advantages of high testing efficiency, convenient installation and clamping as well as high automation degree is disclosed by the invention.

Owner:佛山市迅科管道探测有限公司

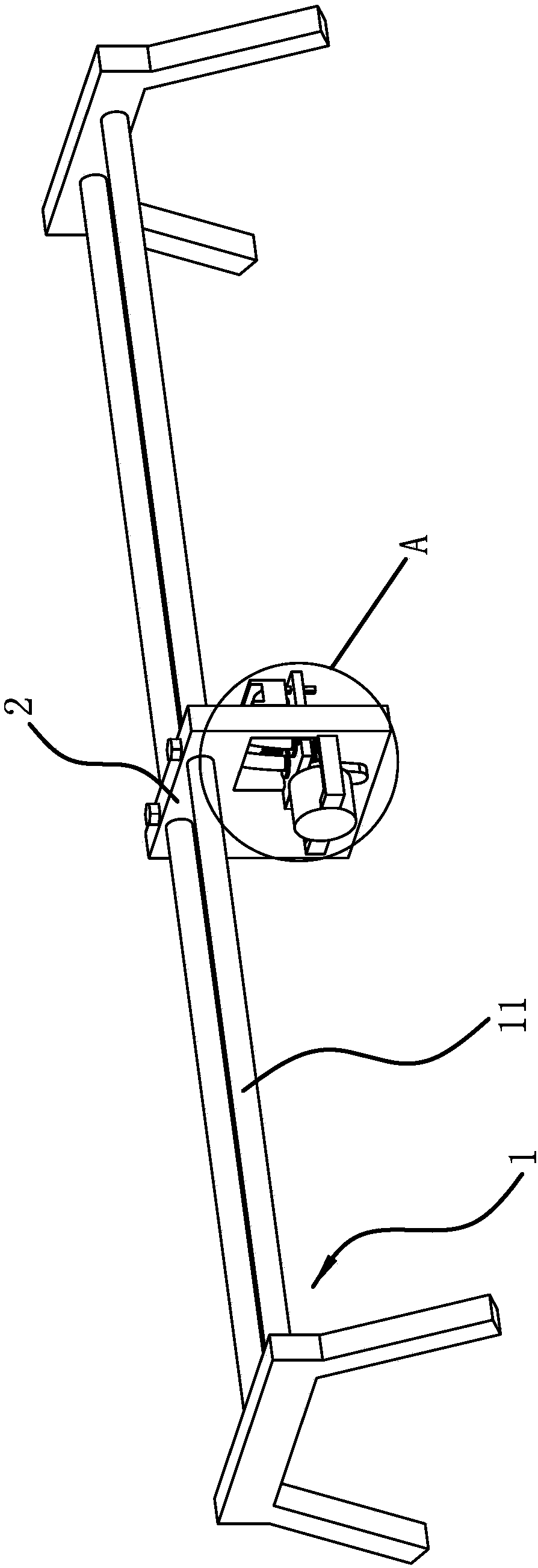

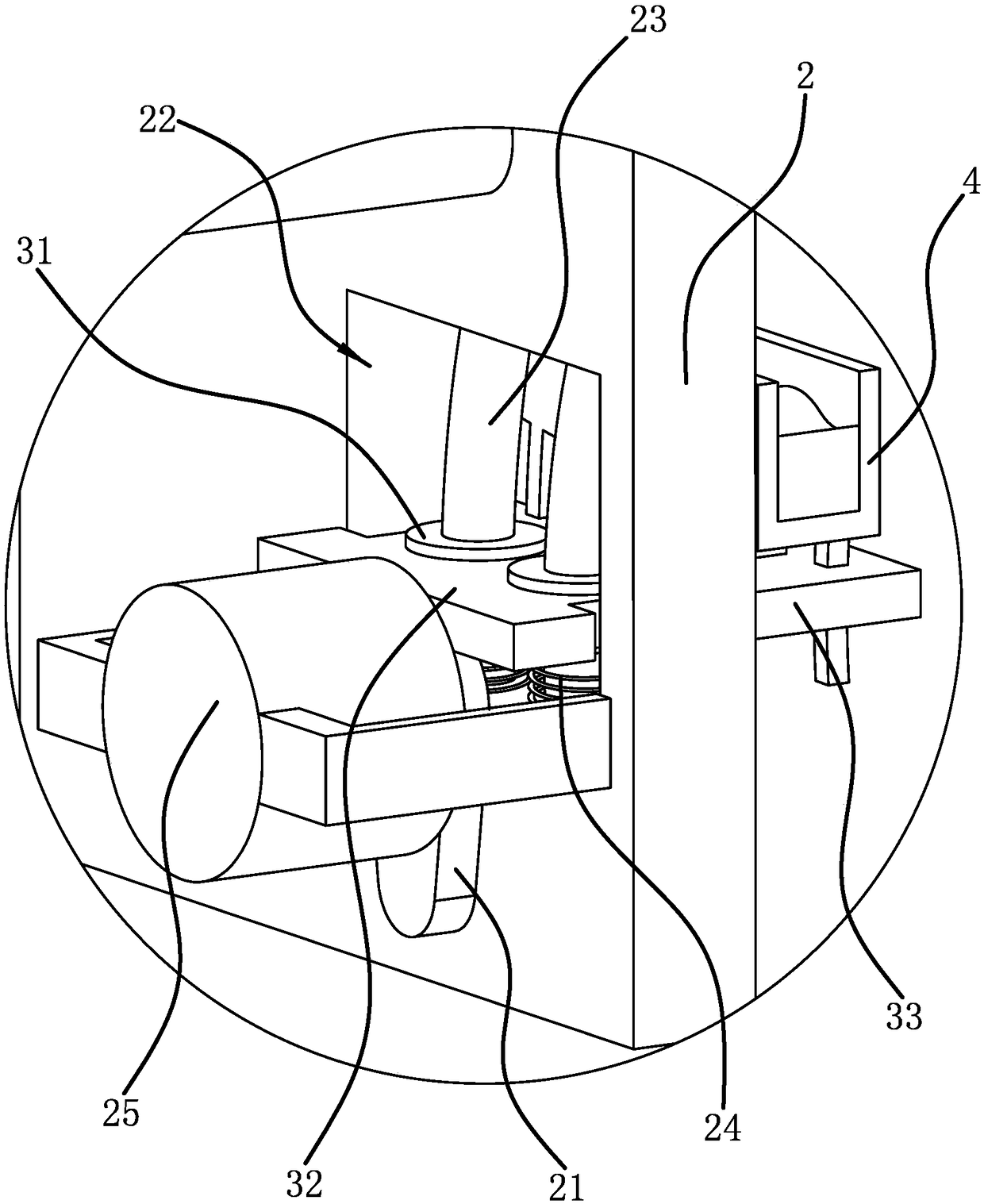

An automatic coating equipment for insulating material of overhead bare wires for live work

ActiveCN112570220BRealize automatic coating operationEasy to installLiquid surface applicatorsCoatingsEngineeringMaterial supply

The invention discloses an automatic coating equipment for insulating material of an overhead bare wire for live work, which includes: a coating device for coating insulating material on the surface of the bare wire; a material supply device for supplying the insulating material to the The coating device transports the insulating material; a traction device is placed on the bare wire, the coating device and the material supply device are respectively connected to the traction device, and the traction device is used to walk on the bare wire and drive the The coating device and the material supply device move relative to the bare wire. The invention has the advantages of compact structure, good action consistency, convenient installation and more automatic performance.

Owner:天津恩泰智能装备有限公司

A template linkage device and method

InactiveCN107829540BGood action consistencyAvoid stickingBuilding constructionsEngineeringComputer engineering

Owner:李宜君

Double-synchronous direct-acting belt drive roller shutter type flapping-wing unmanned aerial vehicle

PendingCN113895616AImprove aerodynamic efficiencyReduce resistanceOrnithoptersAir-flow influencersFlapping wingReduction drive

