Patents

Literature

43 results about "Coil bind" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coil bind is a style of setup used in various levels of NASCAR racing. Coil bind setups utilize very soft front springs and very stiff rear springs to control the pitch attitude of the body. This is in contrast with conventional setups which place the stiffer springs at the front of the car for superior mechanical grip, that is grip via the vehicle suspension and tires. Coil bind uses aerodynamics to produce grip.

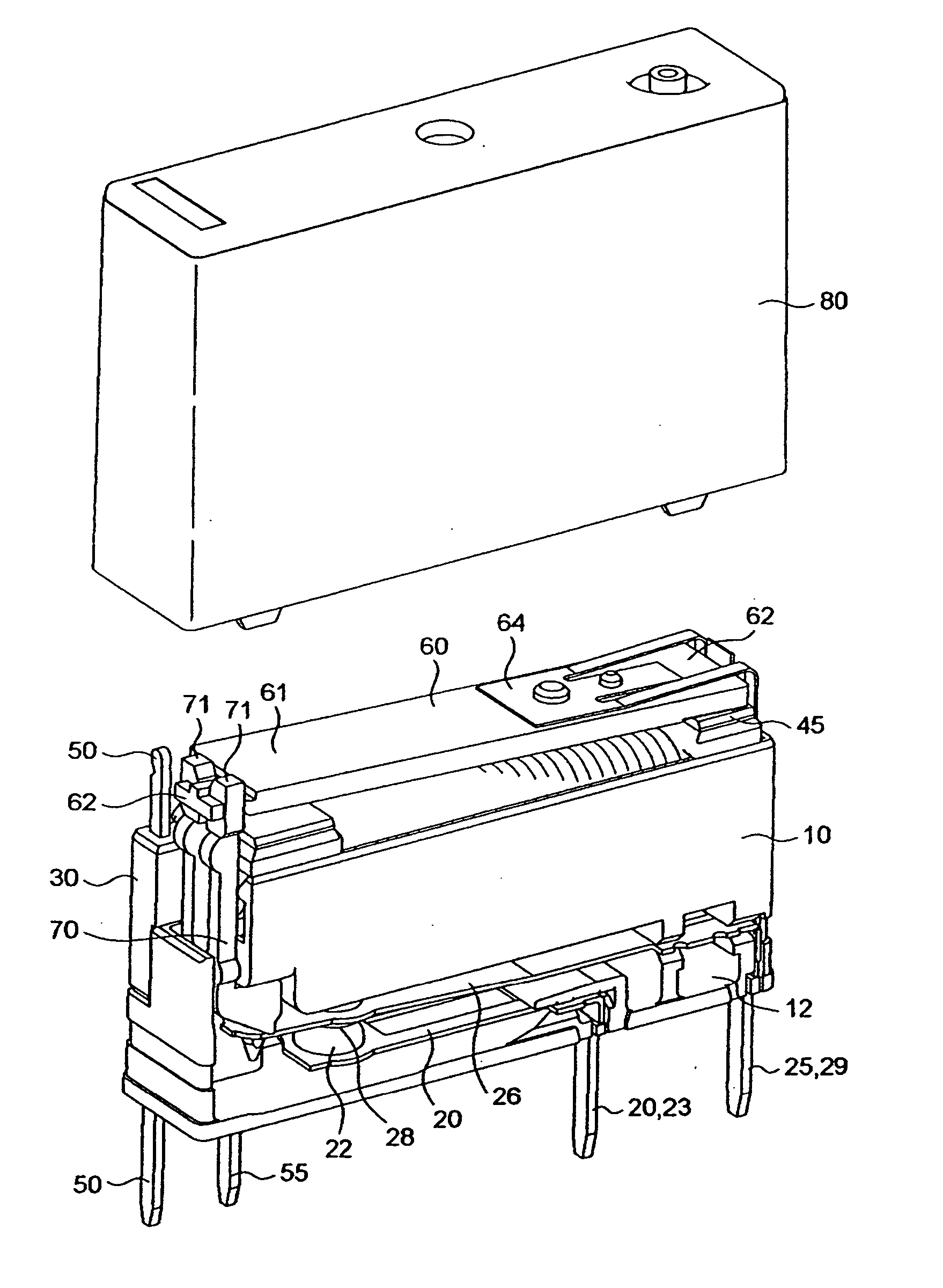

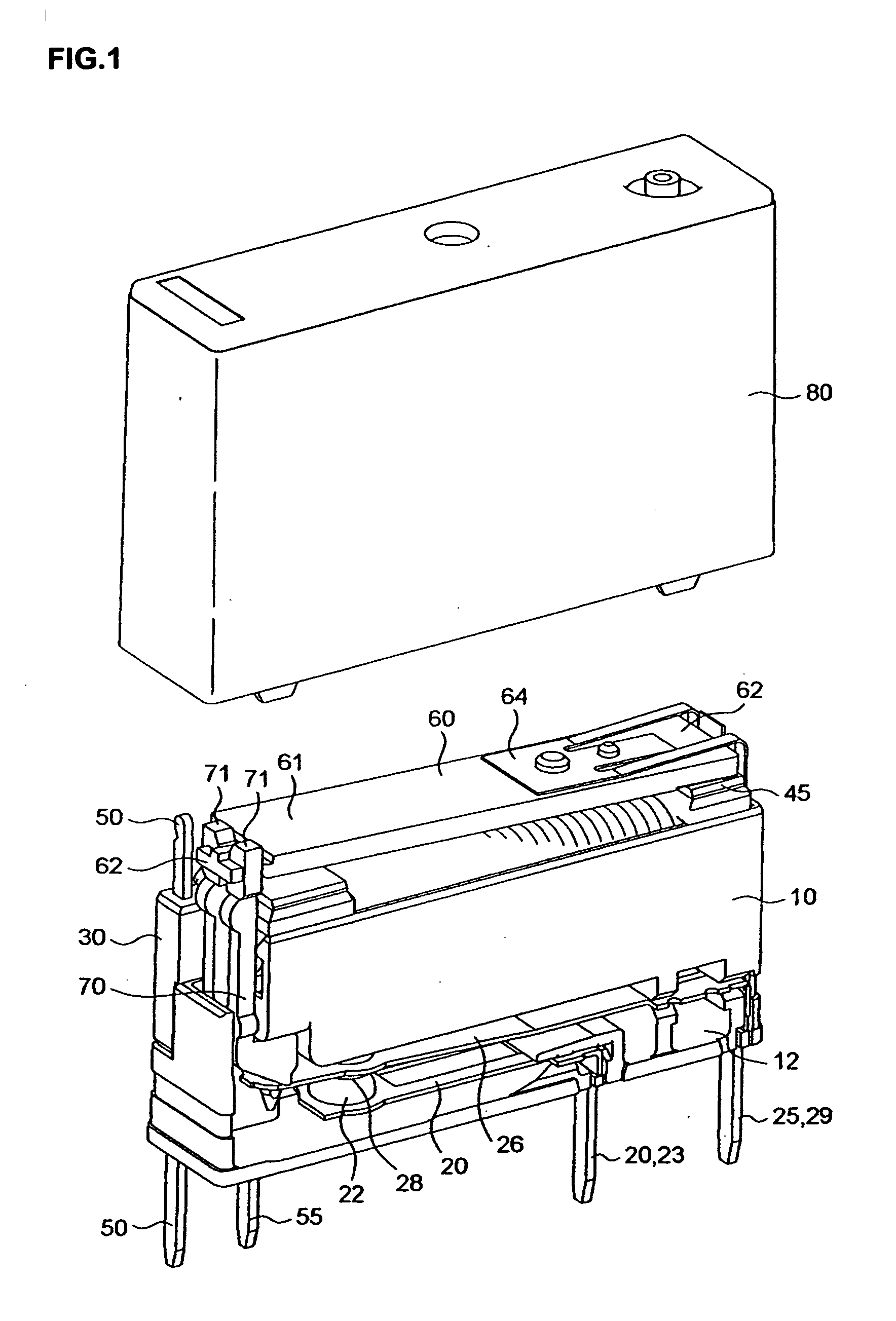

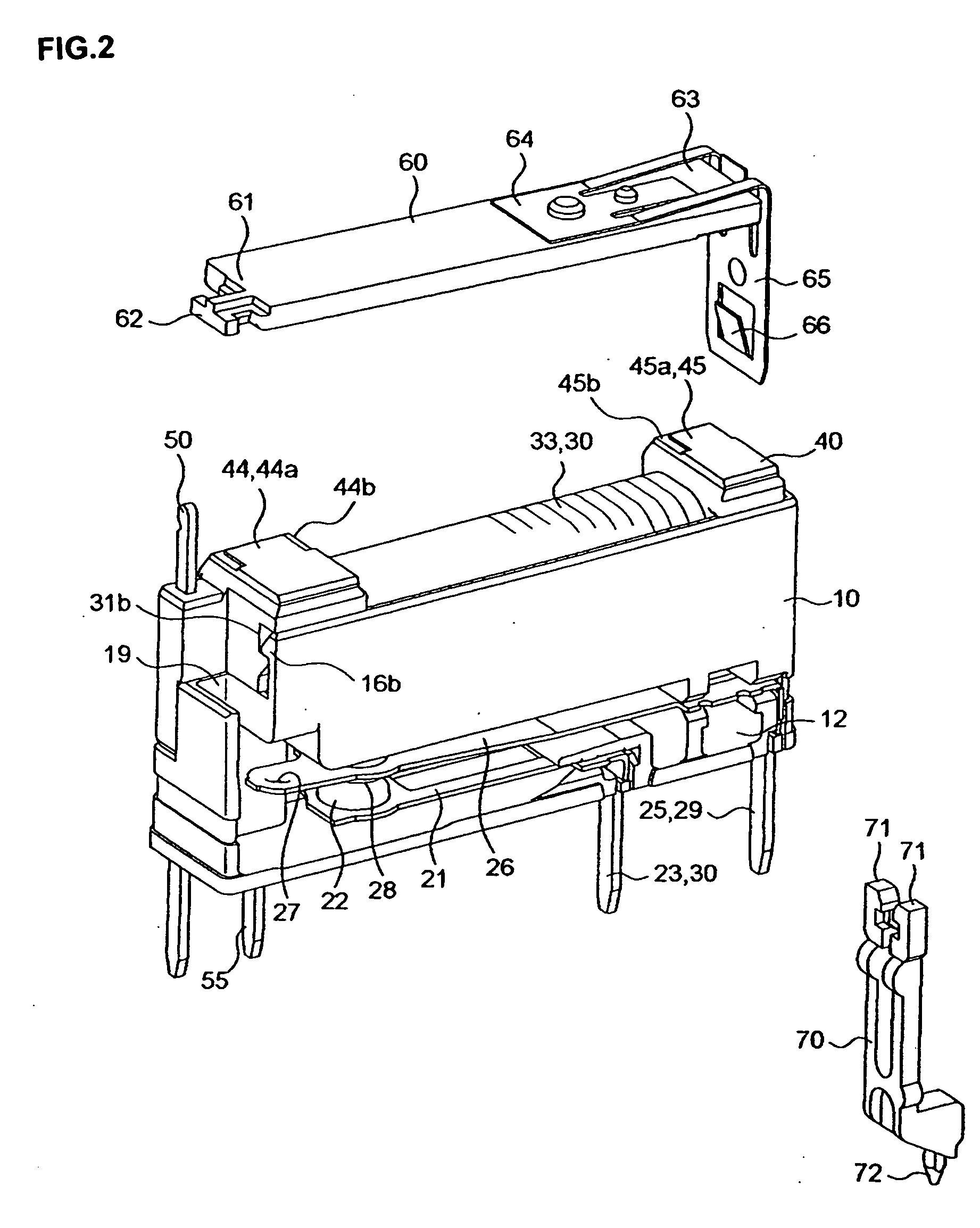

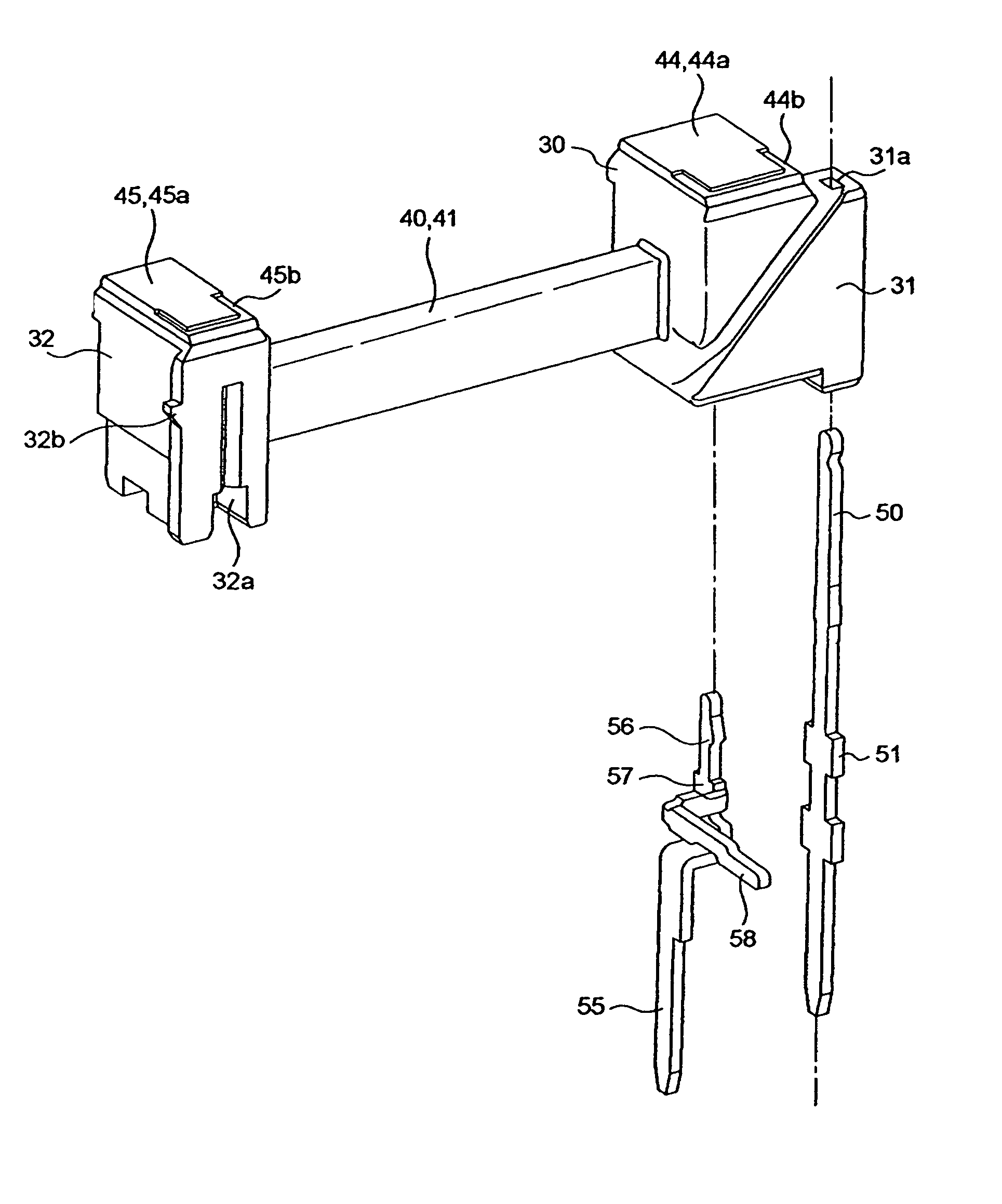

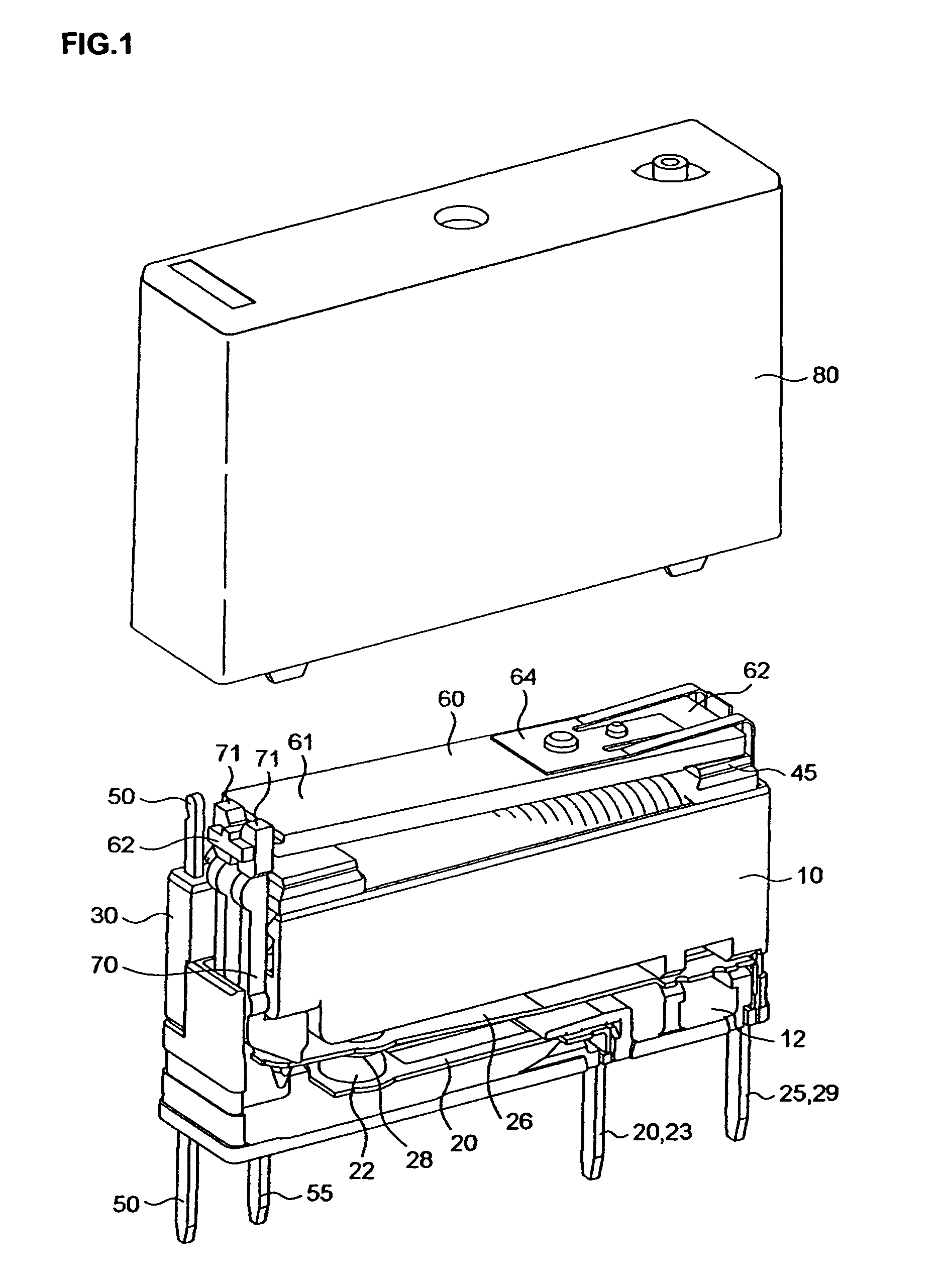

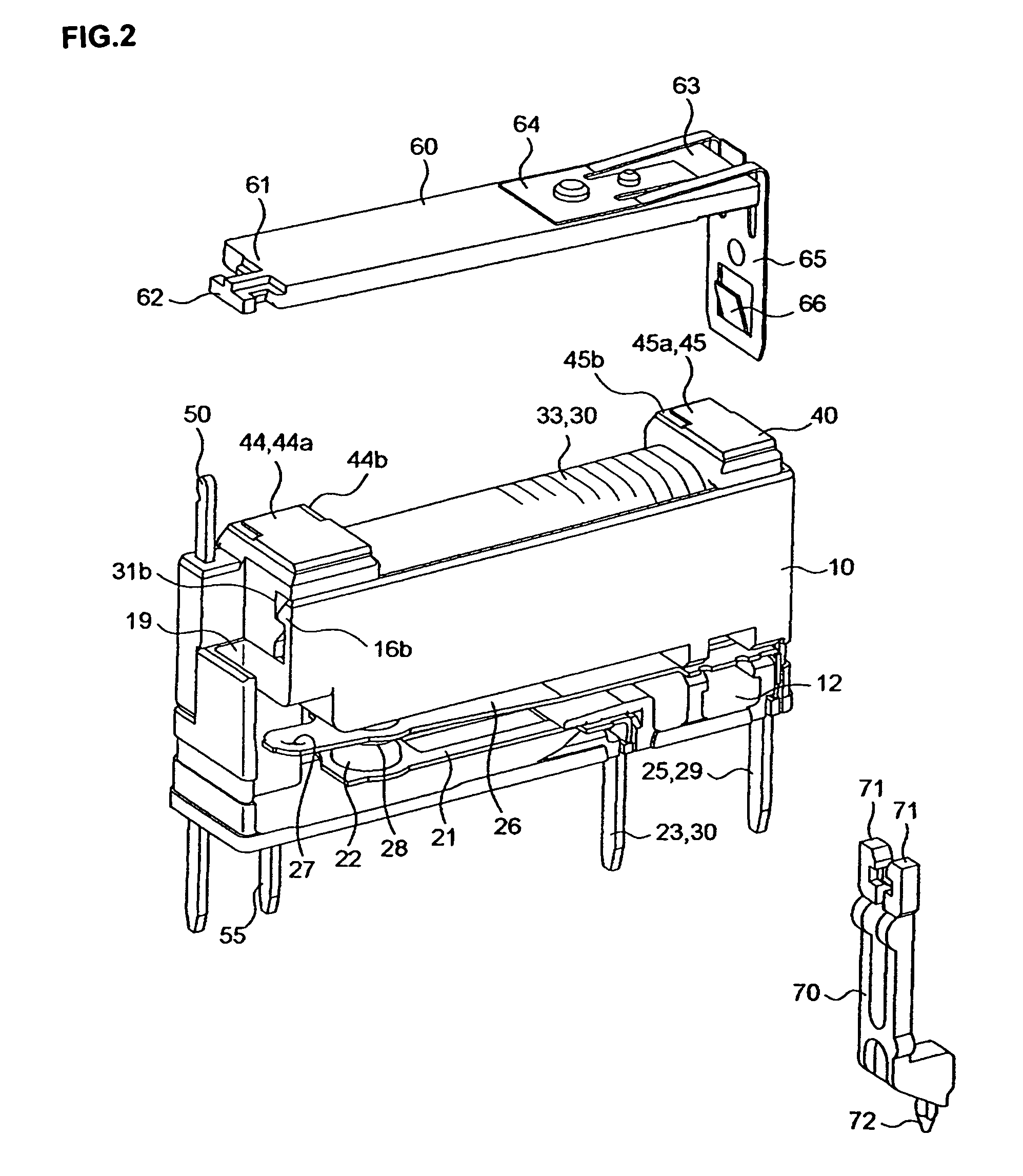

Electromagnetic relay

ActiveUS20050242907A1Shorten the lengthGood insulation propertiesElectromagnetic relay detailsSelector switchesCoil bindEngineering

An electromagnetic relay which is short in length and capable of maintaining a required insulation distance is disclosed. A first coil terminal connecting with one of extension lines of a coil is disposed in the vicinity of one end of a movable iron fragment and a card. A second coil terminal having a binding member which extends from an intermediate portion of the second coil terminal in a horizontal direction and is allowed to be bended toward the electromagnet block with the other of the extension lines of the coil bound to the binding member is further disposed below the electromagnet block.

Owner:ORMON CORP

Electromagnetic relay

ActiveUS6995639B2Shorten the lengthGood insulation propertiesElectromagnetic relay detailsSelector switchesCoil bindEngineering

An electromagnetic relay which is short in length and capable of maintaining a required insulation distance is disclosed. A first coil terminal connecting with one of extension lines of a coil is disposed in the vicinity of one end of a movable iron fragment and a card. A second coil terminal having a binding member which extends from an intermediate portion of the second coil terminal in a horizontal direction and is allowed to be bended toward the electromagnet block with the other of the extension lines of the coil bound to the binding member is further disposed below the electromagnet block.

