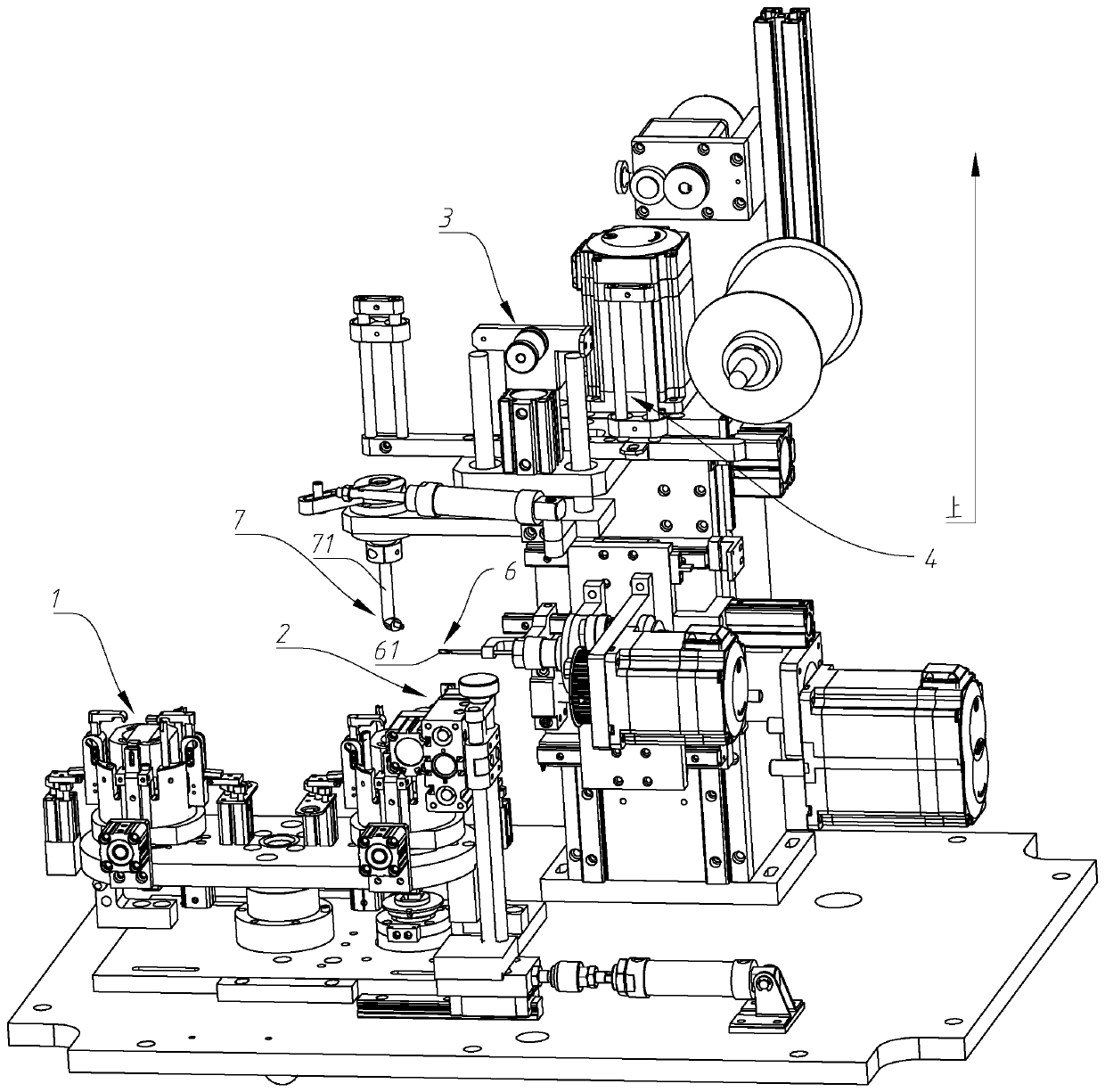

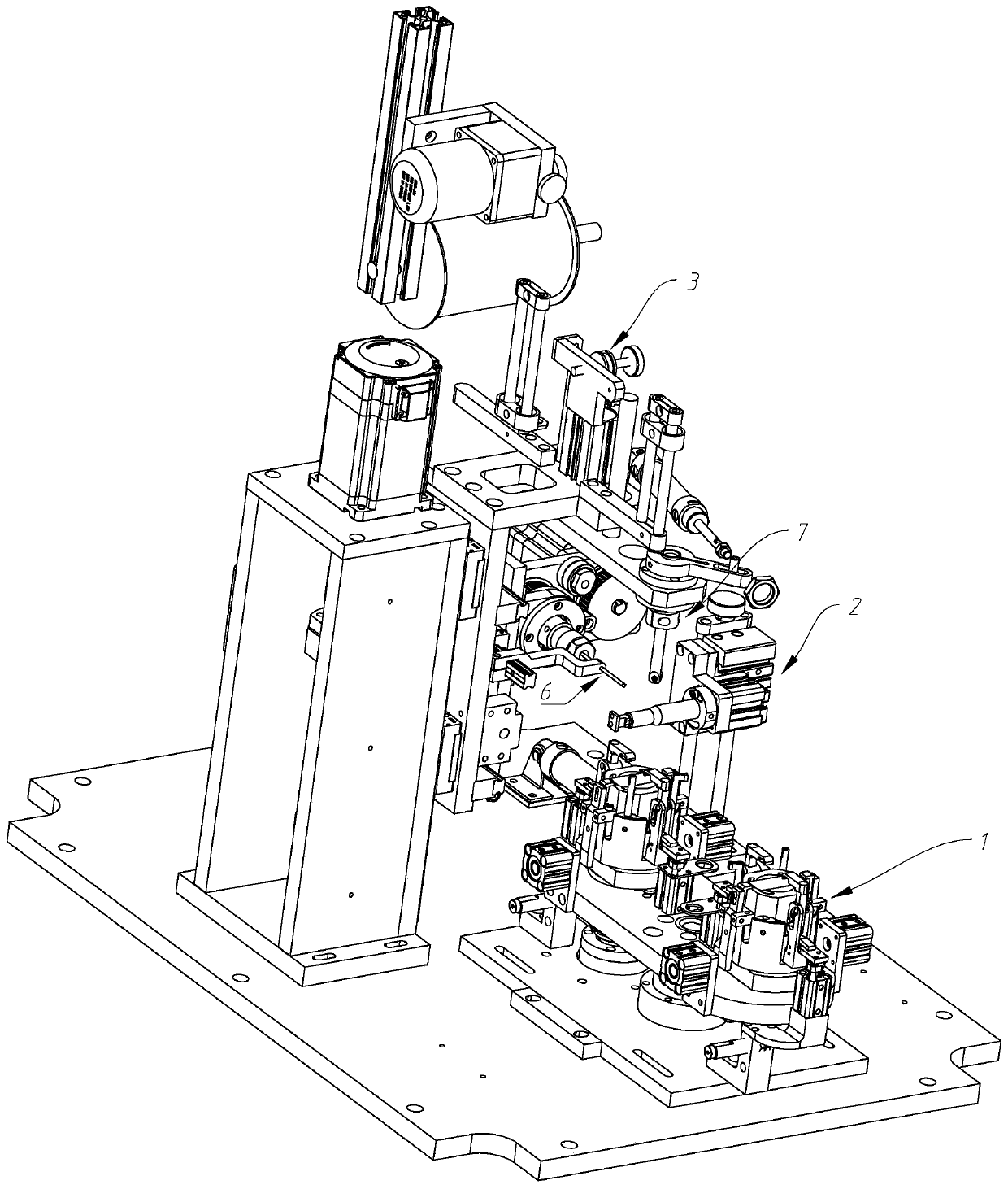

Stator coil binding device

A wire-binding and stator technology, applied in the field of wire-binding machines, can solve the problems of undisclosed wire-binding tension, lack of necessary technical features, unclear plans, etc., and achieve high-efficiency wire-binding, practical solutions, and ingenious ideas Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