The invention relates to a double-synchronous direct-acting belt drive roller shutter type flapping-wing unmanned aerial vehicle. The unmanned aerial vehicle comprises flapping wings, a fuselage top plate, a first speed reducer, a stepping motor, a connecting piece, a second speed reducer, a driving motor, a transmission mechanism, a fuselage bottom plate, a third speed reducer, a motor and slideways, the four slideways in the vertical direction are symmetrically and fixedly installed on the periphery of the fuselage top plate, and the two flapping wings can slide on the slideways; meanwhile, the two flapping wings are connected to the two connecting pieces respectively and can rotate relatively, each flapping wing comprises a flapping wing frame and a roller blind installed on the flapping wing frame, a synchronous belt wheel and a driving motor are further arranged in the flapping wing frame and used for switching between the working state and the reset state of the flapping wings, and the transmission mechanism is connected to the two connecting pieces, the motor arranged on the bottom plate of the fuselage is decelerated by the third speed reducer and then drives the transmission mechanism to move, so that the two connecting pieces synchronously slide up and down, and the two stepping motors respectively arranged on the two connecting pieces are decelerated by the two first speed reducers and then respectively drive the two flapping wings to rotate.

Owner:GLOBAL INST OF SOFTWARE TECH

Disconnecting switch and contact mechanism thereof

The invention discloses a disconnecting switch and a contact mechanism thereof. The contact mechanism comprises a contact pole seat body, a moving contact seat, a moving contact and a static contact, the static contact is fixedly installed on the contact pole seat body, the moving contact seat is rotatably supported on the contact pole seat body, the moving contact is fixedly installed on the moving contact seat, the moving contact seat is provided with an upper seat disc and a lower seat disc, and a gas pushing block is arranged between the upper seat disc and the lower seat disc and extends from the center of the moving contact seat to the edge of the moving contact seat, so that the gas pushing block forms a cavity with the gas channel walls of the upper seat disc, the lower seat disc and the contact electrode seat body when the moving contact is in a closed position, and the gas pushing block pushes gas to flow in the gas channel of the disconnecting switch when the moving contact rotates. The performance of the disconnecting switch product can be improved.

Owner:嘉兴京硅智能技术有限公司

Double-synchronous-swing parallelogram-driven roller shutter type flapping-wing unmanned aerial vehicle

PendingCN113911340ASmall reset resistanceImprove aerodynamic efficiencyOrnithoptersAir-flow influencersFlapping wingReduction drive

The invention relates to a double-synchronous-swing parallelogram-driven roller shutter type flapping-wing unmanned aerial vehicle. The unmanned aerial vehicle comprises flapping wings, swing shafts, connecting pieces, first speed reducers, driving motors, a transmission mechanism, second speed reducers, stepping motors, a fuselage frame, third speed reducers and a motor; the two swing shafts in the horizontal direction are symmetrically and fixedly mounted on the two sides of the fuselage frame, and the two connecting pieces are connected to the two swing shafts correspondingly and rotate relatively; the two flapping wings are connected to the two connecting pieces respectively and can rotate relatively, each flapping wing comprises a flapping wing frame and a roller blind mounted on the flapping wing frame, and a parallelogram mechanism and a driving motor are further arranged in each flapping wing frame and used for switching between the working state and the reset state of the flapping wings; the transmission mechanism is connected to the two connecting pieces; and the motor drives the transmission mechanism to move after being decelerated by the third speed reducer, so that the two connecting pieces synchronously swing up and down, and the two stepping motors respectively drive the two flapping wings to rotate after being decelerated by the two second speed reducers.

Owner:GLOBAL INST OF SOFTWARE TECH

An automatic valve leak detection equipment

ActiveCN105784285BSave human effortImprove efficiencyDetection of fluid at leakage pointTest efficiencyEngineering

The invention discloses an automatic valve leak-checking device and relates to the field of valve sealing performance test. The device comprises a pedestal and a water tanker which is arranged on the pedestal; the water tank is therein provided with two polished rods; the two polished rods are vertically arranged and the upper ends of the polished rods extend out from the water tank; a fixed plate which is connected with the two polished rods is arranged over the water tank; an upper sealing mechanism which is used for sealing the upper end of the valve, a lower sealing mechanism which is used for sealing the lower end of the valve, and a positioning support which is used for positioning the valve are arranged between the fixed plate and the water tank bottom; the fixed plate is provided with an air cylinder which is used for driving the upper sealing mechanism. The invention is aimed at solving the problems of inconvenient clamping, low efficiency, high labor consumption and low automation degree in present valve sealing performance test methods, and provides a valve leak-checking device which has high test efficiency, convenient clamping, and high automation degree.

Owner:JIANG SU YAN DIAN FA MEN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com