Owner:ORMON CORP

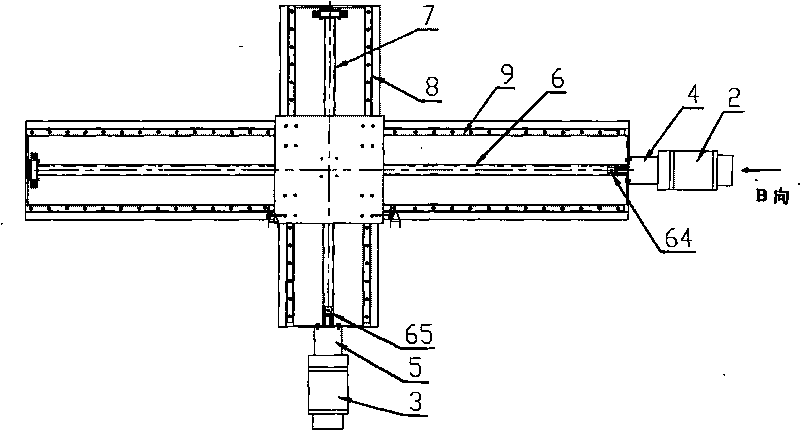

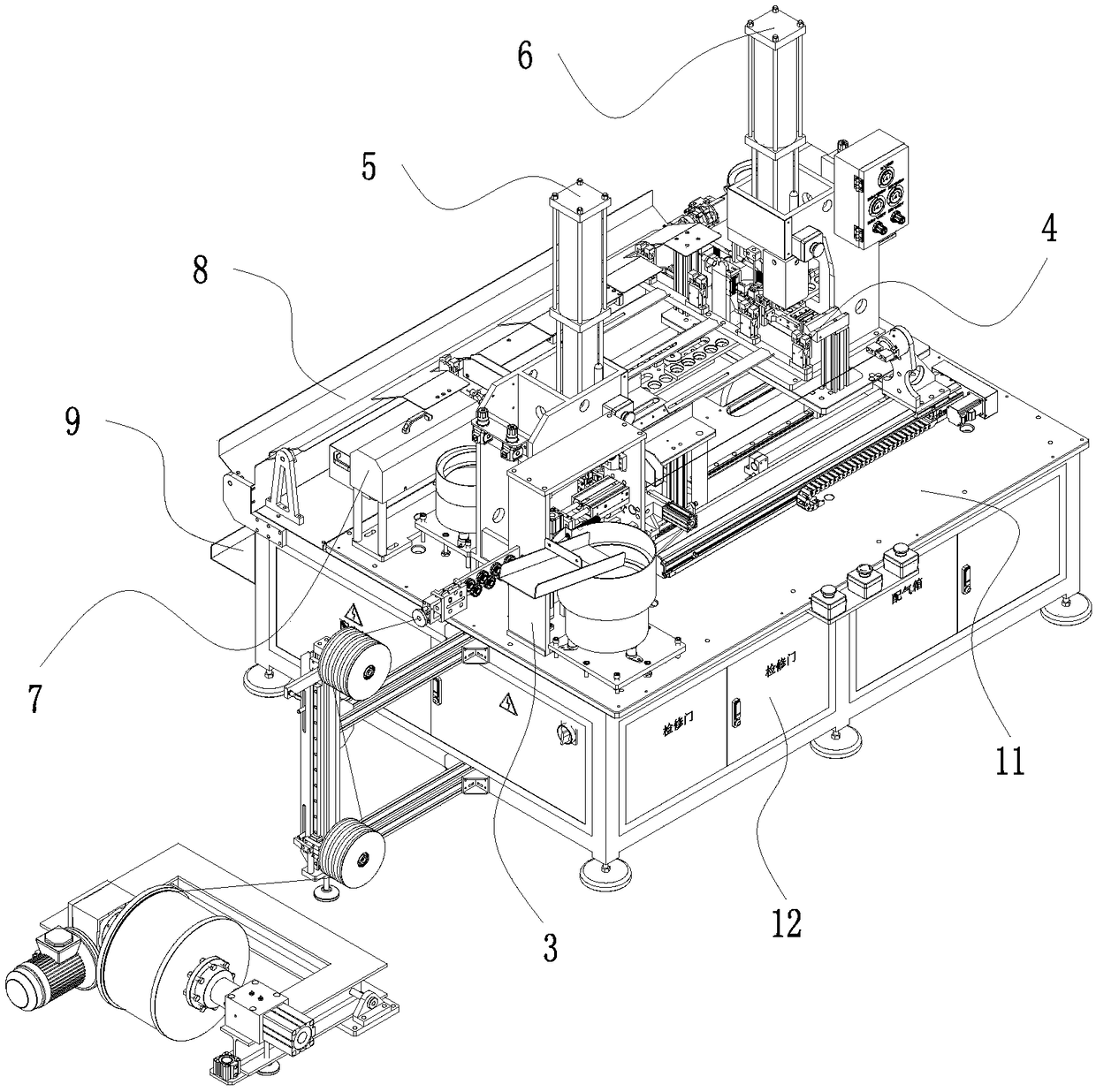

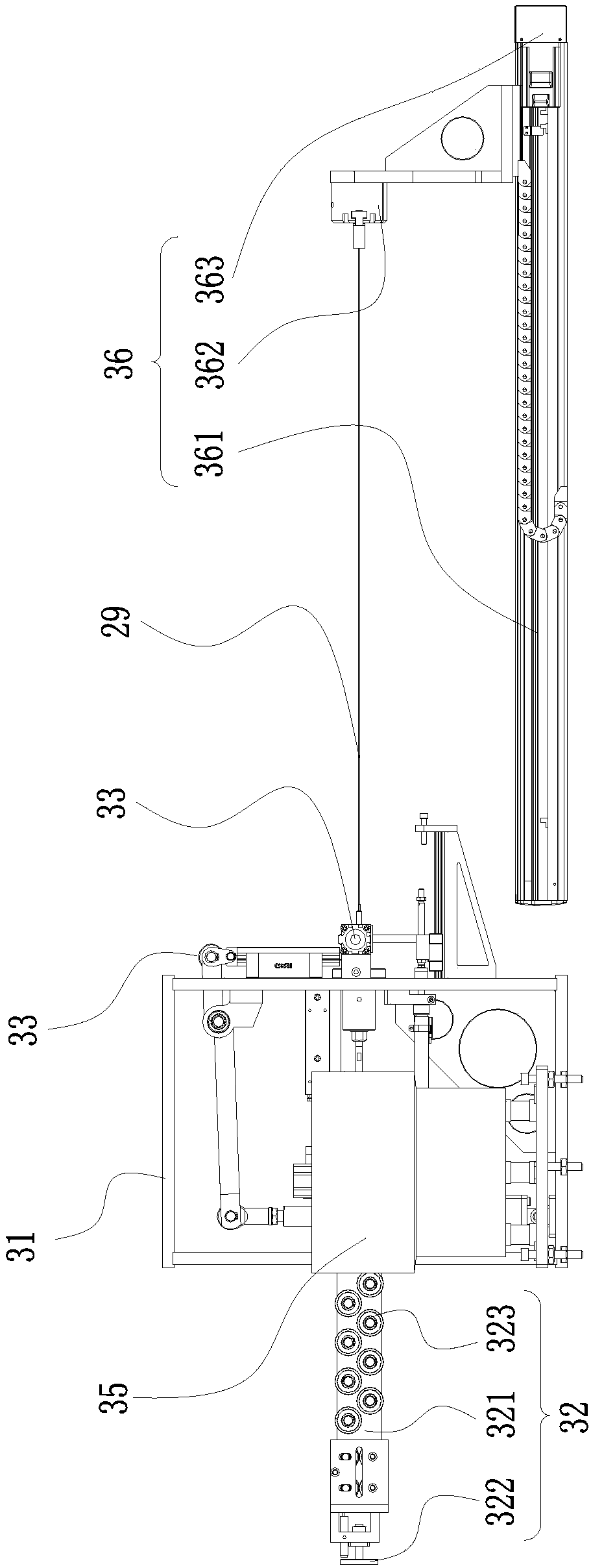

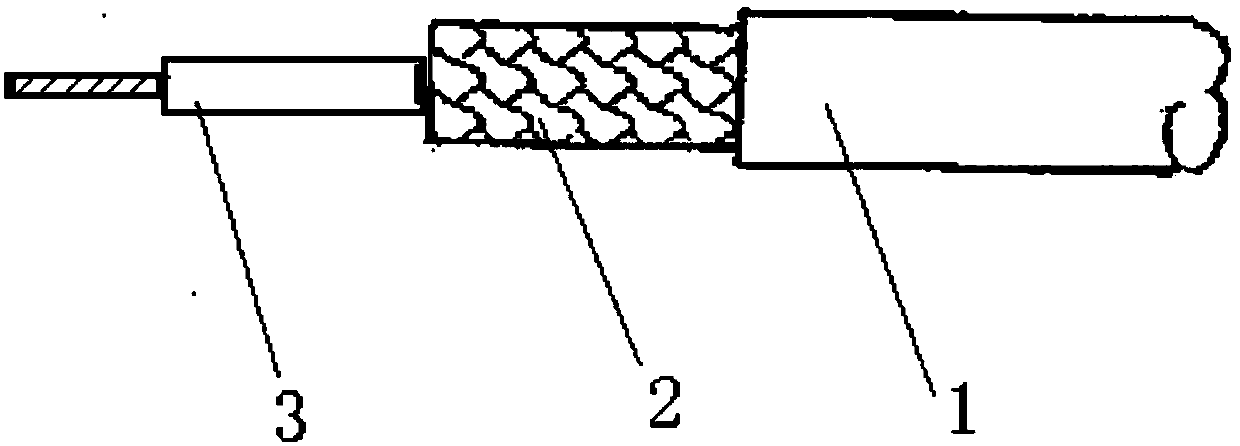

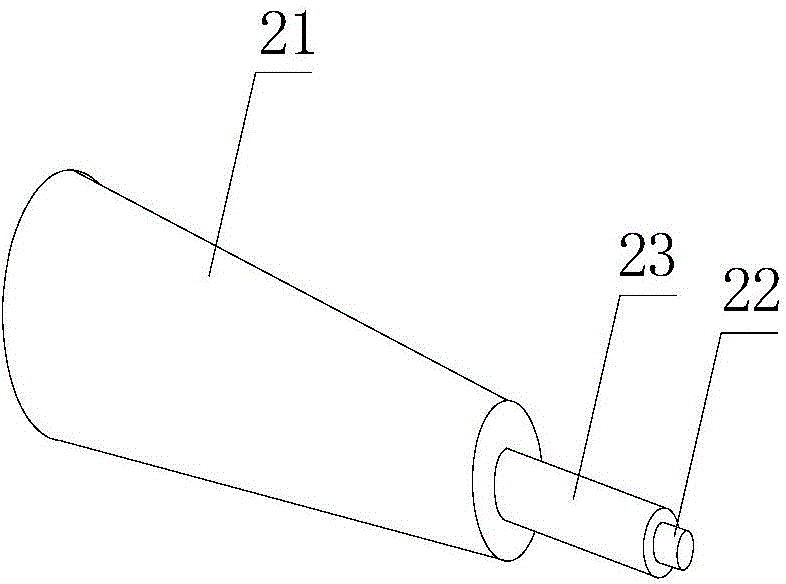

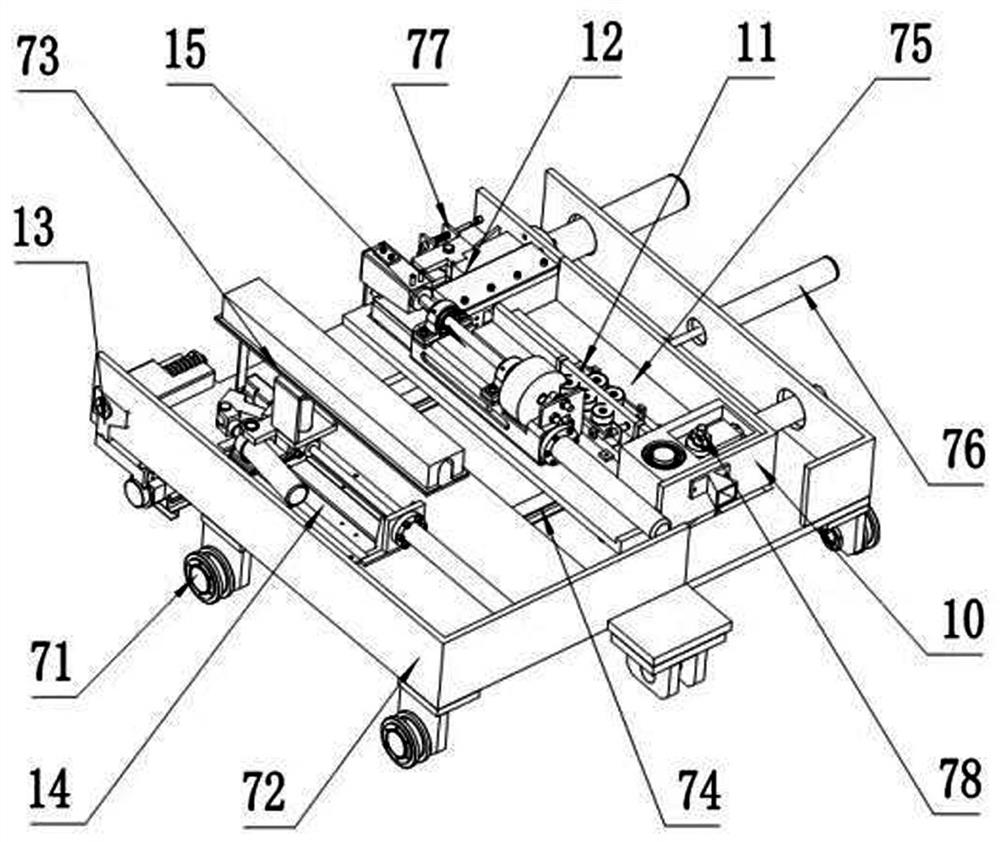

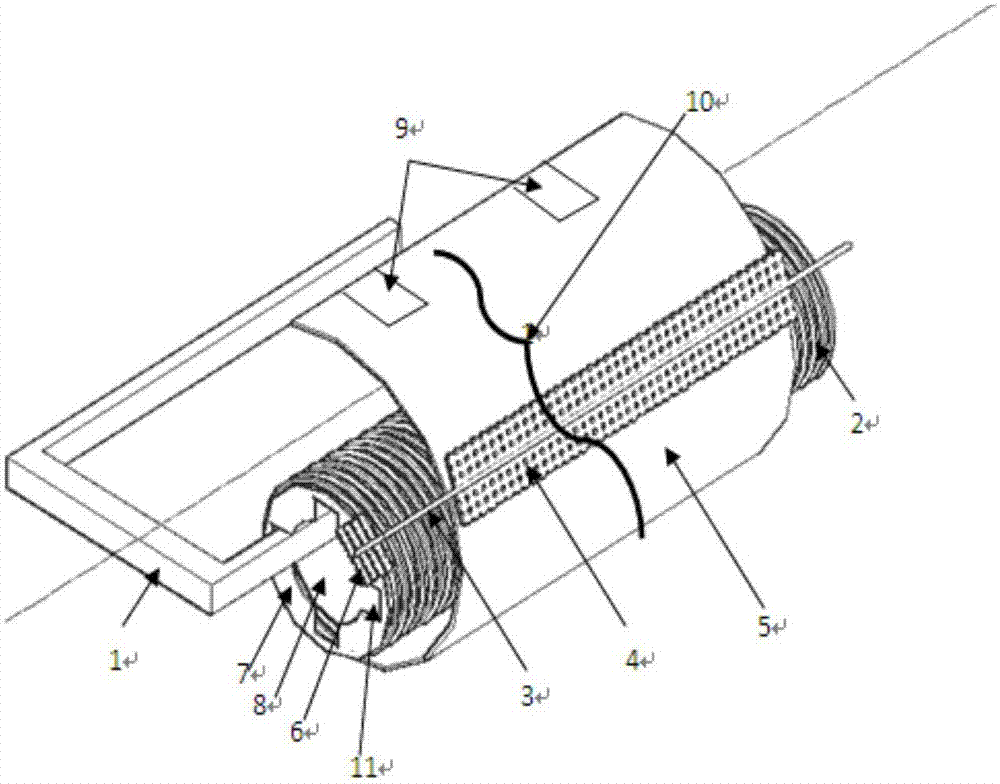

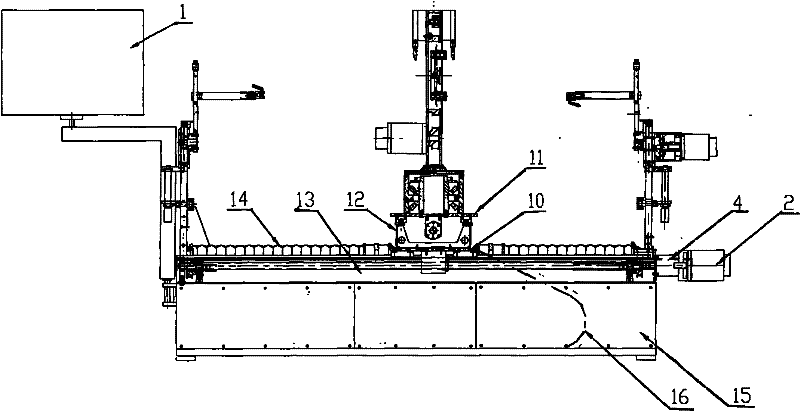

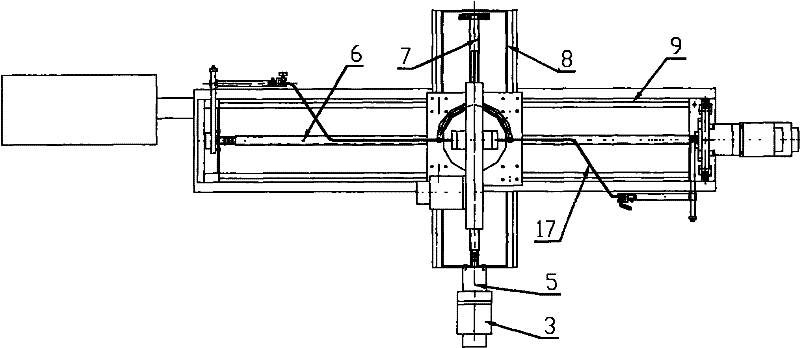

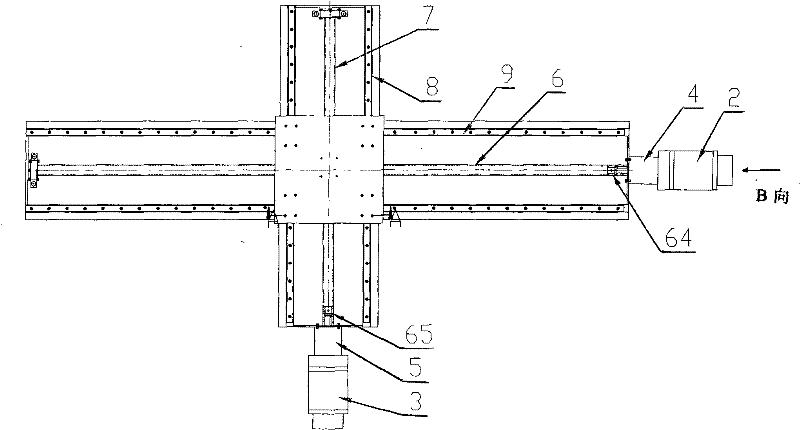

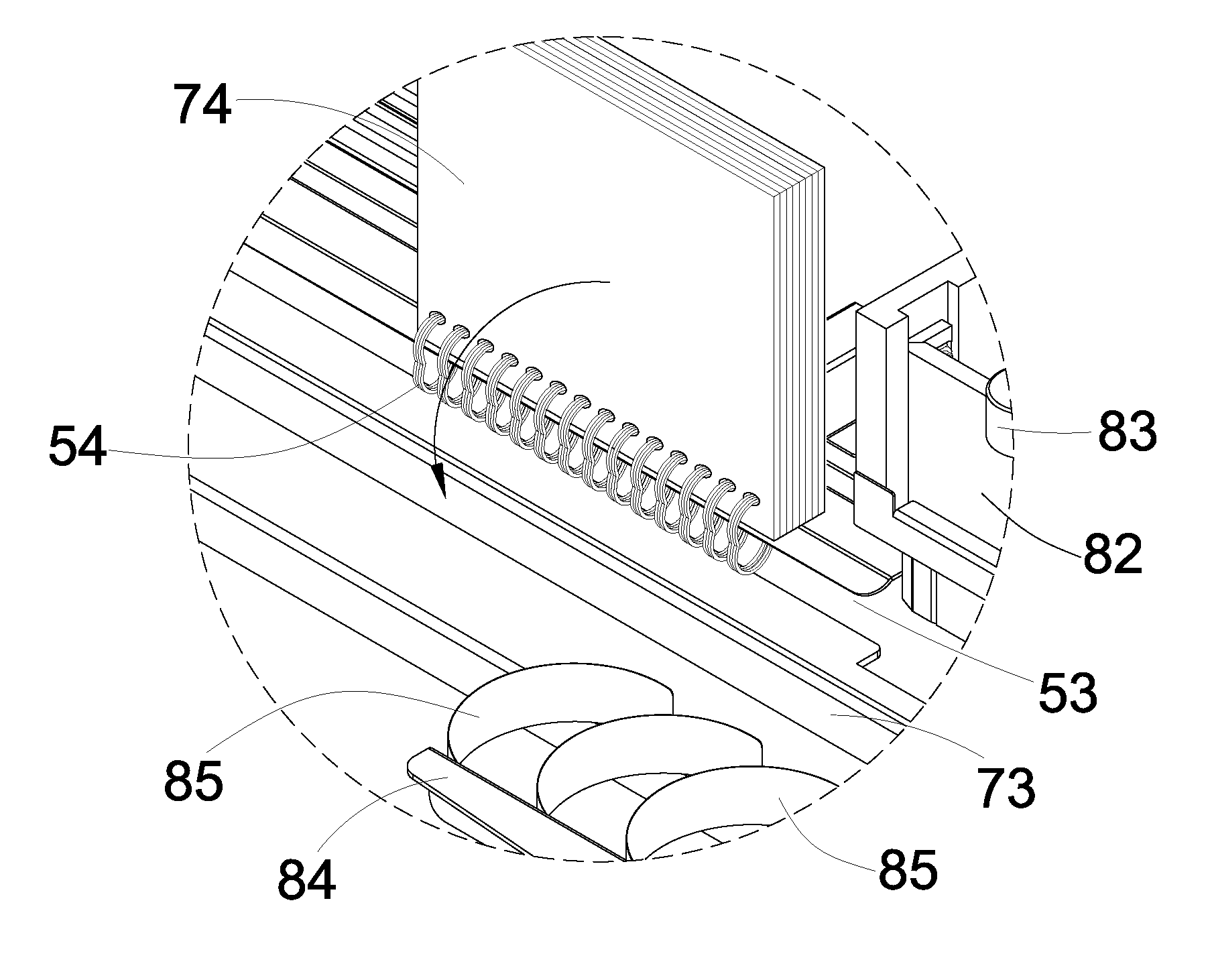

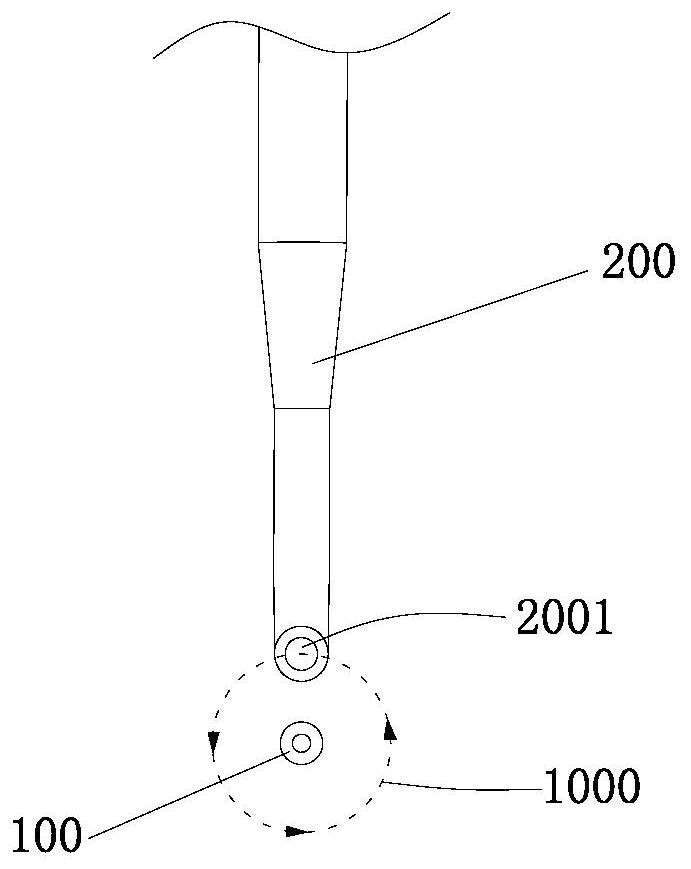

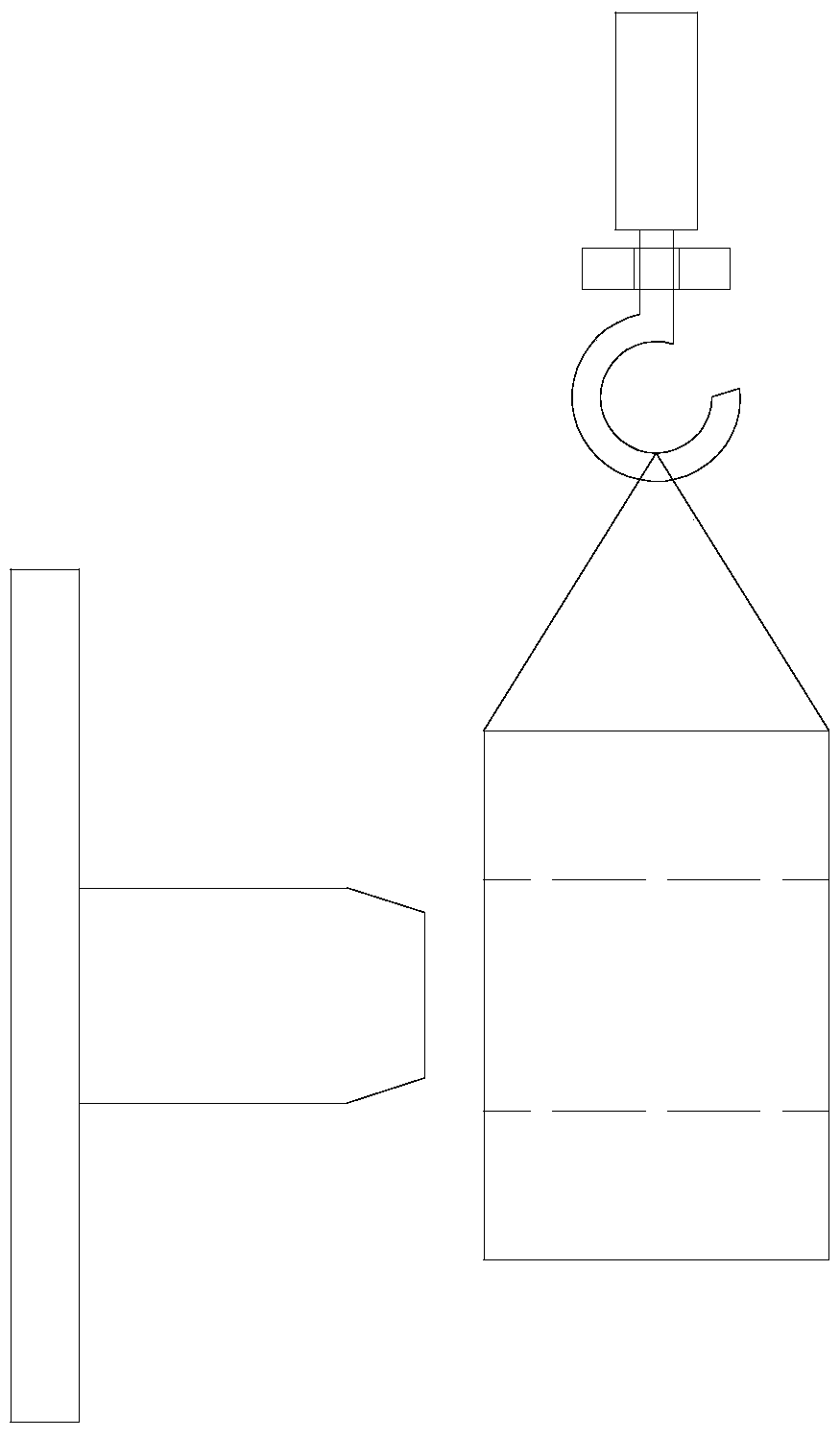

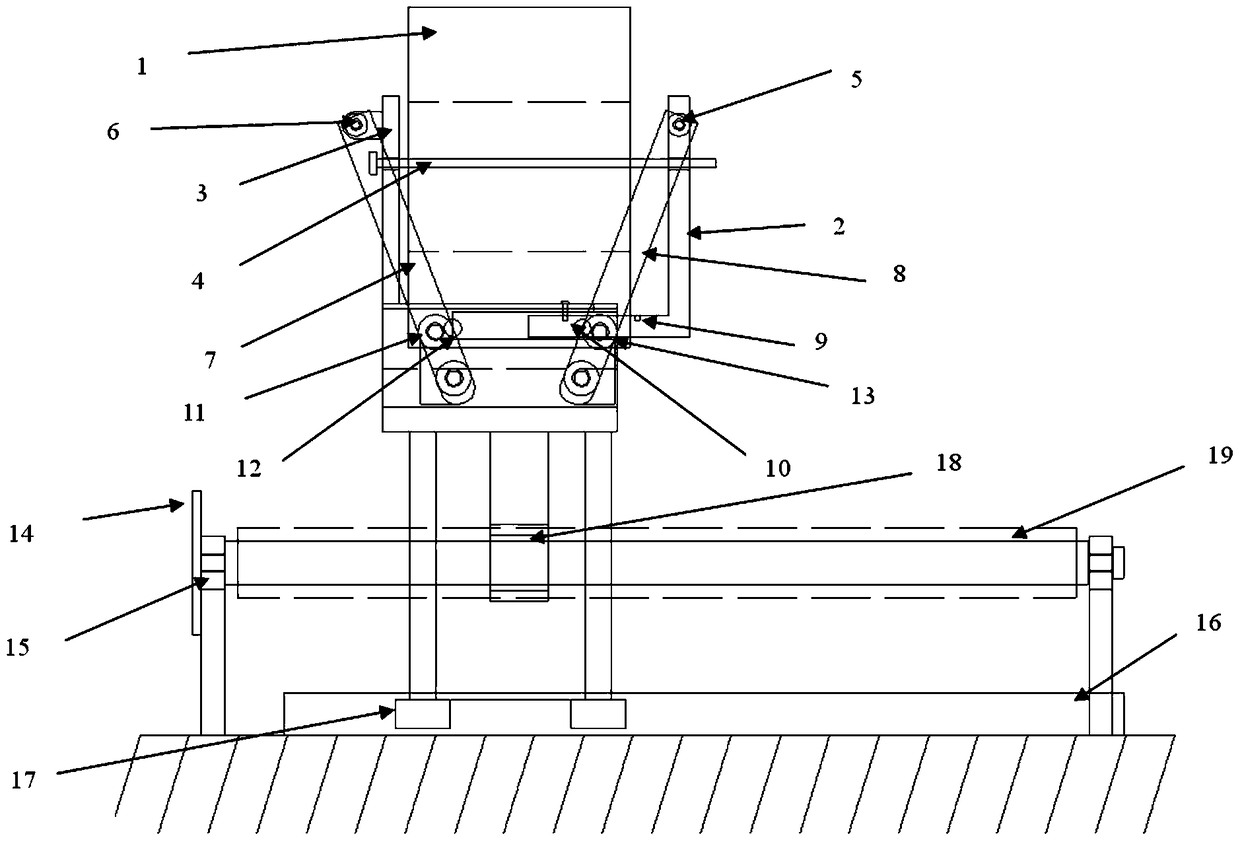

Rotor coil binding machine of wind power generator

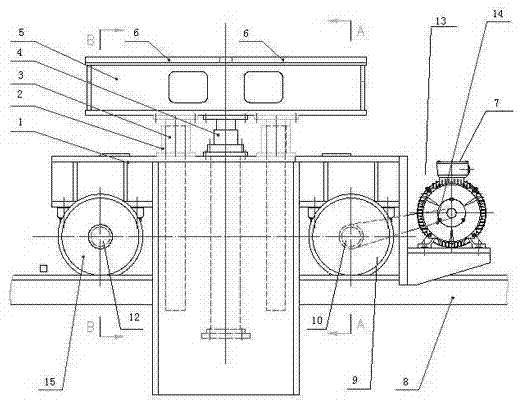

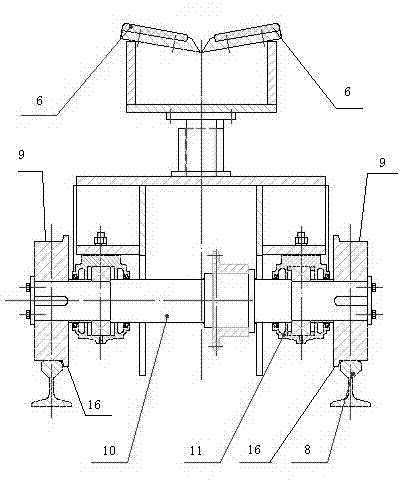

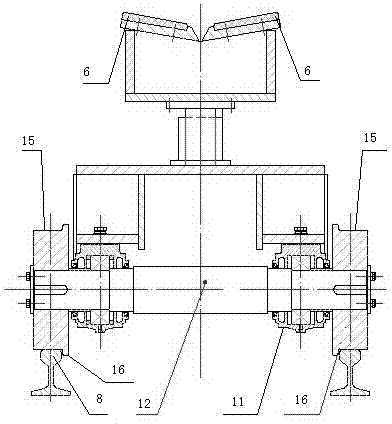

InactiveCN101707421AFit tightlySufficient clamping rangeManufacturing dynamo-electric machinesWind energy generationCoil bindCoupling

The invention relates to the technology of rotor coil binding of generators, in particular to a rotor coil binding machine of a wind power generator. The invention solves the problems of large labor intensity, low efficiency and difficult control of quality caused by manual binding because of the insulation of the rotor coil of the traditional wind power generator. The rotor coil binding machine of the wind power generator comprises a numerical control system, a stand, a feeding system, a rotor coil clamping synchronous device and a lapping head, and mainly comprises a servo motor, a decelerator, a ball screw, as well as a trailing plate and a linear guide rail connected by a shaft coupler, a synchronous driving pulley, a synchronous driven pulley and a synchronous belt, wherein the synchronous belt with a tension wheel is arranged on the synchronous driven pulley, the shaft coupler is arranged between synchronous transmission pulleys at the bottom end, and the synchronous driving pulley and the synchronous driven pulley at the upper end are respectively provided with a rocking arm, a left clamp rod, a right clamp rod and a clamp. Compared with the binding machine in the prior art, the rotor coil binding machine of the wind power generator has reasonable structure, favorable effect and optimal cost performance.