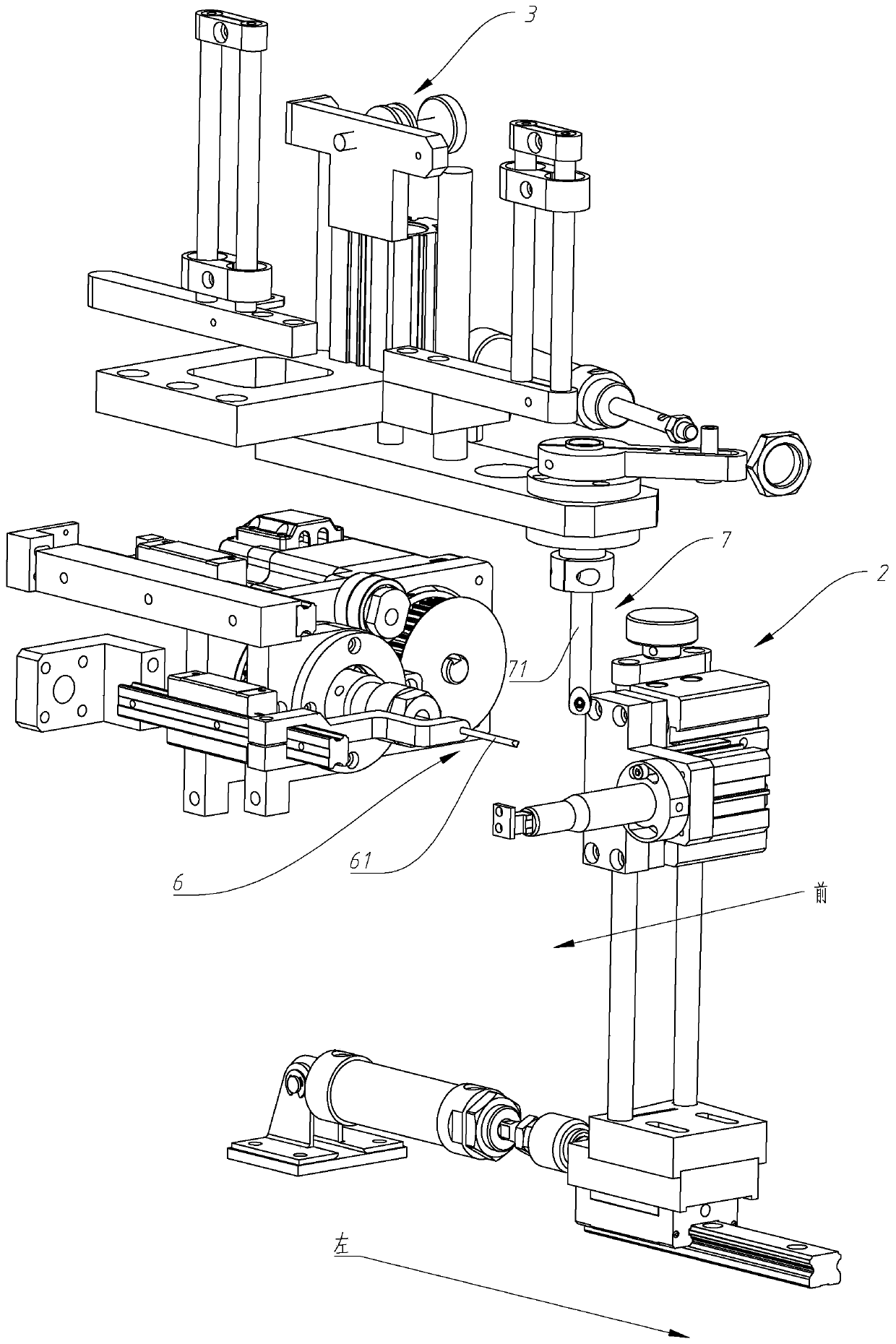

[0067] Telescopic drive source 25, front and rear drive source 26, left and right drive source 27 are air cylinders or hydraulic cylinders or magnetic cylinders. The movable ends of the telescopic drive source 25 and the front-rear drive source 26 can expand and contract along the front-rear direction, and the movable ends of the front-rear drive source 26 are fixedly connected to the fixed end of the telescopic drive source 25 . The moving ends of the left and right drive sources 27 can expand and contract in the left and right directions, and their fixed ends are fixedly connected to the fixed ends of the front and rear drive sources 26. The structure is simple and practical, and the scheme is feasible.

[0068] The thread clamping mechanism 2 of the present invention can clamp and bind the thread and cut off the tail thread of the last coil to perform the next round of thread binding. It can bind multiple coils on the same copper coil at one time, and the thread binding effi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com