Patents

Literature

63 results about "Spiral binding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coil binding, also known as spiral binding, is a commonly used book binding style for documents. This binding style is known by a number of names including spiral coil, color coil, colorcoil, ez-coil, plastic coil, spiral binding, plastikoil and coilbind.

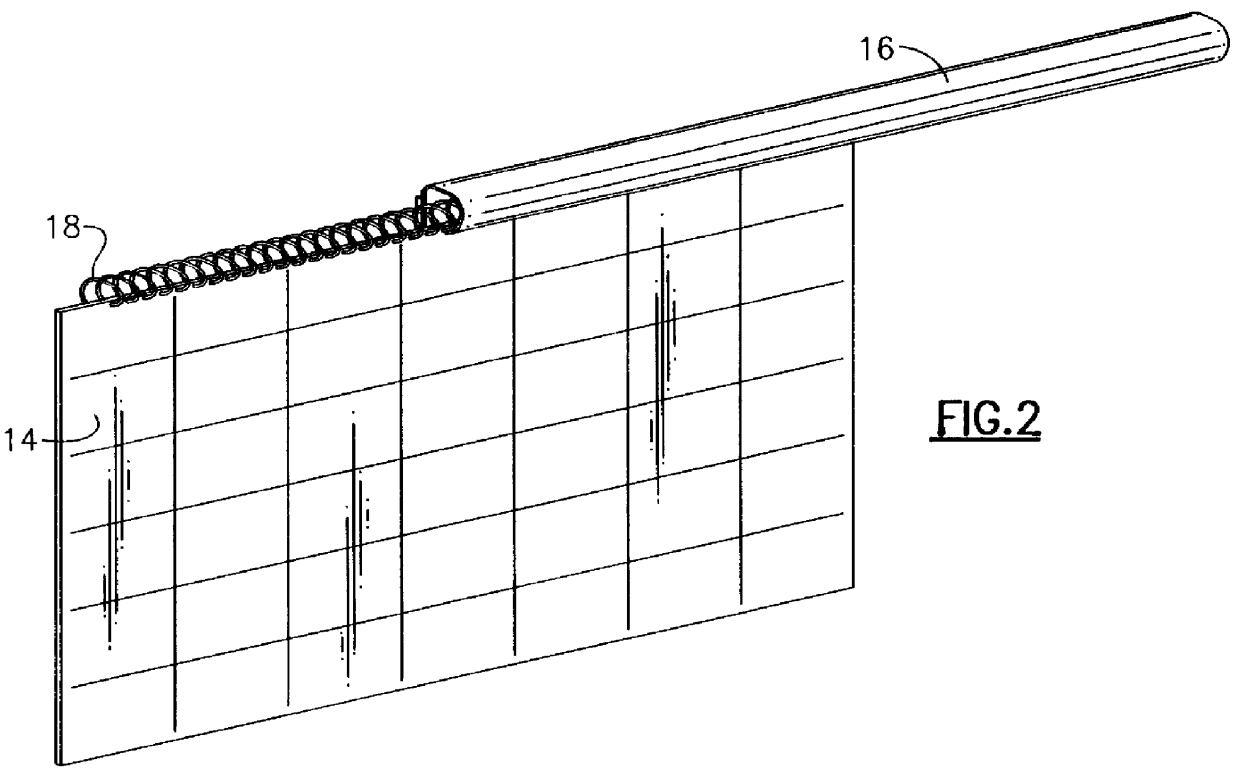

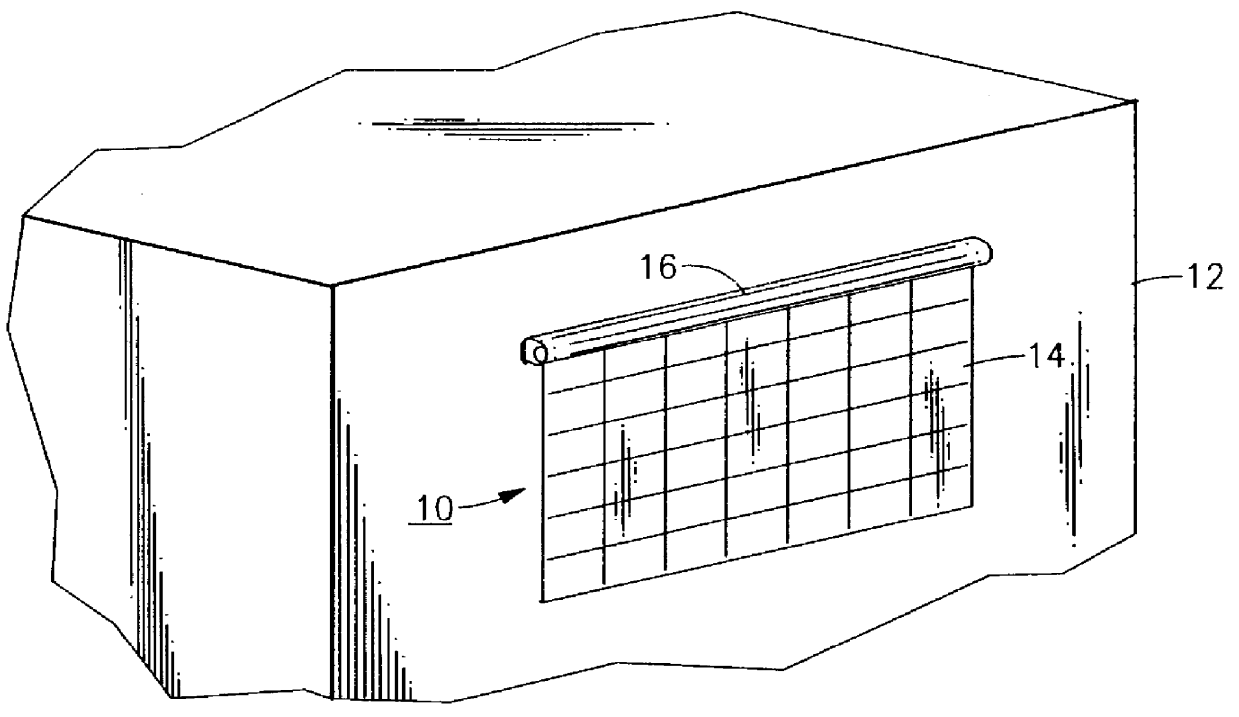

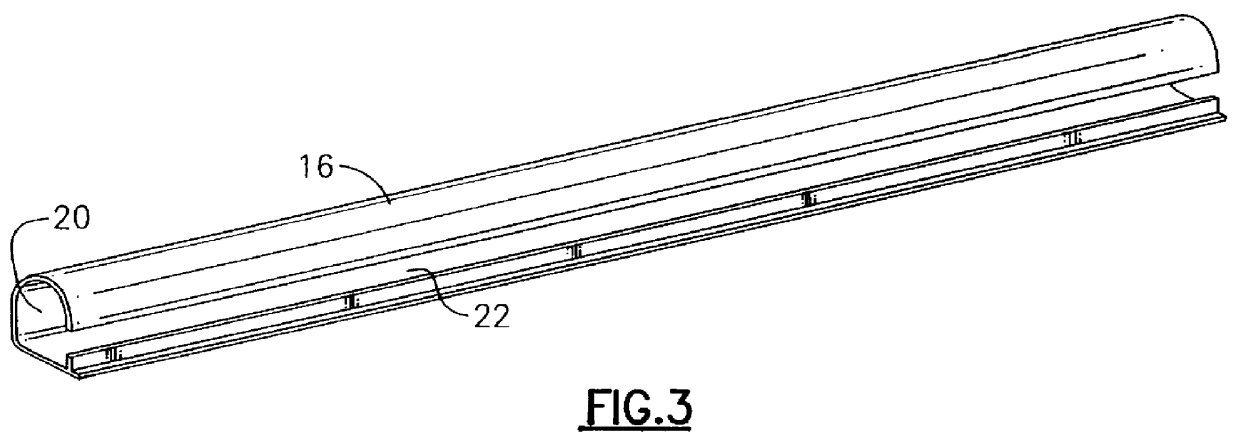

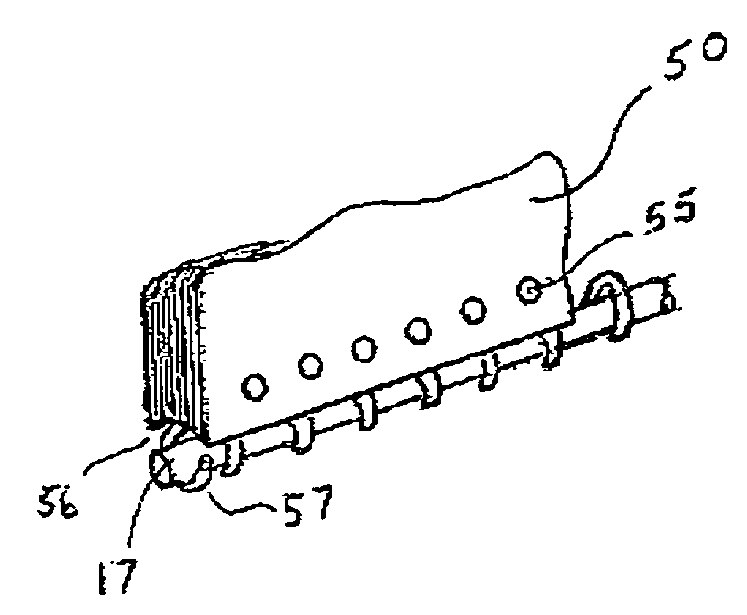

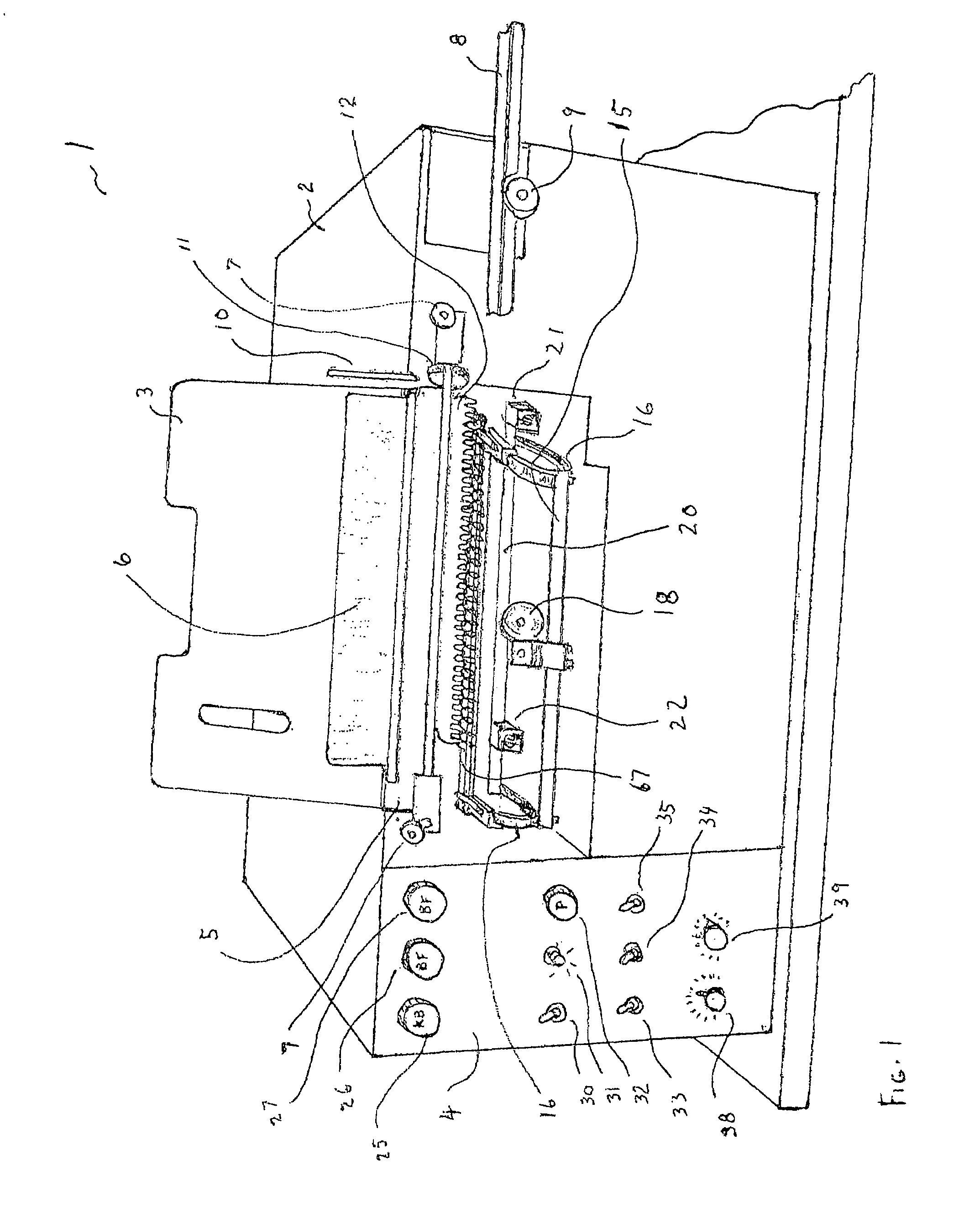

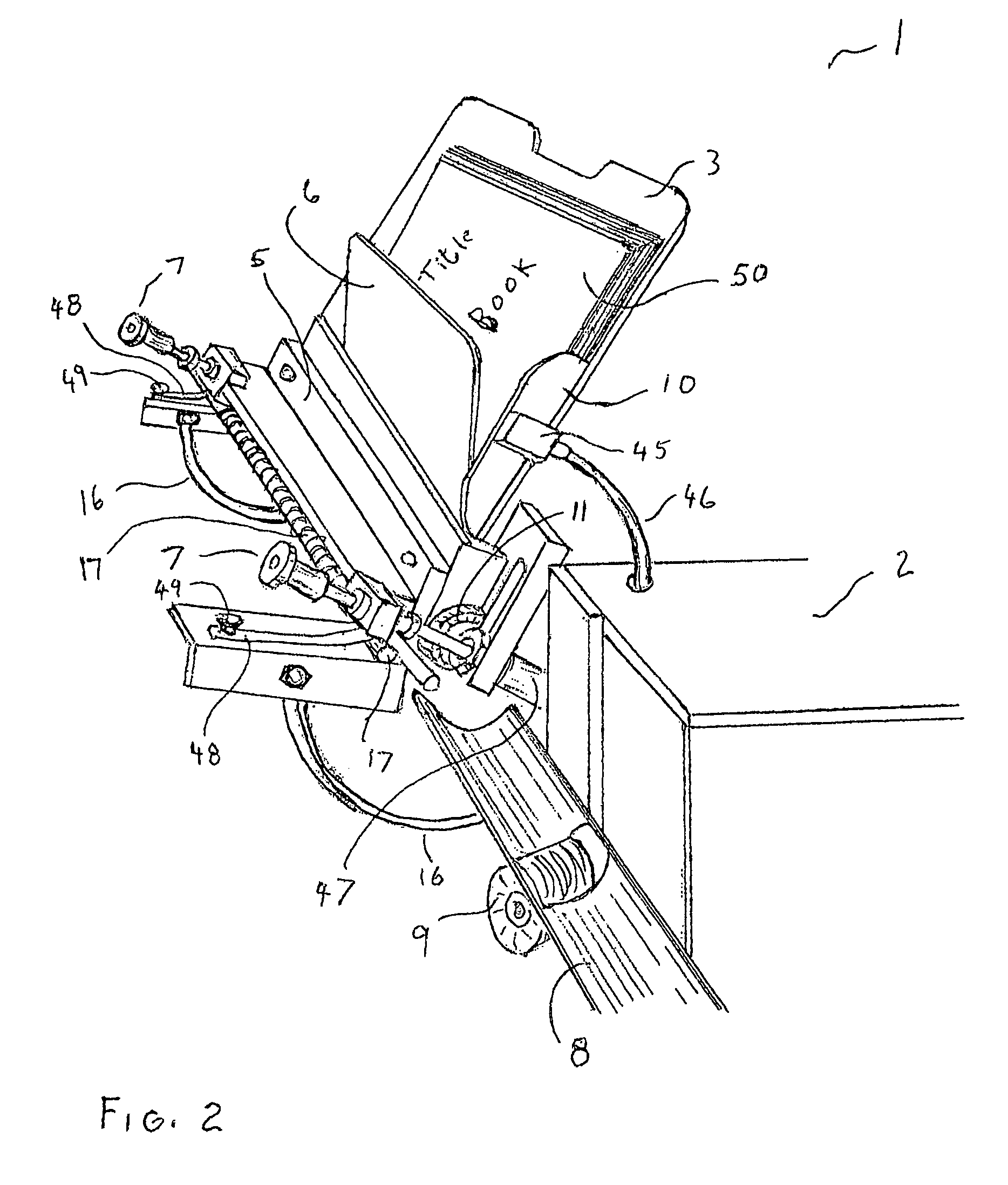

Hangable calendar assembly

A hangable wall calendar has a stack of sheets that are bound at one edge with a spiral binding or other suitable flip binding. The calendar may have a stitch binding, or be cloth-bound or stapled. An elongated generally tubular hanger member for the calendar has a generally D-shaped profile, with a magnetic strip on the back and a slot running along a bottom wall. The slot is narrower than the diameter of the flip binding but large enough to accomodate the stack of sheets. The calendar can be slipped out of the holder and flipped to a different sheet, and then slid back into place. Alternatively, the hanger member can have a generally P-shaped profile.