Owner:CRRC YONGJI ELECTRIC CO LTD

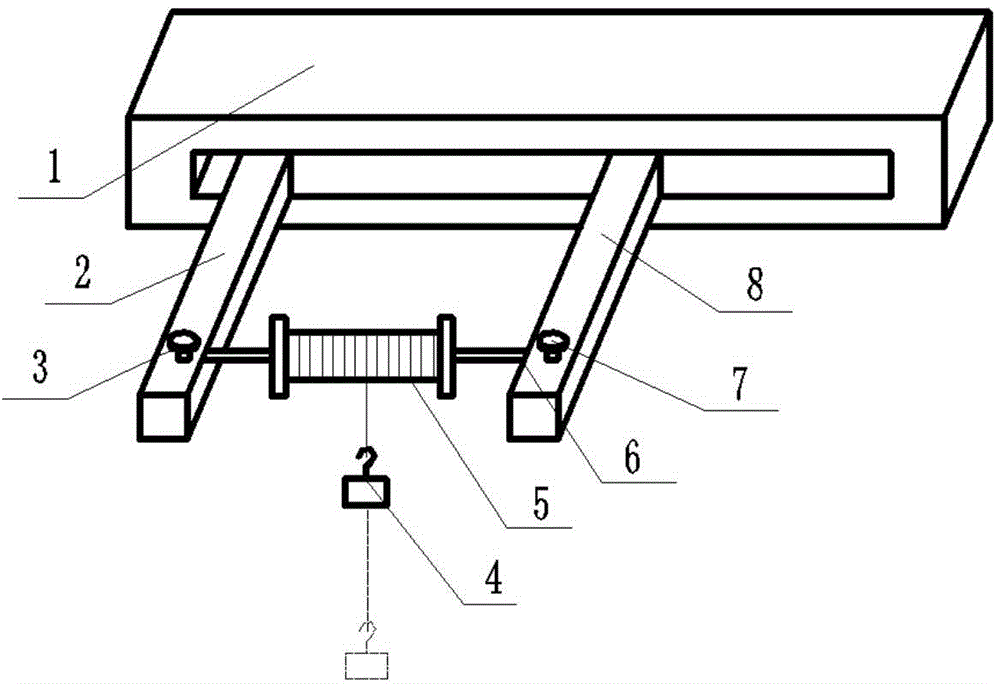

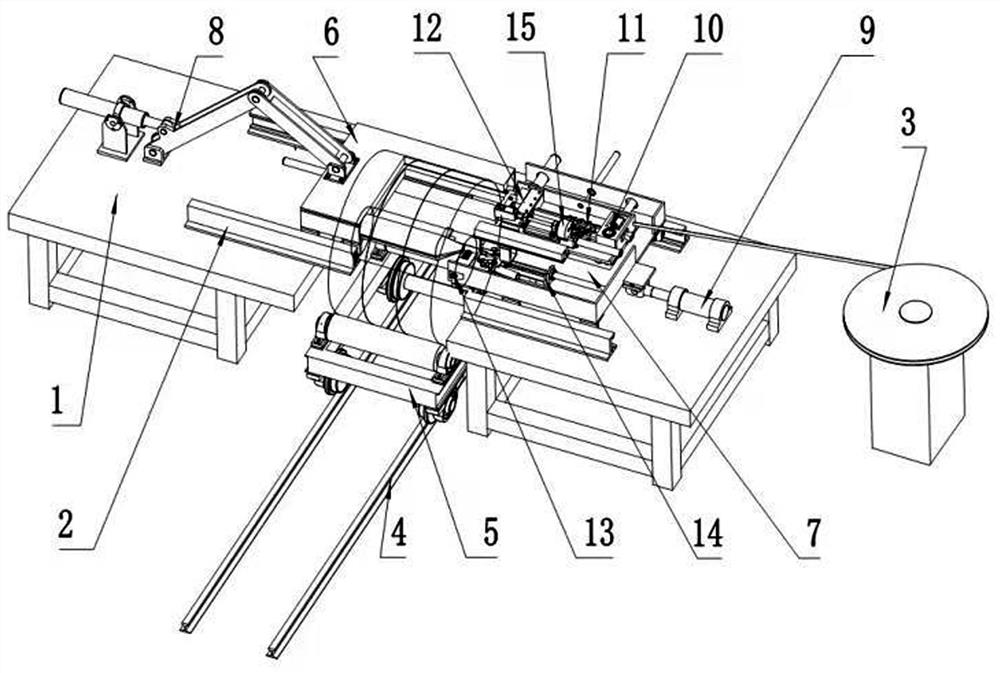

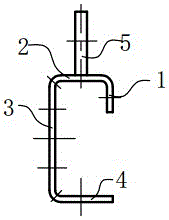

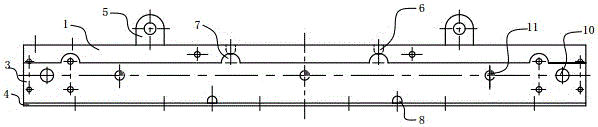

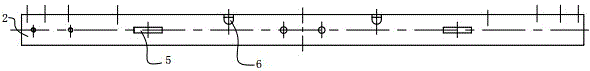

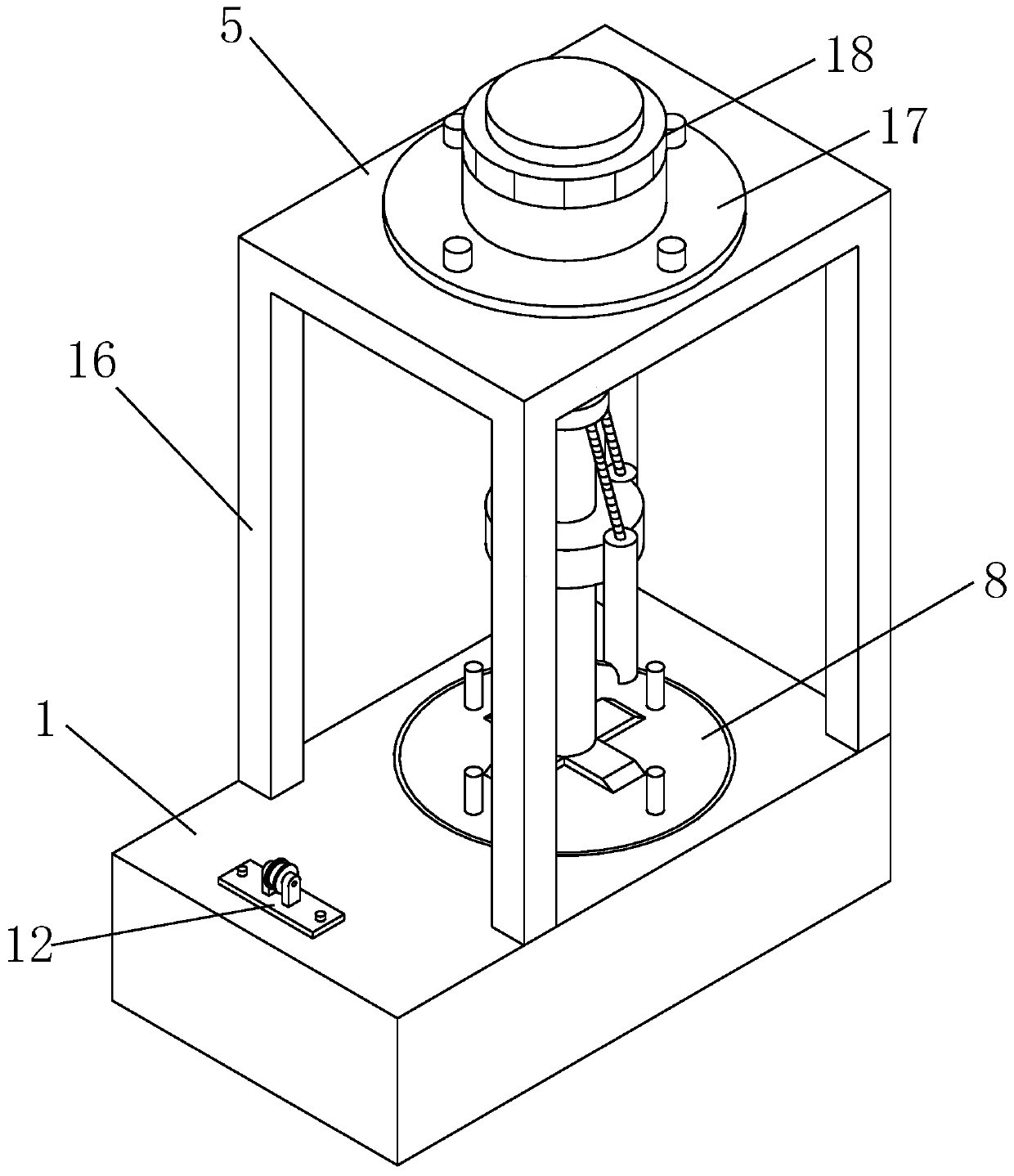

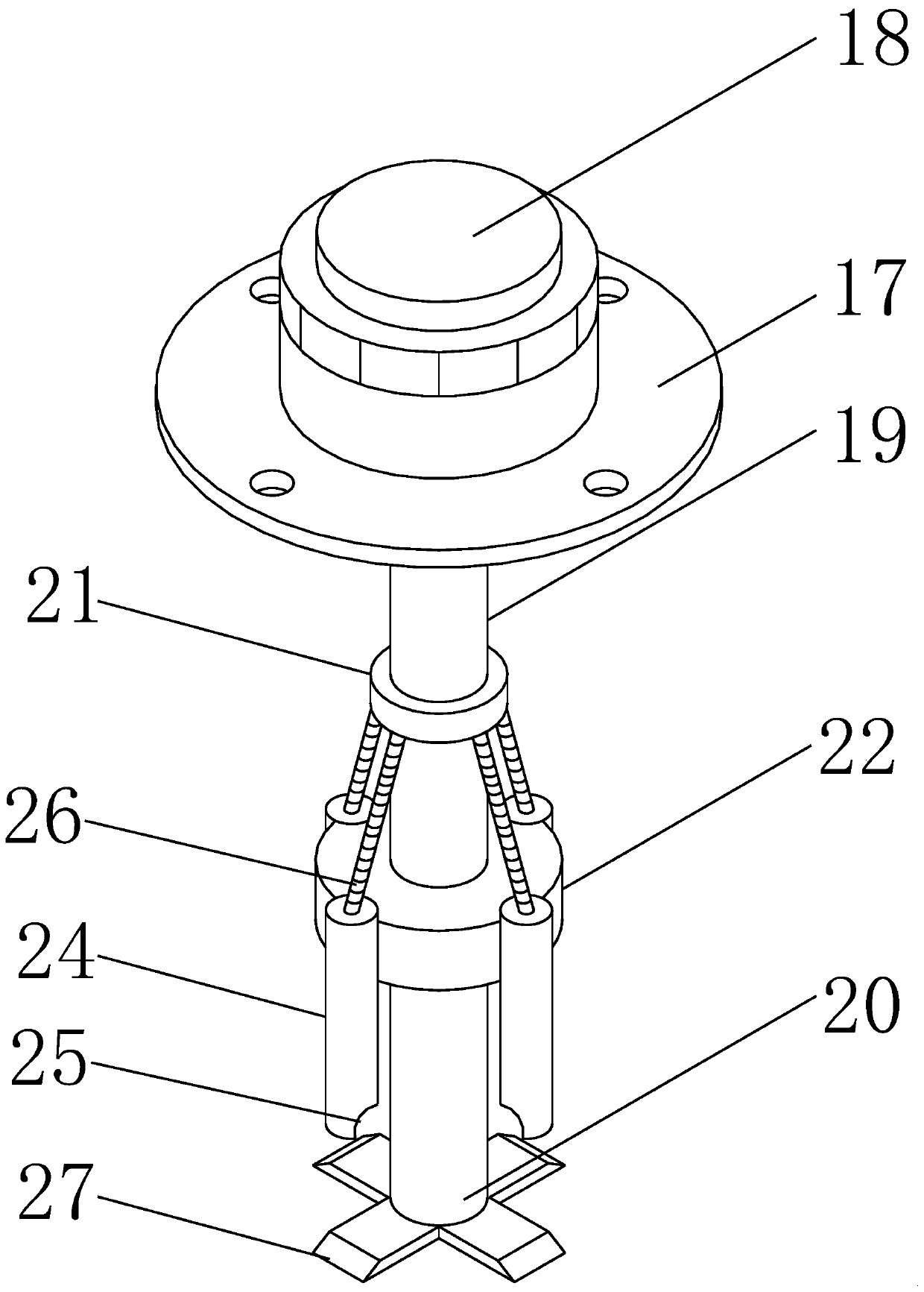

A tool for testing bobbin coil binding power and a method therefor

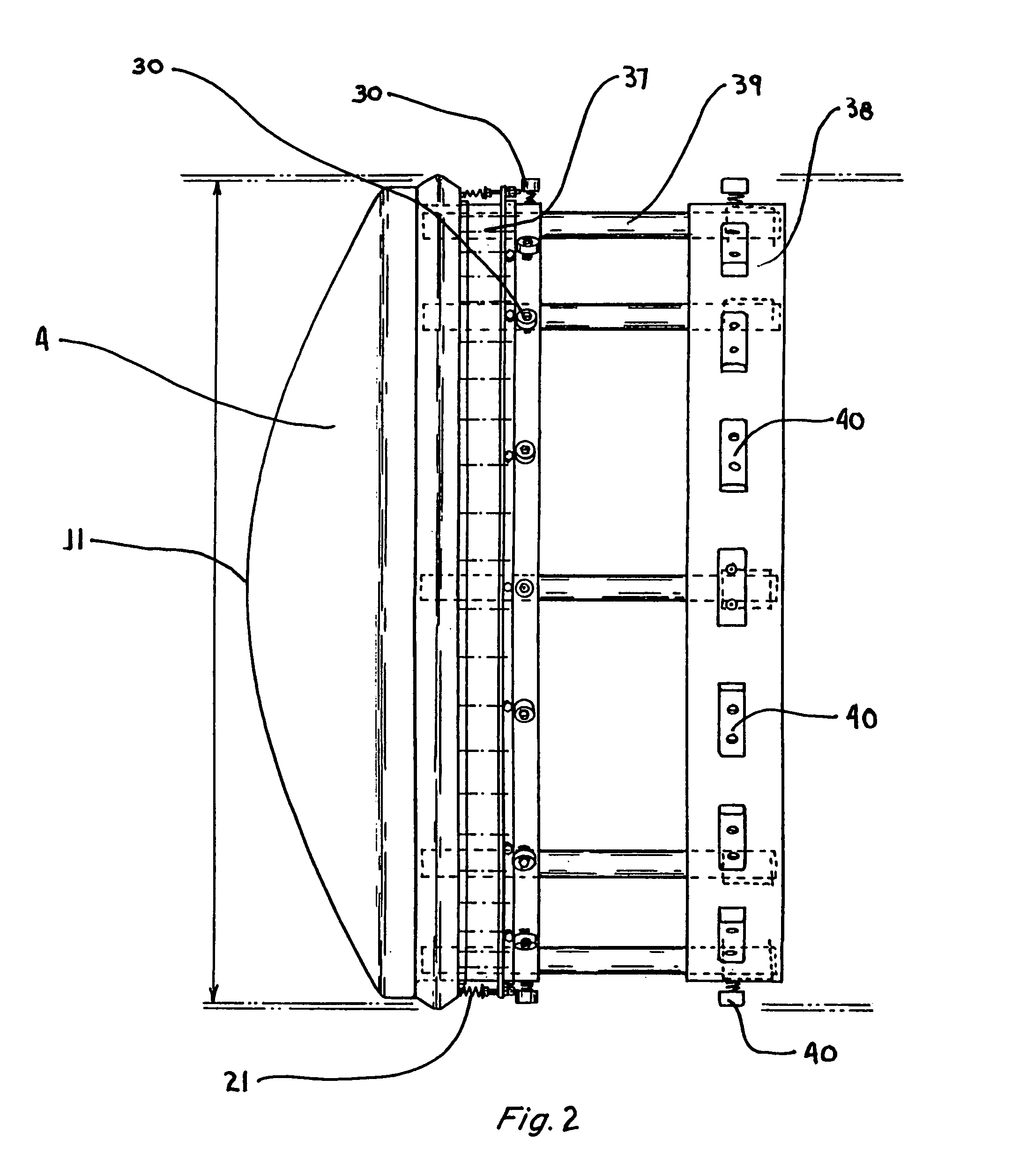

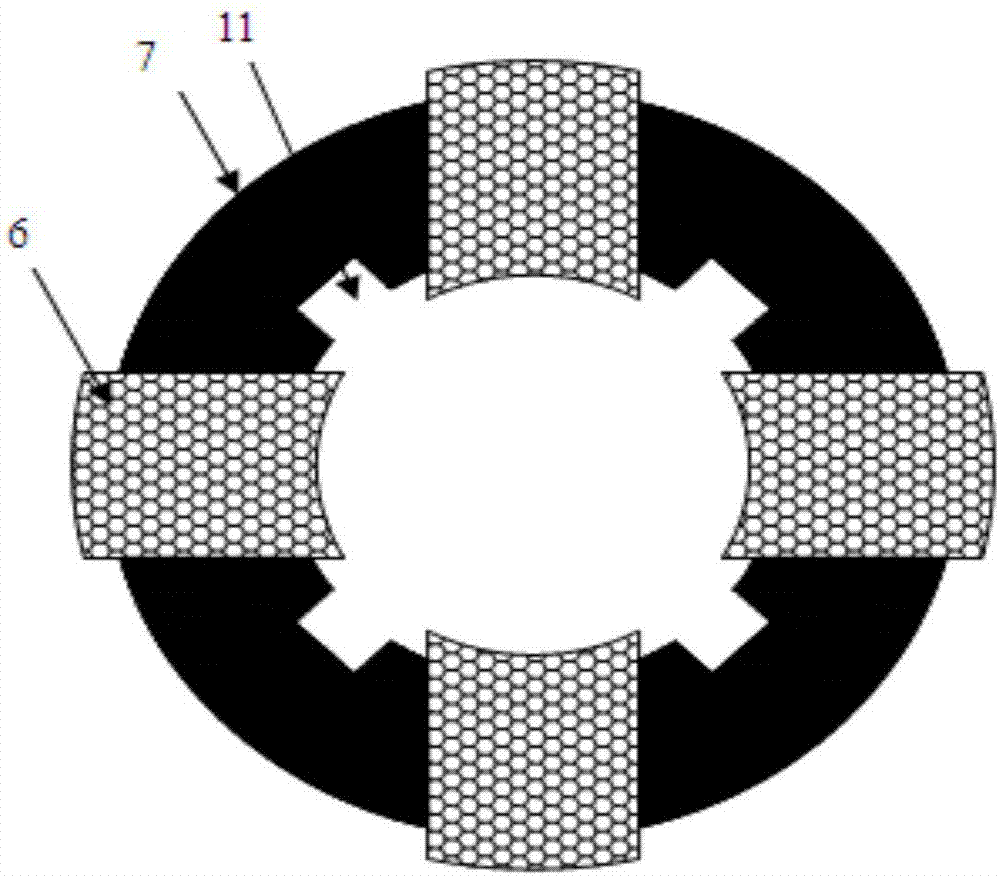

ActiveCN105651687AAdjust the cohesion valueCohesion value quantification and controlUsing mechanical meansMaterial analysisCoil bindBobbin

The invention relates to a tool for testing bobbin coil binding power and a method therefor. The tool comprises a guide rail base (1), a first suspended rod (2), a first lock screw (3), a load (4), a bobbin coil (5), a central spindle (6), a second lock screw (7) and a second suspended rod (8). At the tangential direction of the outmost coil layer of the bobbin coil (5), the load (4) is hung on a self-adhesive varnished wire at an end of the bobbin coil (5), the weight of the load (4) is increased gradually until the self-adhesive varnished wire on which the load (4) is hung is separated from the bobbin coil (5), and then the weight of the load (4) is a binding power value of the outmost coil layer of the bobbin coil (5). Through results of coil binding power testing, heating temperature and heating time in heat bonding process parameters can be adjusted, and therefore binding power values of bobbin coils can be quantified and controlled.

Owner:FLIGHT AUTOMATIC CONTROL RES INST

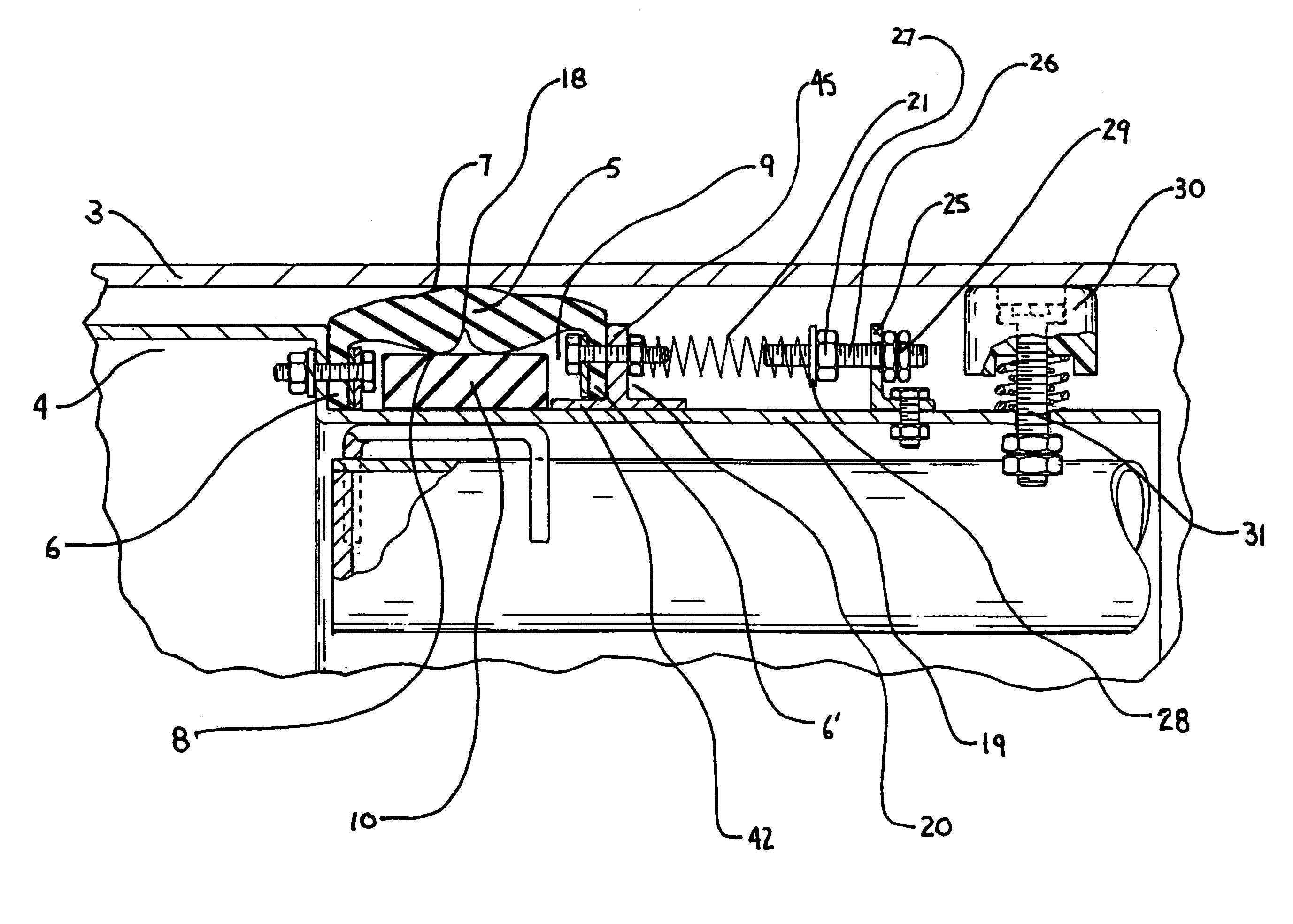

Tank piston seal and stabilizing system

An improved seal and stabilizing system for a piston head in a tank cylinder provides a better mechanism for discharging and wiping a cylinder when heavy liquids such as chocolate or peanut butter are being dispensed. The seal system now includes a free-floating block inside the seal and grooves in the inner lower part of the hollow seal. The block and grooves keep the upper, outer part of the seal from deforming away from the inner surface of the cylinder that facilitates complete discharging and wiping of the material from the cylinder tank. The tensioning mechanism of the seal is made from a unitary and annular ring T-ring that easily slides on the rear surface of the piston head. In order to stabilize the movement of the piston head down the cylinder, clockwise and counterclockwise springs are provided for the stabilizing shoes. The dual spring arrangement prevents coil binding of the springs. The springs and stabilizing shoes maintain the piston head cross section parallel to the cross section of the cylinder.

Owner:PISTON TANK CORP

Coil car

The invention discloses a coil car, comprising a car body, a walking mechanism, a lifting seat and a lifting cylinder, wherein the walking mechanism is arranged on the car body; the lifting seat is arranged above the car body; and the lifting cylinder is fixed at the middle of the car body and controls the lifting seat to lift. The coil car is characterized in that the top of the lifting seat is V-shaped; two lining boards are respectively fixed at two opposite V-shaped inclined planes; and a gap required by a coil binding strip is preserved between the two lining boards on the two inclined planes. A large lifting stroke of the V-shaped lifting seat can be achieved; and the arranged lining boards not only play a role of protecting the finished strip, but also are convenient to bind the coil or dismantle the binding strip. The whole coil car is easy to manufacture and install, hollow in foundation pit, suitable for hot rolling of the coil and cold rolling of the coil, suitable for production lines such as a pickling line, a cold mill unit and a rewinding unit, and wide in application; the foundation construction is reduced; and the cost is also reduced.

Owner:WISDRI ENG & RES INC LTD

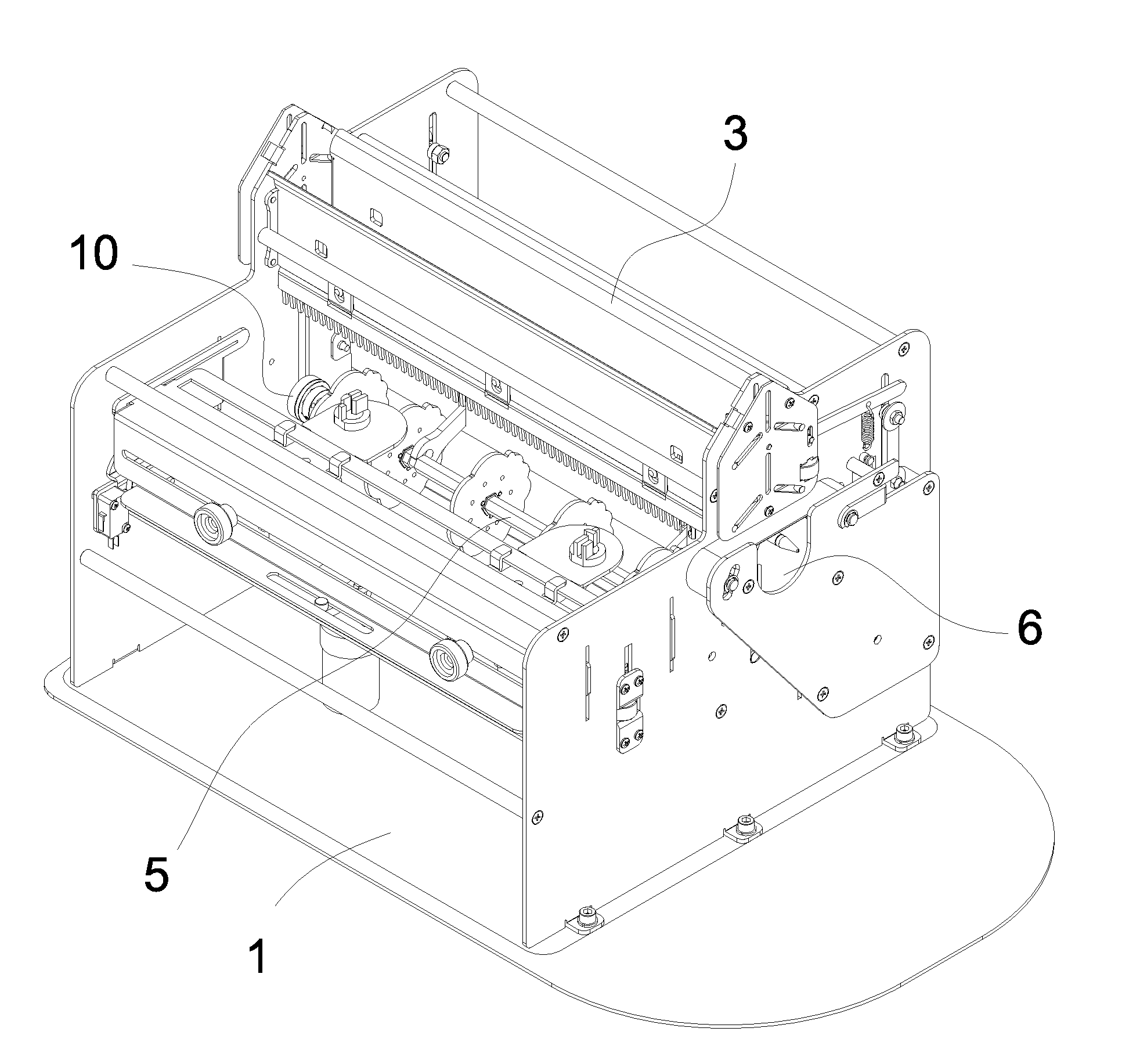

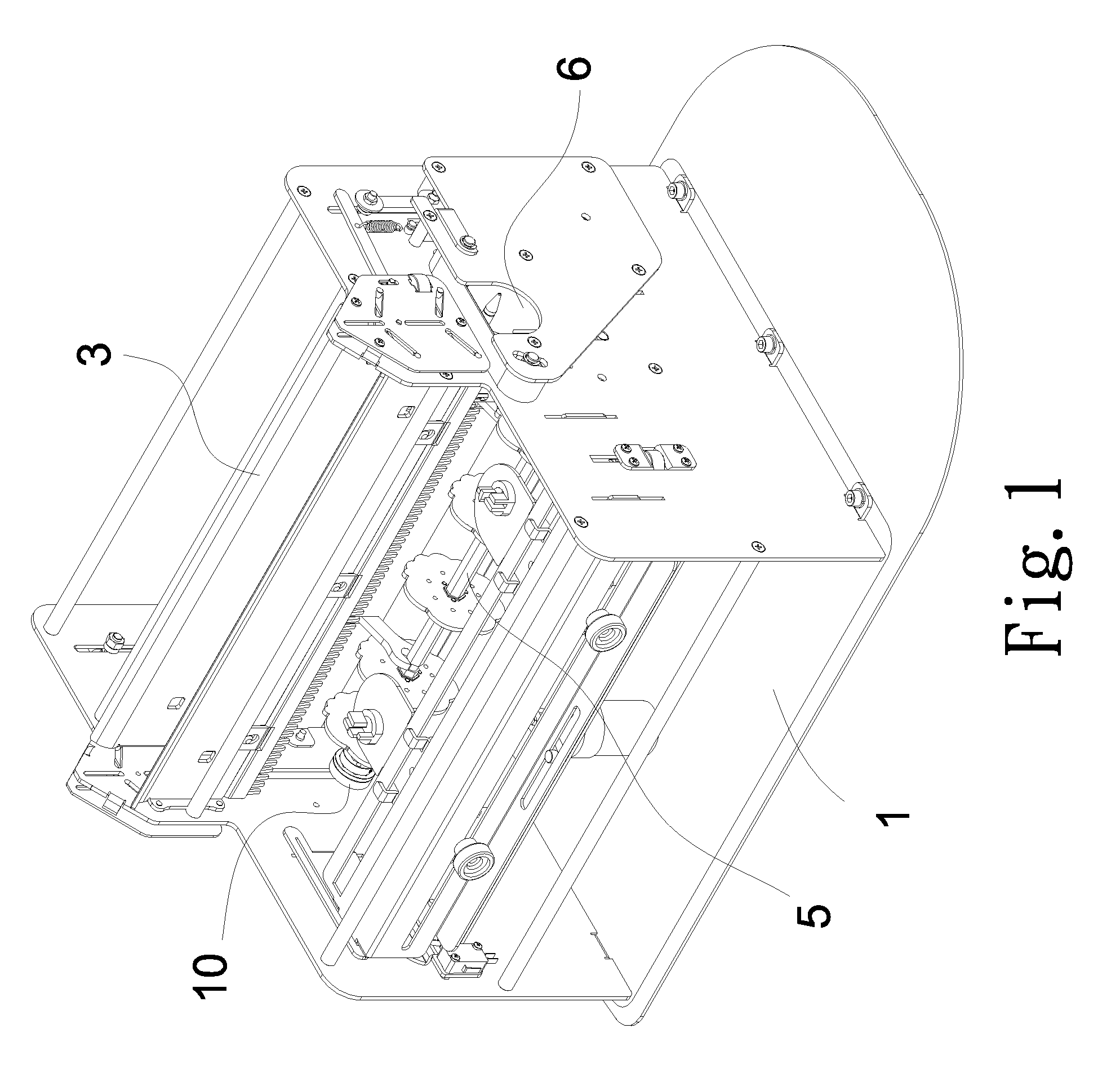

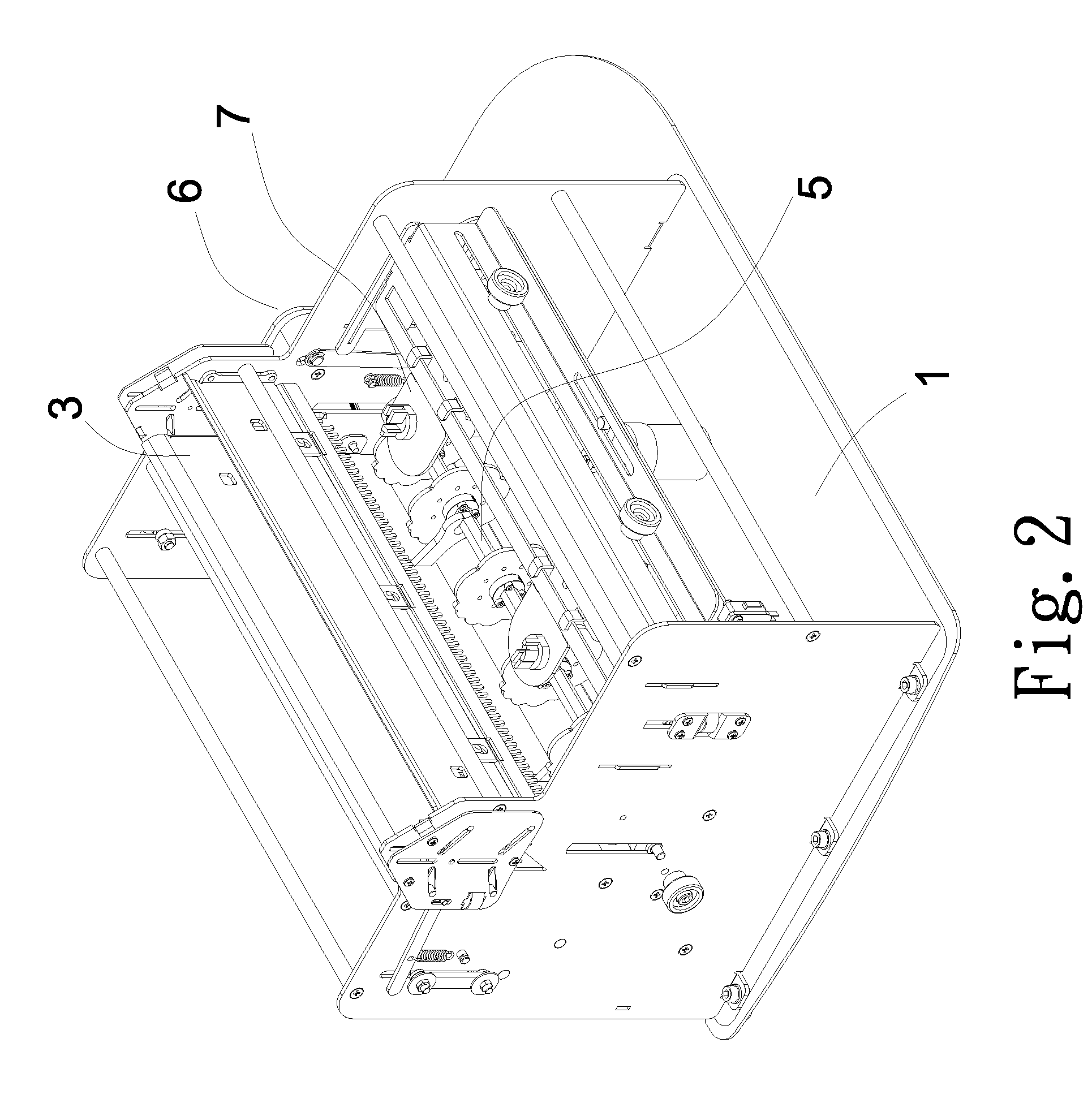

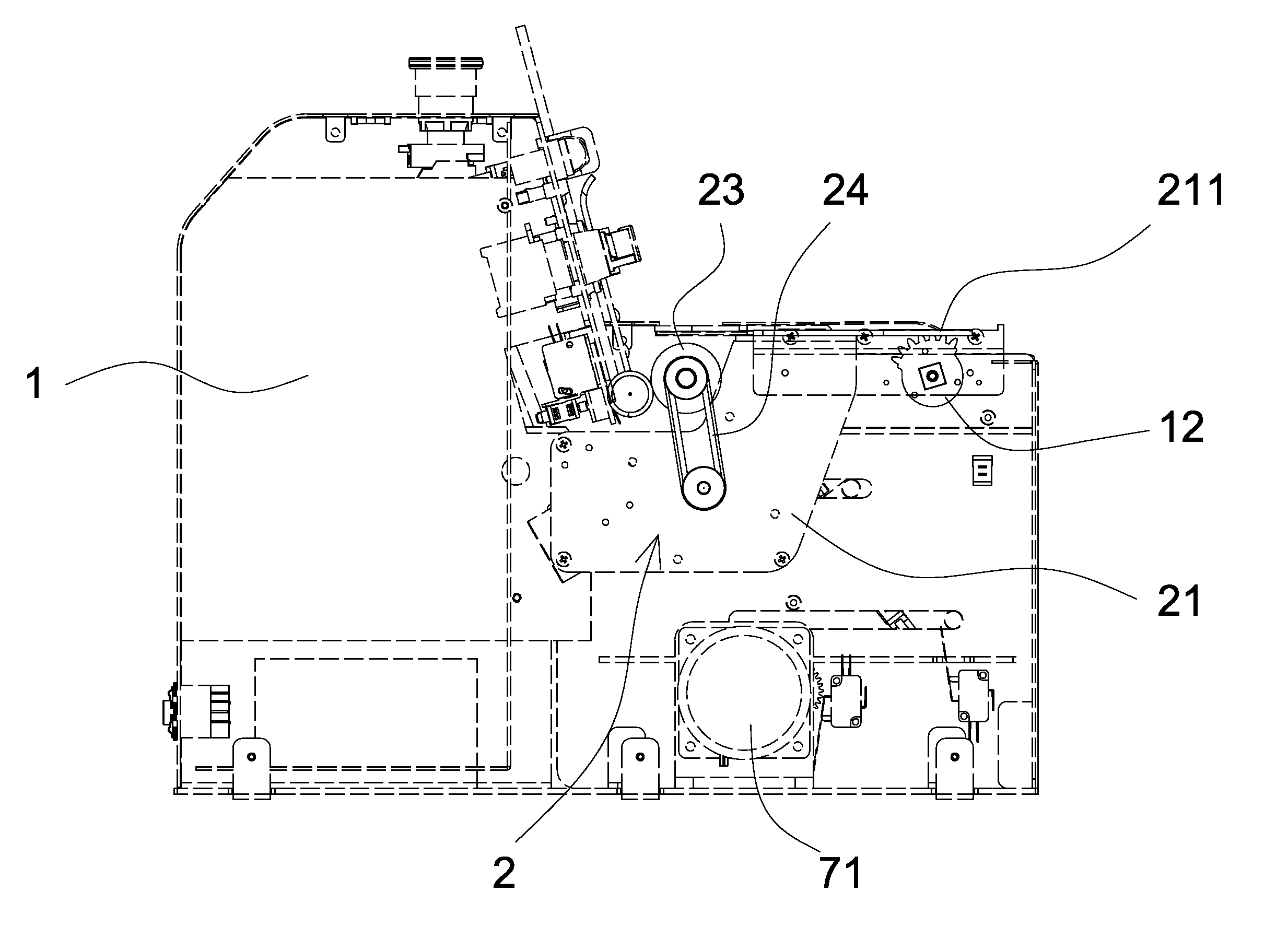

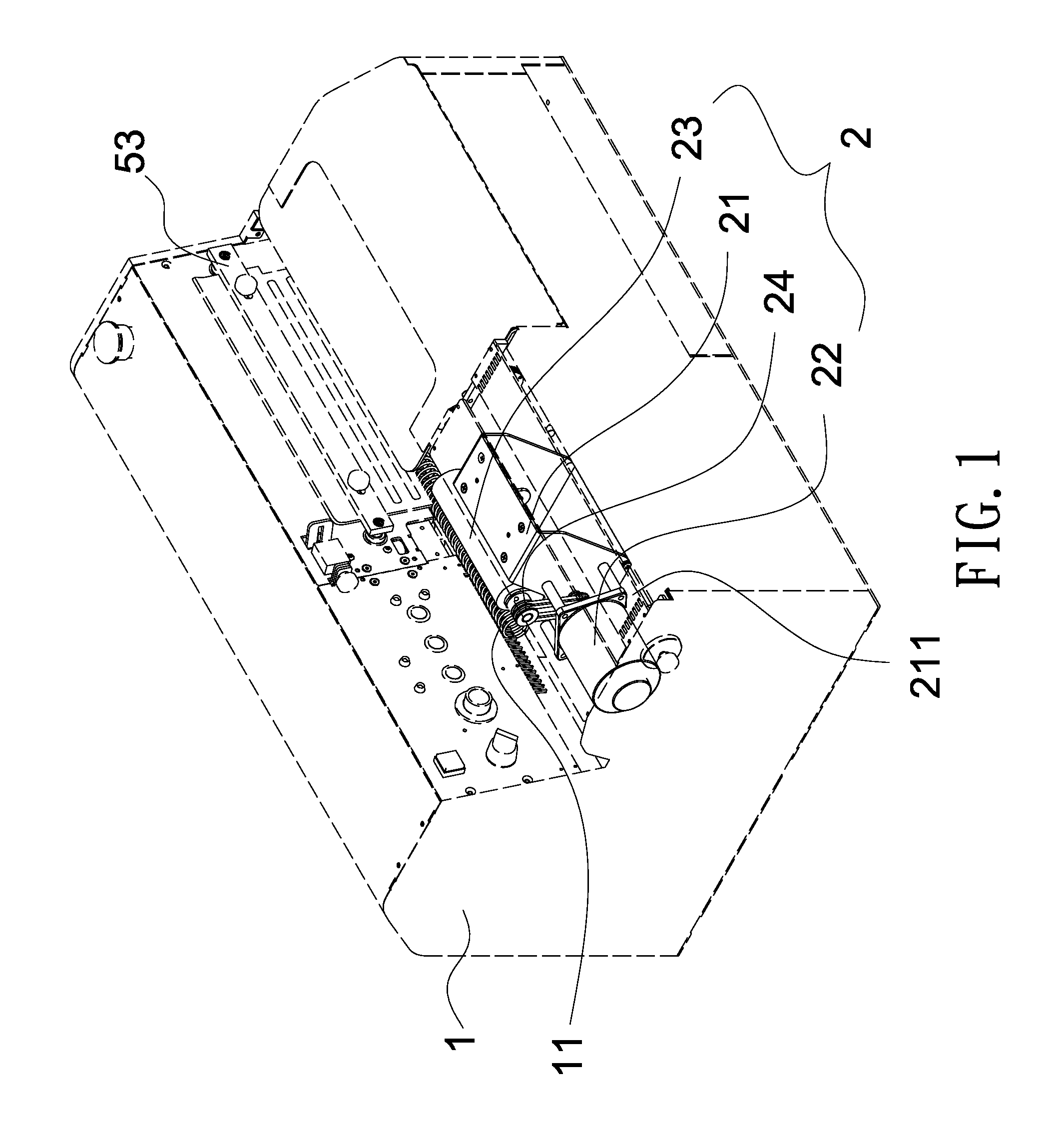

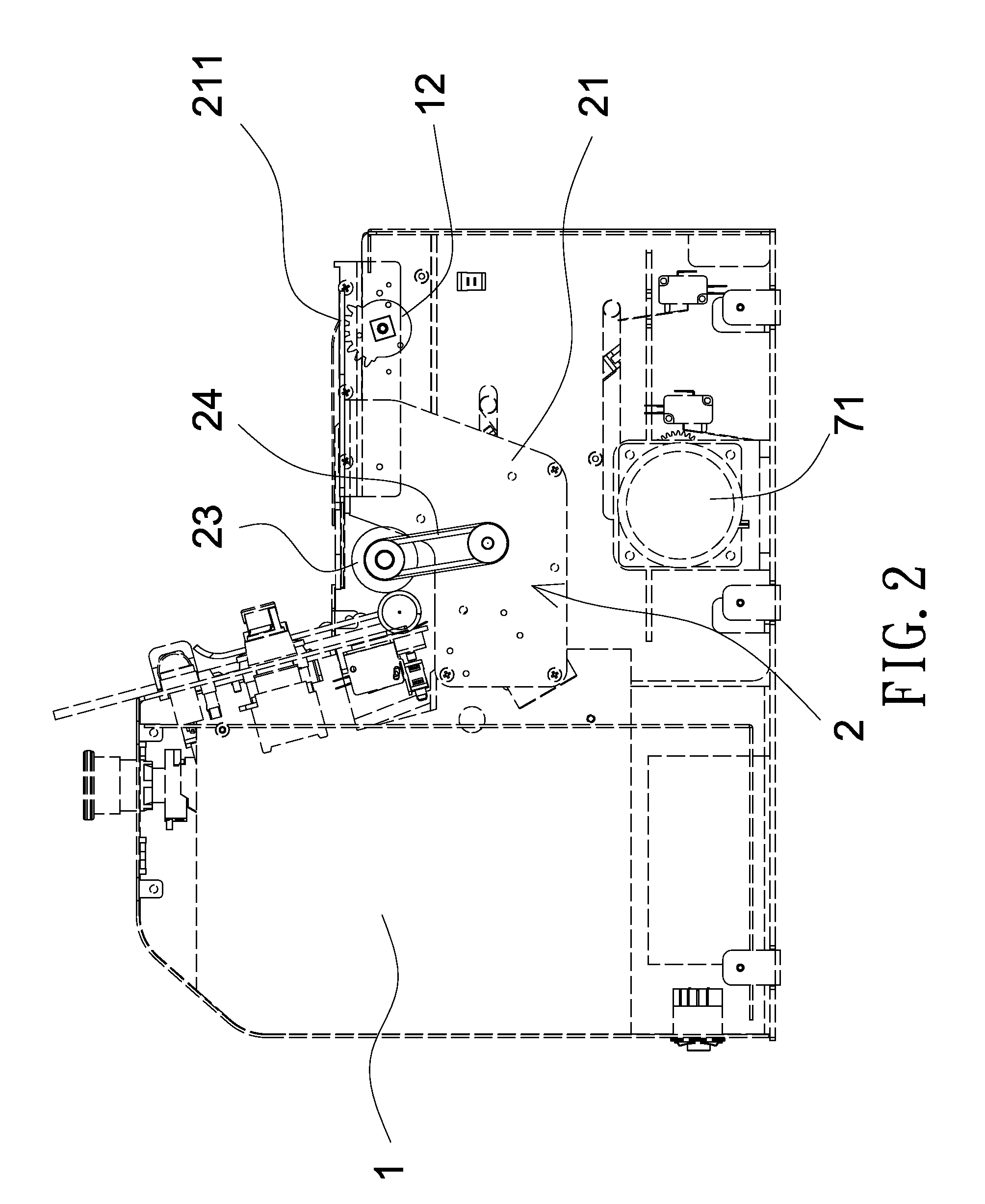

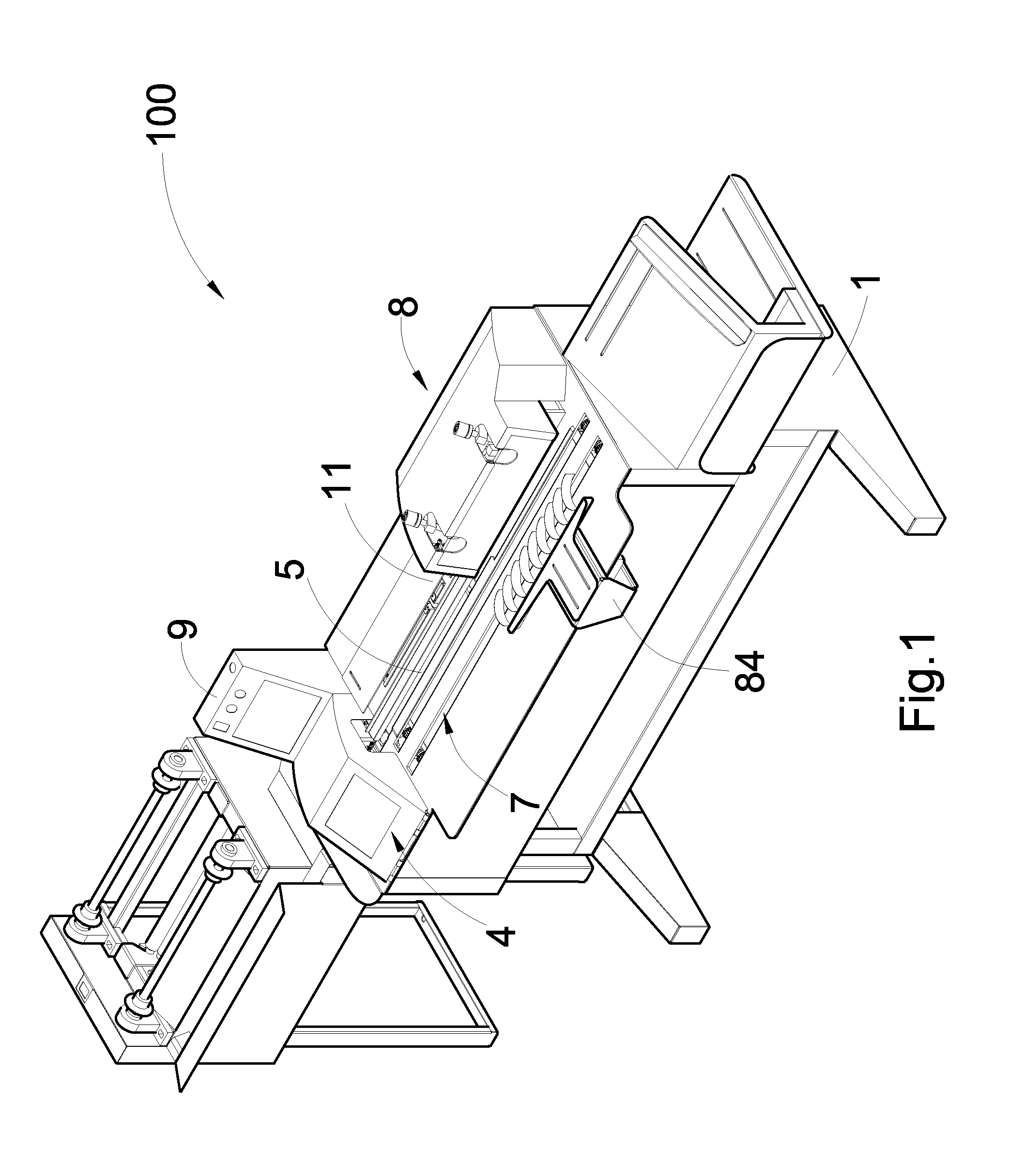

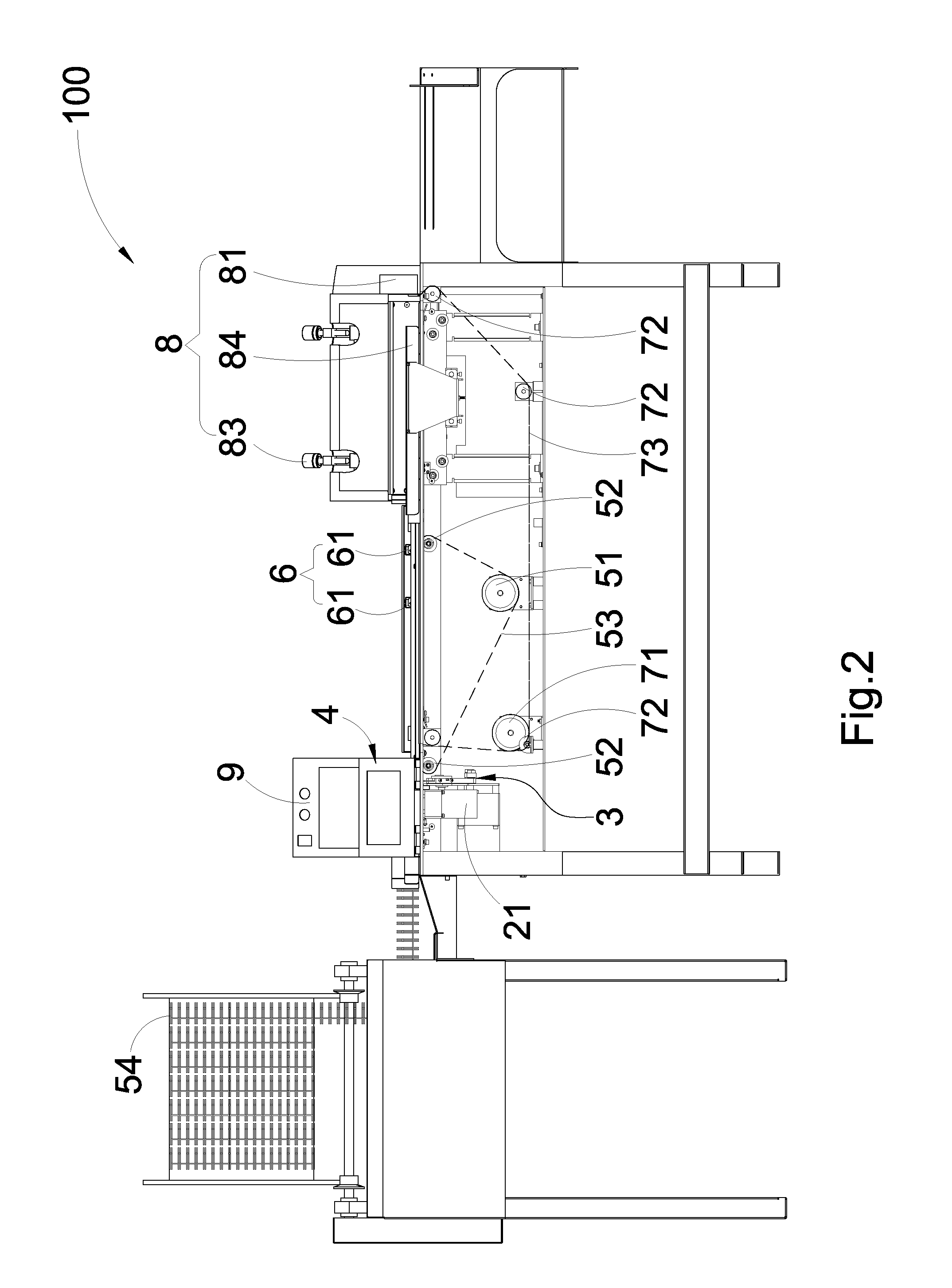

Automatic Book Coil Binding Machine

An automatic book coil binding machine comprising a table, a driving motor, a paper clipping apparatus, a linkage apparatus, a paper alignment apparatus, a coil guiding apparatus and a coil cutting apparatus is provided. When the paper clipping apparatus is driven by the driving motor and the linkage apparatus to a paper clipping position, the paper alignment apparatus is simultaneously driven to locate at a paper detaching position. The coil guiding apparatus is then driven to a guiding position to lead a coil in. The coil cutting apparatus moves to a cutting position to cut the coil at the predetermined position. Thus, the book and the coils are able to be bound rapidly and precisely.

Owner:CHUNG SHEEN TECH

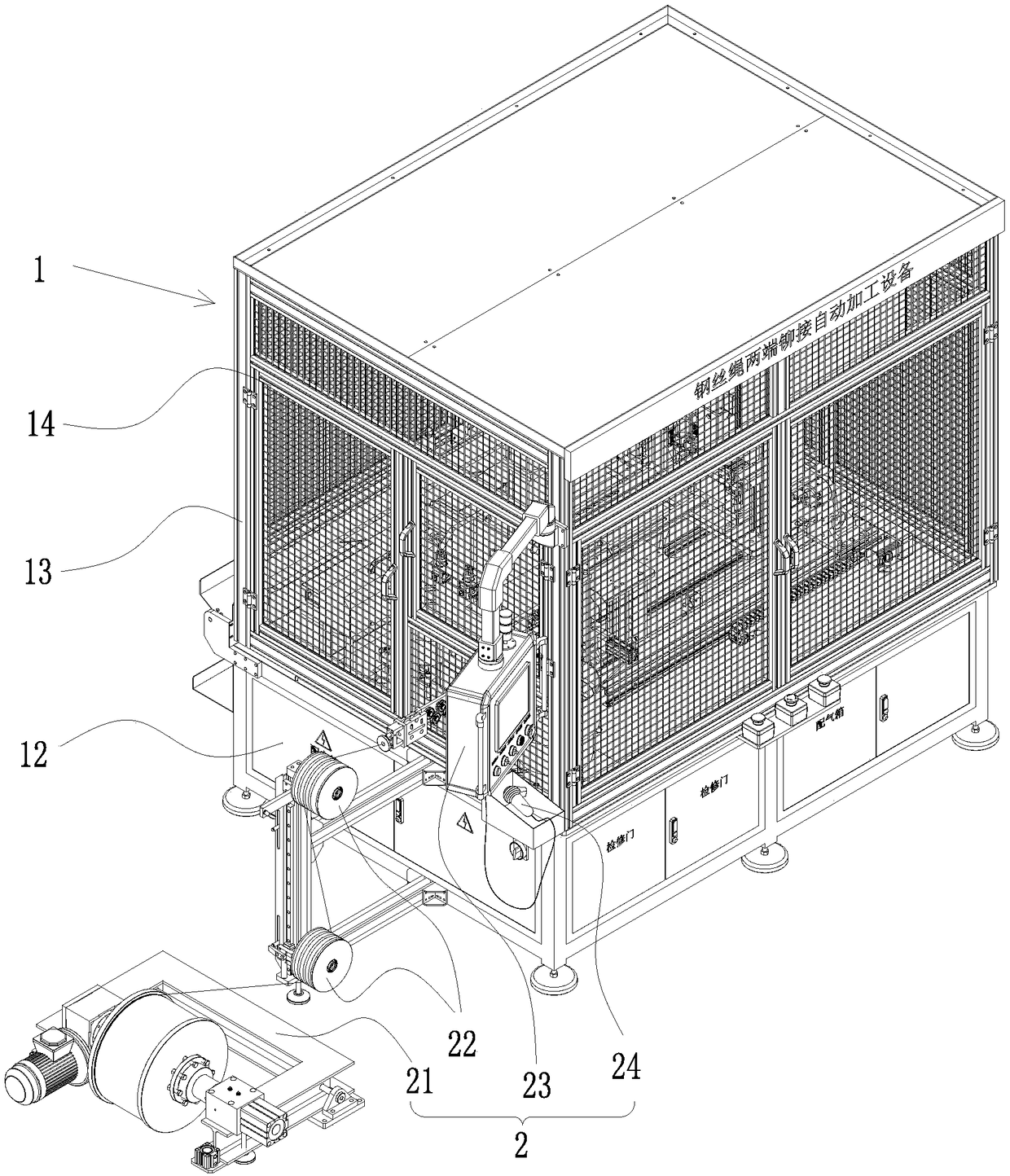

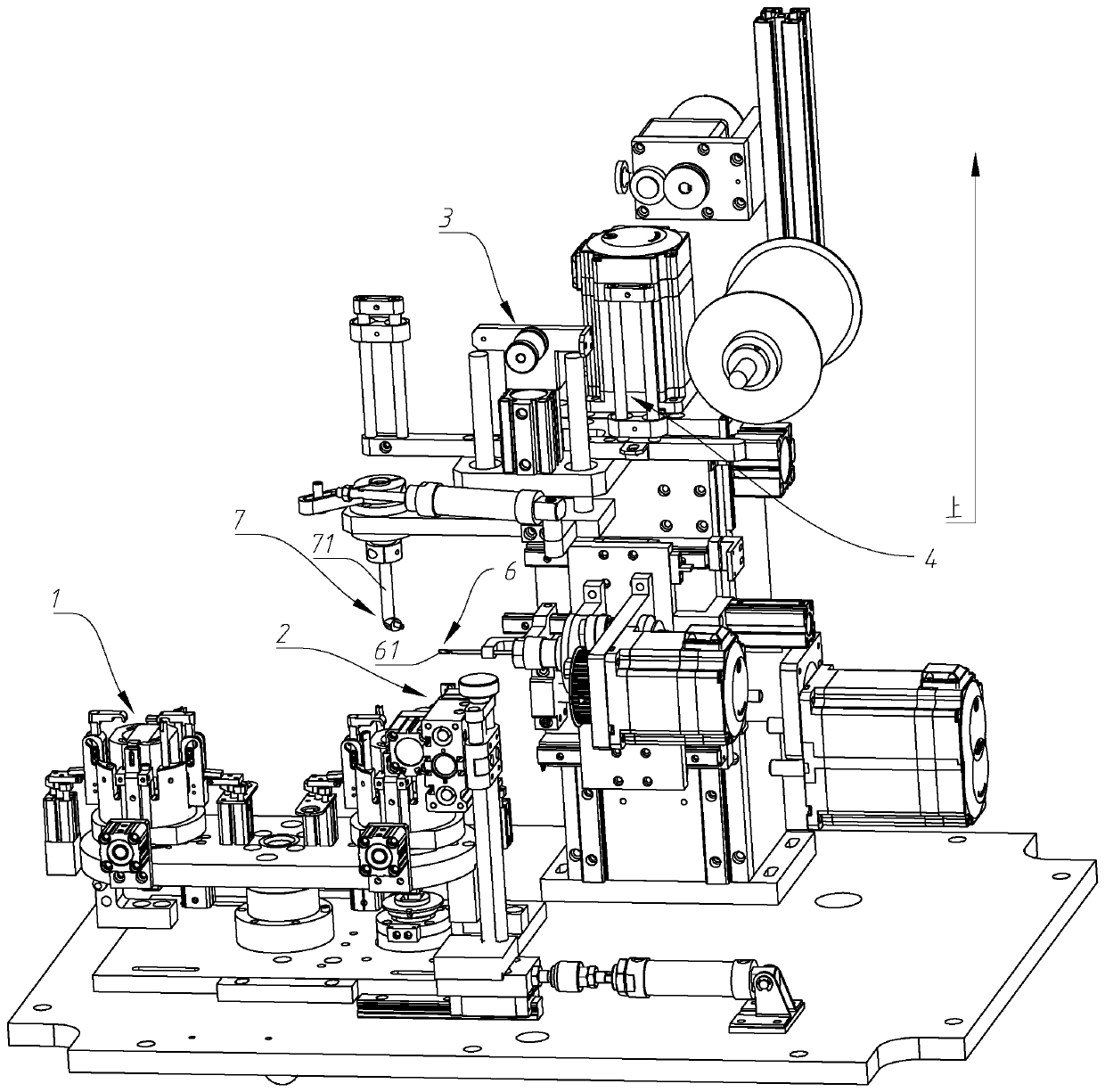

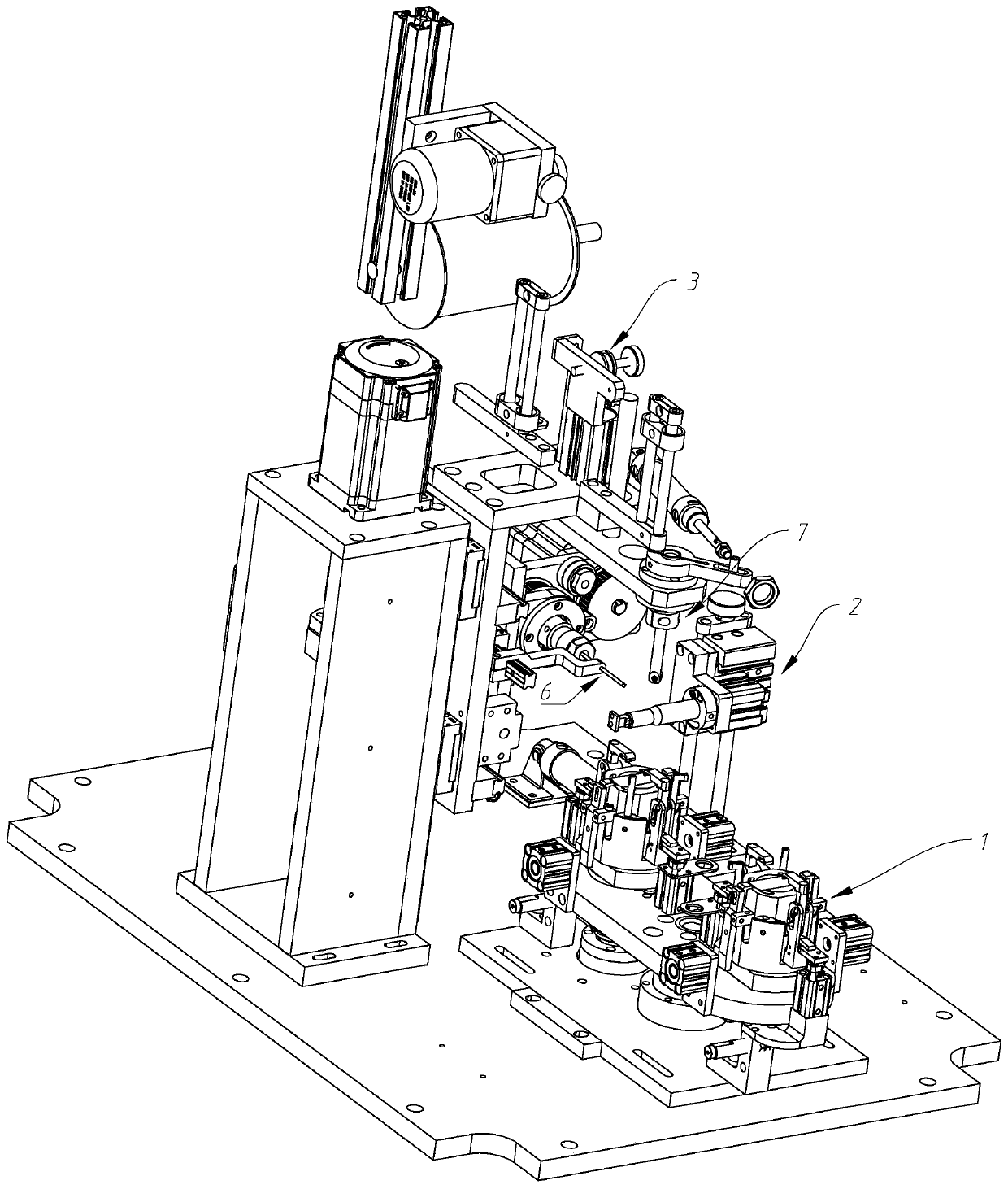

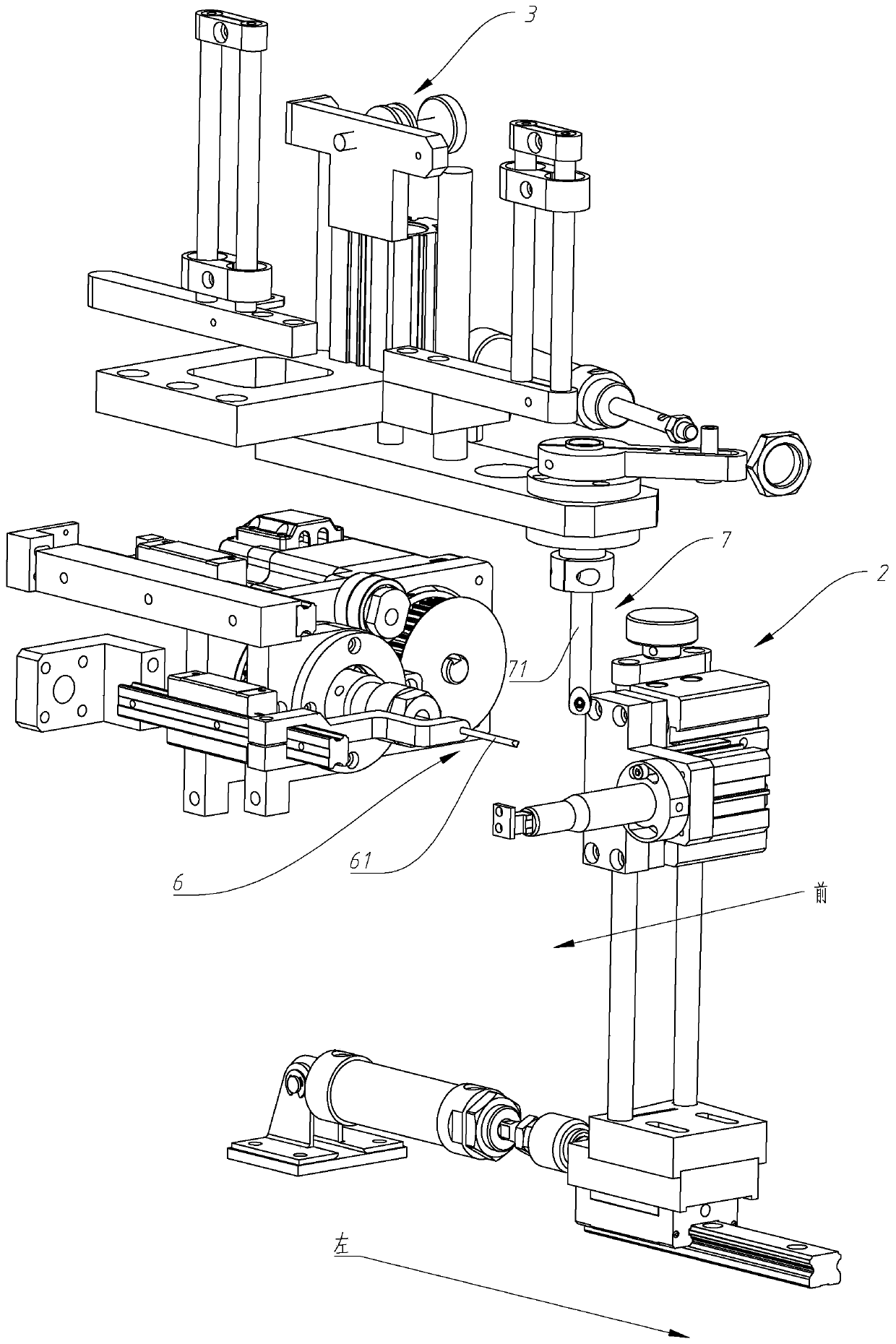

Automatic machining equipment for riveting of two ends of naked steel wire rope

ActiveCN109304412AReduce complexityReduce the risk factorSortingMetal working apparatusCoil bindEffective length

The invention relates to the technical field of vehicle part machining devices, in particular to automatic machining equipment for riveting of two ends of a naked steel wire rope. According to the automatic machining equipment, code-scanning rope paying-off, coil-bound fine cutting, primary riveting, secondary riveting, pulling-out force detection, effective length size detection operation, sorting operation and identification bundling full-process flow are integrated on the same operation unit, high integration is achieved, high-level quality precision and production efficiency are ensured through the intelligent and automatic process flow, and the safety risk and labor intensity are reduced more remarkably.