Owner:MEADWESTVACO CORP

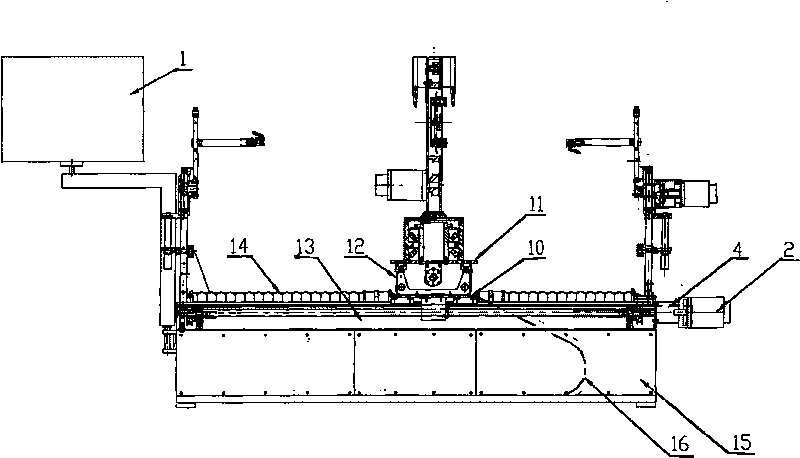

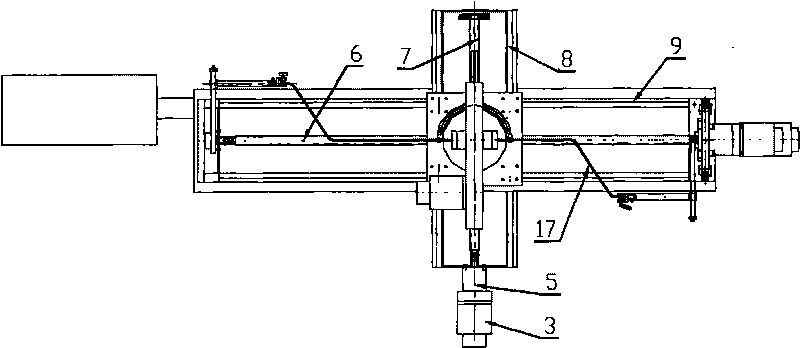

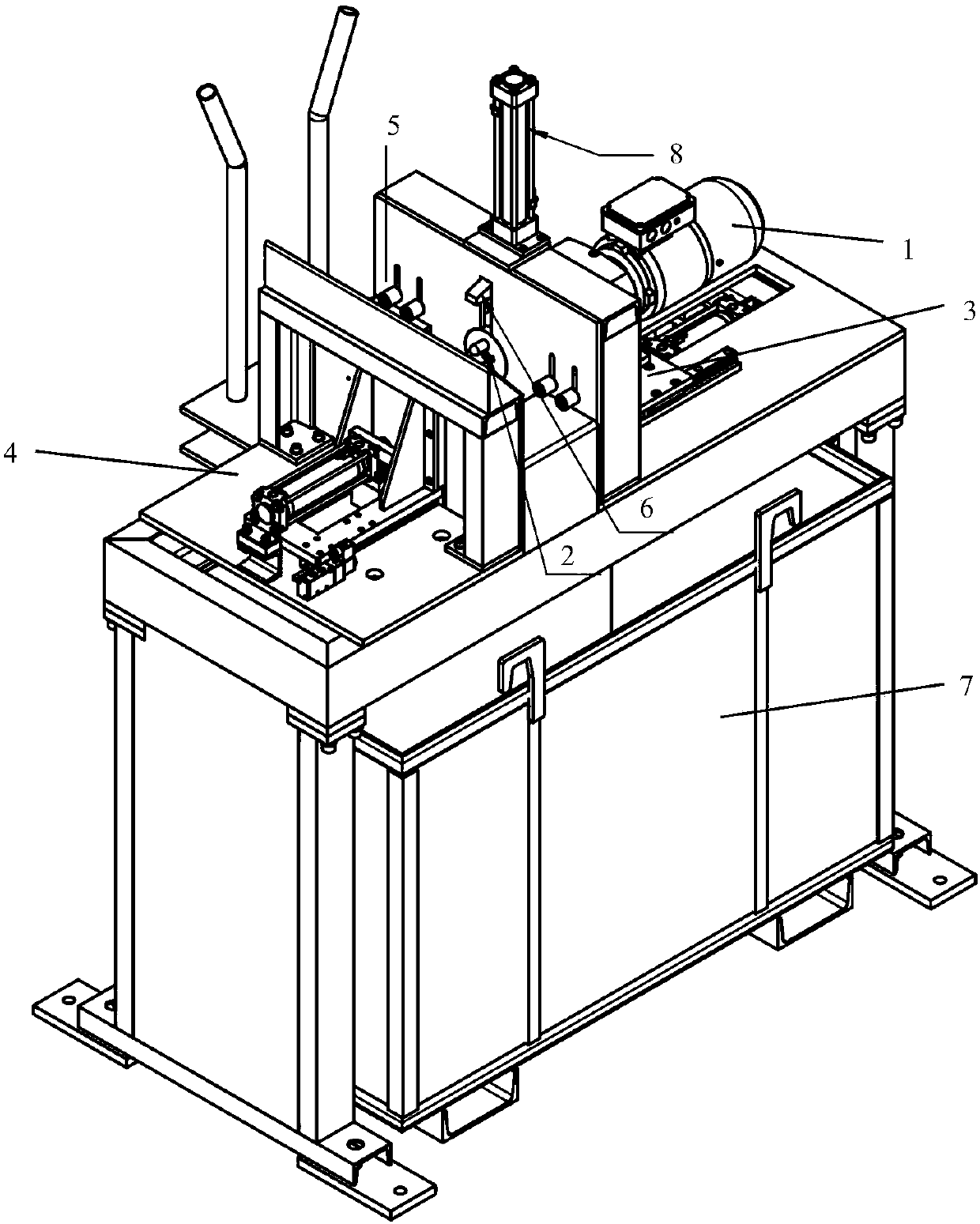

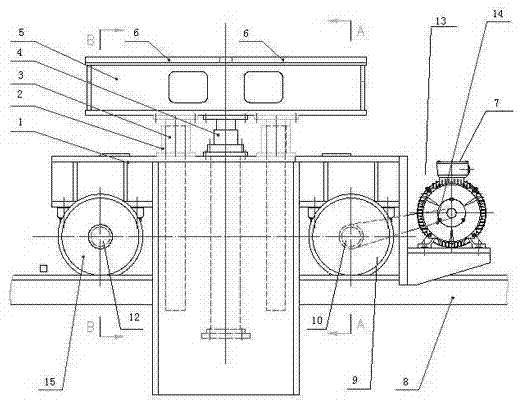

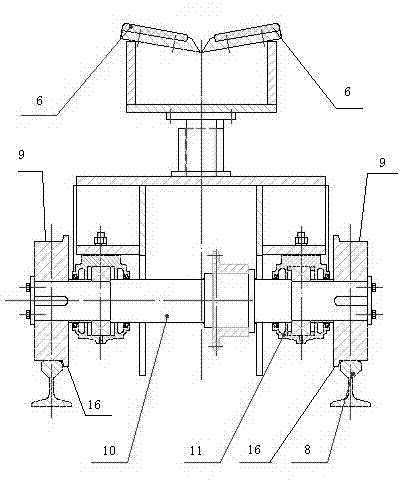

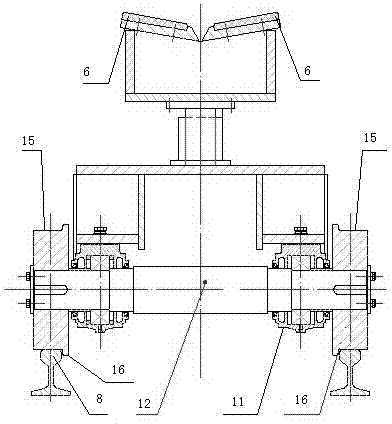

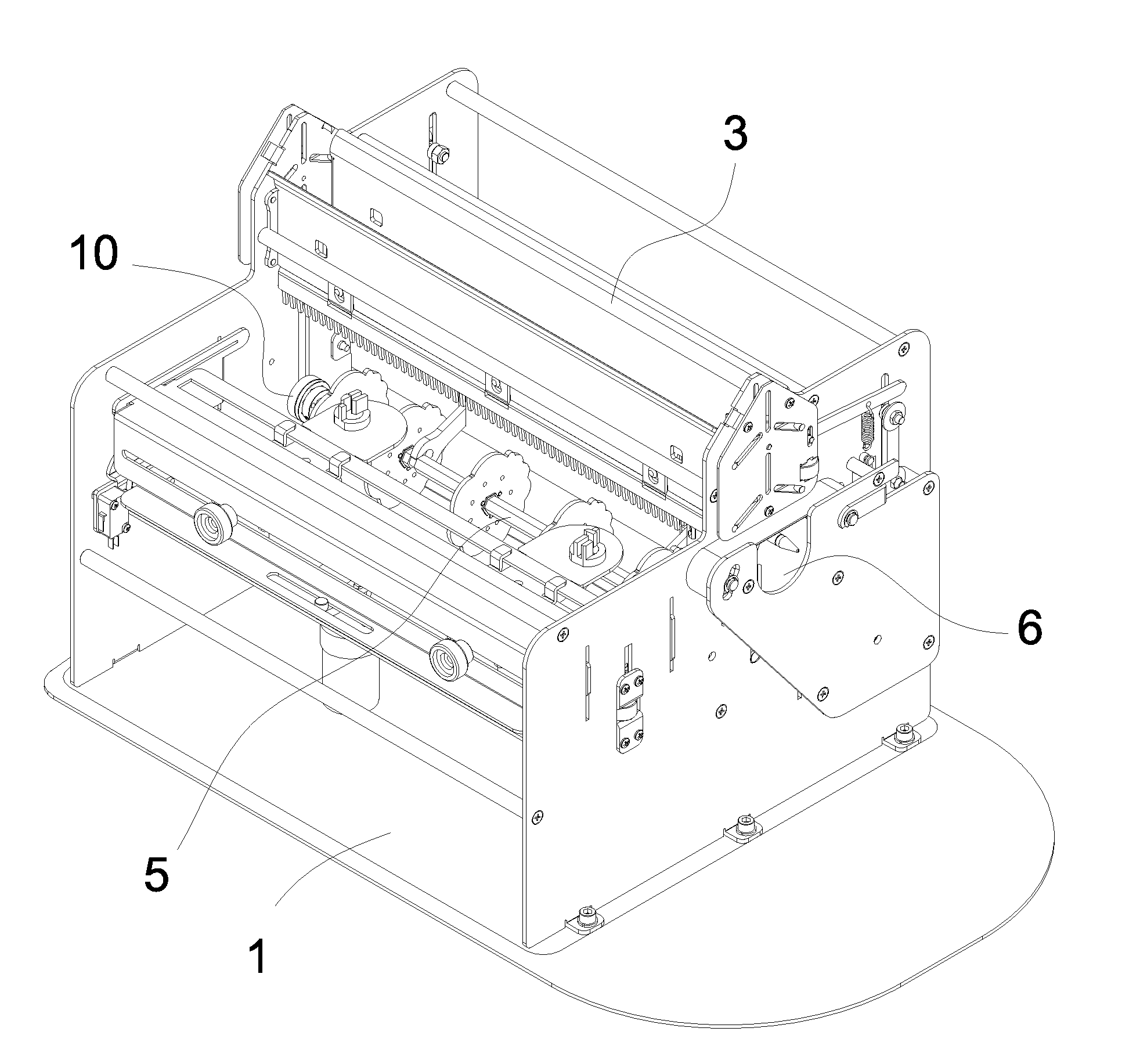

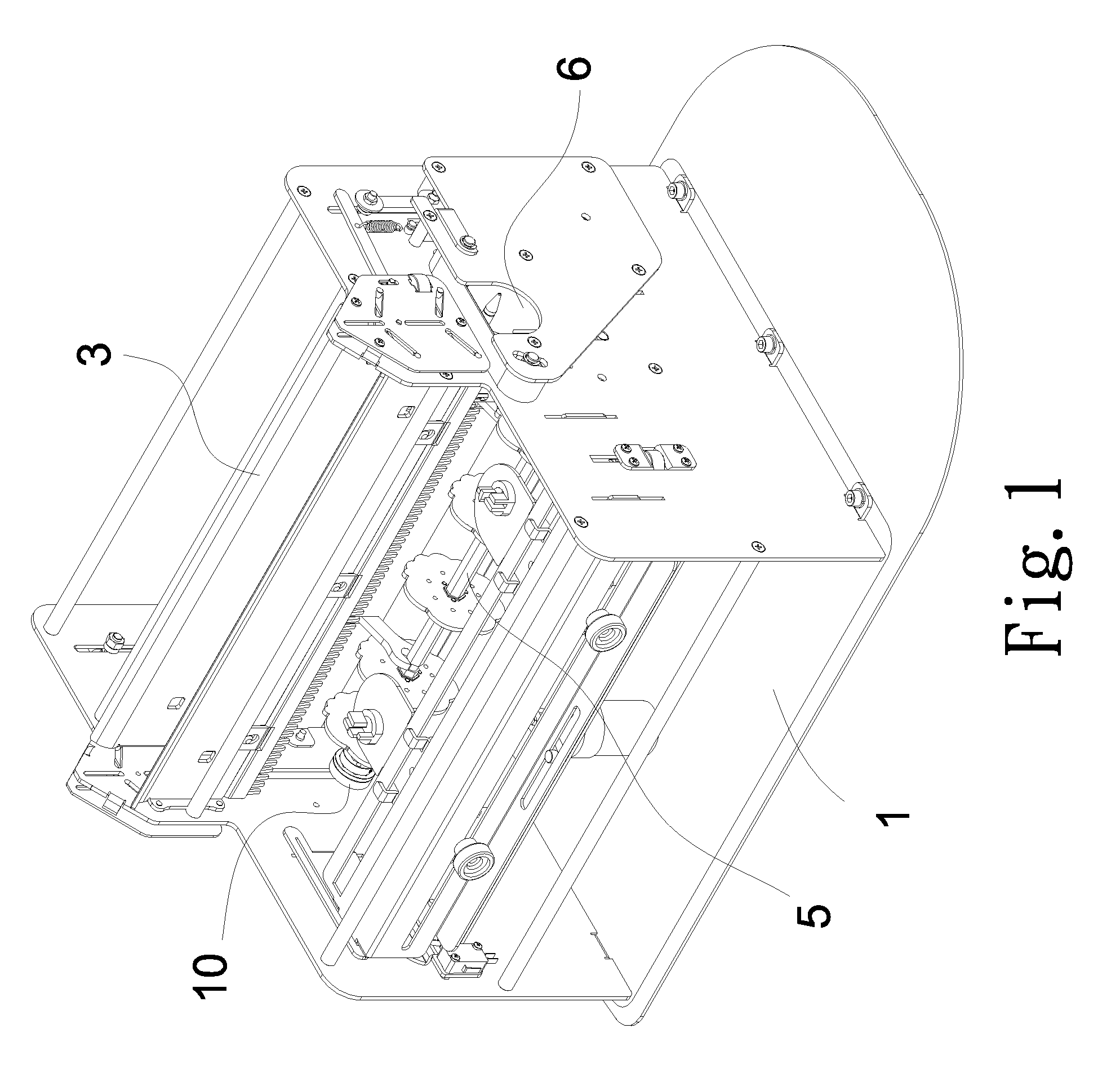

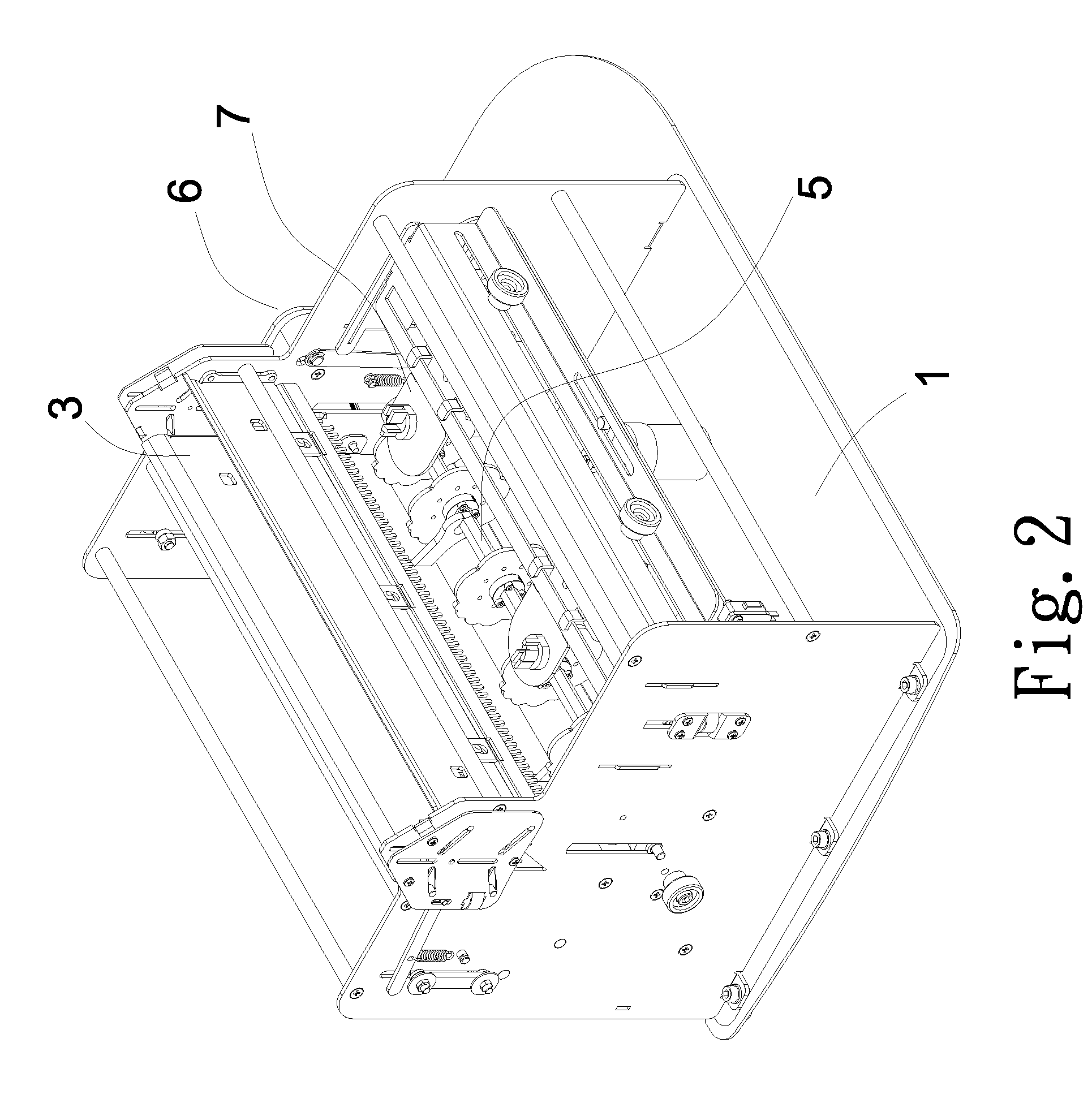

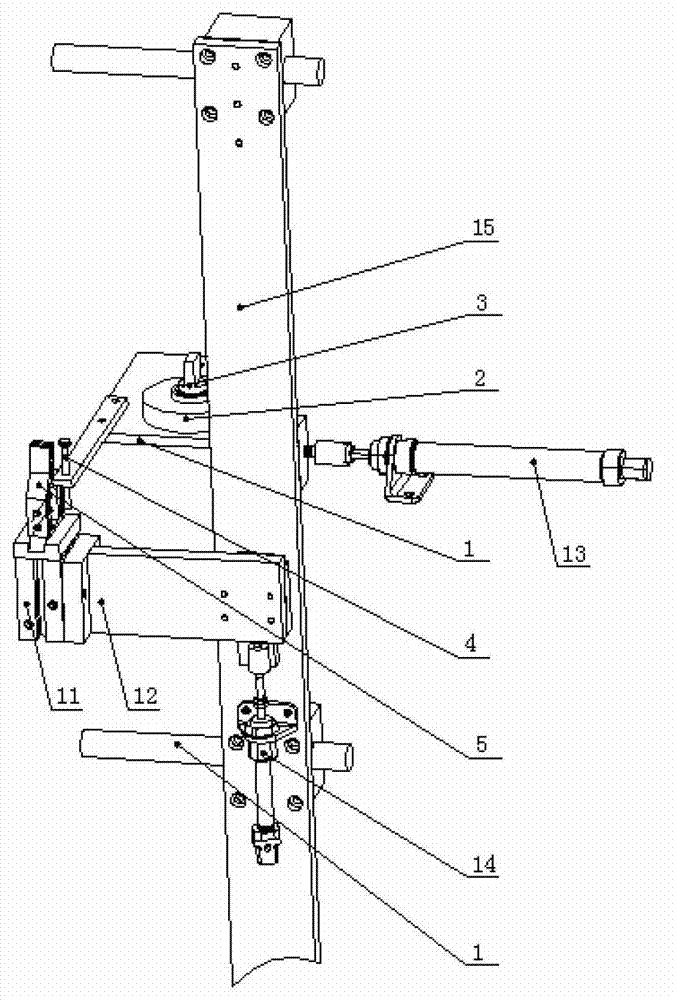

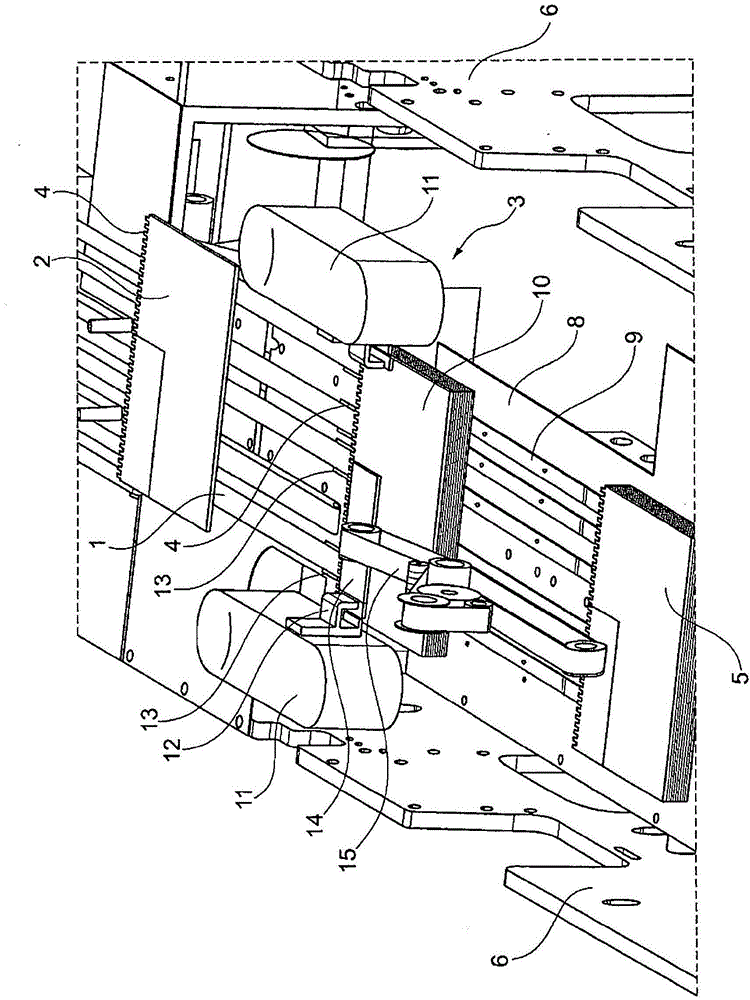

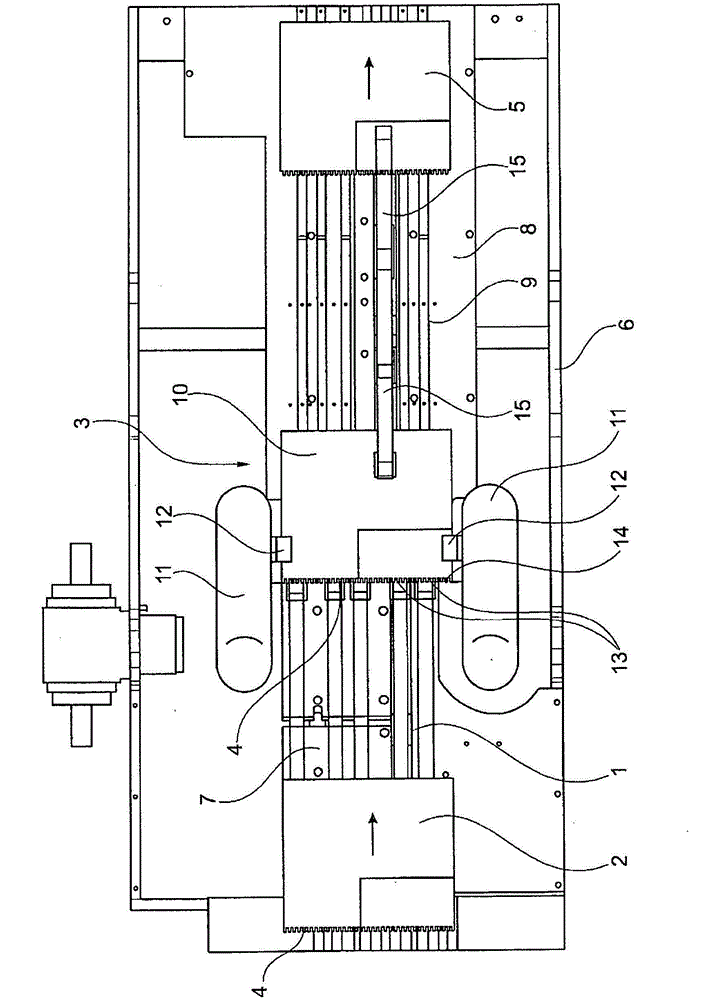

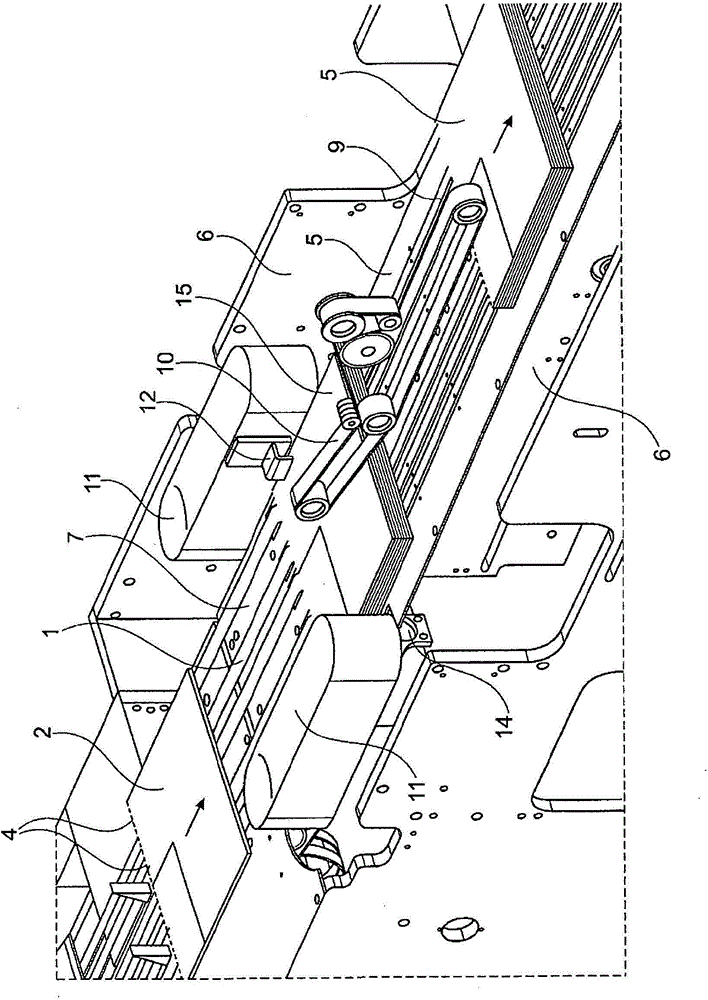

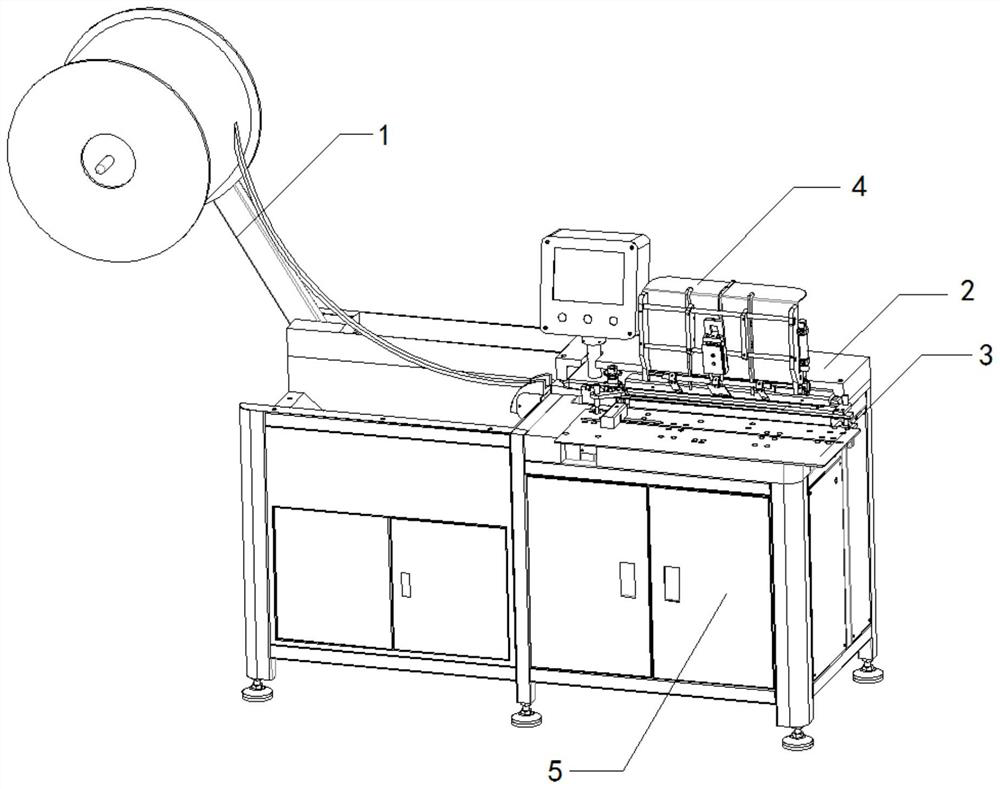

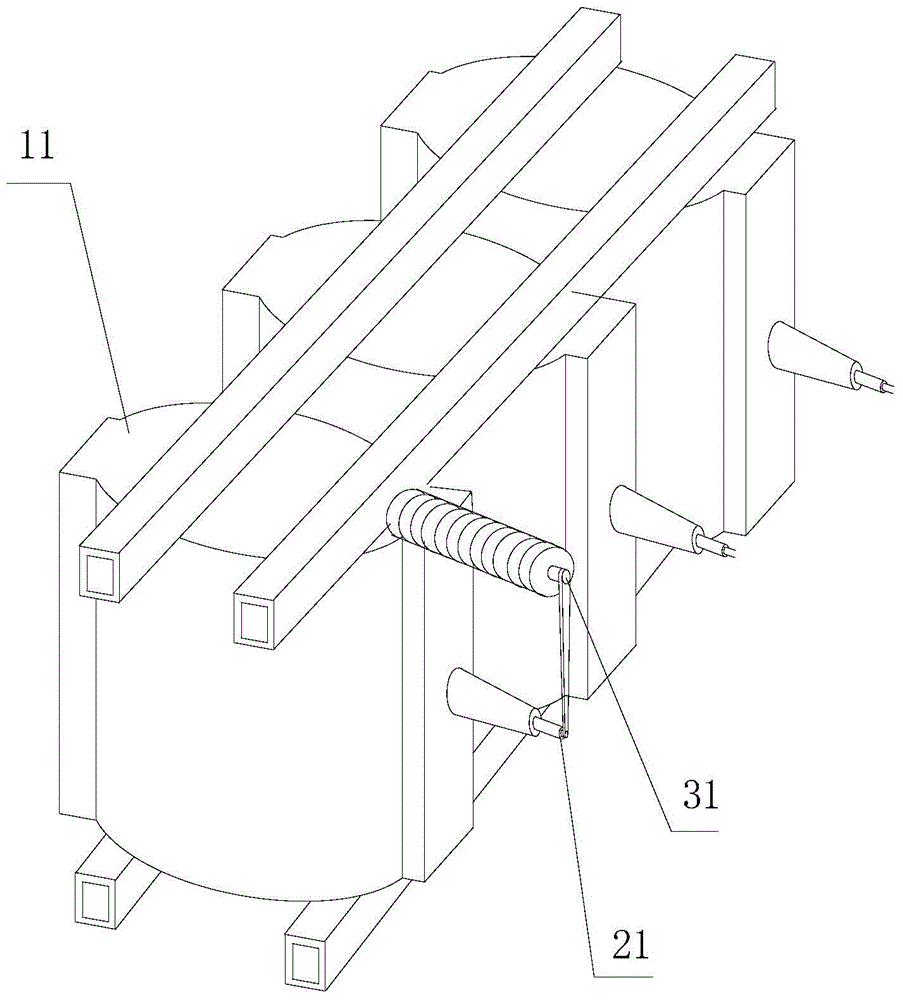

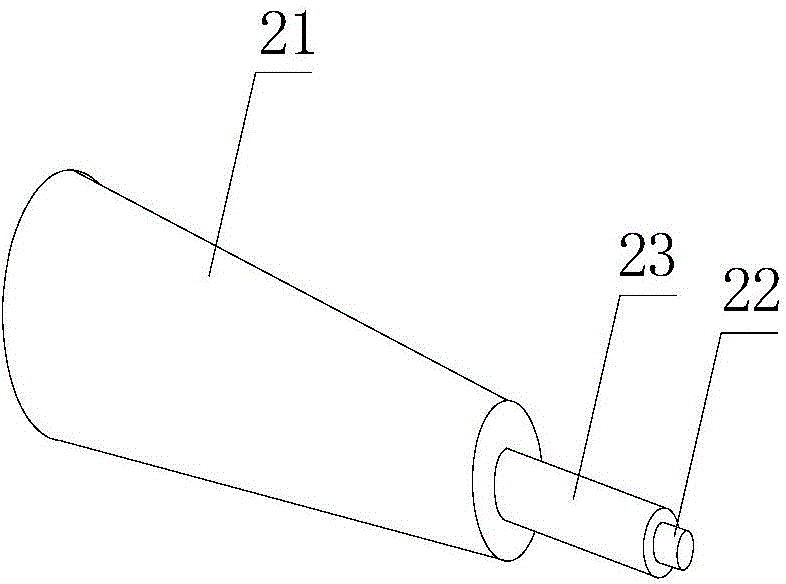

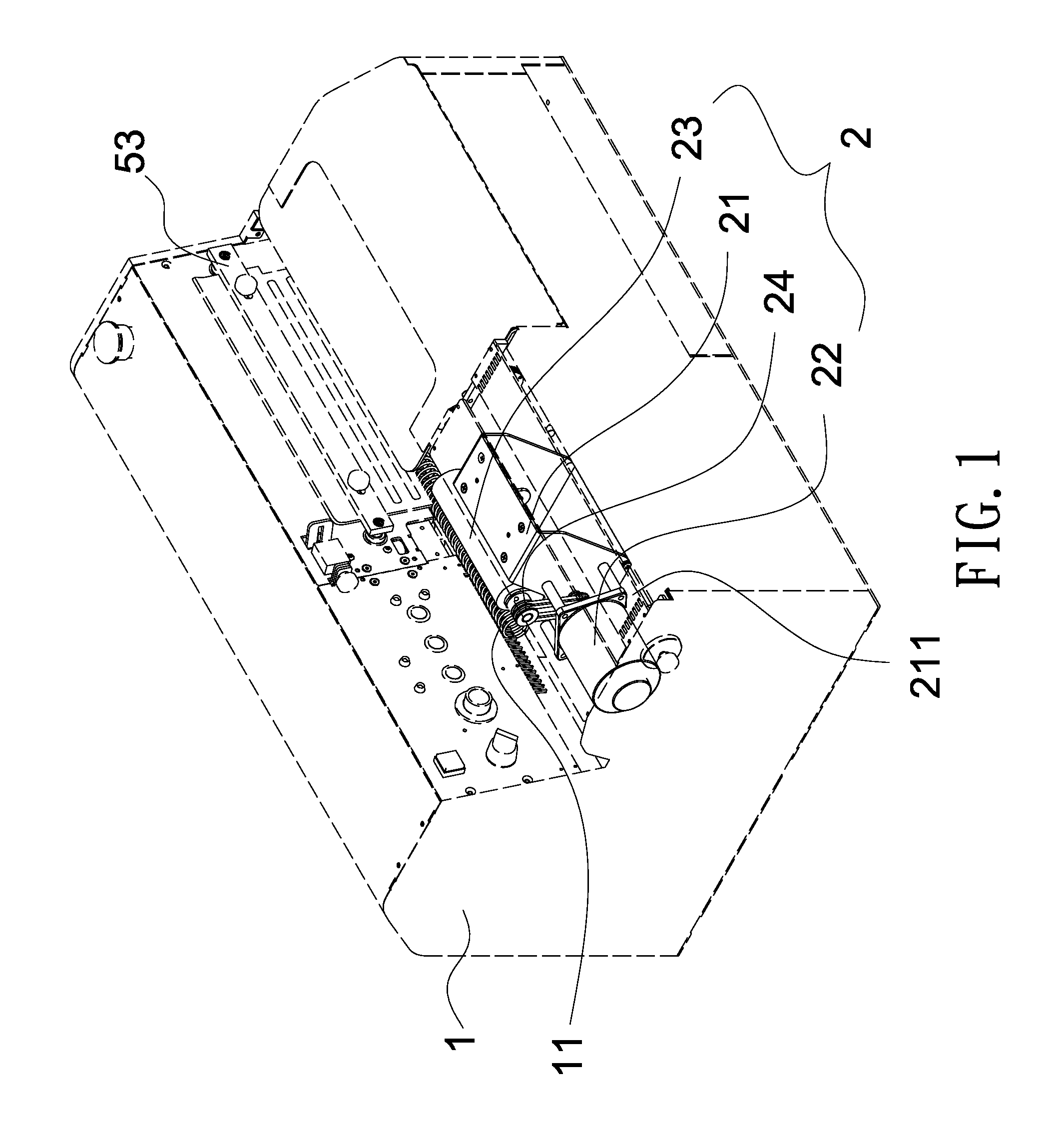

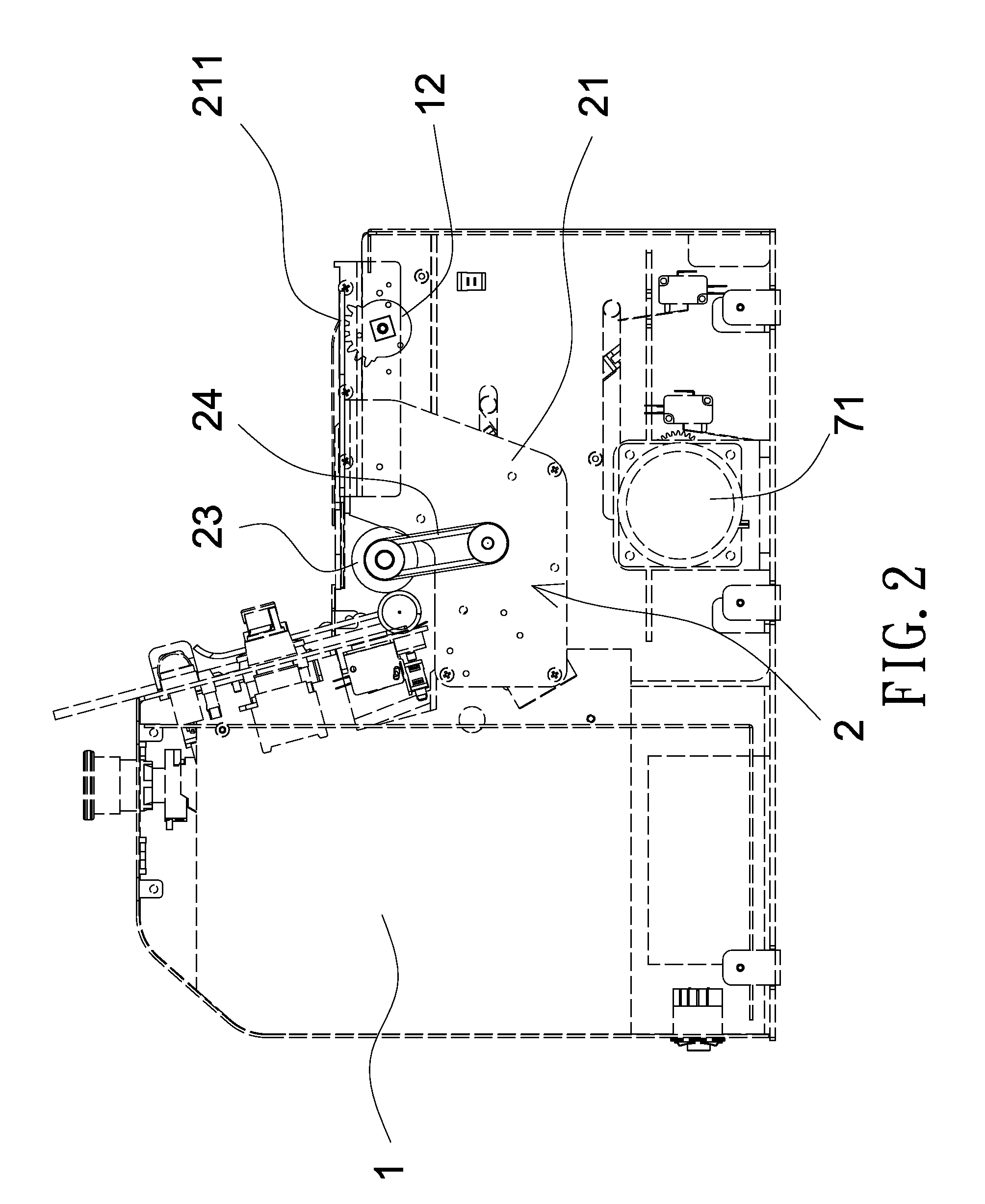

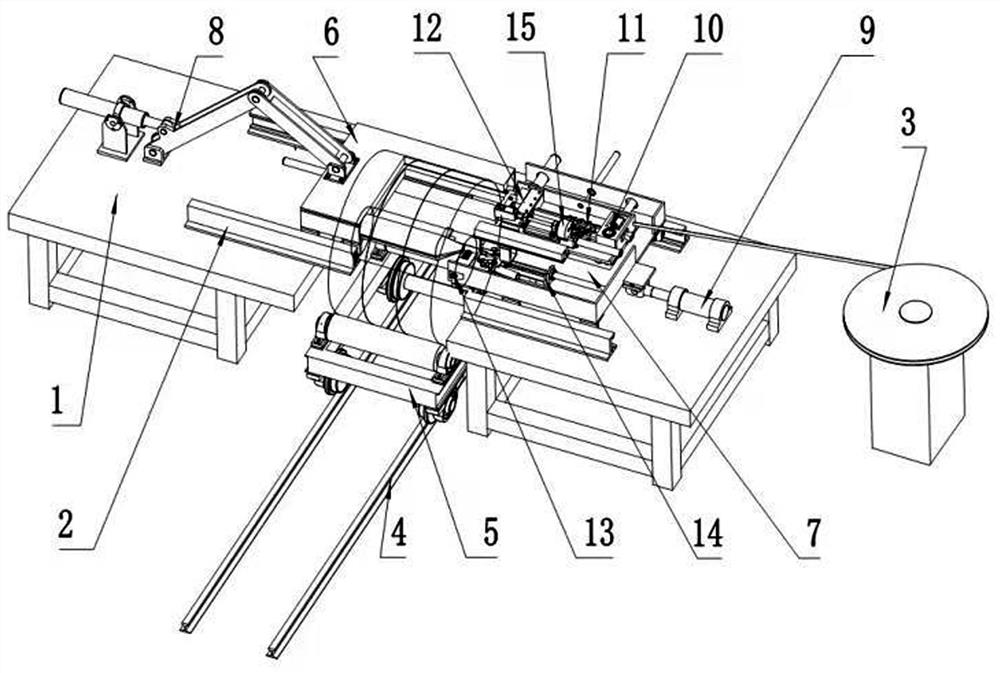

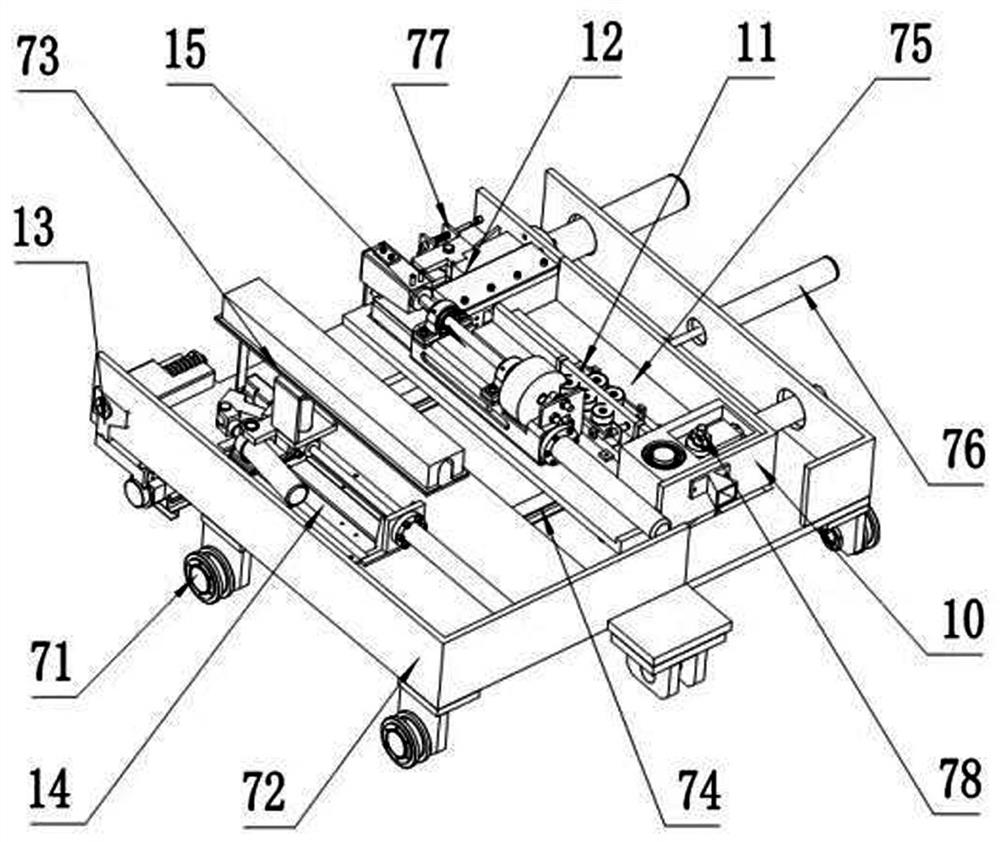

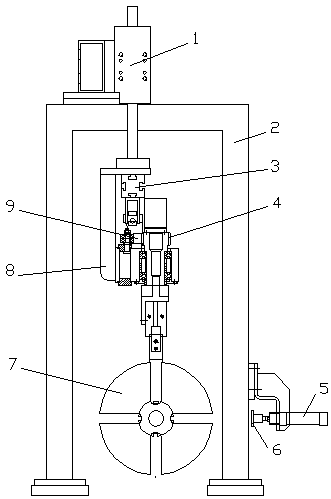

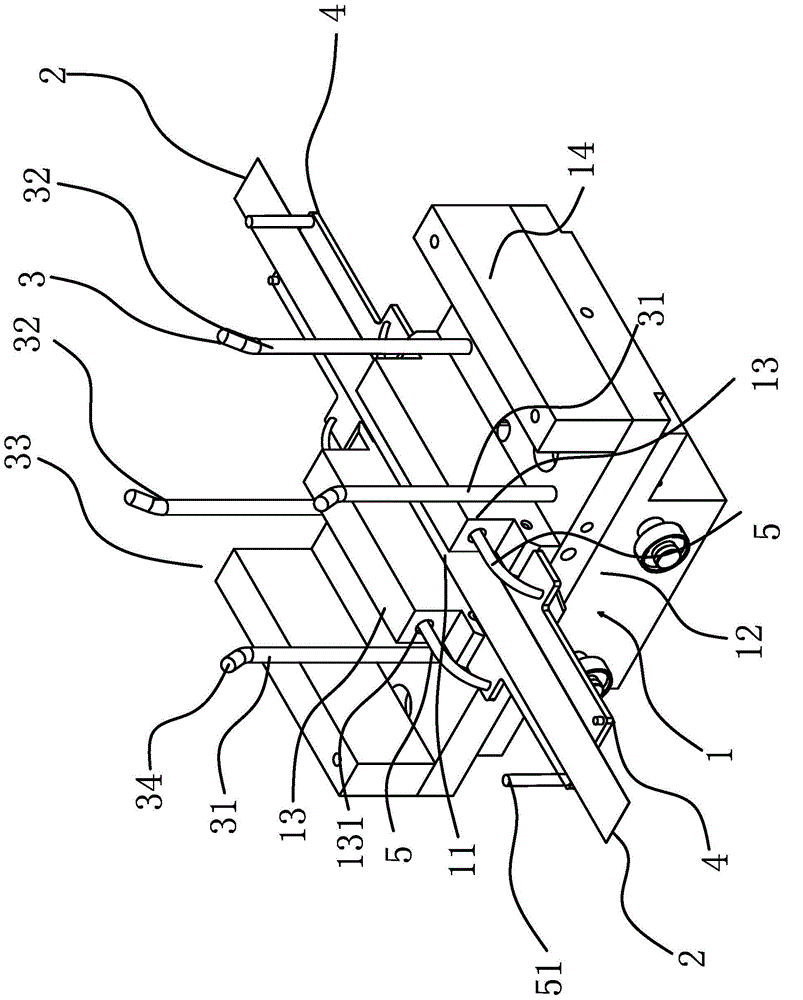

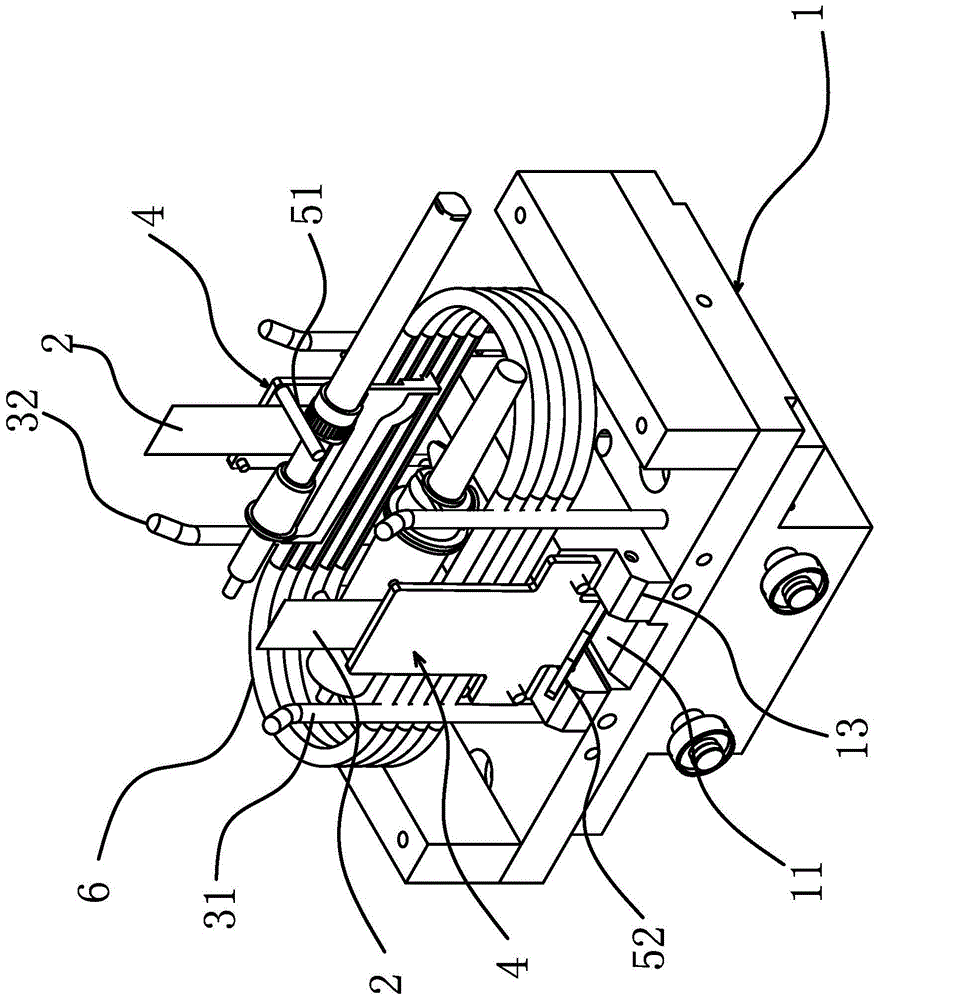