Owner:重庆翔睿捷自动化设备股份有限公司 +1

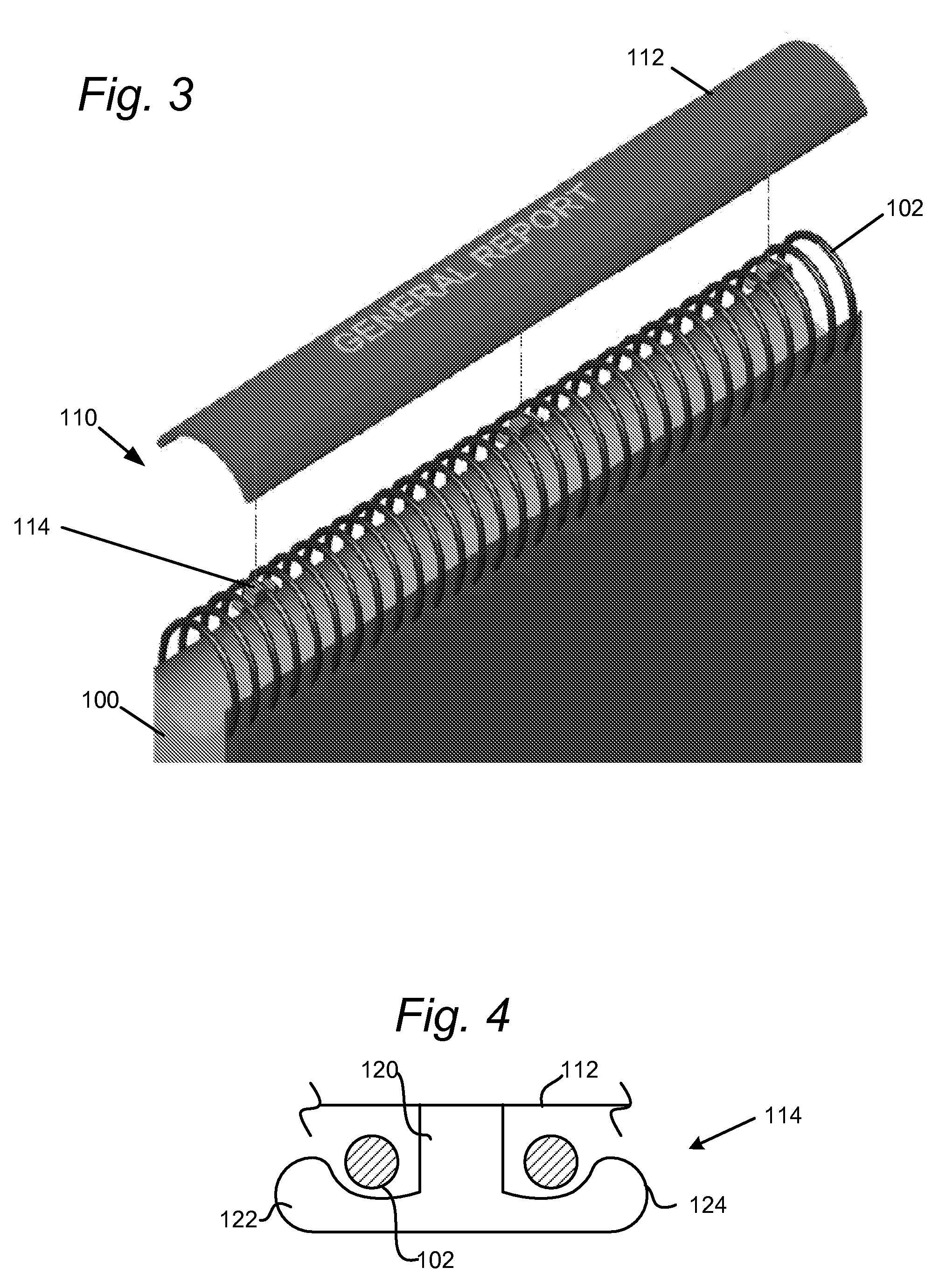

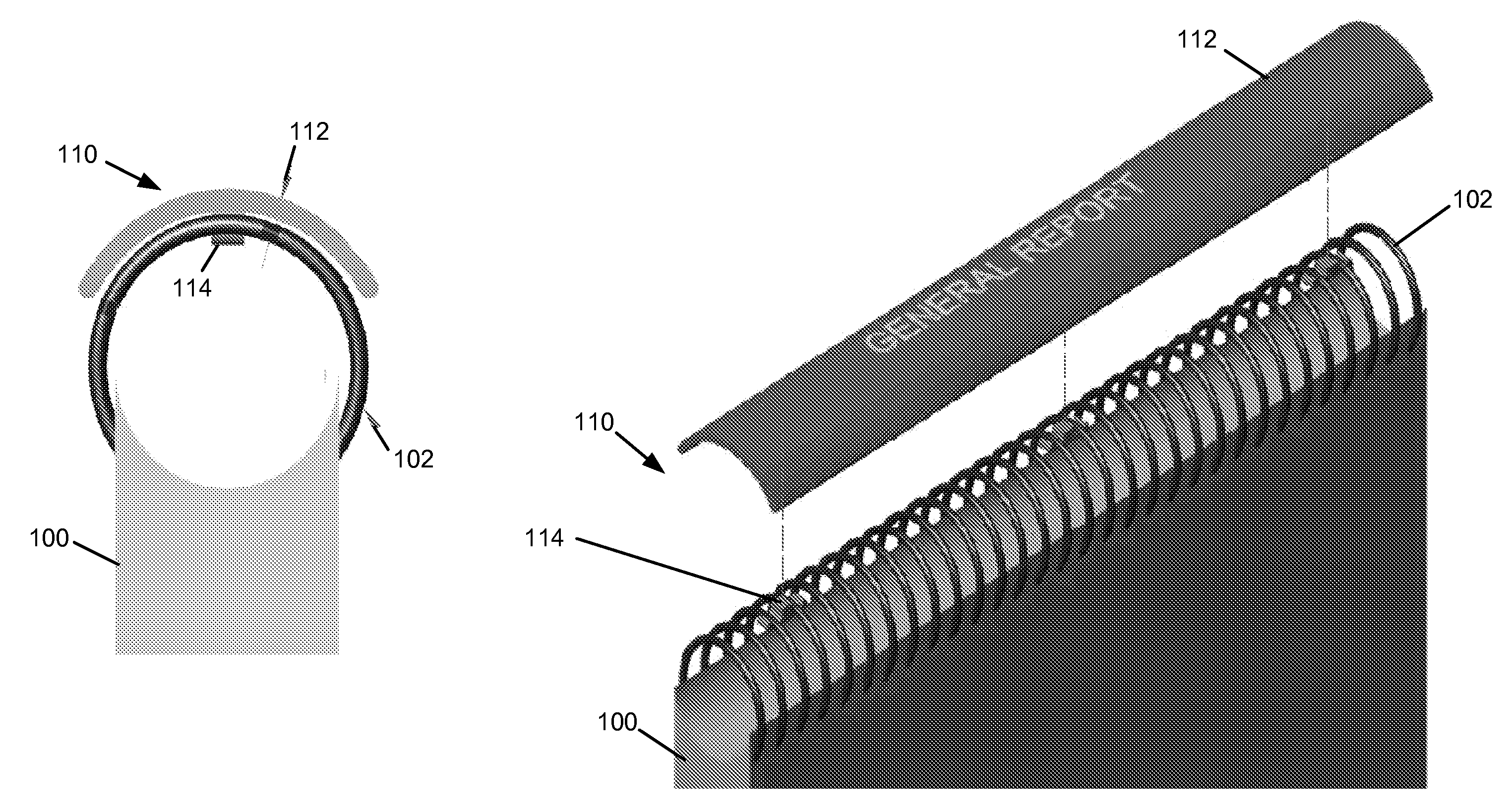

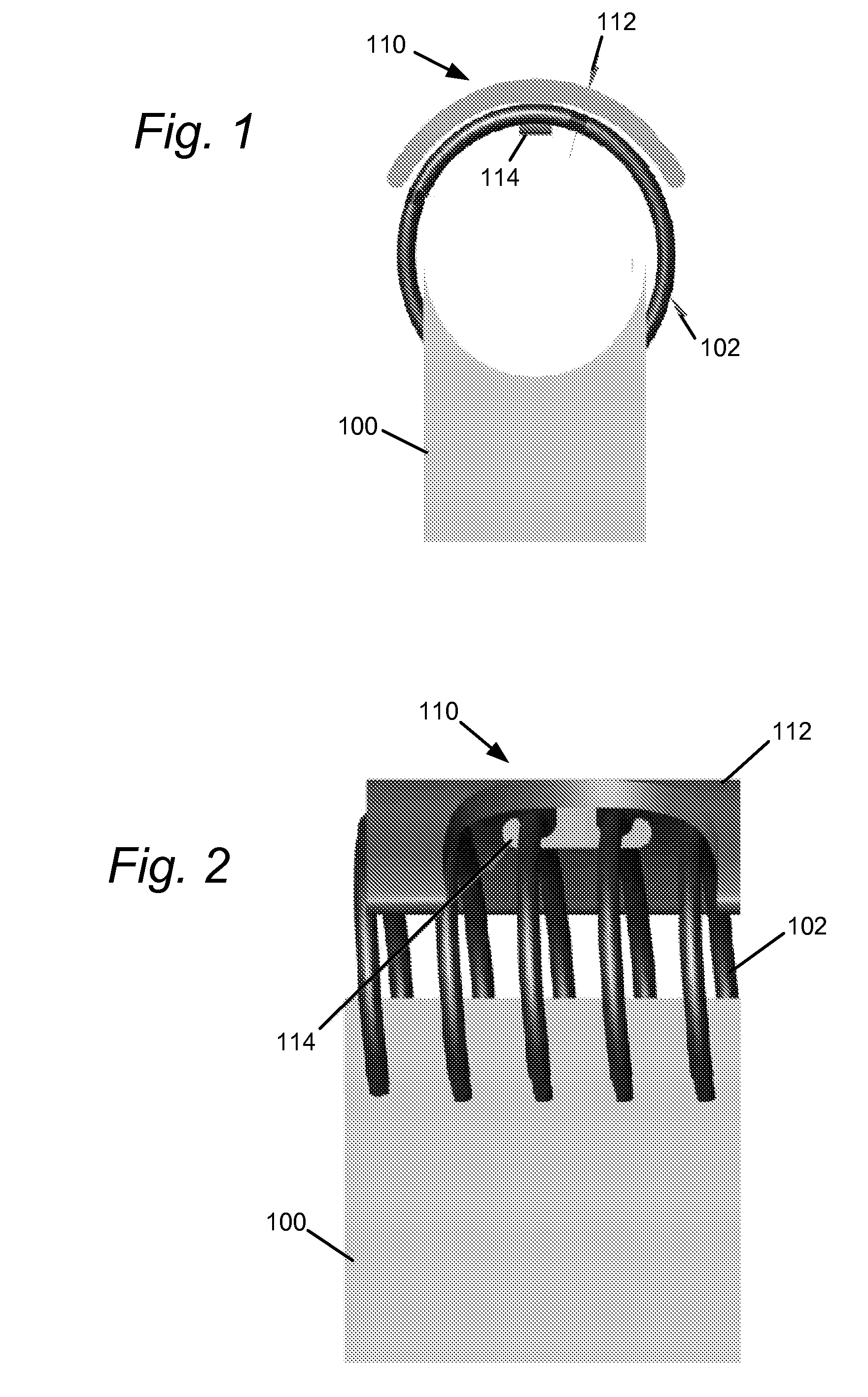

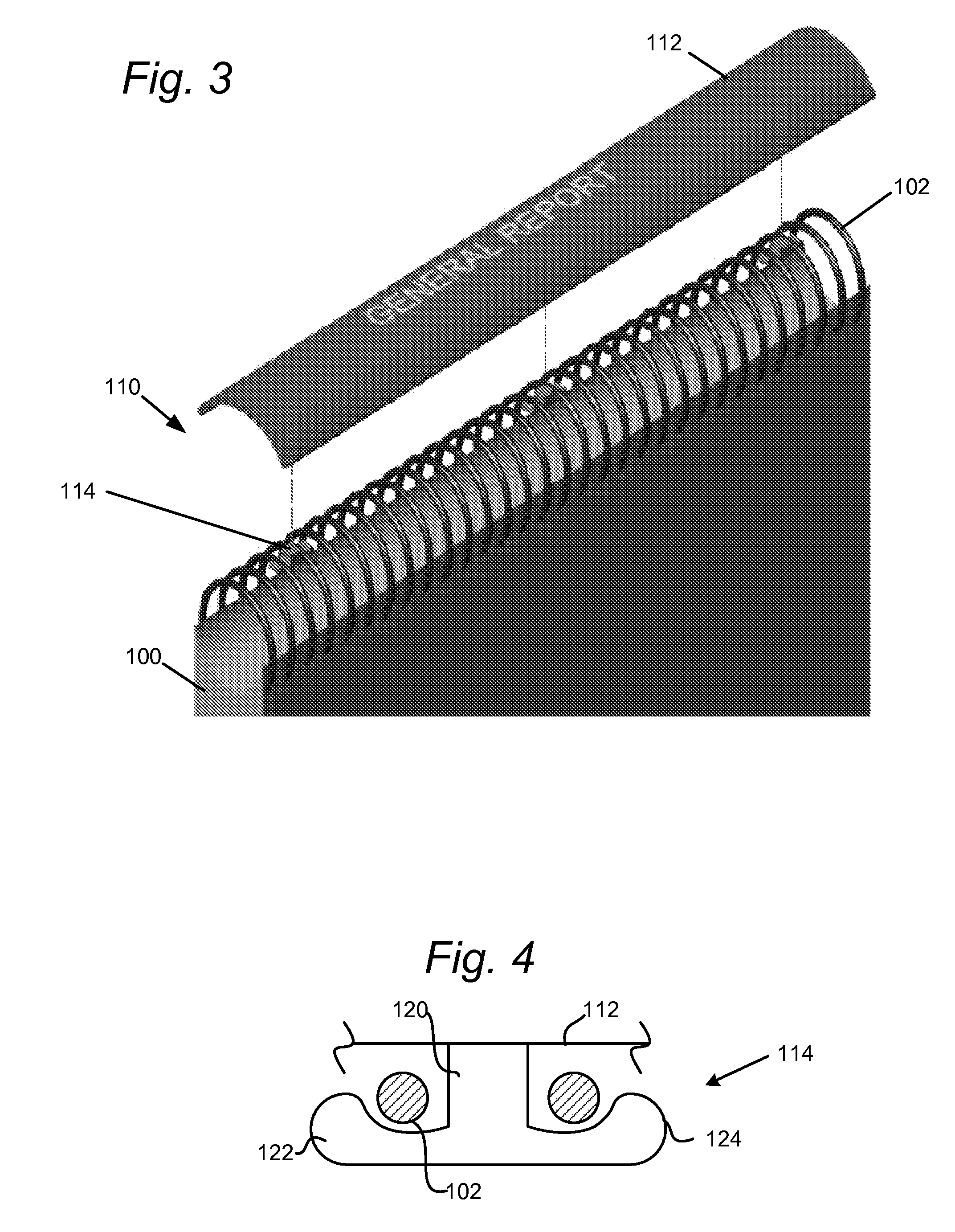

Labeling system for coil binders

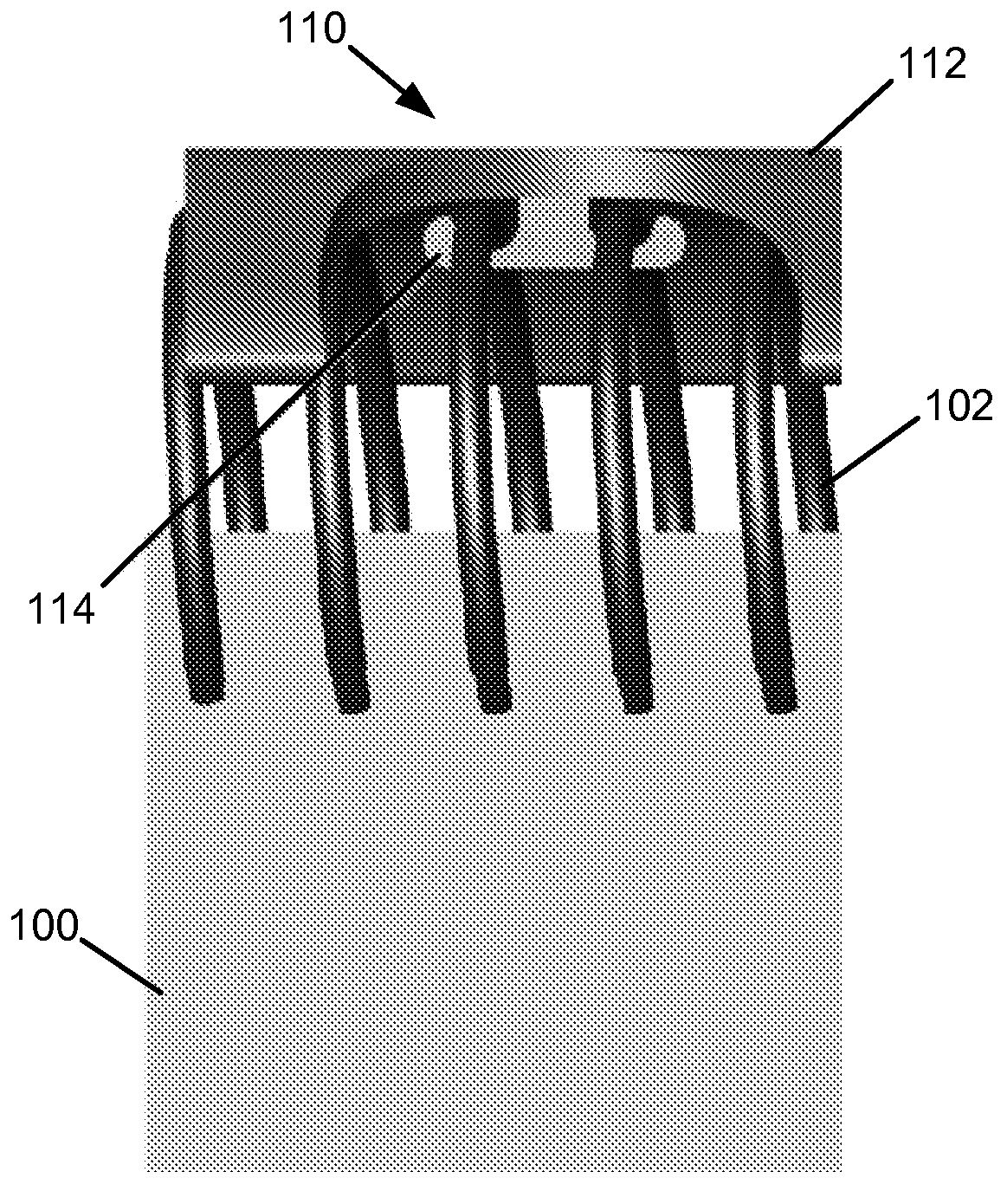

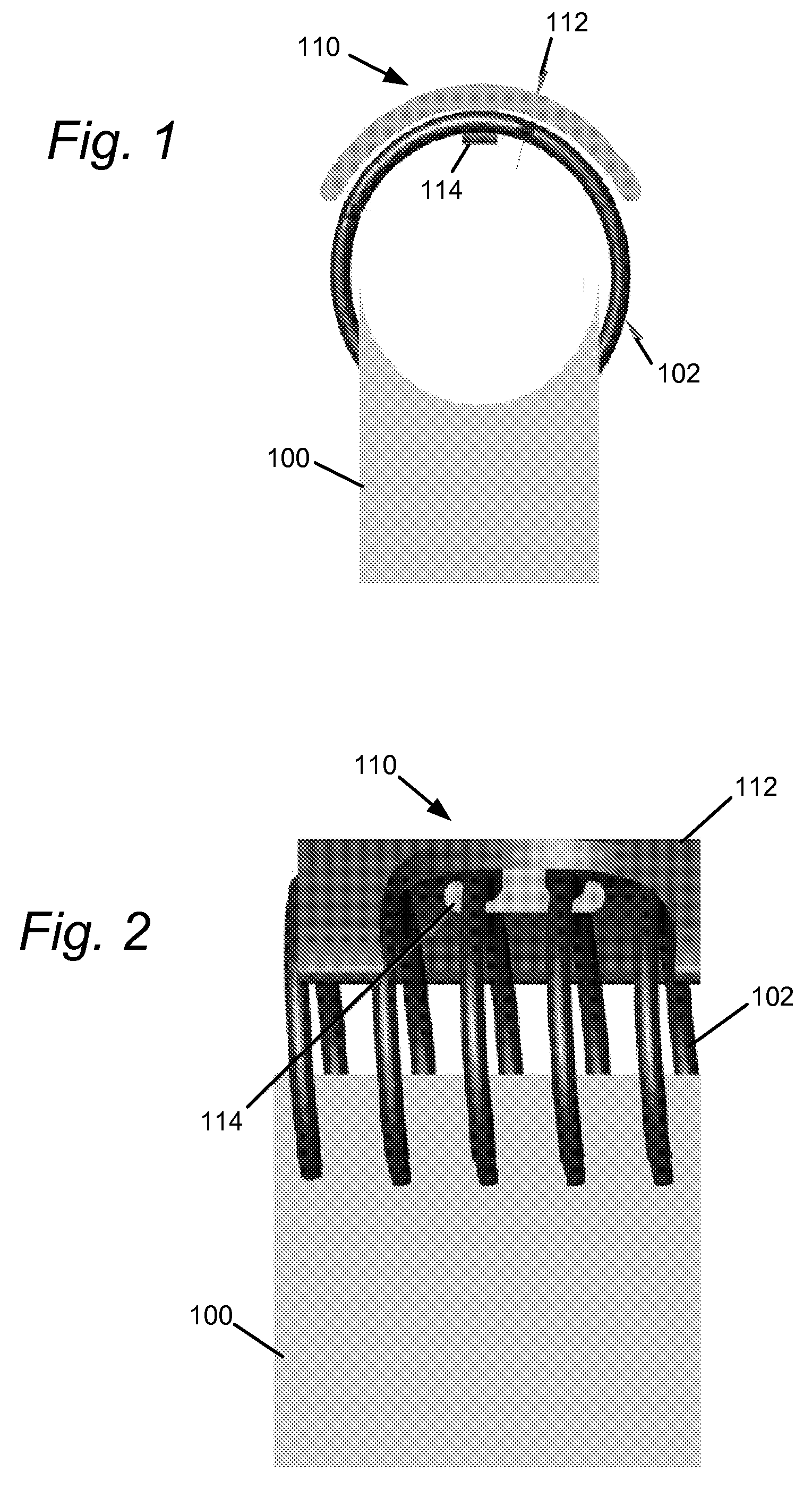

InactiveUS20080141573A1Improve structural rigidityMore rigidStampsFiling appliancesCoil bindSpiral binding

A labeling member is disclosed which attaches to the coil used for the coil binding of documents. The member may be affixed as an aftermarket upgrade to existing coil binding products. In embodiments, the member serves at least two functions. First, the member presents a face along the edge of a coil which may be marked or labeled to allow identification of the coil bound document when shelved or stacked. Second, the member adds structural rigidity to the bound document when placed vertically on a shelf by making the coil more rigid.

Owner:GNESA ARIC M

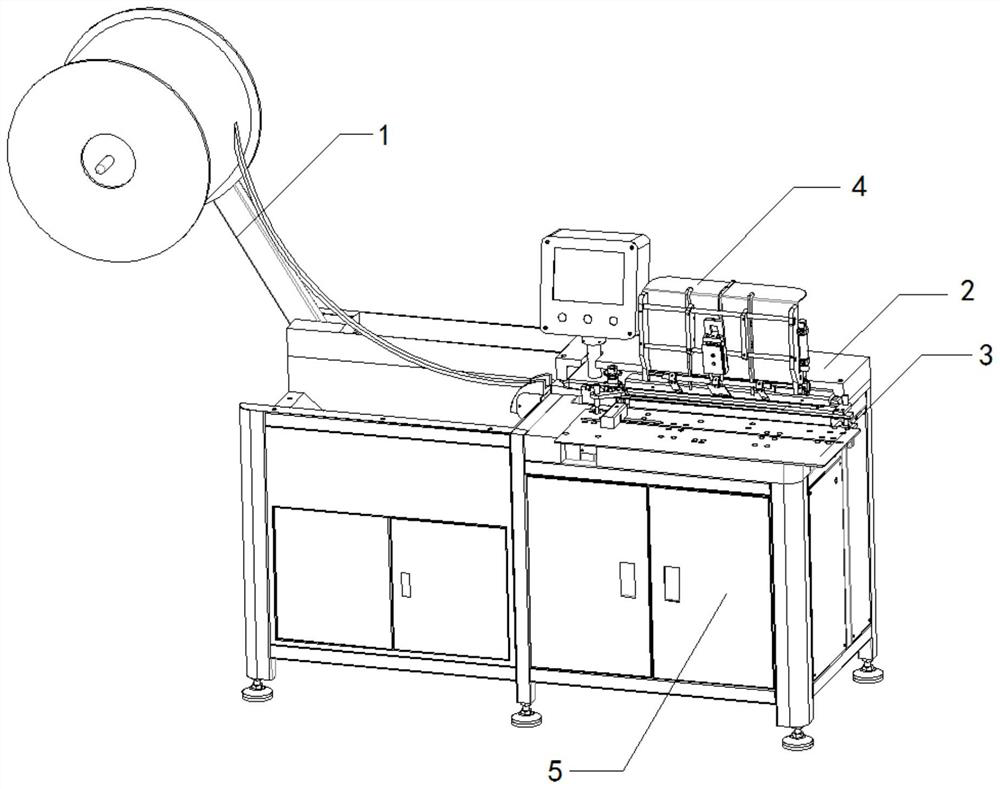

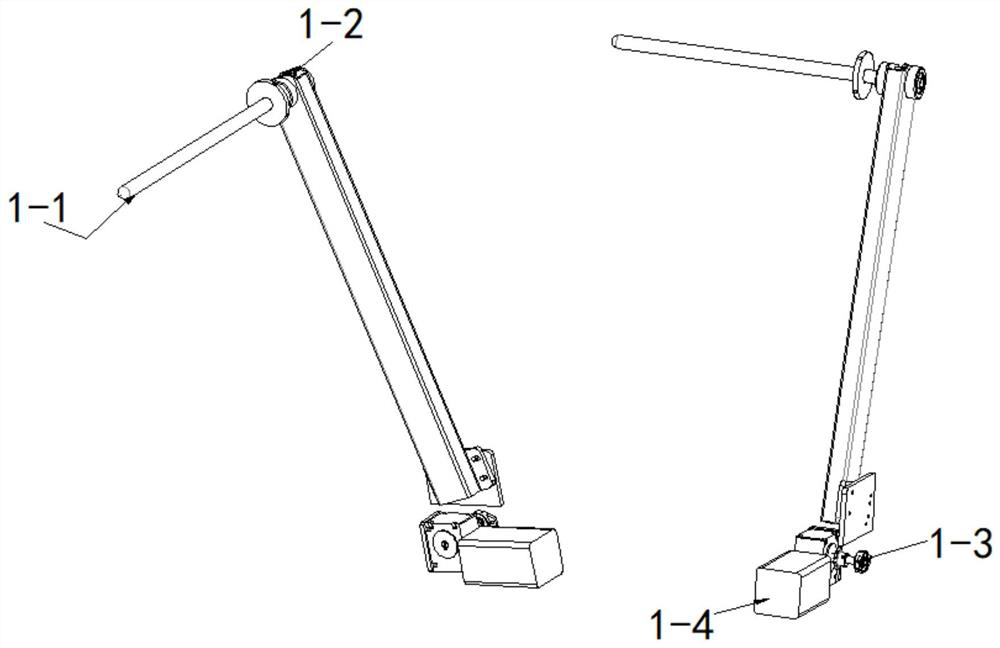

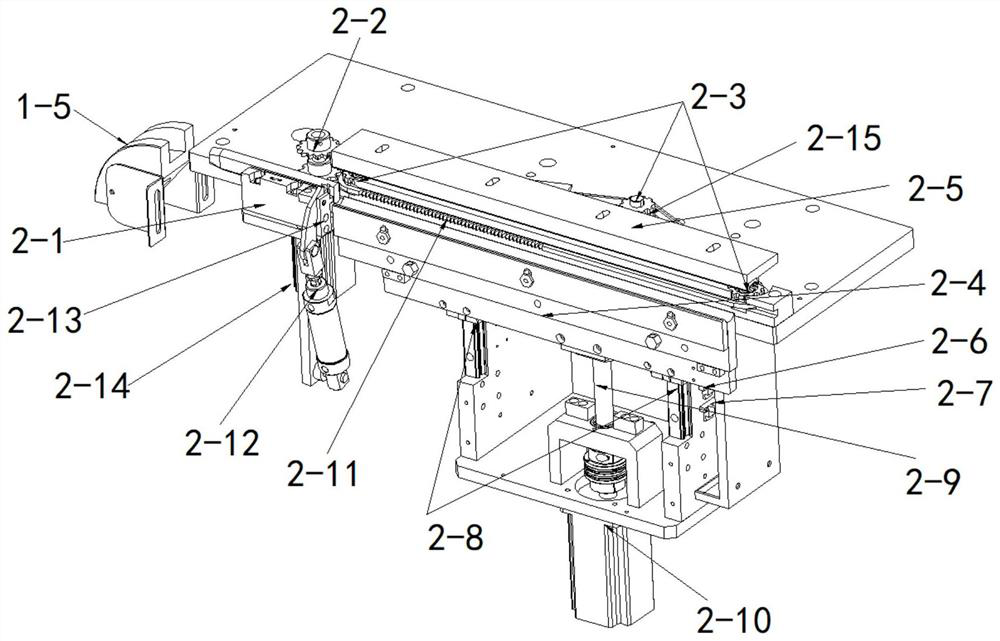

JC-520 double-coil binding machine

The invention relates to the technical field of binding machines, and discloses a JC-520 double-coil binding machine. The JC-520 double-coil binding machine comprises a cabinet body. The left upper corner of the top end of the cabinet body is movably connected with a double-coil placement frame mechanism. A feeding and coil binding mechanism is movably connected with the right side of the double-coil placement frame mechanism. A book placement platform is fixedly installed at the top end of the cabinet body. A hook feeding mechanism is fixedly installed at the top end of the feeding and coil binding mechanism. According to the JC-520 double-coil binding machine, a motor is controlled to feed materials by a double-coil detection proximity switch, an output shaft of the motor can rotate anddrive a driving chain wheel to rotate, the driving chain wheel can rotate to drive a driven chain wheel to rotate, the driven chain wheel can rotate to drive a double-coil placement optical shaft to rotate clockwise, then double coils are taken down from the interior of a packaging box and installed on the double-coil placement optical shaft, and therefore the double coils are inputted from a detection point and arrive at a wire die, and the effects of convenient conveying, labor saving, automatic press fit and automatic adjustment are achieved.