Rotor coil binding machine of wind power generator

InactiveCN101707421AFit tightlySufficient clamping rangeManufacturing dynamo-electric machinesWind energy generationCoil bindCoupling

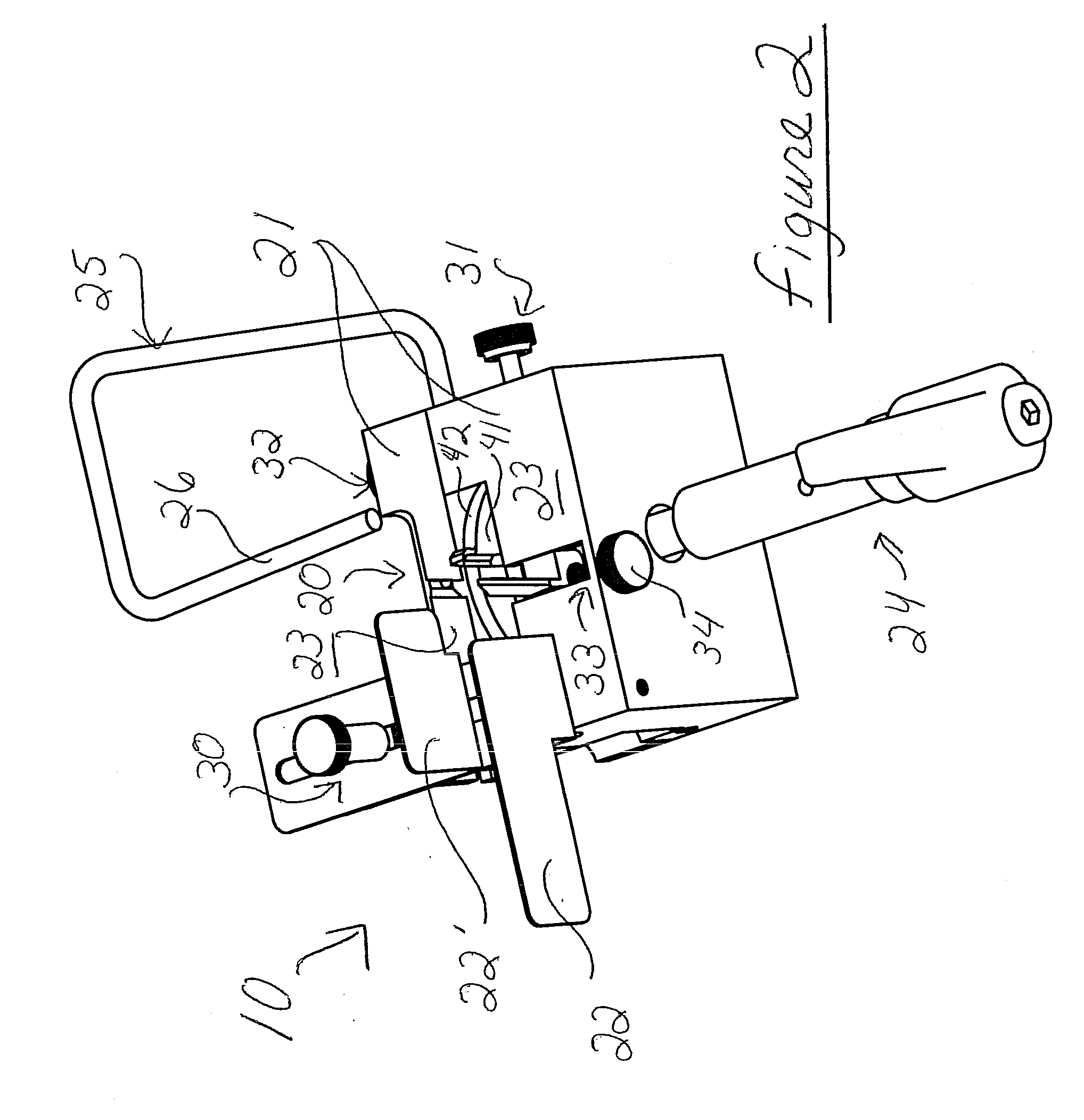

The invention relates to the technology of rotor coil binding of generators, in particular to a rotor coil binding machine of a wind power generator. The invention solves the problems of large labor intensity, low efficiency and difficult control of quality caused by manual binding because of the insulation of the rotor coil of the traditional wind power generator. The rotor coil binding machine of the wind power generator comprises a numerical control system, a stand, a feeding system, a rotor coil clamping synchronous device and a lapping head, and mainly comprises a servo motor, a decelerator, a ball screw, as well as a trailing plate and a linear guide rail connected by a shaft coupler, a synchronous driving pulley, a synchronous driven pulley and a synchronous belt, wherein the synchronous belt with a tension wheel is arranged on the synchronous driven pulley, the shaft coupler is arranged between synchronous transmission pulleys at the bottom end, and the synchronous driving pulley and the synchronous driven pulley at the upper end are respectively provided with a rocking arm, a left clamp rod, a right clamp rod and a clamp. Compared with the binding machine in the prior art, the rotor coil binding machine of the wind power generator has reasonable structure, favorable effect and optimal cost performance.

Owner:CRRC YONGJI ELECTRIC CO LTD

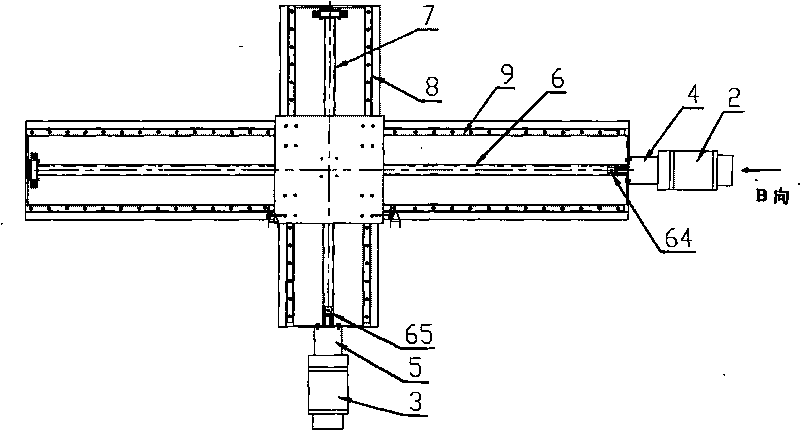

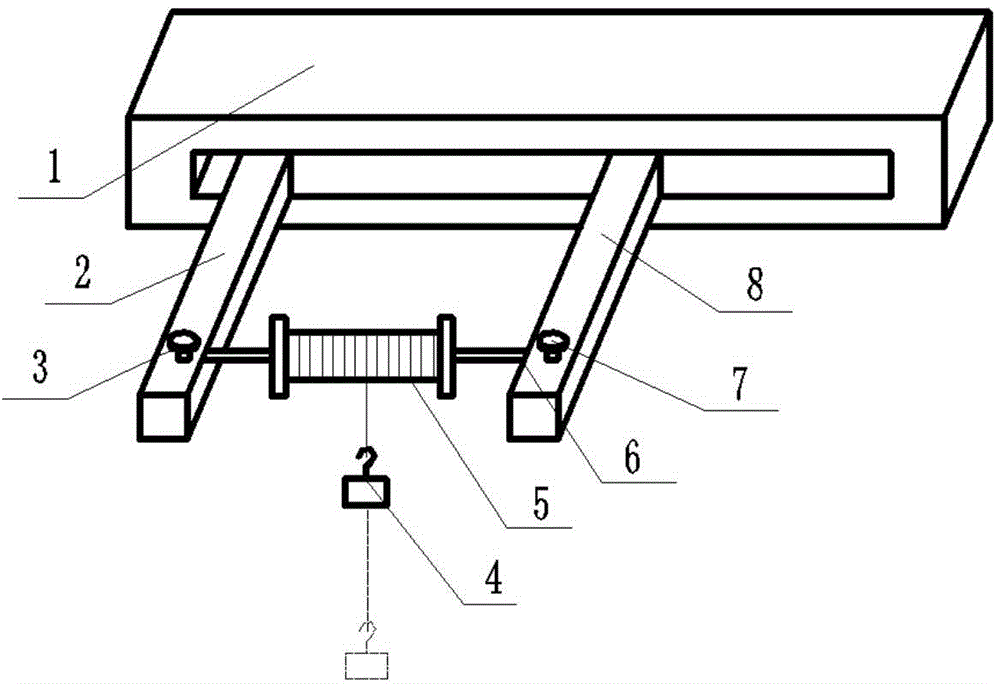

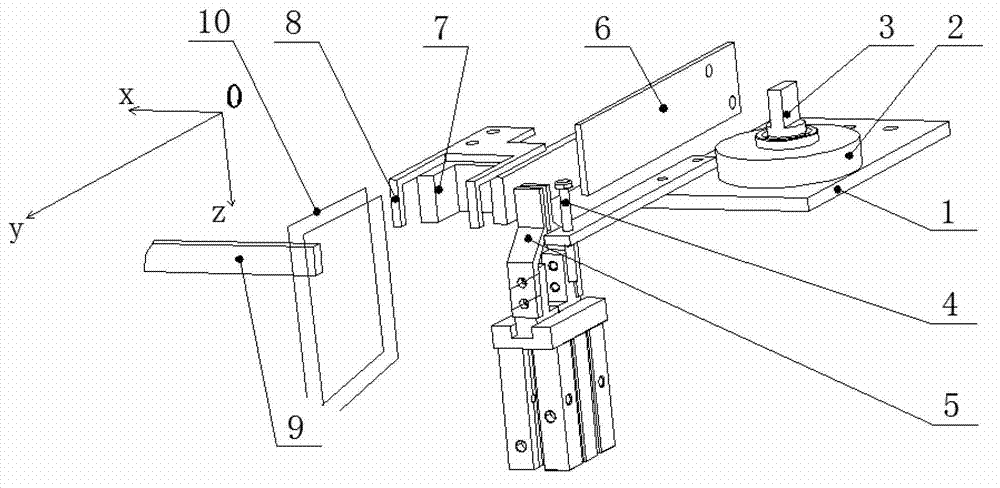

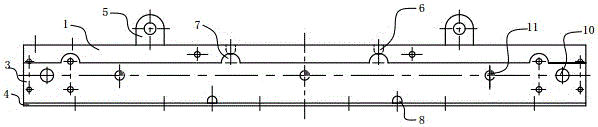

A tool for testing bobbin coil binding power and a method therefor

ActiveCN105651687AAdjust the cohesion valueCohesion value quantification and controlUsing mechanical meansMaterial analysisCoil bindBobbin

The invention relates to a tool for testing bobbin coil binding power and a method therefor. The tool comprises a guide rail base (1), a first suspended rod (2), a first lock screw (3), a load (4), a bobbin coil (5), a central spindle (6), a second lock screw (7) and a second suspended rod (8). At the tangential direction of the outmost coil layer of the bobbin coil (5), the load (4) is hung on a self-adhesive varnished wire at an end of the bobbin coil (5), the weight of the load (4) is increased gradually until the self-adhesive varnished wire on which the load (4) is hung is separated from the bobbin coil (5), and then the weight of the load (4) is a binding power value of the outmost coil layer of the bobbin coil (5). Through results of coil binding power testing, heating temperature and heating time in heat bonding process parameters can be adjusted, and therefore binding power values of bobbin coils can be quantified and controlled.