Owner:张杰

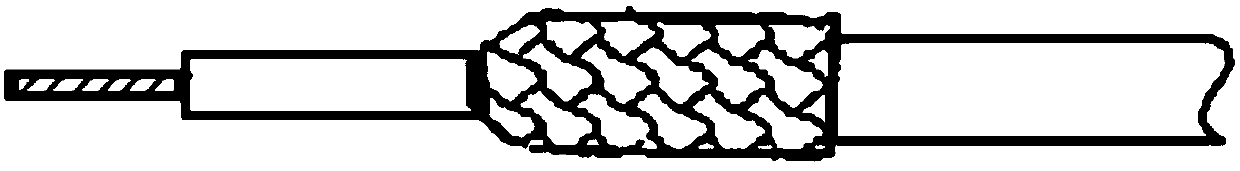

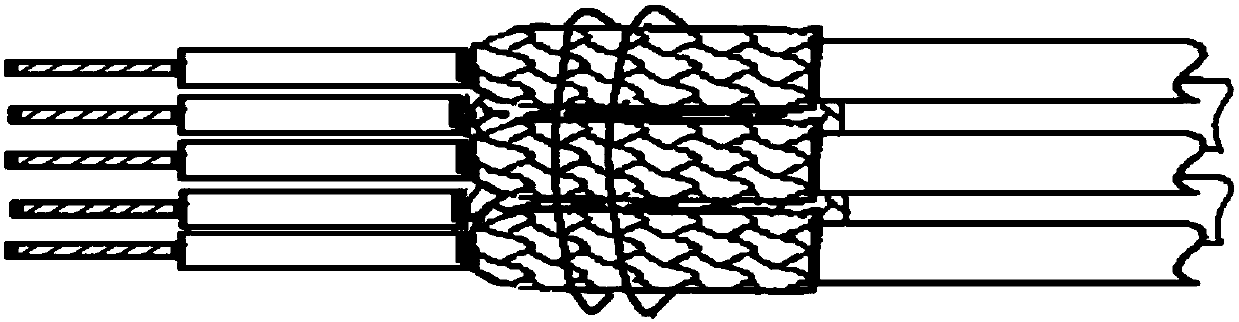

Processing method of shielding layer of shielding wire

InactiveCN107634440AReduce mutual frictionReduce solder jointsLine/current collector detailsCoil bindInsulation layer

The invention relates to a processing method of a shielding layer of a shielding wire. The method comprises steps that step 1, an outer insulation layer at one end of each single core shielding wire is stripped, and the shielding layer is overturned to the outer insulation layer; step 2, all the single core shielding wires are gathered together to be a wire harness, all the overturned shielding layers of all the shielding wires are gathered together, and a binding coil is utilized to wind the overturned shielding layers; step 3, the coil binding portion of the overturned shielding layers is coated with tin, and the coil binding portion is welded with a ground lead; and step 4, a thermal shrinkage casing is sleeved at the overturned shielding layers, and the whole overturned shielding layers are covered by the thermal shrinkage casing. The method is advantaged in that assembling difficulties including an acute angle in a cable bending type rear accessory and small assembling space are solved, a cable harness and a cable clamp manufactured through the method have relatively large gaps, extrusion and wear are reduced, and product reliability is improved.

Owner:SHAANXI QIANSHAN AVIONICS

Dry-type transformer

InactiveCN104575978AReduce distanceLow costTransformers/inductances coils/windings/connectionsCoil bindSpiral binding

The invention provides a dry-type transformer which comprises a cabinet body, a transformer body and a base, wherein the transformer body is arranged on the base in the cabinet body; the transformer body is provided with a high-voltage incoming end and a coil binding post; a connecting line between the end part of the high-voltage incoming end and the end part of the binding post is vertical. The dry-type transformer has the advantages of long service life, material-saving property and the like.

Owner:WUHU JINNIU ELECTRIC

Book Coil Binding Machine

InactiveUS20140093333A1Improve efficiencyIncrease productionSheet bindingBookbinding pressesCoil bindSpiral binding

A book coil binding machine includes a housing, a coil guiding block, a conveying device, a clamping device, a supporting apparatus and a cutting apparatus. The coil guiding block is removably disposed on the housing. The conveying device drives a coil moving forwards along the coil guiding block. The clamping device clamps the book in the book clamping space for the coil being guided into the holes of the book when the clamping device is at the clamping position. The clamping device releases the book when the clamping device is at the releasing position. The supporting apparatus is provided for the book in the book clamping space being abutted thereto when the supporting apparatus is at a supporting position, whereas the supporting apparatus is departed from the book when the supporting apparatus is at a loosening position. The cutting apparatus cuts off the two ends of the coil which are extended out of the book when the cutting apparatus is at a cutting position.

Owner:CHUNG SHEEN TECH

Labeling system for coil binders

InactiveUS7406790B2Improve structural rigidityMore rigidStampsFiling appliancesCoil bindSpiral binding

A labeling member is disclosed which attaches to the coil used for the coil binding of documents. The member may be affixed as an aftermarket upgrade to existing coil binding products. In embodiments, the member serves at least two functions. First, the member presents a face along the edge of a coil which may be marked or labeled to allow identification of the coil bound document when shelved or stacked. Second, the member adds structural rigidity to the bound document when placed vertically on a shelf by making the coil more rigid.

Owner:GNESA ARIC M

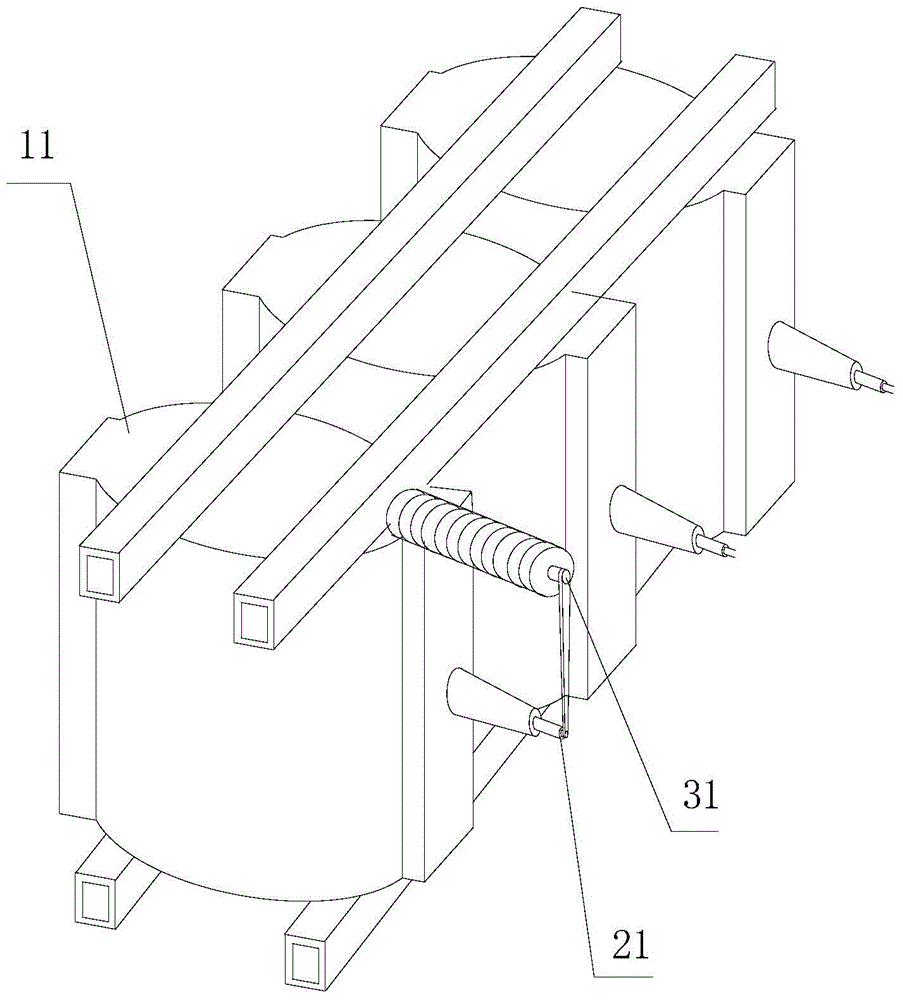

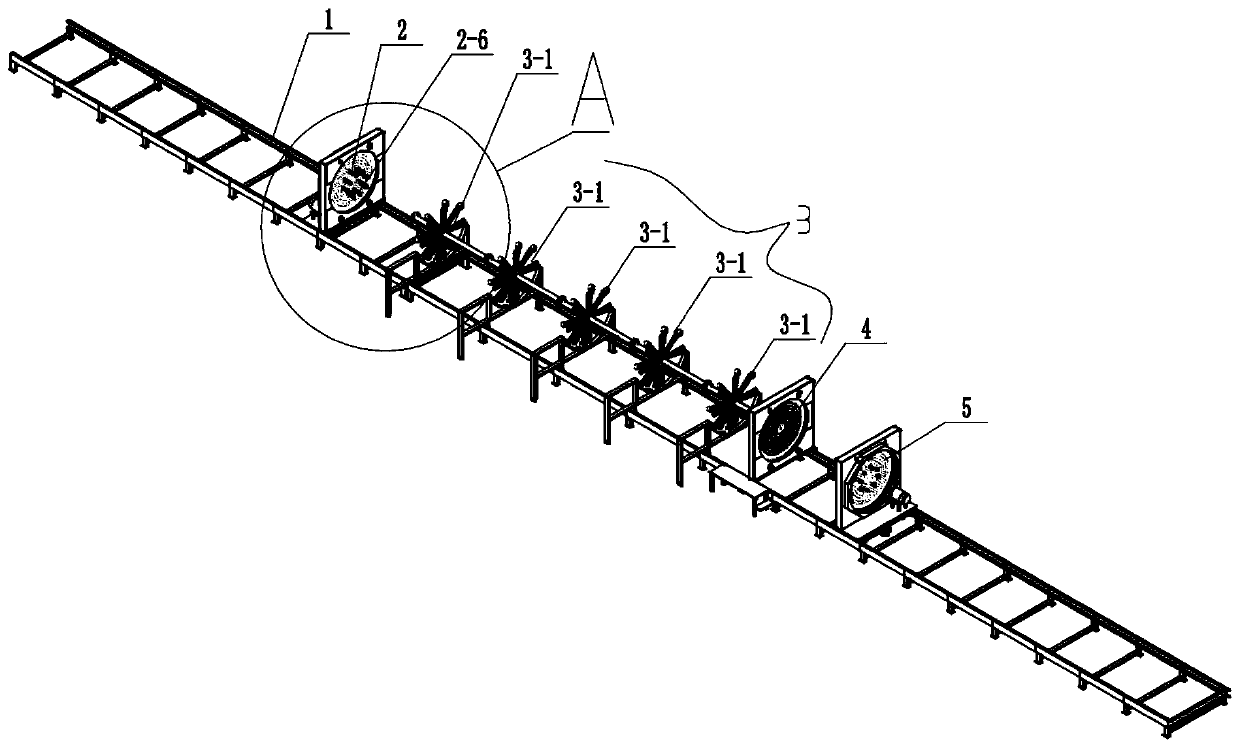

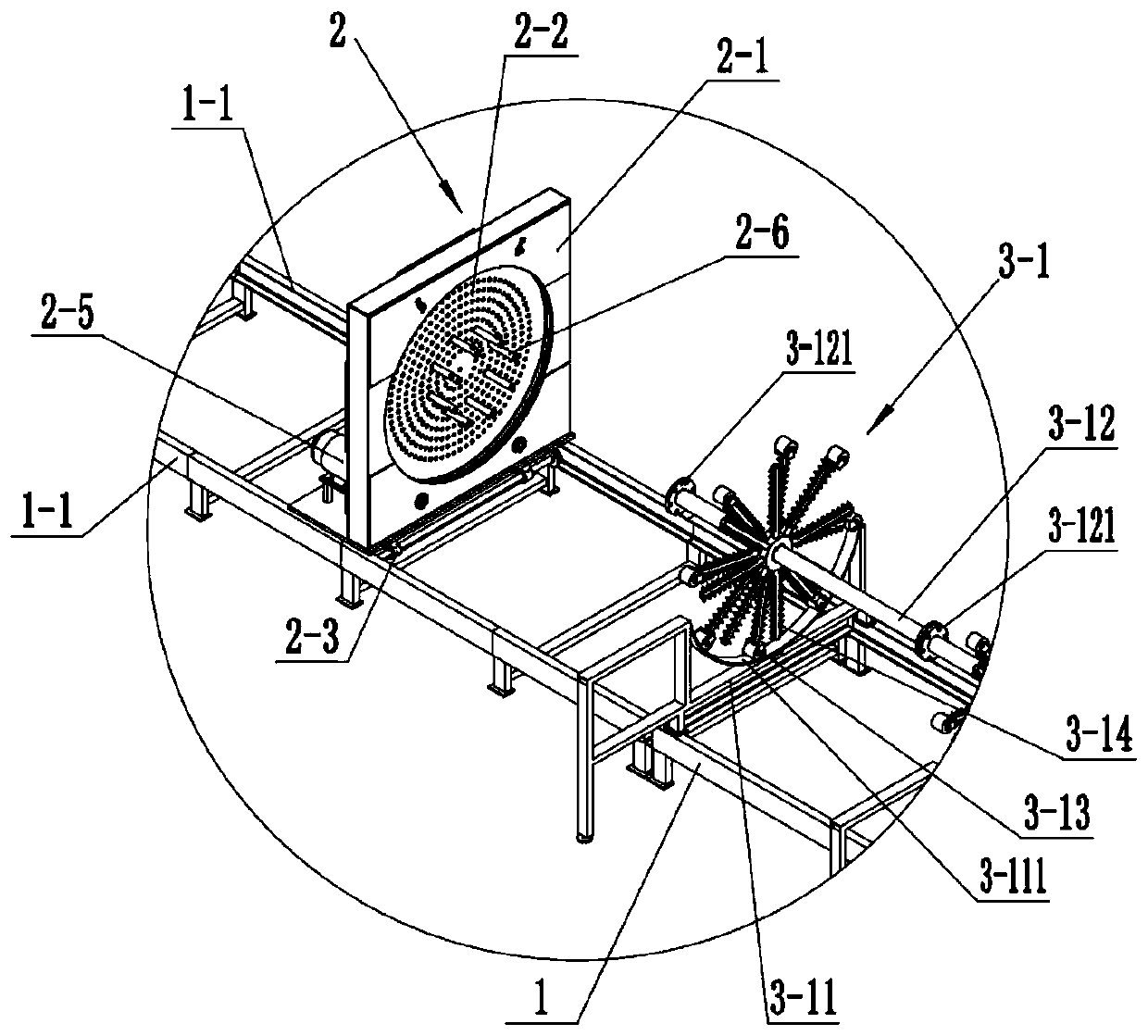

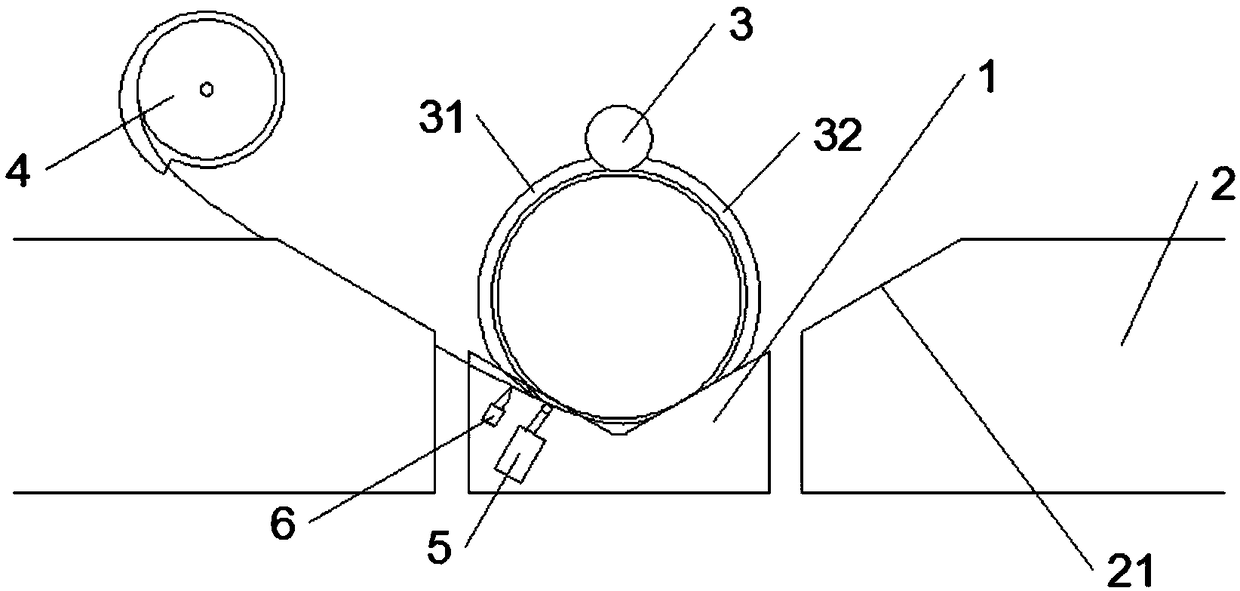

Welding positioning machine for reinforcement cage

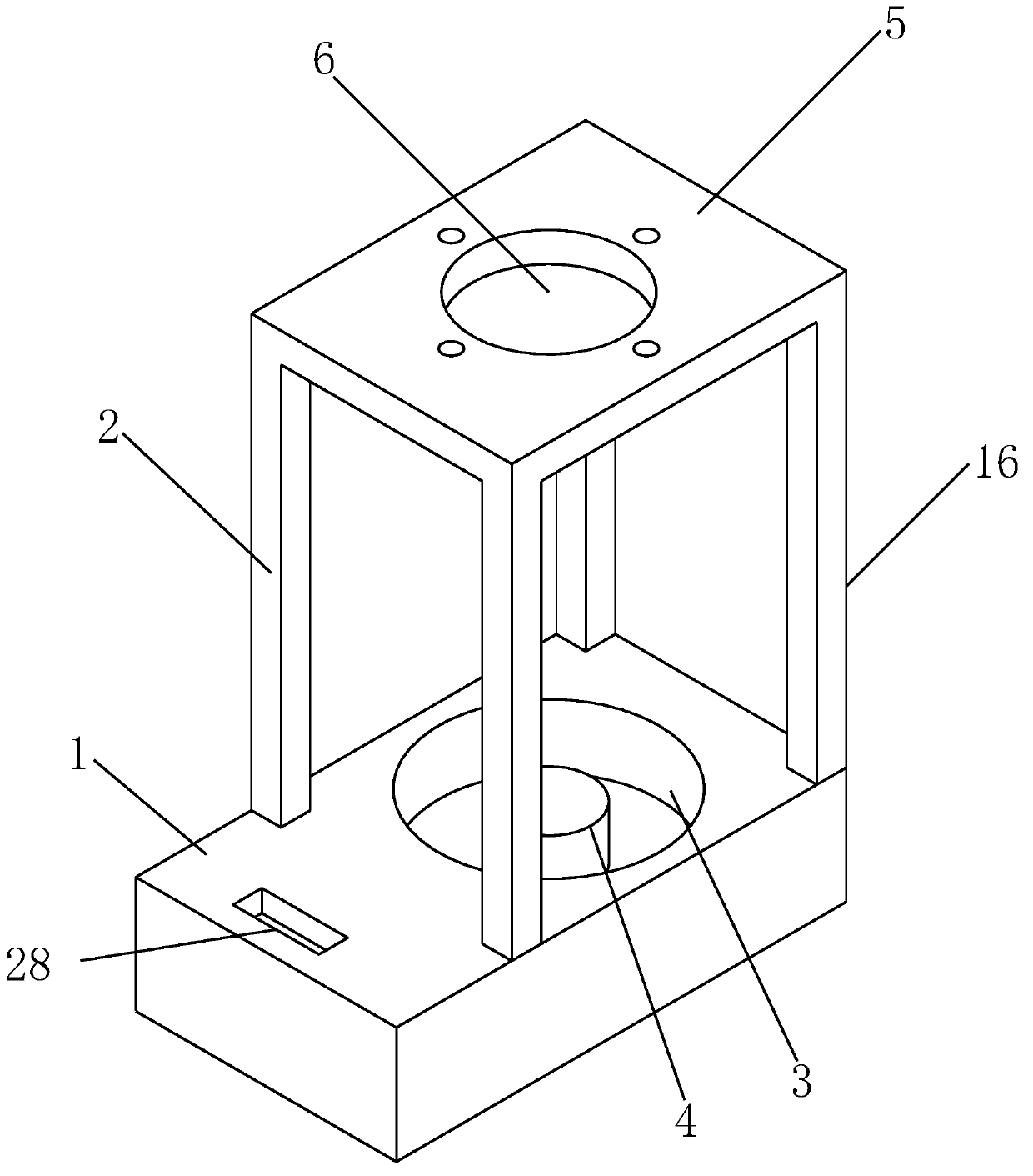

InactiveCN109773397AImprove Winding BindingImprove welding efficiencyMeshed-ring wire networkWelding/cutting auxillary devicesCoil bindStirrup

The invention discloses a welding positioning machine for a reinforcement cage. The machine is characterized by comprising a horizontal rail (1), a main rib tail end pulling rotating device (2), a main rib rotating supporting device (3), a main rib rotating positioning device (4) and a main rib head end pulling rotating device (5), wherein the main rib tail end pulling rotating device (2), the main rib rotating supporting device (3), the main rib rotating positioning device (4) and the main rib head end pulling rotating device (5) are sequentially distributed in the direction of the horizontalrail (1). With the adoption of the machine, each main rib welding section can be rotated and positioned and axially pulled and automatically horizontally fed during coiling and binding stirrups and / or welding of the reinforcement cage, and both time and force can be saved; the stirrup coiling binding and welding efficiency can be greatly improved; and the machine is particularly applicable to coiling binding and welding of stirrups of large-diameter and / or super-long reinforcement cages.

Owner:CHONGQING TECH & BUSINESS INST

Multi-coil binding machine for hot-rolled narrow strip steel

PendingCN112357178AAvoid loose rollsSmooth liftPaper article packagingBinding material applicationHydraulic cylinderCoil bind

The invention provides a multi-coil binding machine for hot-rolled narrow strip steel. The multi-coil binding machine comprises a platform and a transverse track arranged on the platform, wherein an uncoiler is arranged on the right side of the platform; a coil conveying trolley on which steel coil carrier rollers are arranged is arranged on a longitudinal track configured with the platform; a coil penetrating trolley positioned on the left side and a trolley positioned on the right side are arranged on the transverse track; the coil penetrating trolley is provided with a coil penetrating trolley driving mechanism; the trolley is provided with a trolley positioning hydraulic cylinder; a binding belt bending mechanism, a binding belt head clamping and pulling mechanism and a follow-up chassis are arranged on the trolley; and a two-roller clamping and conveying mechanism, a clamping roller straightening mechanism, a binding belt shearing and bending mechanism, an electromechanical limiting switch and a welding machine are arranged on the follow-up chassis. The multi-coil binding machine can replace manual binding, and the automation degree of binding, the safety and reliability of work, the binding quality and the binding speed are greatly improved.

Owner:张少壮

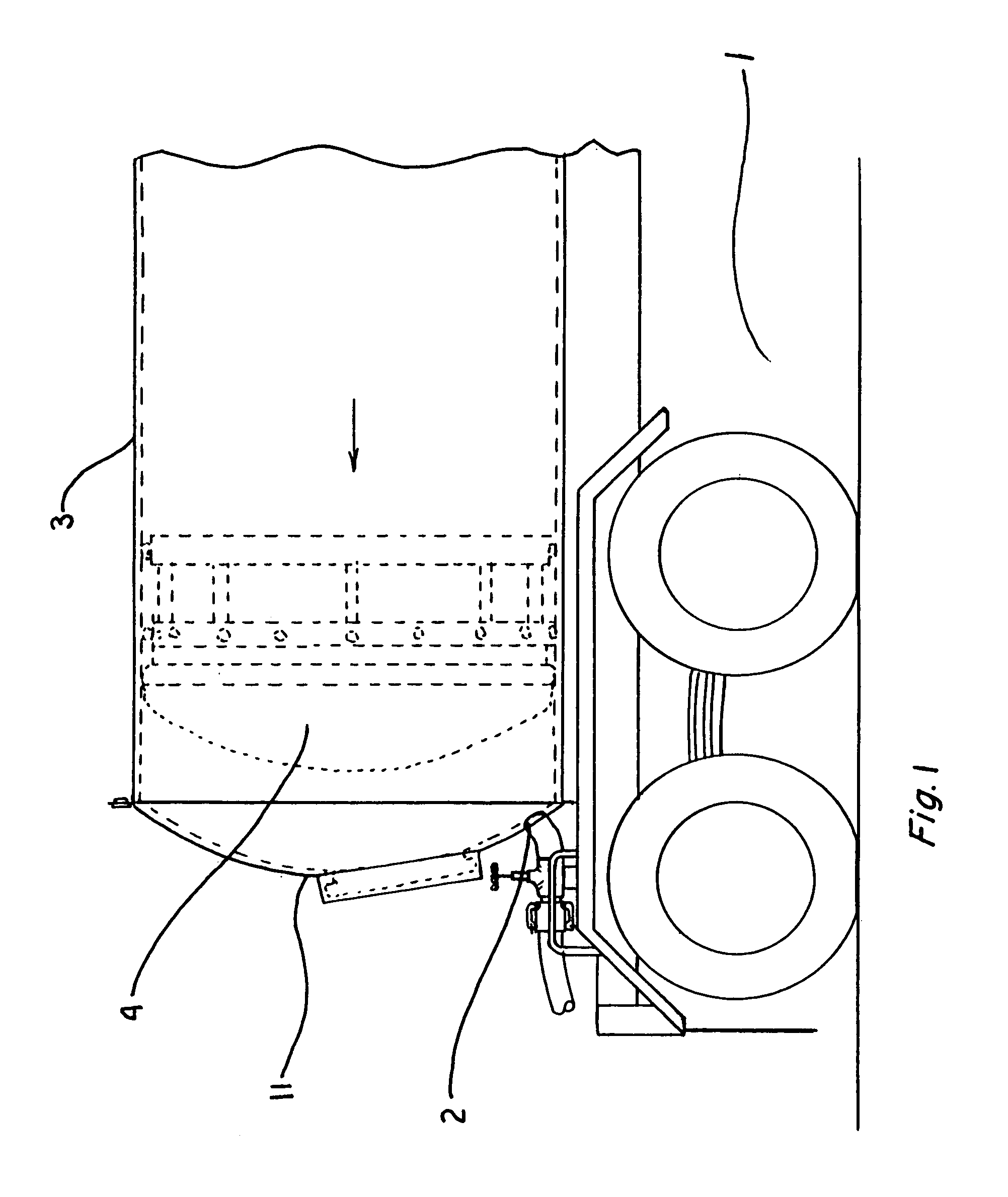

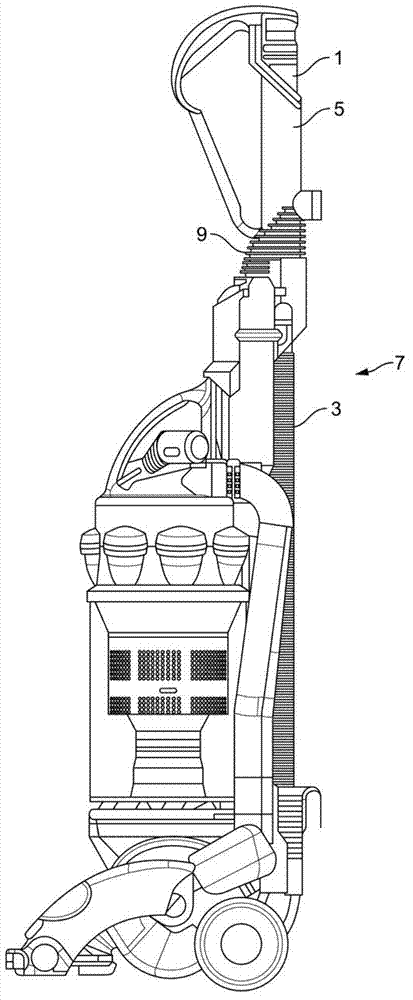

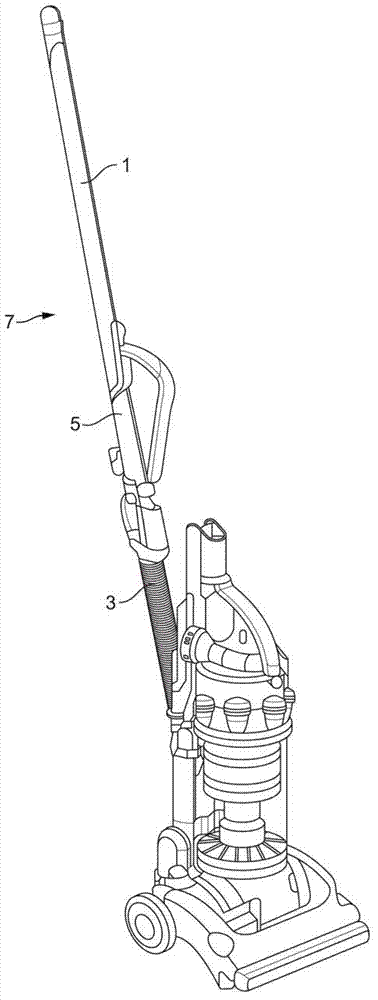

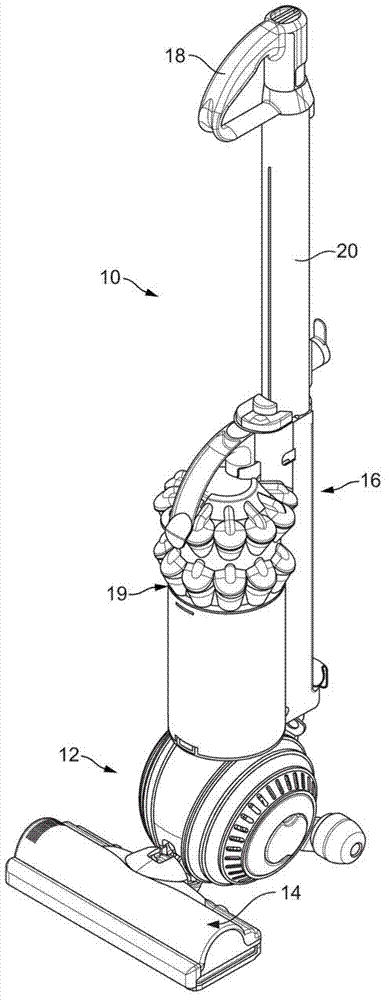

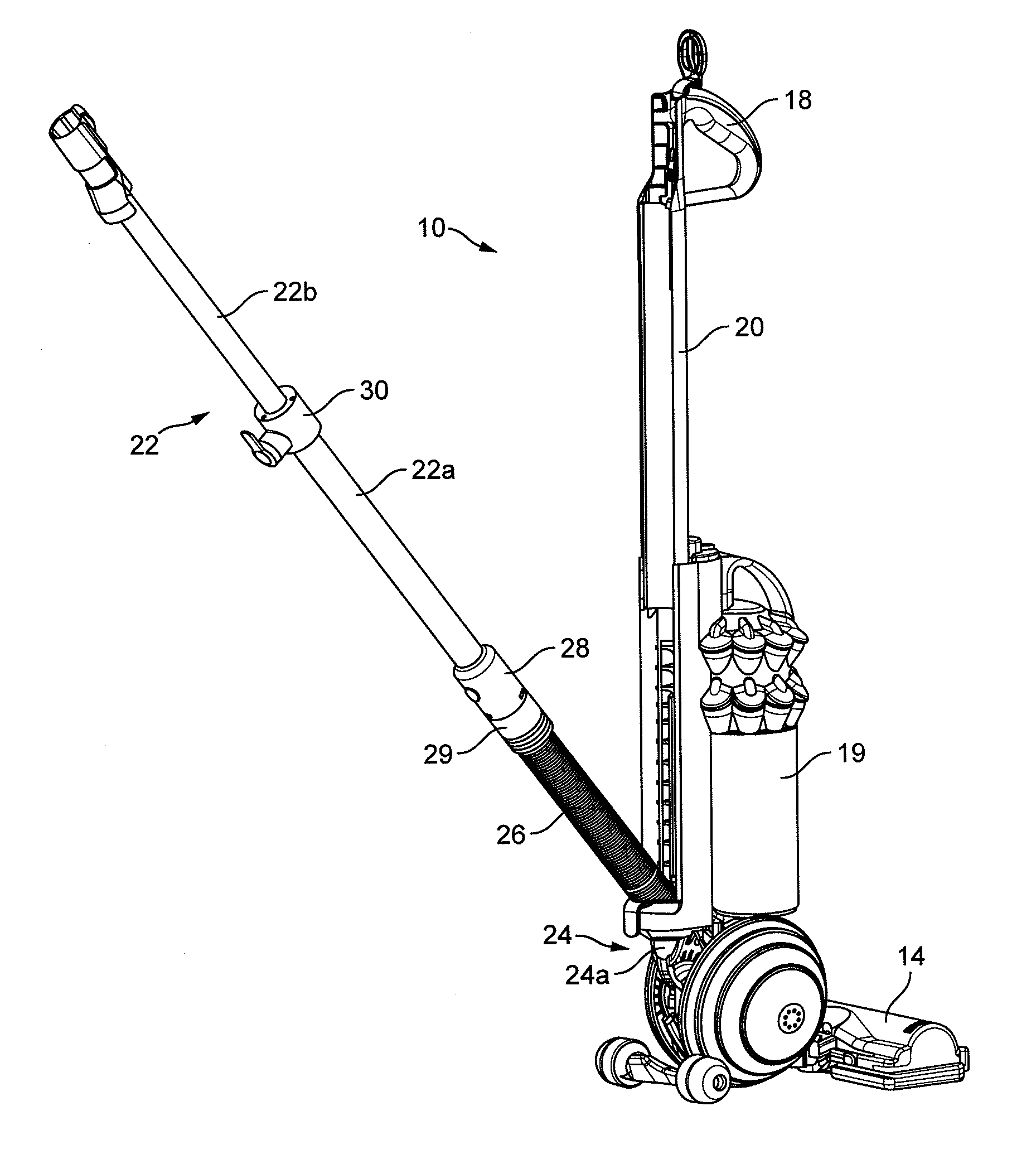

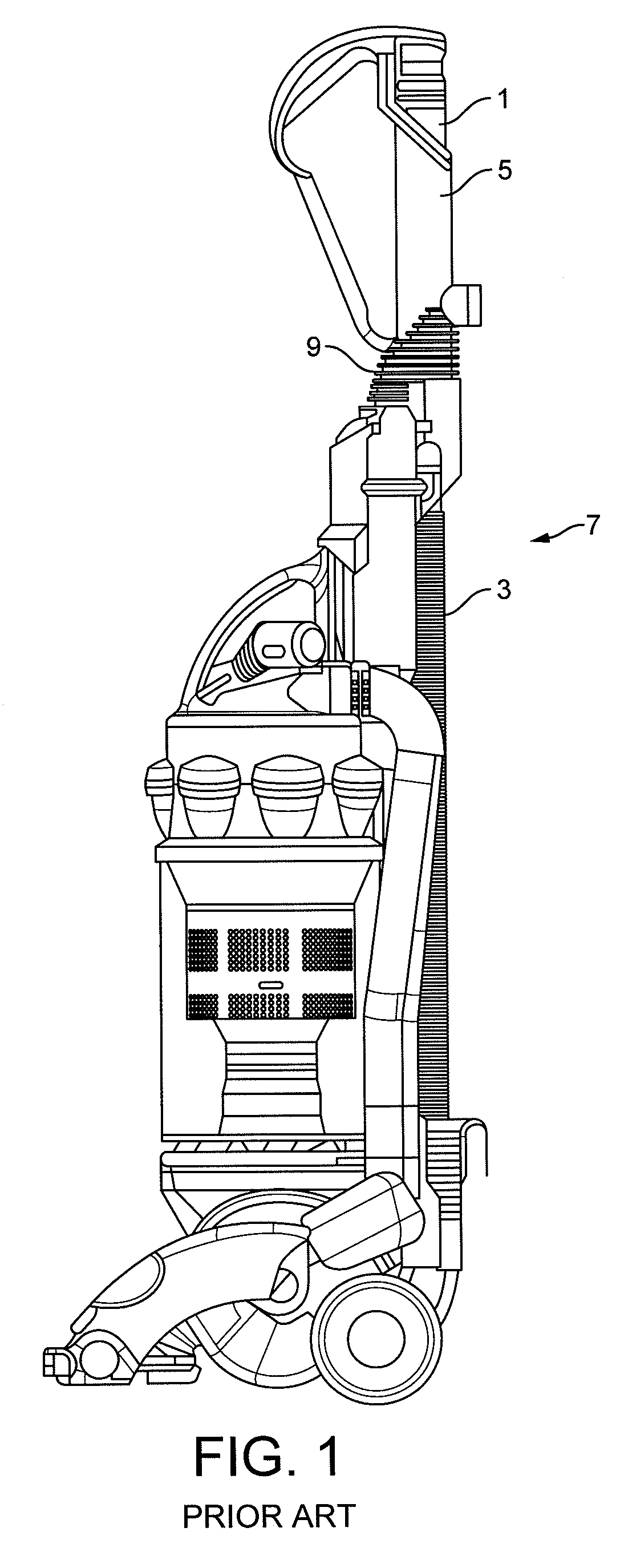

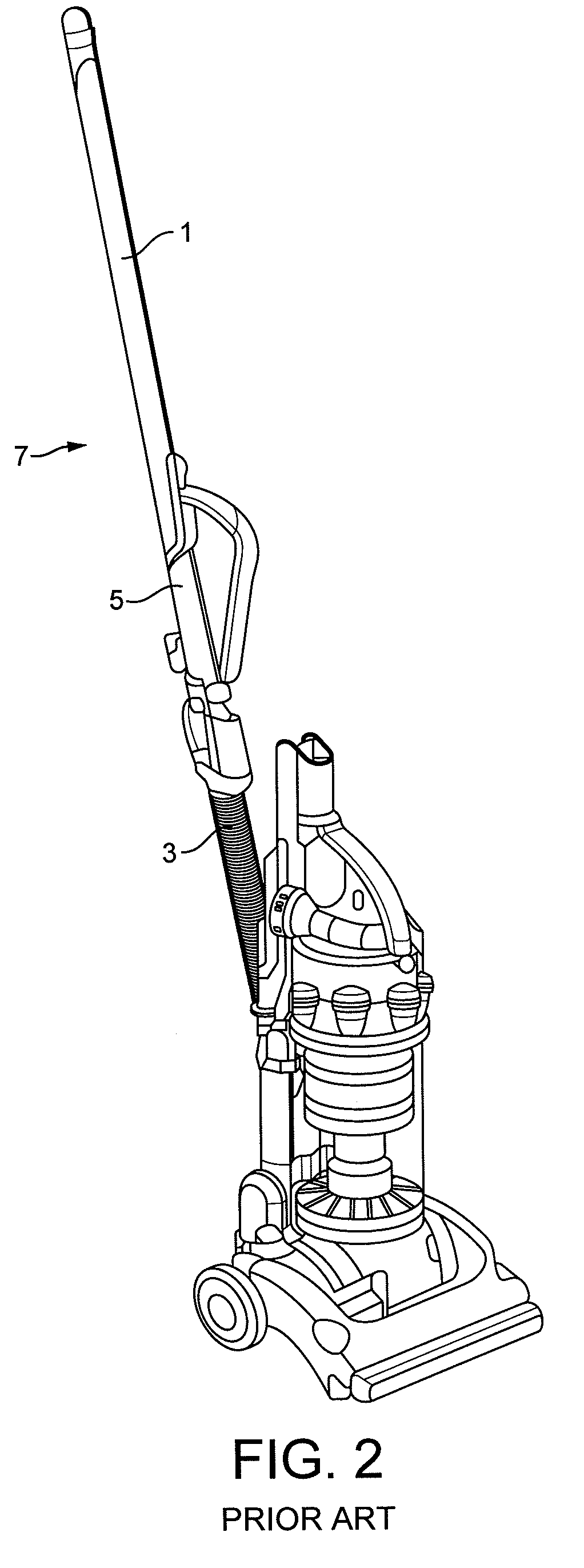

Upright vacuum cleaner

An upright vacuum cleaner comprising a wand 22a fluidly connected to a separating apparatus on the cleaner via a hose 26 and which is used, as required, to clean above the level of the floor. The wand 22a is at least partly retractable inside the hose 26 for storage, and a hose catch 28 is provided at the end of the hose 26, this hose catch 28 being biased towards a locking position in which the hose catch 28 locks the wand 22a in an extended position. The hose 26 is a stretch hose arranged, in its coil-bound state, to act as a reaction member against which a user may readily force the biased hose catch 28 out of said locking position using the extended wand 22a. A manual release button is also provided.

Owner:DYSON TECH LTD

Upright vacuum cleaner

An upright vacuum cleaner comprising a wand fluidly connected to a separating apparatus on the cleaner via a hose and which is used, as required, to clean above the level of the floor. The wand is at least partly retractable inside the hose for storage, and a hose catch is provided at the end of the hose, this hose catch being biased towards a locking position in which the hose catch locks the wand in an extended position. According to the invention, the hose is a stretch hose arranged, in its coil-bound state, to act as a reaction member against which a user may readily force the biased hose catch out of said locking position using the extended wand.

Owner:DYSON TECH LTD

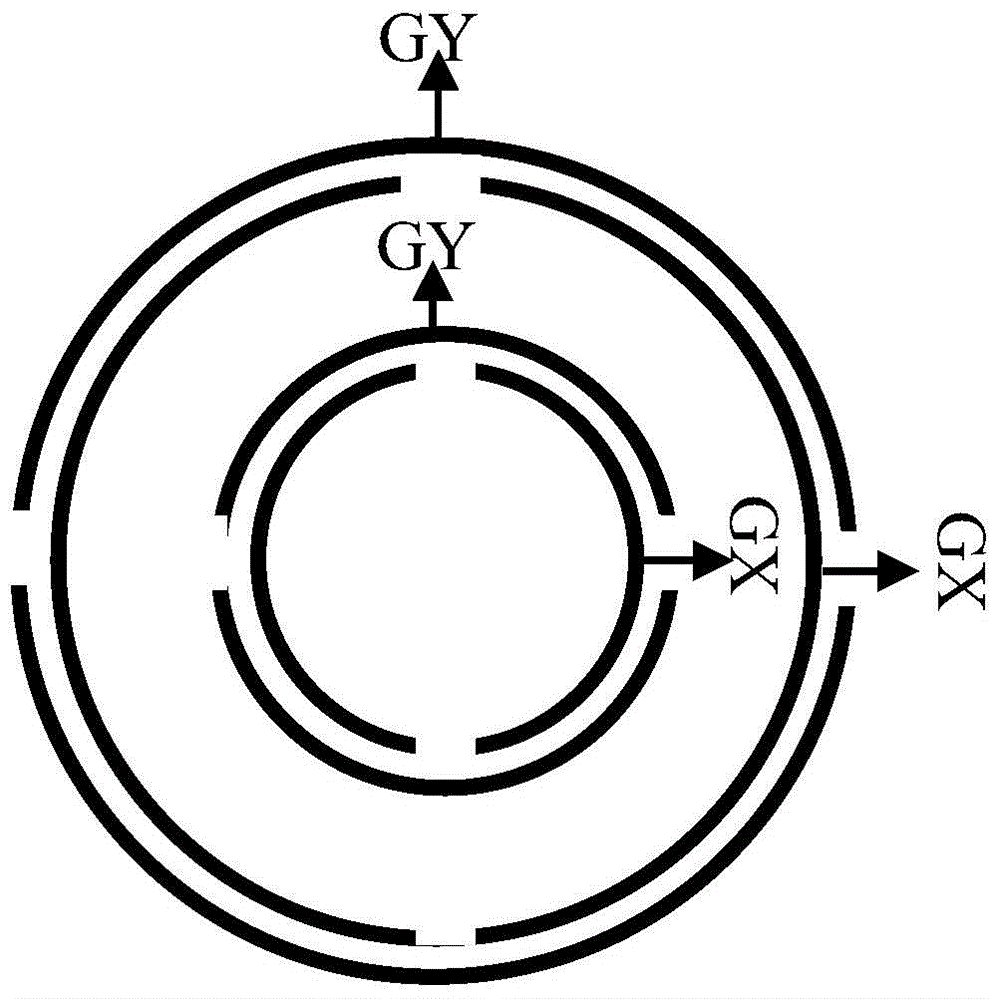

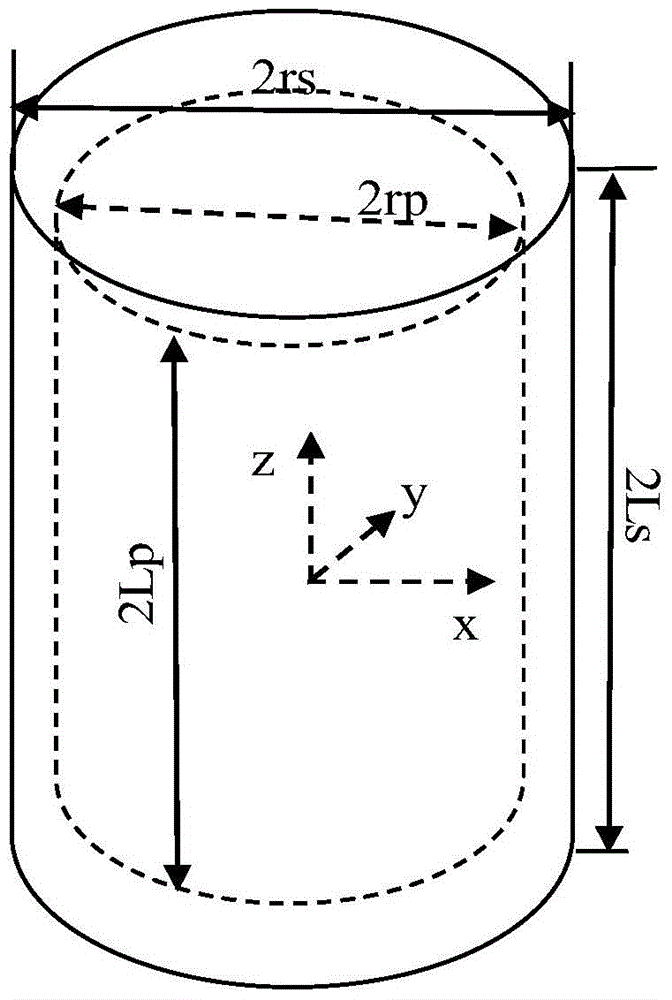

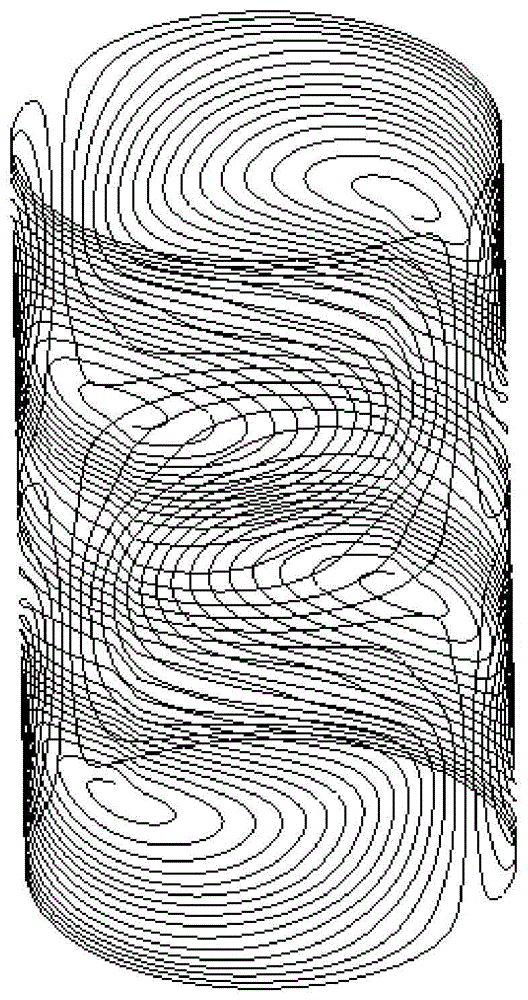

Gradient Coil Design Method Combining Functional Function and Simulated Annealing Algorithm

InactiveCN104007407BRapid designEfficient designMagnetic measurementsSpecial data processing applicationsCoil bindSpiral binding

Owner:HOHAI UNIV

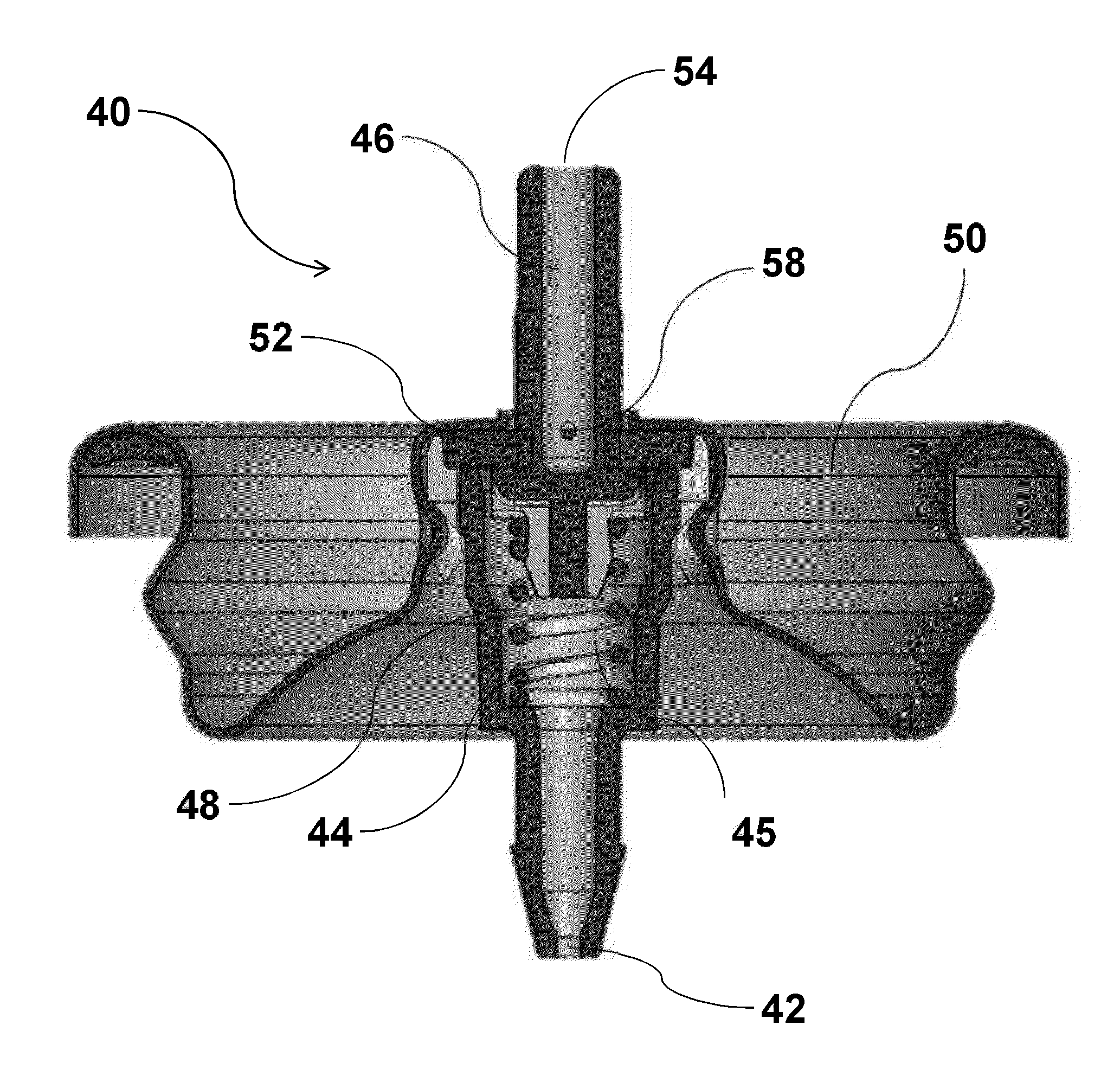

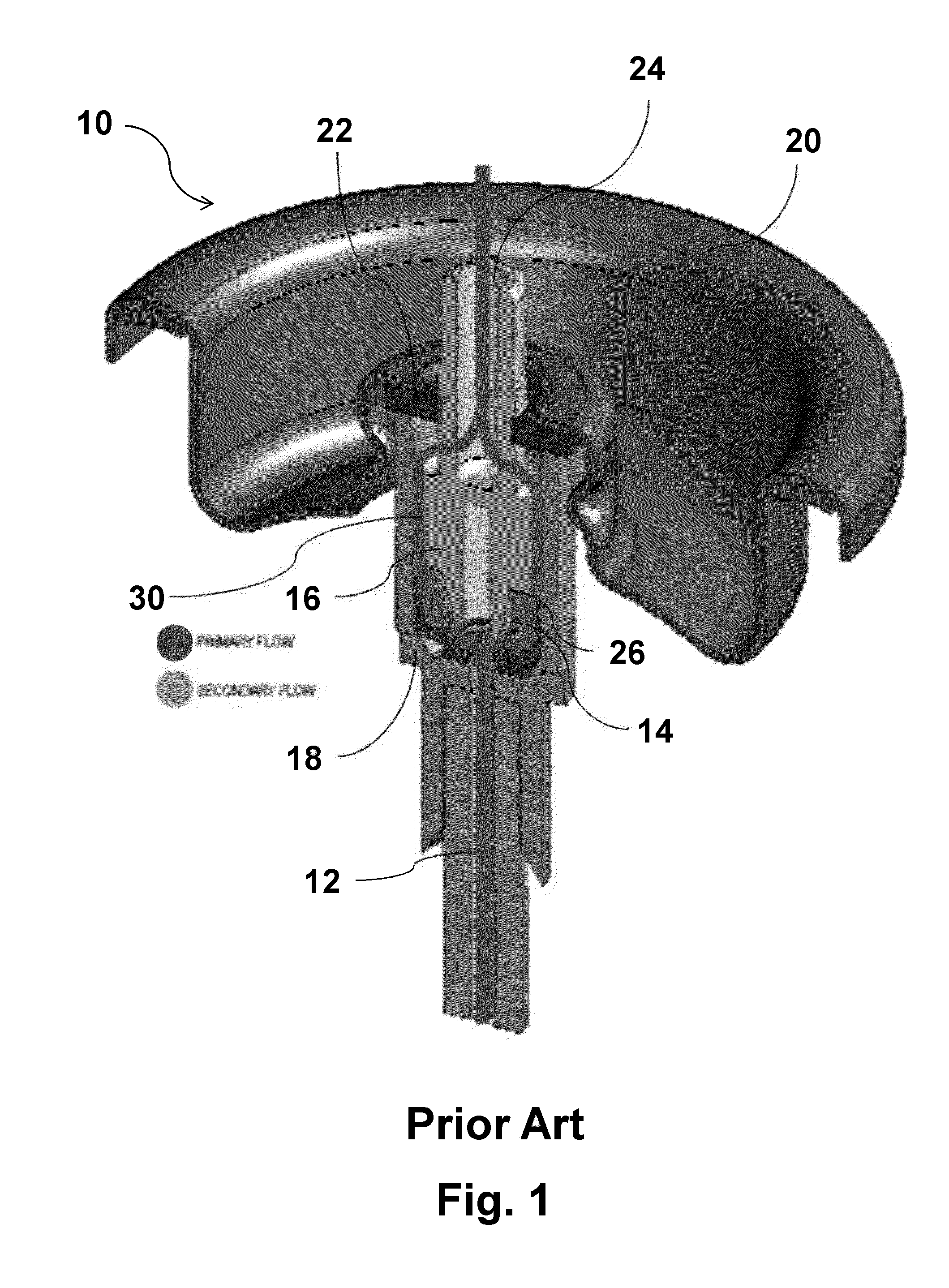

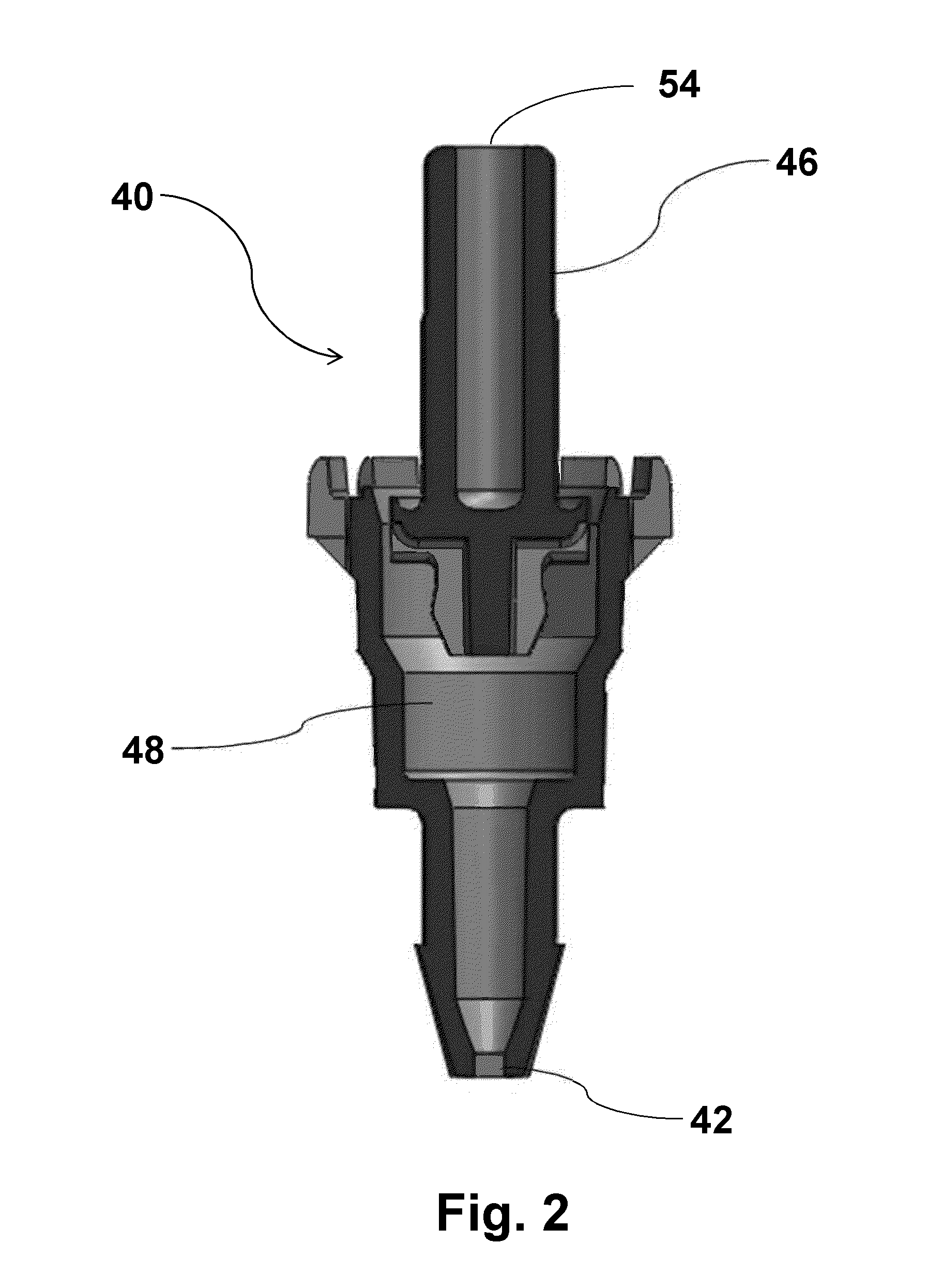

Aerosol valve with defined flow paths

InactiveUS20160009481A1Well mixedReduce reunionOpening closed containersBottle/container closureCoil bindEngineering

An aerosol valve having a valve stem, valve stem housing, compression spring, and a hard stop formed by the interaction of valve stem and valve stem housing is provided. The hard stop prevents the compression spring from becoming fully compressed, or coil-bound, when the valve stem is pressed to dispense a product formulation from the container, thereby creating open spaces between coils of the compression spring and providing a defined flow path for the product formulation. The aerosol valve increases mixing and turbulence of the product formulation that reduce agglomerations of solids that might otherwise block the flow paths. The additional defined flow path also directs more of the product to the valve stem aperture, further increasing dispensing of the product formulation from the container. A method of using the aerosol valve is provided.

Owner:PRECISION VALVE CORP

Transformer abnormal-shape clamp member

InactiveCN105118624AEasy to processEasy to installTransformers/inductances magnetic coresCoil bindSpiral binding

The invention relates to the transformer clamp member field and discloses a transformer abnormal-shape clamp member, which comprises a front plate, a top plate, a back plate and a bottom plate that are molded as a whole and sequentially connected, wherein the front plate and the back plate are respectively and vertically connected at the same side of the top plate; the bottom plate is vertically connected to the back plate and the bottom plate is located at the same side with the top plate; a top face of the top plate is connected to a lifting lug; the front plate is provided with a terminal connecting hole that is used for mounting a high-voltage connecting terminal of a transformer; the back plate is provided with a binding tie hole that is used for connecting a coil binding tie and a counter-pull bolt hole that is used for connected two abnormal-shape clamp members of the transformer; and the bottom plate is provided with a mounting hole that is used for fixing the abnormal-shape clamp members of the transformer. By adopting the transformer abnormal-shape clamp member, an iron core of the transformer is clamped more tightly; and the clamp member has the advantages of convenient processing, simple operation and easy popularization.