Owner:FLIGHT AUTOMATIC CONTROL RES INST

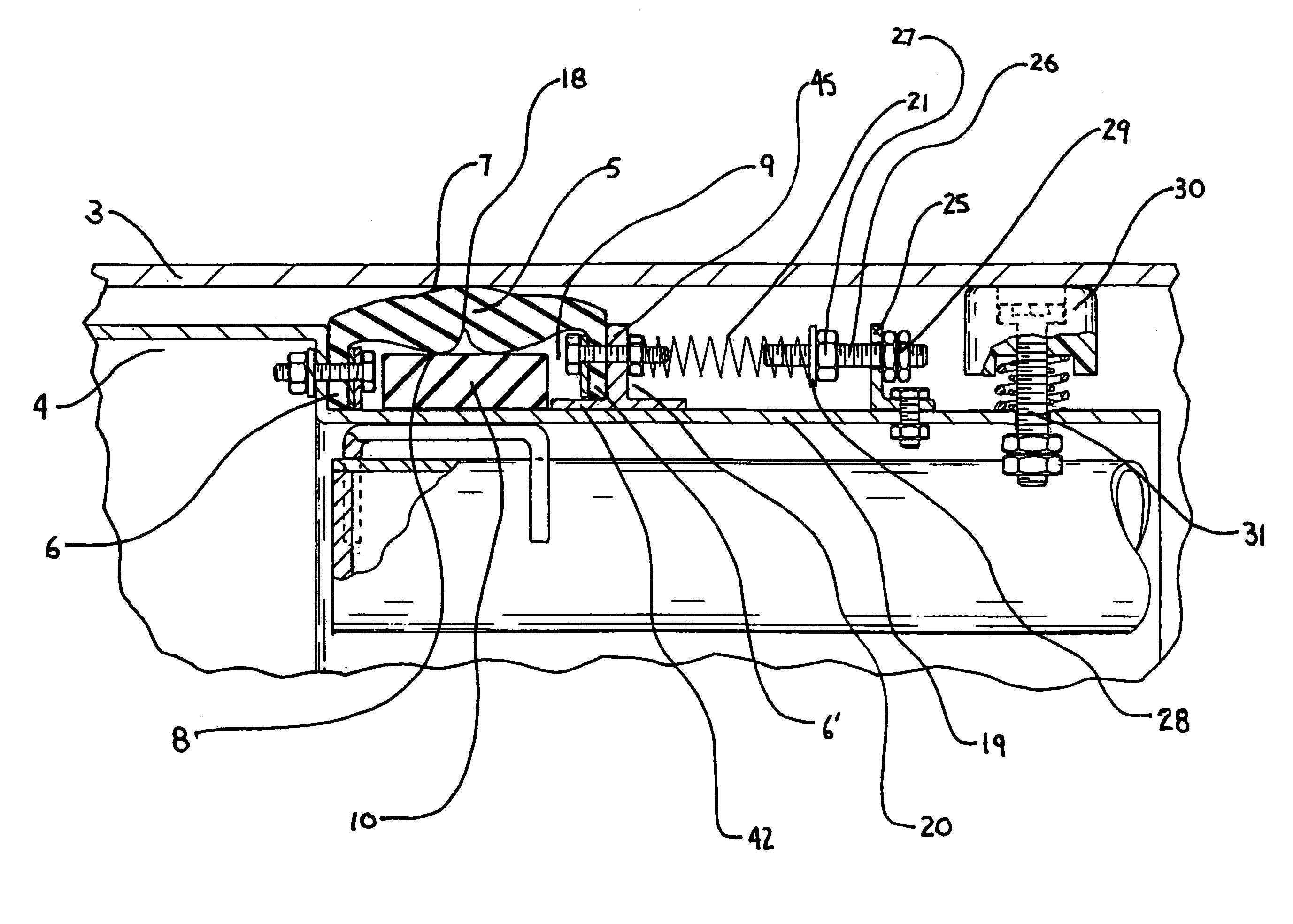

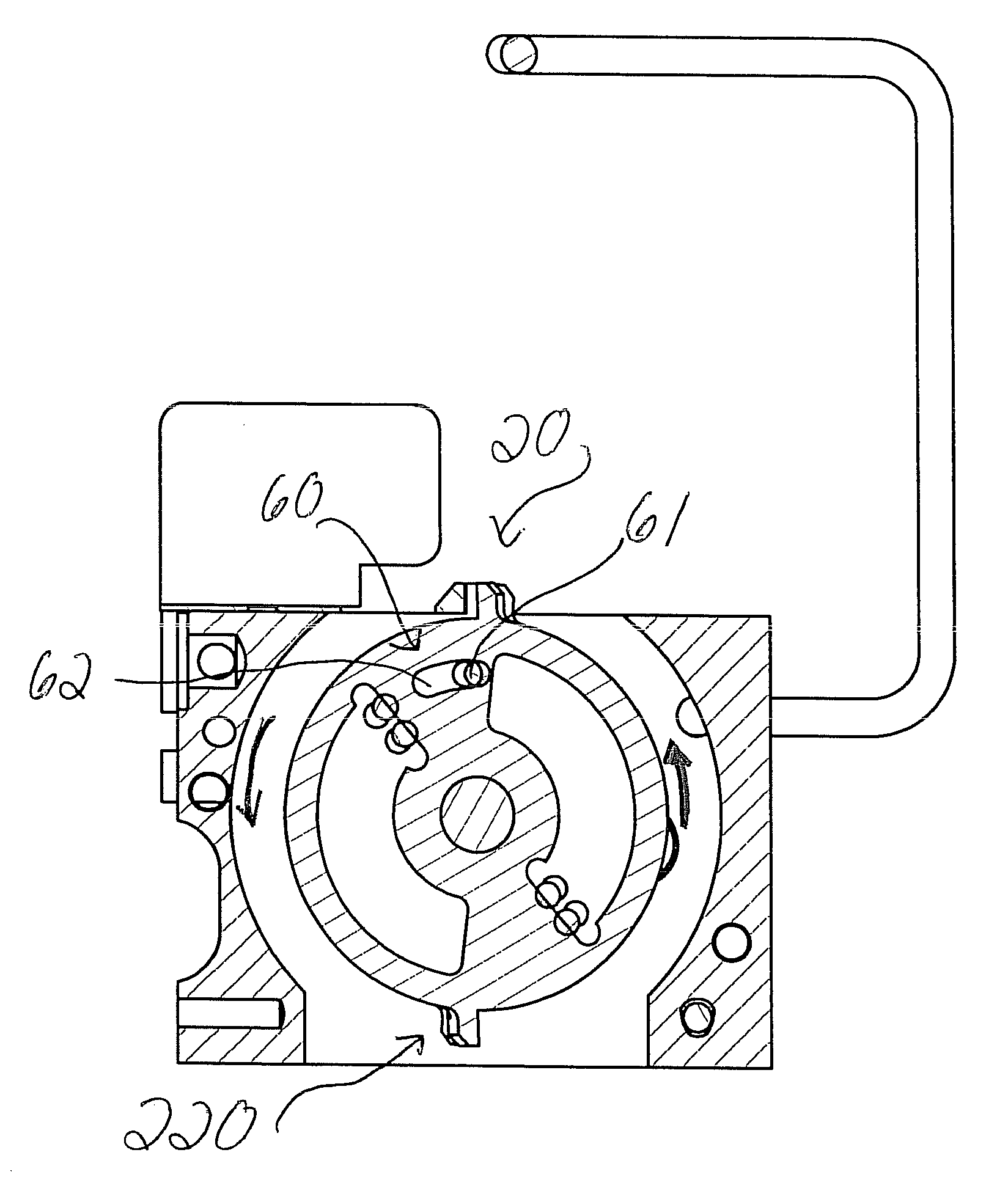

Tank piston seal and stabilizing system

An improved seal and stabilizing system for a piston head in a tank cylinder provides a better mechanism for discharging and wiping a cylinder when heavy liquids such as chocolate or peanut butter are being dispensed. The seal system now includes a free-floating block inside the seal and grooves in the inner lower part of the hollow seal. The block and grooves keep the upper, outer part of the seal from deforming away from the inner surface of the cylinder that facilitates complete discharging and wiping of the material from the cylinder tank. The tensioning mechanism of the seal is made from a unitary and annular ring T-ring that easily slides on the rear surface of the piston head. In order to stabilize the movement of the piston head down the cylinder, clockwise and counterclockwise springs are provided for the stabilizing shoes. The dual spring arrangement prevents coil binding of the springs. The springs and stabilizing shoes maintain the piston head cross section parallel to the cross section of the cylinder.

Owner:PISTON TANK CORP

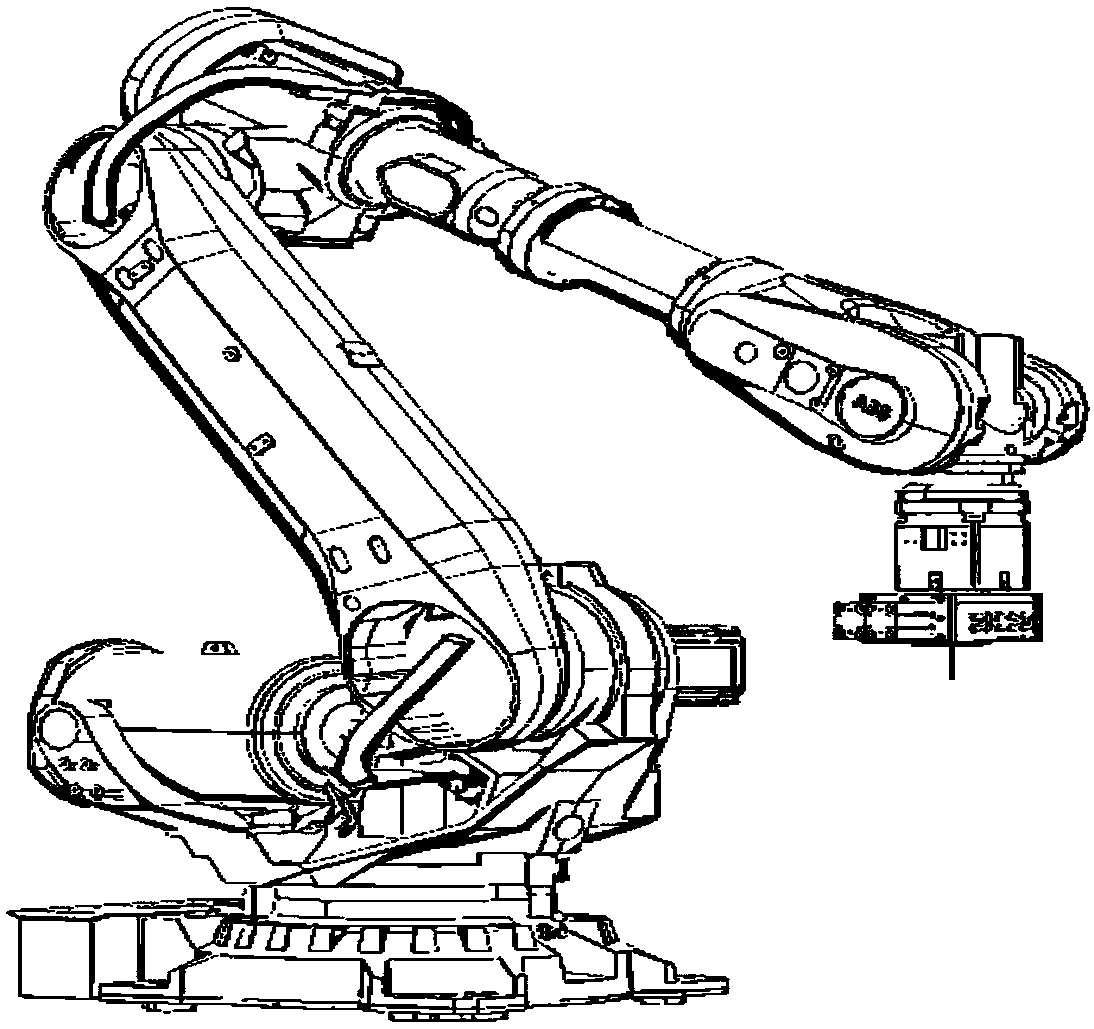

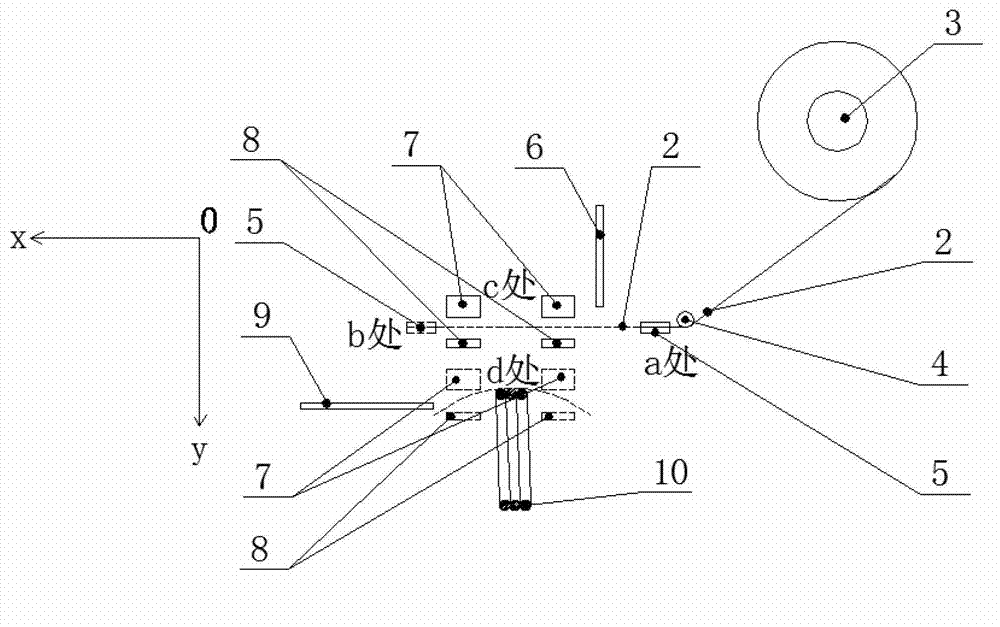

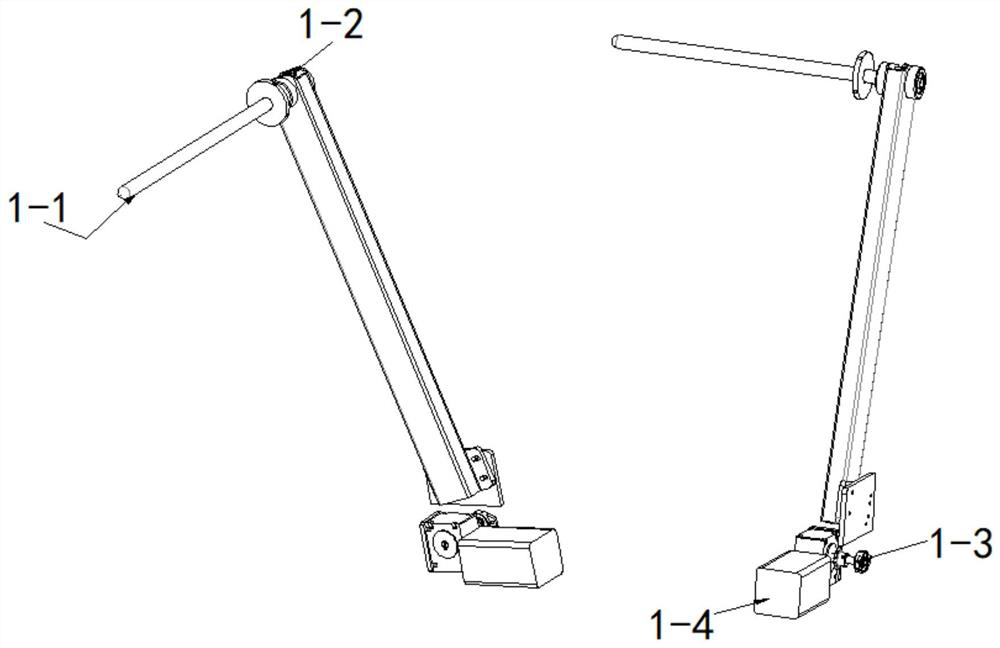

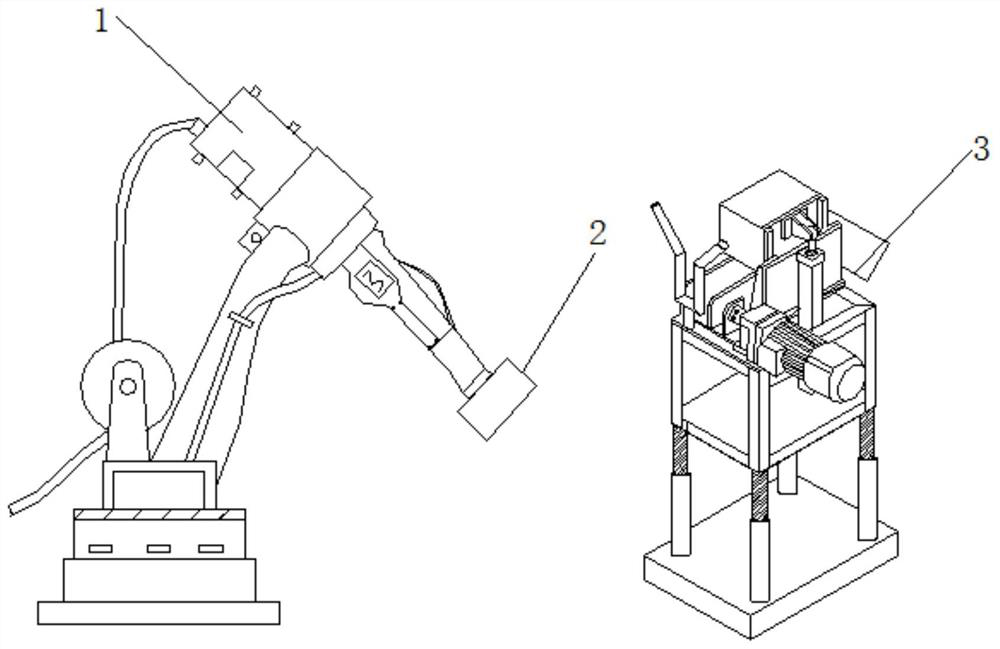

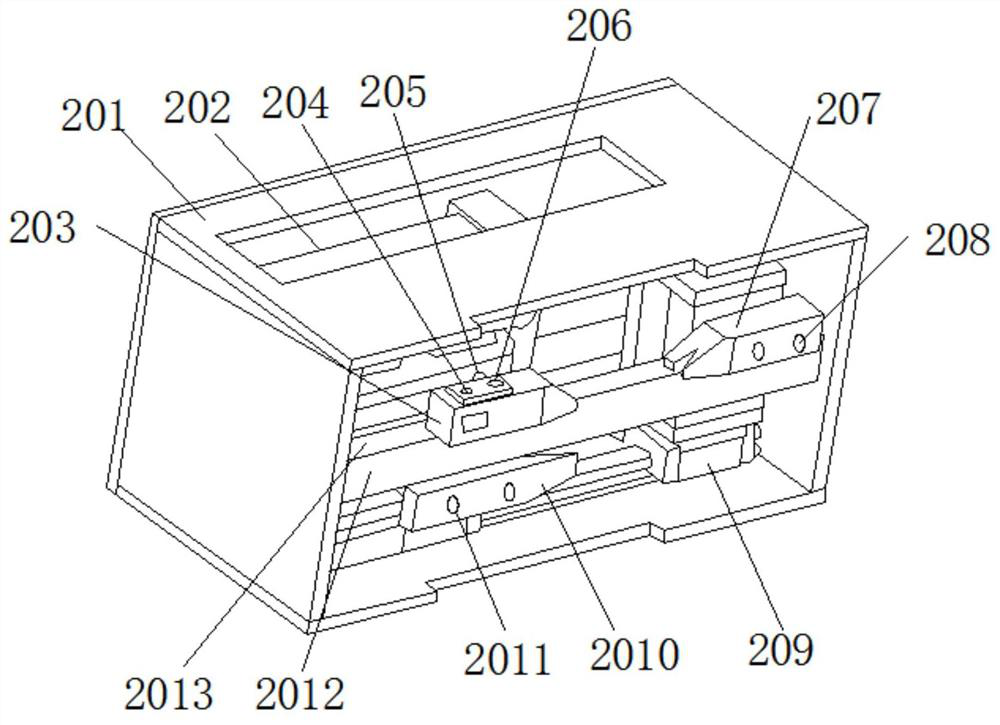

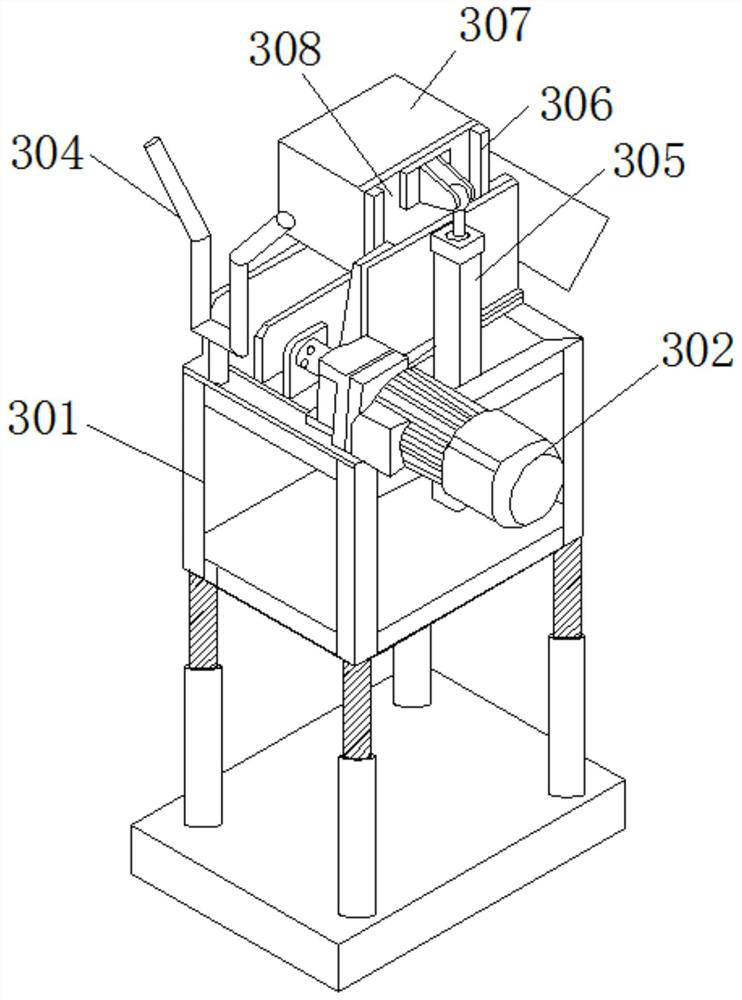

Full-automatic steel coil unbaling robot and control method thereof

InactiveCN109775068AImprove compatibilityRealize automatic positioningArticle unpackingManipulatorProduction lineAutomatic control

The invention provides a full-automatic steel coil unbaling robot and a control method thereof. A robot body, a binding belt shearing deice, a binding belt recycling device, a control cabinet and a driving device are included, wherein the binding belt shearing device is arranged on a mechanical arm of the robot body, and comprises a clamping knife and a shearing knife; the binding belt recycling device is used for recycling a steel coil binding belt; the driving device drives movement of the binding belt shearing device and the binding belt recycling device; the control cabinet comprises a robot control cabinet and a PLC control cabinet; and the robot control cabinet controls movement of the mechanical arm, and the PLC control cabinet controls the driving device. The full-automatic steel coil unbaling robot is high in compatibility, and steel coil binding belts in different types can be treated; the full-automatic steel coil unbaling robot achieves automatic positioning and recognizingunbaling and recycling of the steel coil binding belt, and achieves continuous production of automatic control of a production line, and is high in mechanical precision, and fast and efficient; and unbaling of the steel coil binding belt is achieved through a full-automatic control mode, the production efficiency is greatly improved, the labor cost is lowered, and safety accidents are reduced.

Owner:SHANGHAI BAOSIGHT SOFTWARE CO LTD

Coil car

The invention discloses a coil car, comprising a car body, a walking mechanism, a lifting seat and a lifting cylinder, wherein the walking mechanism is arranged on the car body; the lifting seat is arranged above the car body; and the lifting cylinder is fixed at the middle of the car body and controls the lifting seat to lift. The coil car is characterized in that the top of the lifting seat is V-shaped; two lining boards are respectively fixed at two opposite V-shaped inclined planes; and a gap required by a coil binding strip is preserved between the two lining boards on the two inclined planes. A large lifting stroke of the V-shaped lifting seat can be achieved; and the arranged lining boards not only play a role of protecting the finished strip, but also are convenient to bind the coil or dismantle the binding strip. The whole coil car is easy to manufacture and install, hollow in foundation pit, suitable for hot rolling of the coil and cold rolling of the coil, suitable for production lines such as a pickling line, a cold mill unit and a rewinding unit, and wide in application; the foundation construction is reduced; and the cost is also reduced.

Owner:WISDRI ENG & RES INC LTD

Automatic Book Coil Binding Machine

An automatic book coil binding machine comprising a table, a driving motor, a paper clipping apparatus, a linkage apparatus, a paper alignment apparatus, a coil guiding apparatus and a coil cutting apparatus is provided. When the paper clipping apparatus is driven by the driving motor and the linkage apparatus to a paper clipping position, the paper alignment apparatus is simultaneously driven to locate at a paper detaching position. The coil guiding apparatus is then driven to a guiding position to lead a coil in. The coil cutting apparatus moves to a cutting position to cut the coil at the predetermined position. Thus, the book and the coils are able to be bound rapidly and precisely.

Owner:CHUNG SHEEN TECH

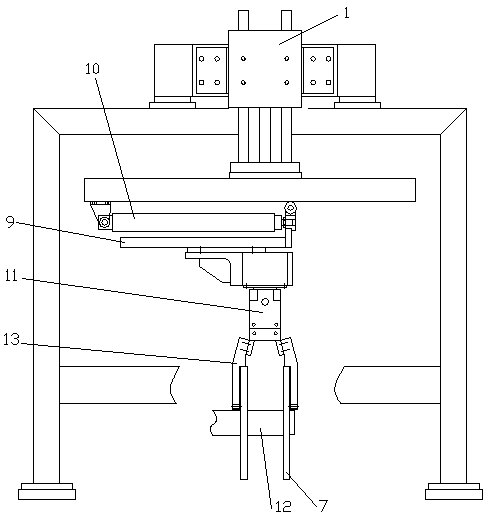

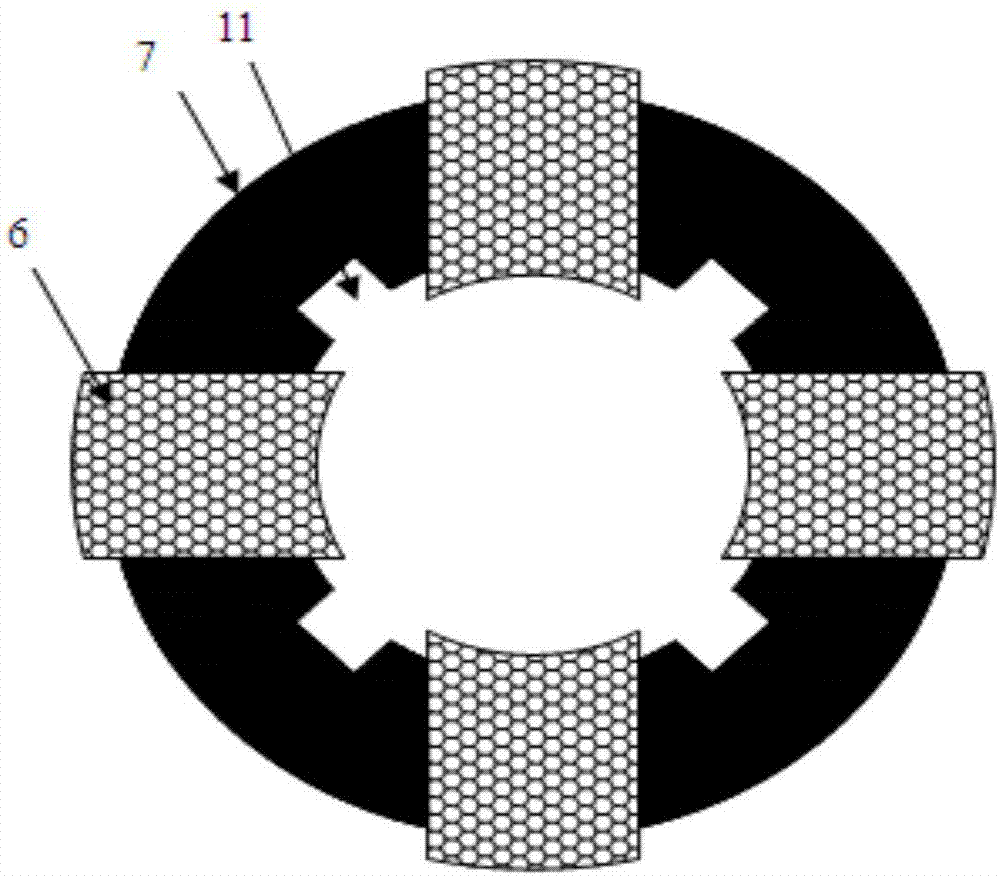

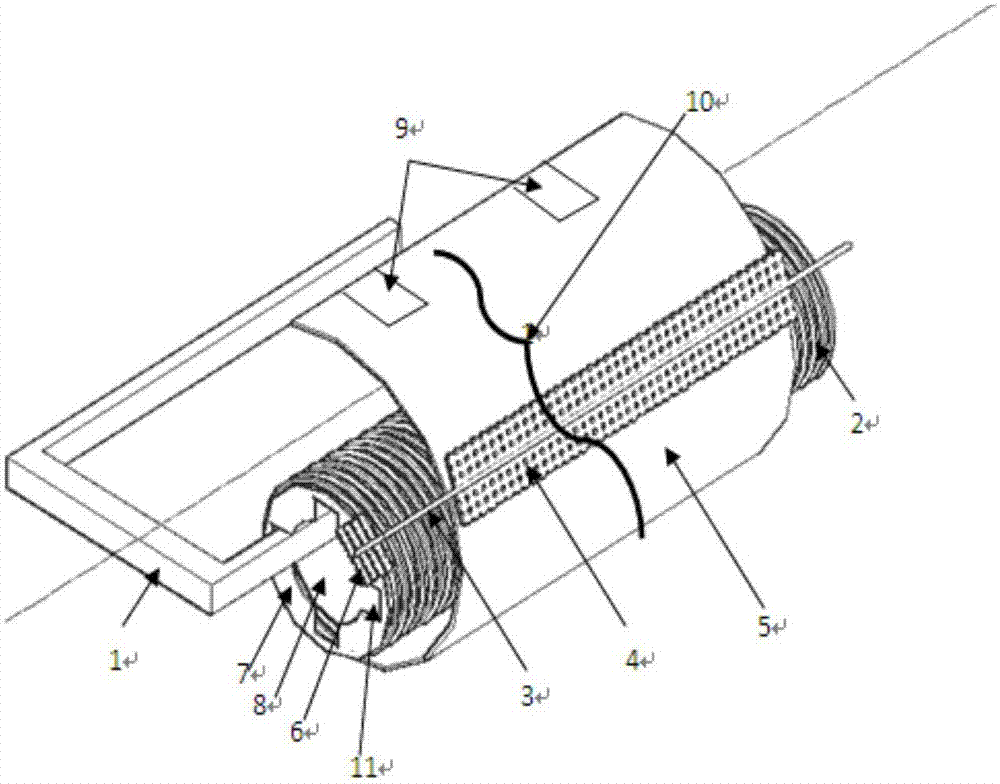

Automatic coil binding device and stator coil winding machine with the same installed

InactiveCN103929019AHigh degree of automationManufacturing dynamo-electric machinesWinding machineSpiral binding

The invention aims to provide an automatic coil binding device and a stator coil winding machine with the same installed, wherein the stator coil winding machine can automatically complete coil winding, coil binding and coil unloading. The automatic coil binding device comprises an adhesive tape preparing device, an adhesive tape cut-off device, an adhesive tape feeding device and an adhesive tape coil binding device. The stator coil winding machine comprises the automatic coil binding device, and further comprises a baffle, a coil winding device, a coil die advancing and retreating device and a coil clamping and shearing device. A coil die in the coil die advancing and retreating device is arranged within a rotation range of a coil winding rod of the coil winding device. A movable coil clamping block in the coil clamping and shearing device and a fixed coil clamping block in the coil clamping and shearing device are installed above the coil die in the coil die advancing and retreating device and outside the rotation range of the coil winding rod in the coil winding device. The baffle and a coil binding rod in the automatic coil binding device are installed at the position of a notch in the coil die in the coil die advancing and retreating device and directly face a rear adhesive tape feeding clamp in the automatic coil binding device and a front adhesive tape feeding clamp in the automatic coil binding device, the baffle is located on the inner side of the notch, protrudes out to the outer side of the notch and is fixed onto a machine frame, and the coil binding rod is completely located on the inner side of the notch. By means of the automatic coil binding device and the stator coil winding machine, the degree of automation of stator coil winding is greatly increased.