Owner:CHONGQING WANGBIAN ELECTRIC GRP CORP

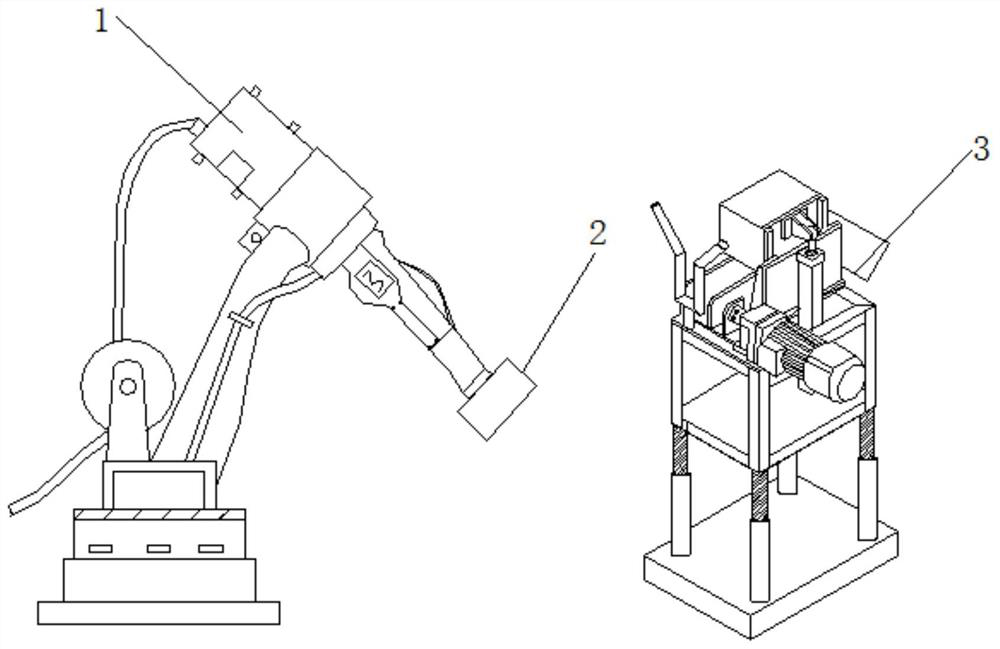

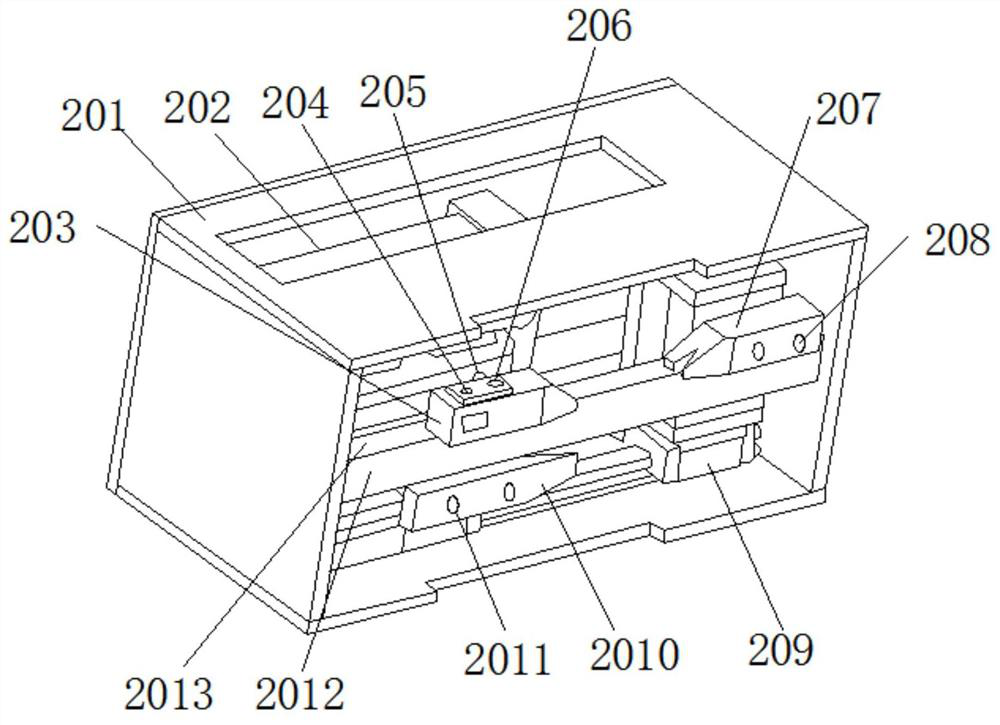

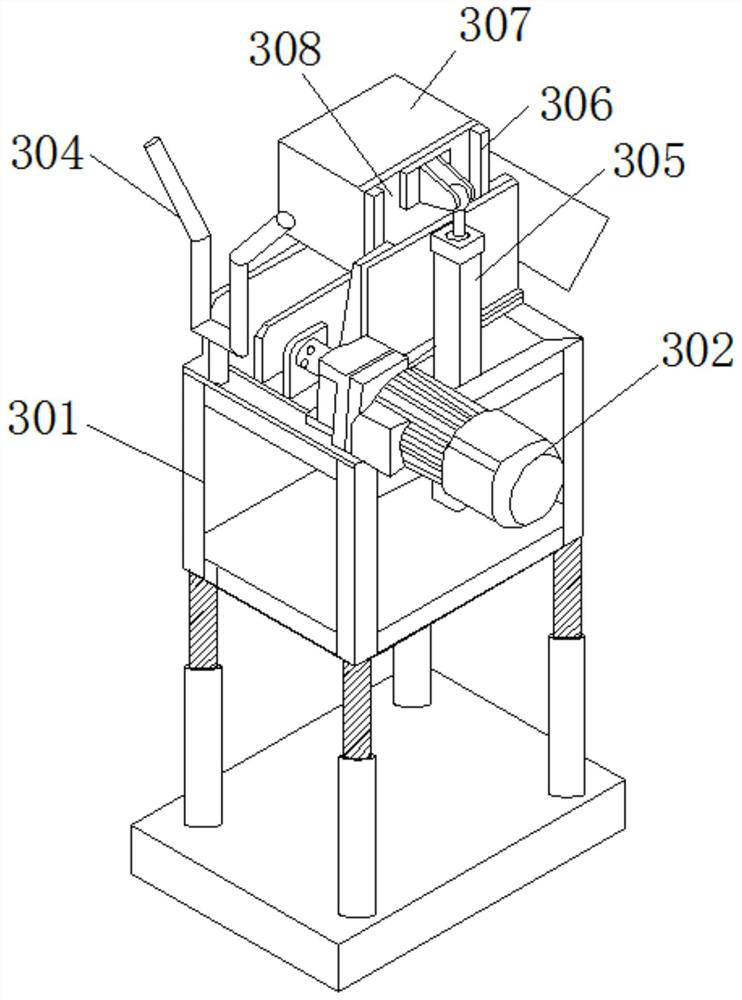

Device and method for dismounting and recovering steel coil binding belt by robot

ActiveCN112340161AEven by forceLess stringent requirementsBinding material removalCoil bindAir spring

The invention relates to a device for dismounting and recovering a steel coil binding belt by a robot. The device for dismounting and recovering the steel coil binding belt by the robot comprises a robot body, wherein a binding belt dismounting end executor is installed at one side of the robot body; a shell body fixedly connected with one end of the robot body is not included in the binding beltdismounting end executor, and a linear guide rail I is fixedly connected to one side of the inner wall of the shell body; and the linear guide rail I is fixedly connected with the an air cylinder I. According to the invention, a binding belt is located at any position between two clamps, strict requirements on locating and motion tracks of the end executor are reduced, meanwhile, when the bindingbelt is shoveled up, two sides of the binding belt are shoveled up at the same time, and the binding belt dismounting end executor is uniformly stressed and does not bear an overlarge torque; and dovetail groove designs at the end parts of the clamps can also accurately locate the position of the shoveled binding belt to adapt to the change of the tightness of the binding belt, the clamp at the side where scissors are located, adopts an air spring, the action of clamping the binding belt at first, and then shearing the binding belt can be realized, and in this way, the process of shearing after clamping can be completed by one-time action of the air cylinder, and the working efficiency is increased.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

Coil binding anti-scratch device

The invention discloses a coil binding anti-scratch device, which comprises an inner protective plate, an outer protective plate and an end protective plate, wherein the inner protective plate is arranged along the inner wall of the coil, the outer protective plate is wrapped outside the coil, a plastic mesh belt is arranged on the outer protective plate which is passed through by a bundle line, and the end protective plate includes an annular ring and end backing plates which are circumferentially arranged on the annular ring. The invention has the advantages of simple structure easy operation, high strength, good toughness, and long service lives of the inner and outer protective plates, is capable of effectively preventing coil scratch during binding, reducing production cost, and benefiting subsequent pickling process with the design of the end protective plate.

Owner:NANJING IRON & STEEL CO LTD

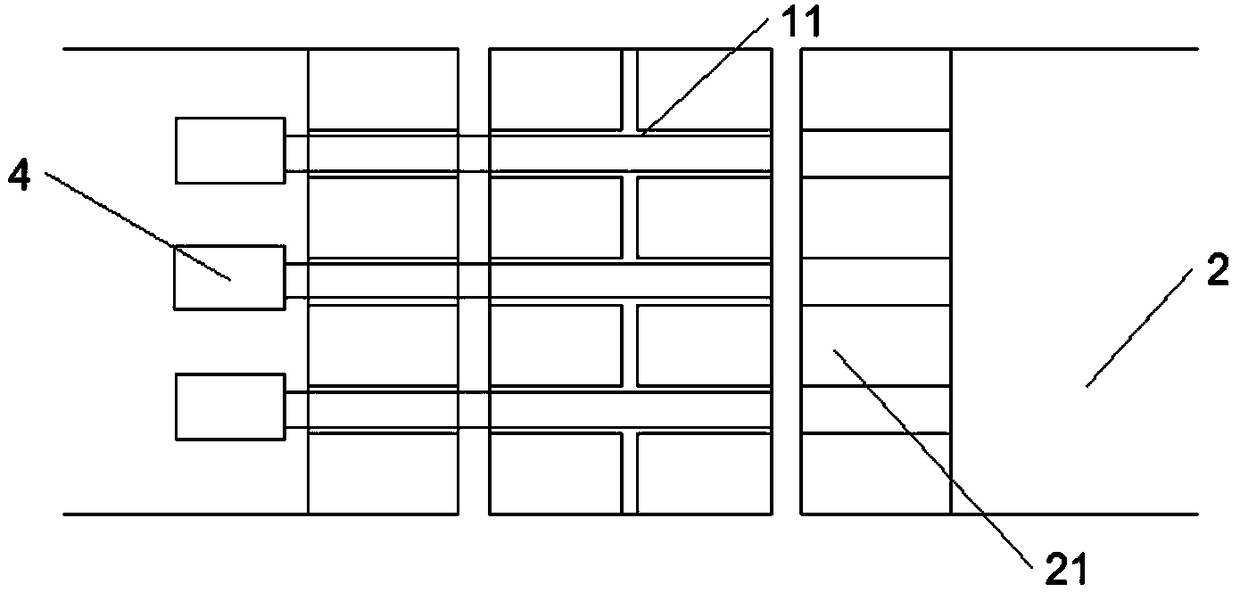

Strip steel coil binding device

PendingCN108341086ATo achieve the purpose of automatic binding strip steel coilBinding material applicationBundling machine detailsCoil bindSpiral binding

The invention provides a strip steel coil binding device. The device comprises a saddle and roller ways on the two sides of the saddle, pre-downward-sliding ways are arranged between the saddle and the roller ways, a plurality of binding belt grooves are formed in the upper surfaces of the pre-downward-sliding ways and the upper surface of the saddle, belt conveying units are arranged above one ends of the binding belt grooves, a binding belt unit capable of surrounding a strip steel coil is arranged above the saddle, a spot welding gun and a belt cutting knife are arranged at the belt feedingend of each binding belt groove in the saddle, and the spot welding guns and the belt cutting knives can penetrate through the saddle to be in contact with binding belts; and the binding belt unit comprises an arc-shaped first binding belt wall and a second binding belt wall opposite to the first binding belt wall, and the top end of the first binding belt wall and the top end of the second binding belt wall are hinged to each other. According to the strip steel coil binding device, the binding belt unit capable of surrounding the strip steel coil is adopted to cooperate with the belt cuttingknives and an electric welding machine, so that the purpose of automatically binding the strip steel coil is achieved.

Owner:TIANJIN HAIGANG STEEL SHEET

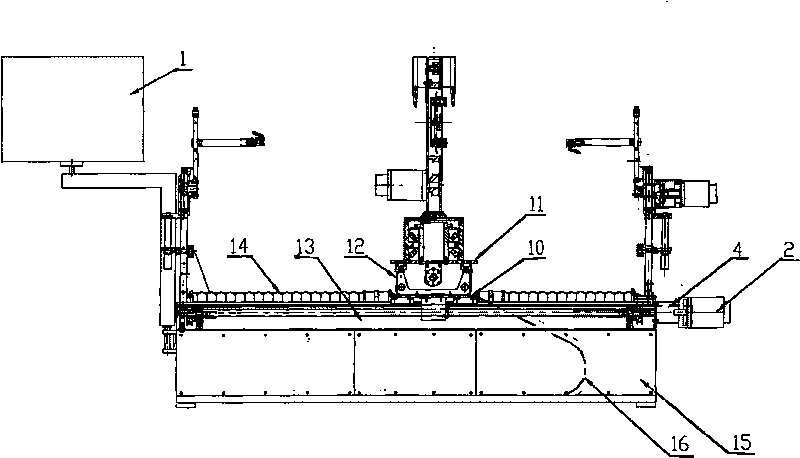

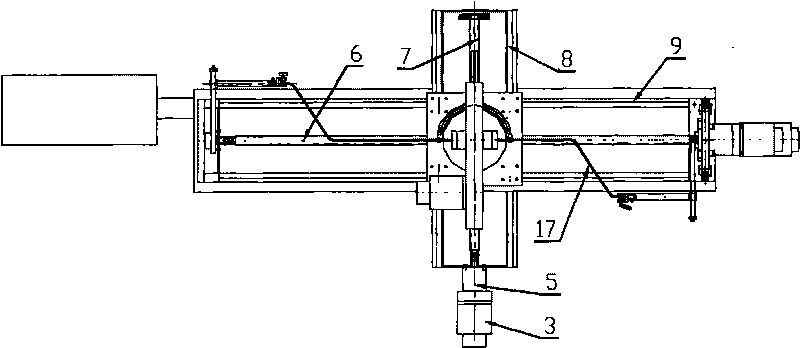

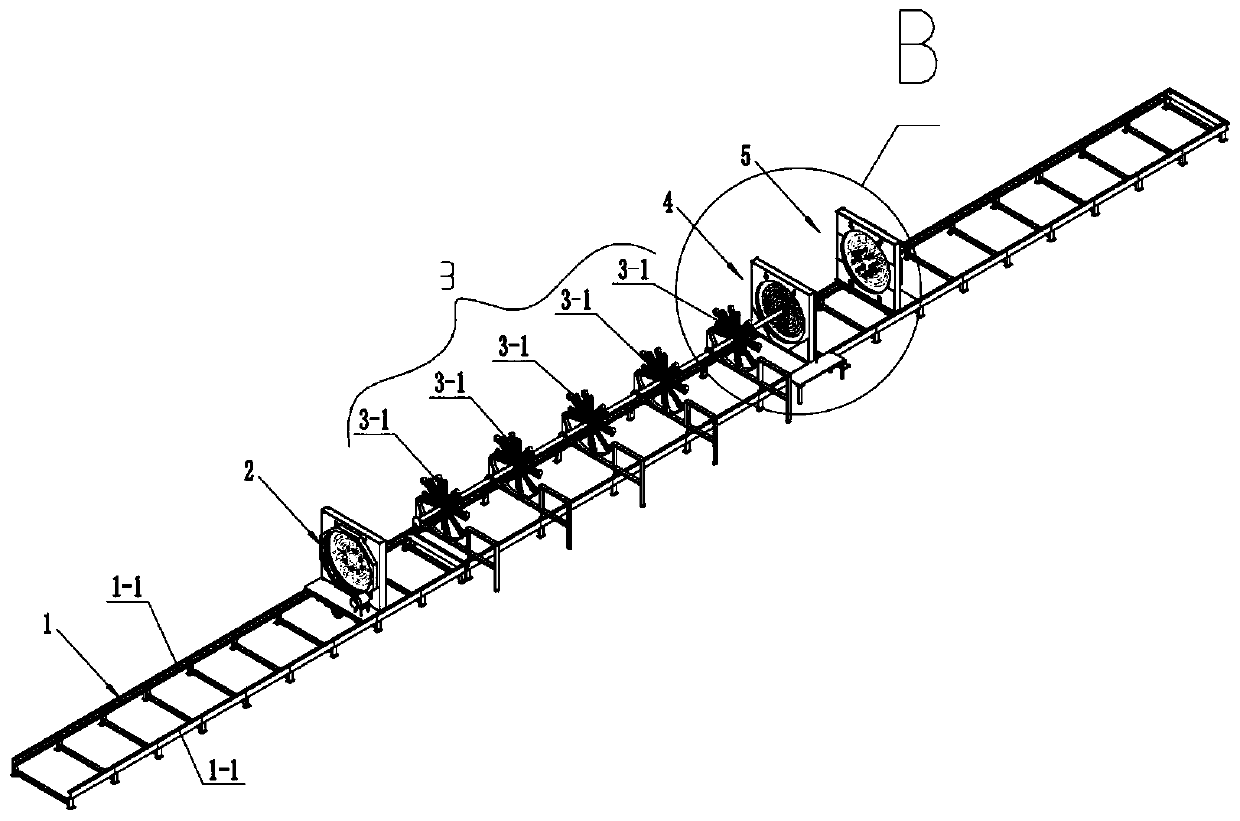

Rotor coil binding machine of wind power generator

InactiveCN101707421BFit tightlySufficient clamping rangeManufacturing dynamo-electric machinesWind energy generationCoil bindCoupling

The invention relates to the technology of rotor coil binding of generators, in particular to a rotor coil binding machine of a wind power generator. The invention solves the problems of large labor intensity, low efficiency and difficult control of quality caused by manual binding because of the insulation of the rotor coil of the traditional wind power generator. The rotor coil binding machine of the wind power generator comprises a numerical control system, a stand, a feeding system, a rotor coil clamping synchronous device and a lapping head, and mainly comprises a servo motor, a decelerator, a ball screw, as well as a trailing plate and a linear guide rail connected by a shaft coupler, a synchronous driving pulley, a synchronous driven pulley and a synchronous belt, wherein the synchronous belt with a tension wheel is arranged on the synchronous driven pulley, the shaft coupler is arranged between synchronous transmission pulleys at the bottom end, and the synchronous driving pulley and the synchronous driven pulley at the upper end are respectively provided with a rocking arm, a left clamp rod, a right clamp rod and a clamp. Compared with the binding machine in the prior art, the rotor coil binding machine of the wind power generator has reasonable structure, favorable effect and optimal cost performance.

Owner:CRRC YONGJI ELECTRIC CO LTD

Semi-automatic coil binding machine

InactiveUS20130061976A1Save manpower andShorten the timeWire articlesSheet bindingCoil bindWinding machine

A semi-automatic coil binding machine includes a machine b as e, a coil pitch control mechanism, a cutting mechanism, a coil conveyor mechanism, a coil stop mechanism, a document conveyor mechanism and a press fit mechanism: the coil pitch control mechanism conveys a spiral coil to a predetermined length; the cutting mechanism cuts the spiral coil to a predetermined length; the coil conveyor mechanism conveys the cut spiral coil; the coil stop mechanism stops the spiral coil at a threading position from which the spiral coil is threaded onto a pile of documents; the document conveyor mechanism conveys the pile of documents with a spiral coil threaded to a press-fit position at which the spiral coil and the documents are pressed by the press fit mechanism for the spiral coil securely bonded to the documents at bookbinding and substantially increased throughput.

Owner:INNOSTAR TECH PTE

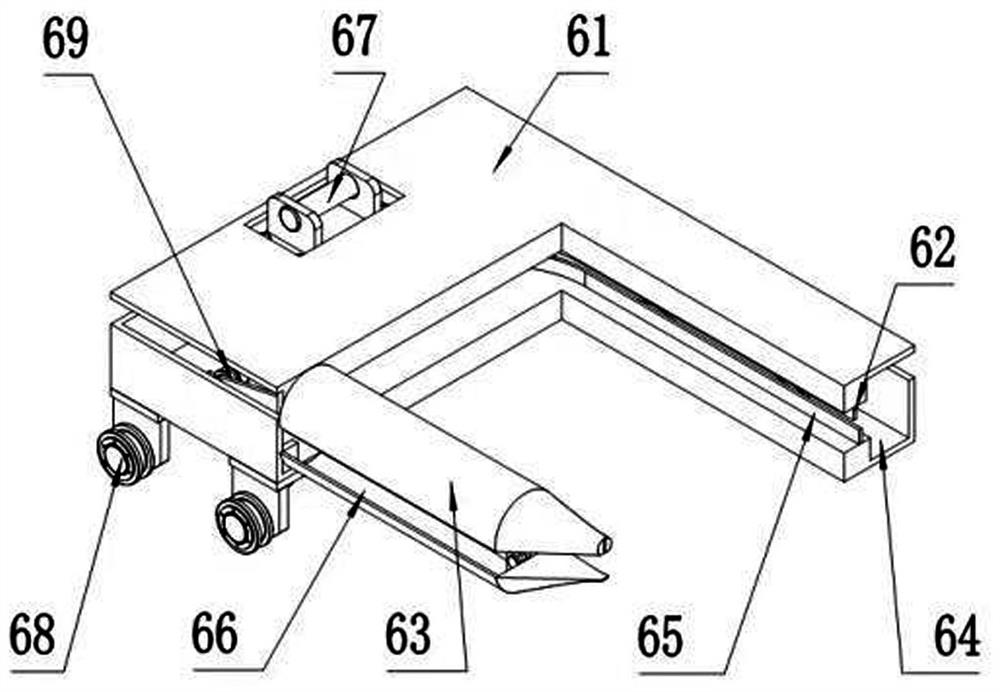

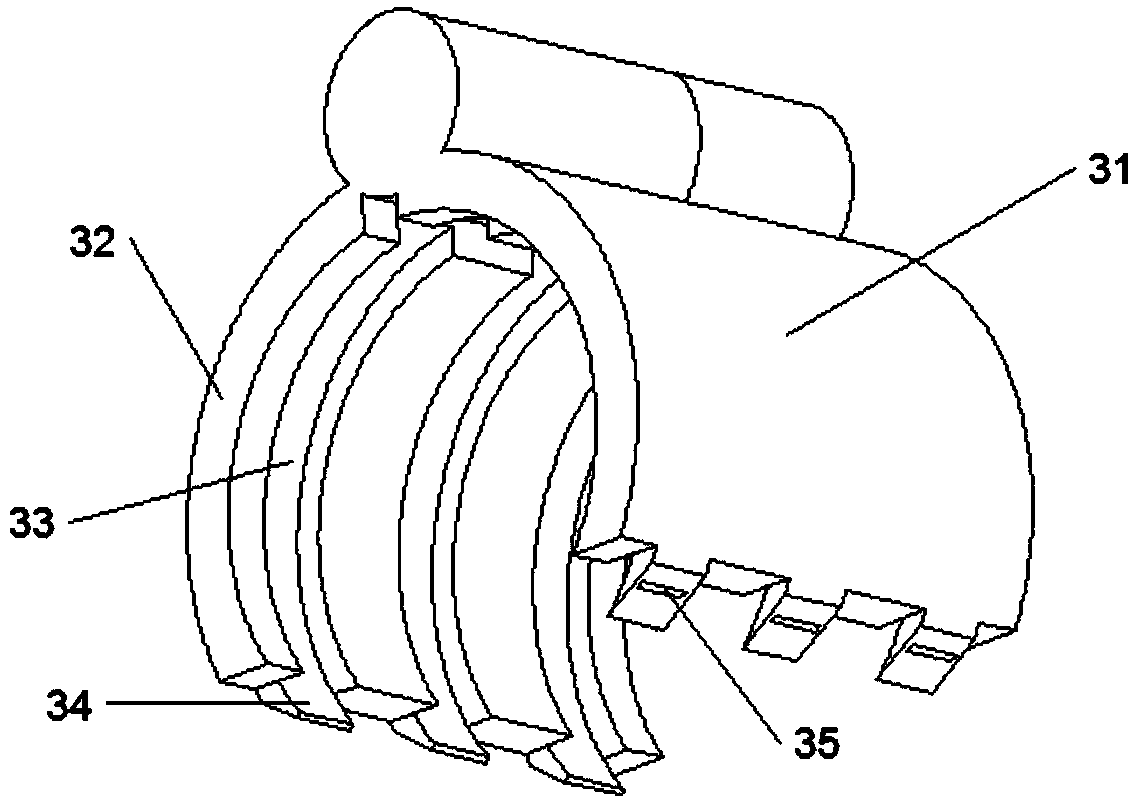

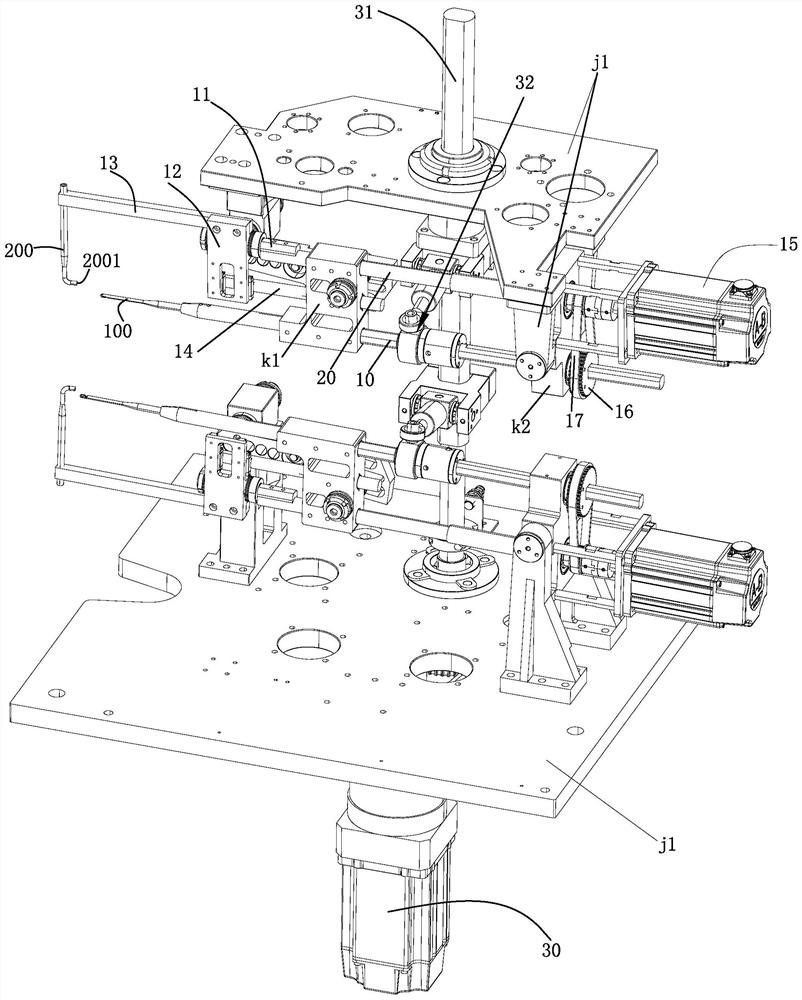

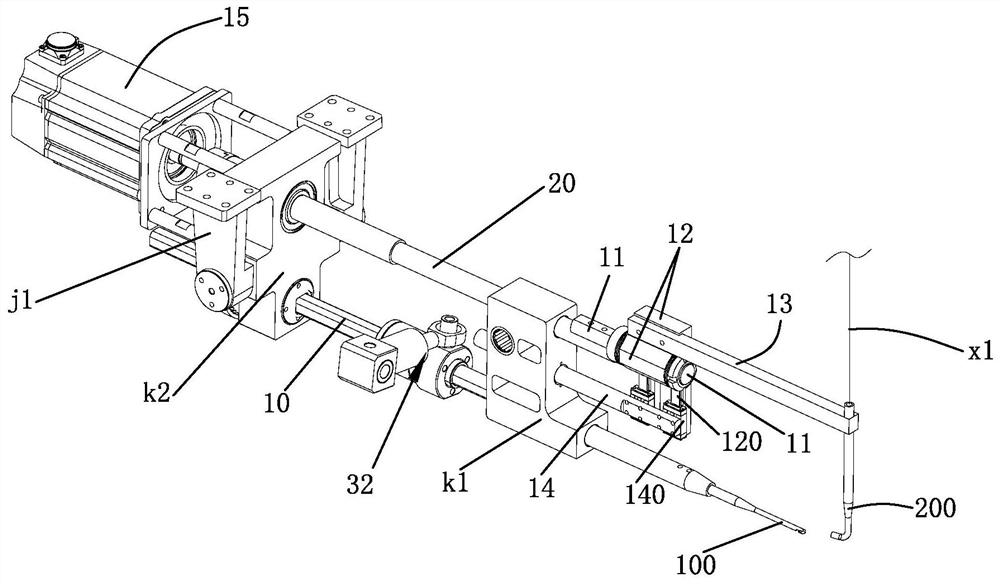

Stator coil binding mechanism

PendingCN111987876AEnhanced binding effectQuality improvementManufacturing dynamo-electric machinesCoil bindStator coil

The invention relates to a stator coil binding mechanism. The binding mechanism comprises an equipment frame and a binding unit rotationally arranged on the equipment frame. The binding unit comprisesa crochet hook, a swing nozzle, a supporting assembly, a first supporting shaft arranged on the supporting assembly and used for supporting the crochet hook, and a second supporting shaft arranged onthe supporting assembly and used for supporting the swing nozzle. The binding mechanism further comprises a first driving mechanism for driving the binding unit to rotate so as to switch the positions of the crochet hook and the swing nozzle in the up-down direction, and a second driving mechanism for driving the crochet hook to do front-back telescopic motion. The binding unit further comprisesa third driving mechanism and a transmission mechanism. Only one driver for providing power for the swing nozzle and the crochet hook is arranged in the binding mechanism. Therefore, the action consistency of the two mechanisms is better, the difficulty of debugging and maintenance work is reduced, the debugging and maintenance cost is greatly reduced, the overall use stability of the binding mechanism is better, the binding efficiency of the binding mechanism is improved, the overall structure of the binding mechanism is more compact, and the manufacturing cost of equipment is reduced.

Owner:ALLIANCE AUTOMATIONSUZHOUCO

An installation device for steel coil strapping

ActiveCN106553786BEnsure safetyShorten the timeBundling machine detailsCoil bindProtection mechanism

Owner:BAOSHAN IRON & STEEL CO LTD

Stator coil binding device

PendingCN110266151AControl tensionFixed implementationManufacturing dynamo-electric machinesCoil bindSpiral binding

The invention discloses a stator coil binding device, and belongs to the technical field of coil binding machines. An existing coil binding device can only bind a binding coil on a copper coil of a stator at a time, and if a plurality of binding coils need to be bound on the copper coil at a time, the operation cannot be finished, so that the coil binding efficiency is low. A coil clamping mechanism can clamp the binding coil and cut the tail coil part of the previous binding coil to carry out the next round of coil binding, so that the plurality of coils can be bound on the same copper coil at a time, and the coil binding efficiency is high. A fixed connection piece abuts against the edge, not provided with the coil, of the stator or / and the side wall of the stator, so that the stator is fixed; the fixed connection piece is not in contact with the coil, so that the deformation of the coil cannot be caused, and a coil hooking gap in the lower end part of the coil is not influenced; the structure is simple and practical; the scheme is feasible; the prejudice of the prior art is broken; and the conception is ingenious. A pressing piece which can abut against the binding coil is arranged on a pole in a penetrating mode; and the friction resistance provided by the pressing piece is utilized for controlling the tension of coil binding, so that a relatively stable coil binding tension force can be provided.

Owner:浙江丰源智能装备有限公司

A fully automatic cable coiling machine

ActiveCN108792814BSimple structureReasonable designFilament handlingBundling machine detailsCoil bindRobot hand

The invention belongs to a full-automatic cable coiling binding machine. The full-automatic cable coiling binding machine comprises a device base, wherein the top of the device base is provided with acombing device and a mechanical arm fixing frame arranged on one side of the combing device, a first mounting hole is formed in the upper surface of the device base corresponding to the inside of themechanical arm fixing frame, a rotating shaft is arranged at the center of the first mounting hole, a second mounting hole is formed in the fixing plate of the mechanical arm fixing frame corresponding to the top of the first mounting hole, and a mechanical arm unit is arranged in the second mounting hole; and the interior of the first mounting hole is connected with a rotary disc device througha bearing, a rotating shaft hole matched with the rotating shaft is formed in the bottom of the rotating disc device, a groove matched with a grabbing disc is formed in the middle of the upper surfaceof the rotating disc device, and a plurality of winding rods are arranged on the edge of the upper surface of the rotating disc device. The full-automatic cable coiling binding machine has the advantages of being simple in structure, reasonable in design, high in wire coiling speed, and low in labor intensity, and can comb the coiled cable.

Owner:郑州恒天铜业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com