Owner:佛山市顺德区恒日鑫电器有限公司

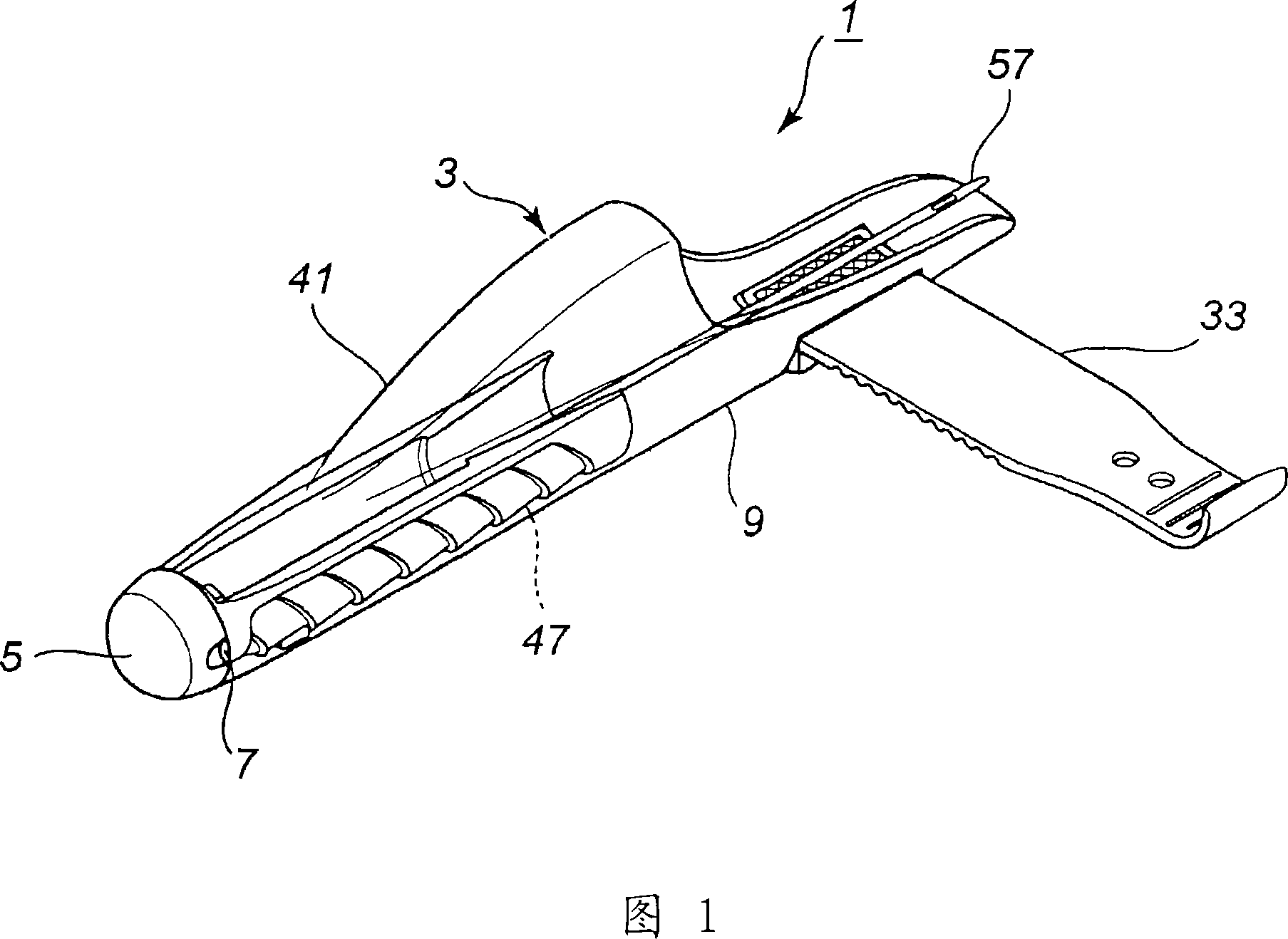

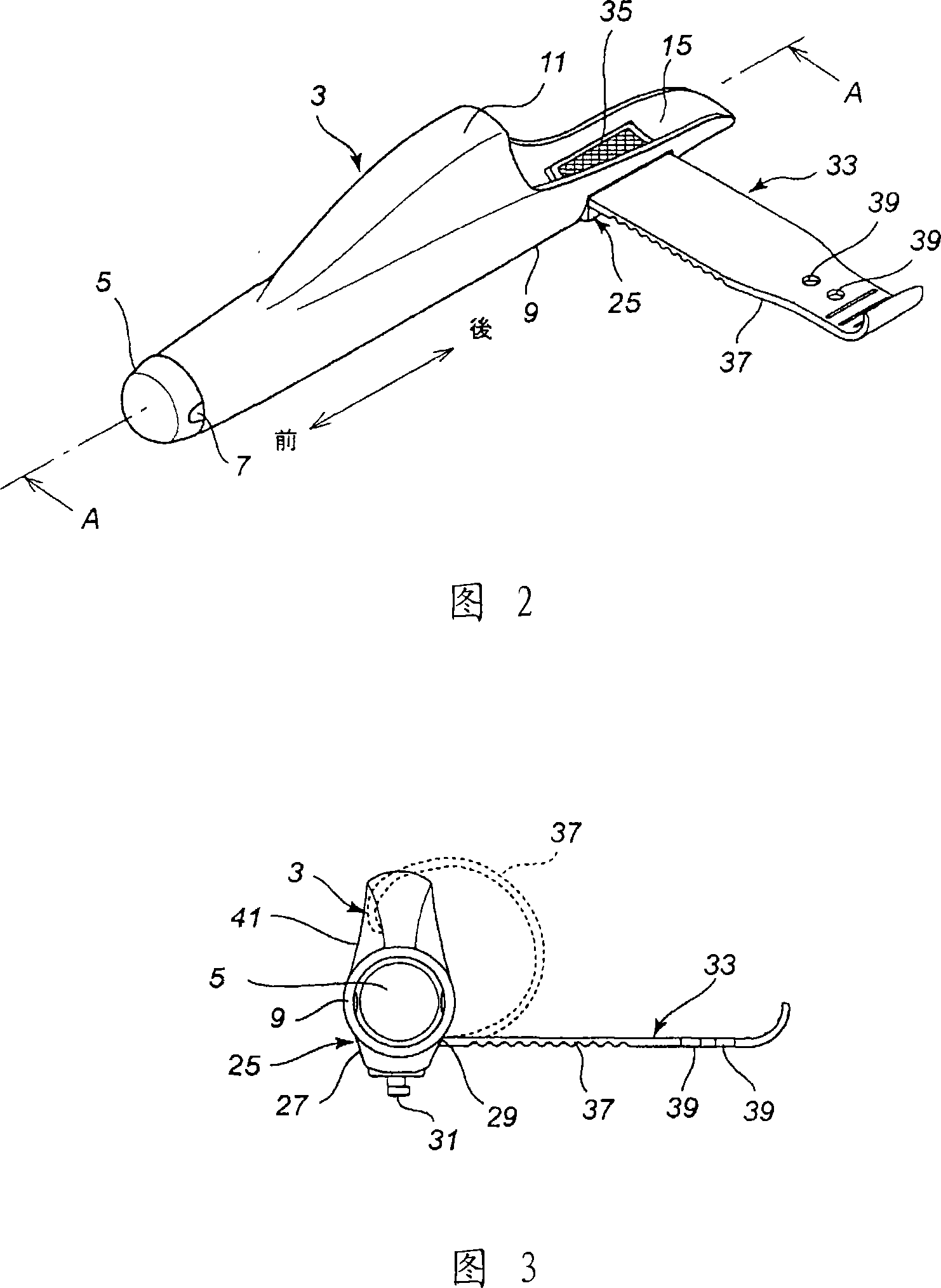

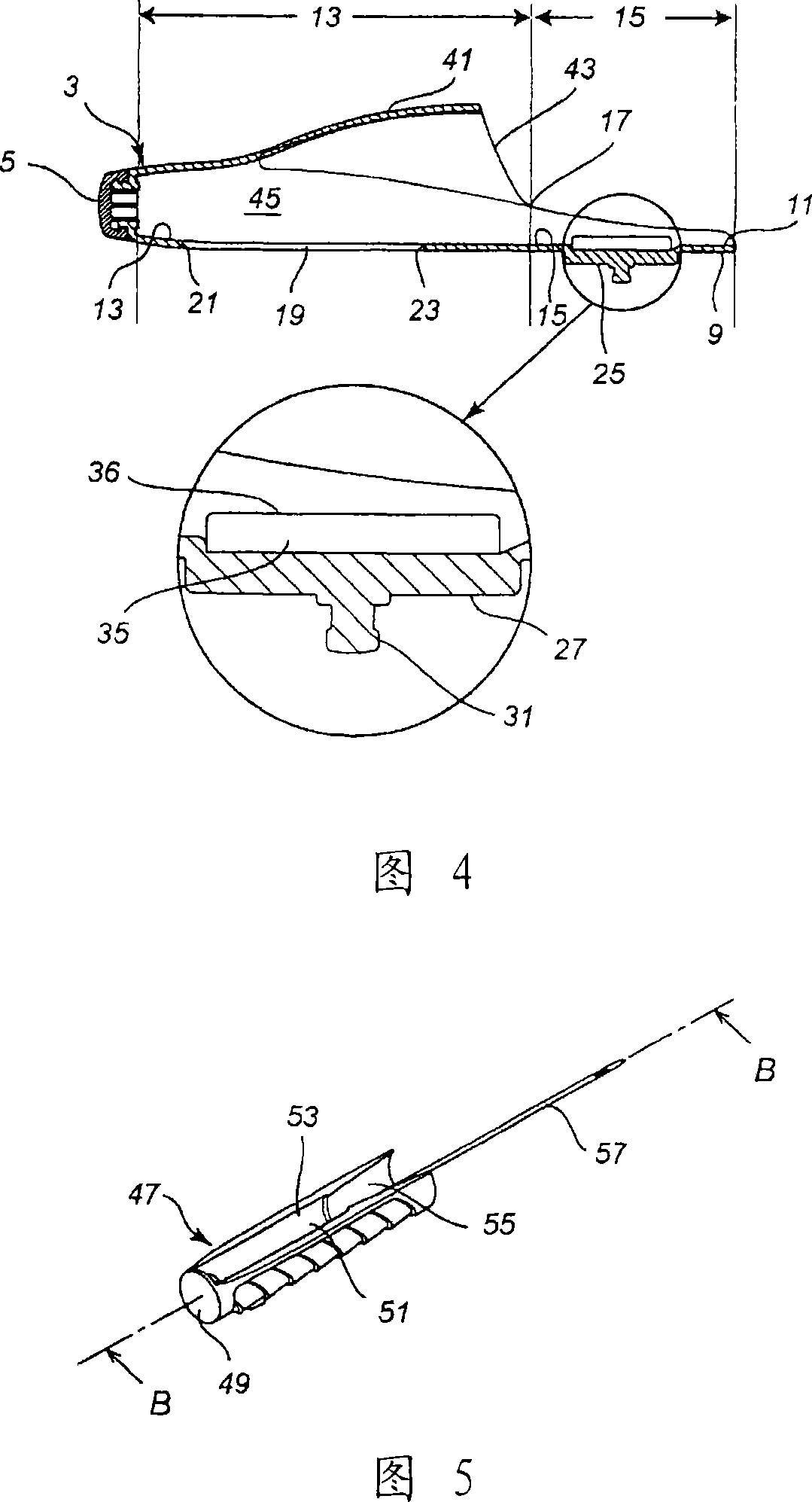

Crimper for binding coil

InactiveUS20080142110A1Easily and manually configuredEasily interchangeableWire articlesSheet bindingSpiral bindingEngineering

A crimper for spiral-binding coil comprises at least one, and preferably multiple, crimping assemblies including crimping elements that move generally parallel to each other to preferably cut, bend and / or reform an end of the coil for retaining the coil in the book or pamphlet. The movement of the crimping elements may be rotational in parallel planes, or translational in parallel lines. Preferably, multiple sets of crimping elements may be interchanged easily and without tools, for example, by being located on rotating members and are circumferentially spaced apart so that one set is used at a time. For each diameter of coil filament within the range of coil diameters for which a particular crimping set is designed, a member of the crimping assembly is adjusted to change the size / dimension(s) of the space into which the newly-cut end of the coil is forced, preferably adjusting that space to be slightly smaller than the diameter of the coil filament. This way, a bending member forces the newly-cut coil end against a bracing member and into the smaller space, and, in doing so, preferably heats, stretches, and generally reforms the end into a new crimped end that stays in that position over the use of the book.

Owner:PERFORMANCE DESIGN

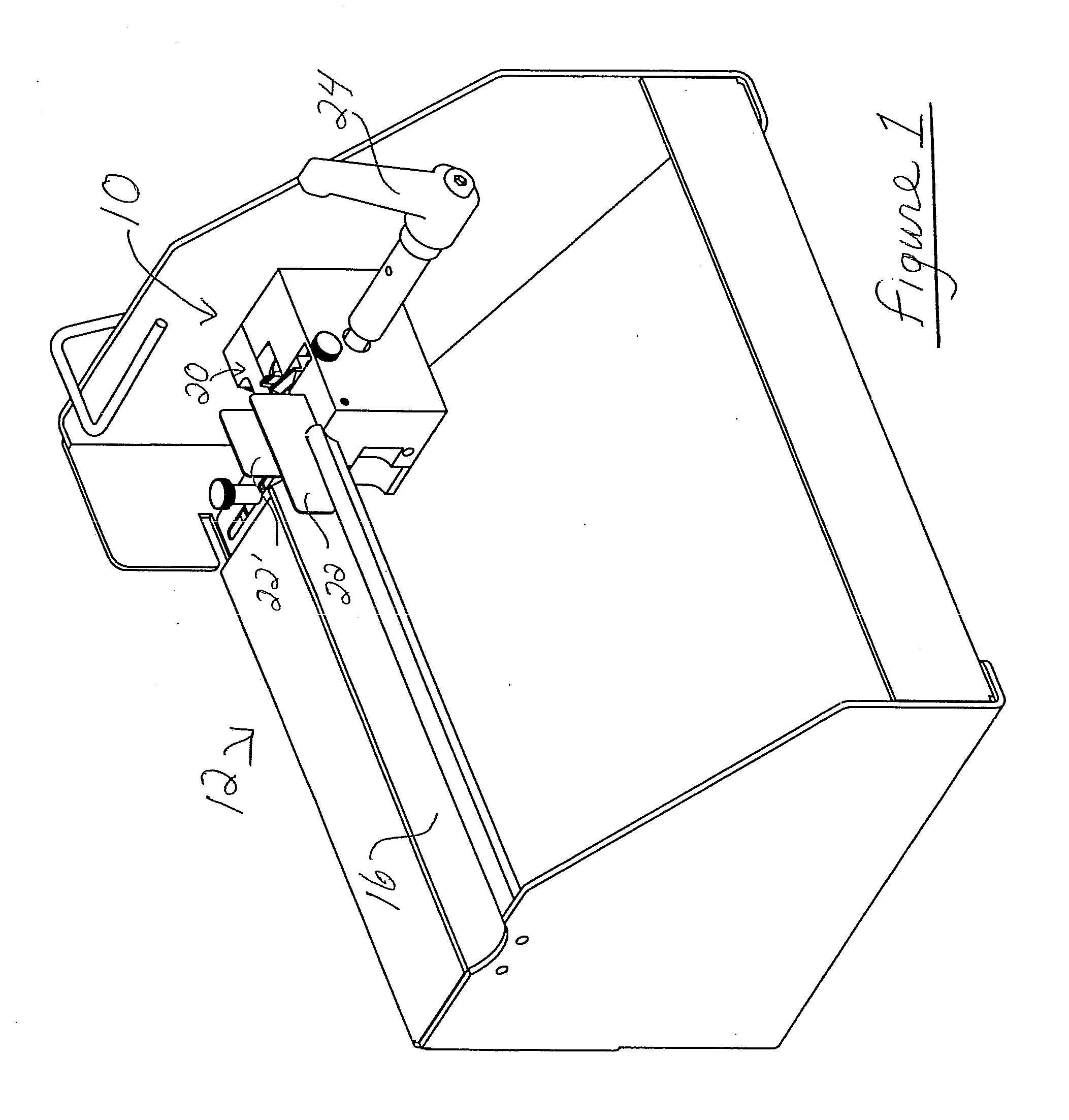

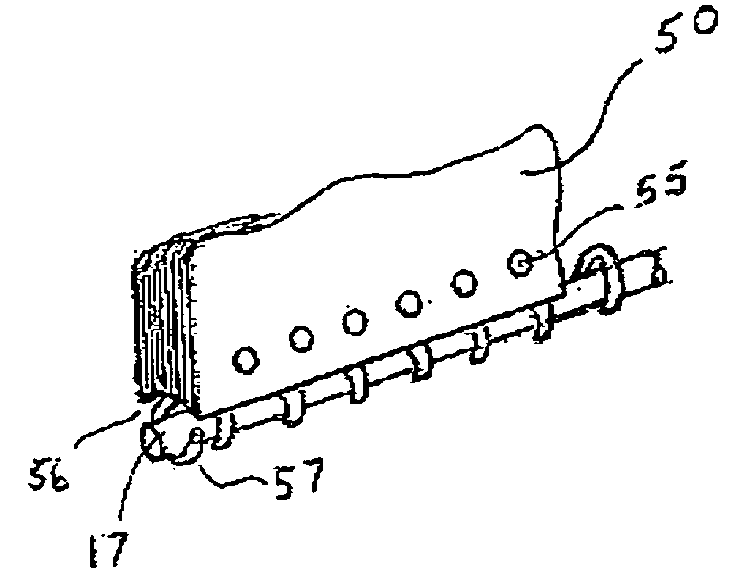

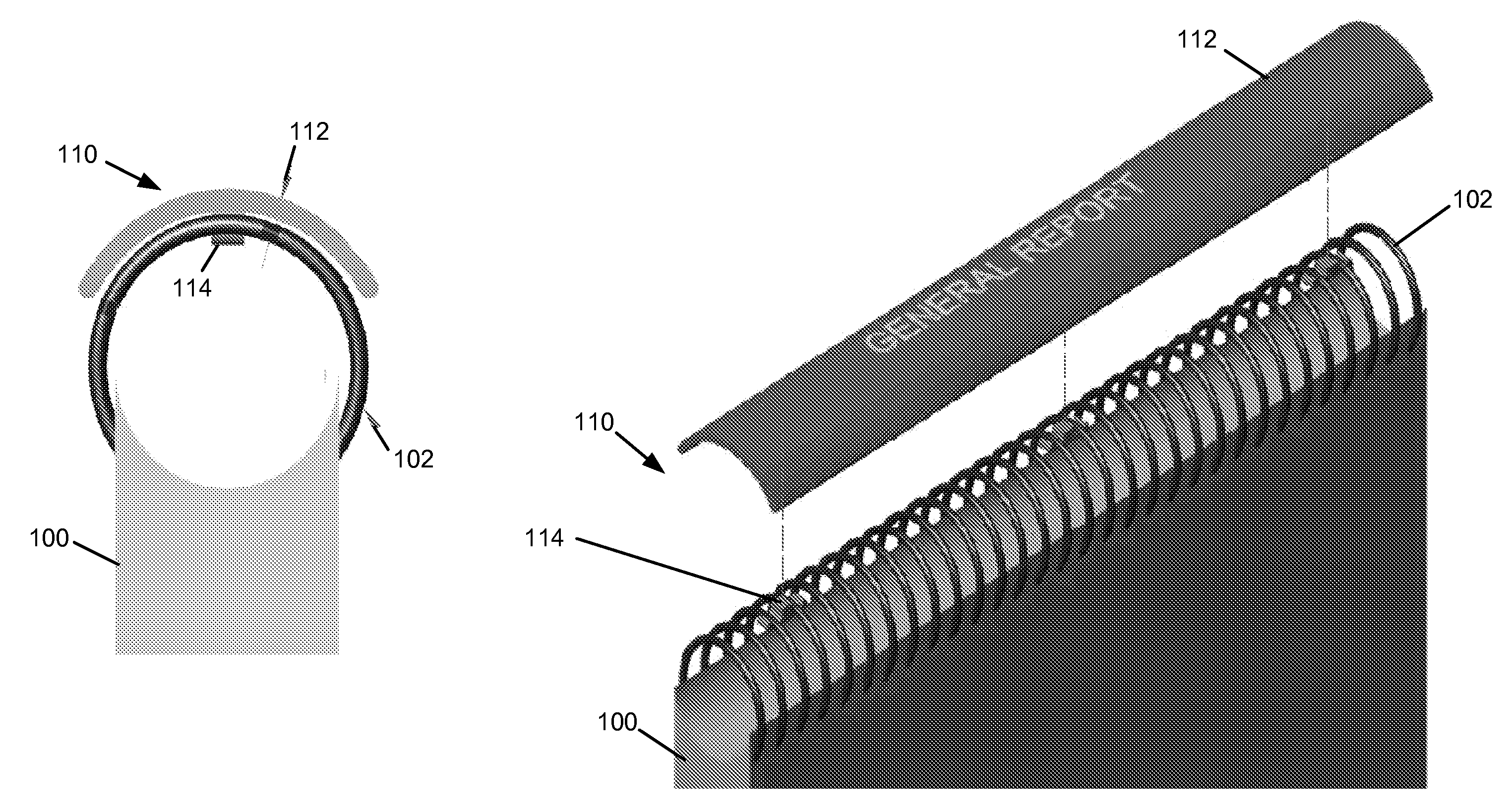

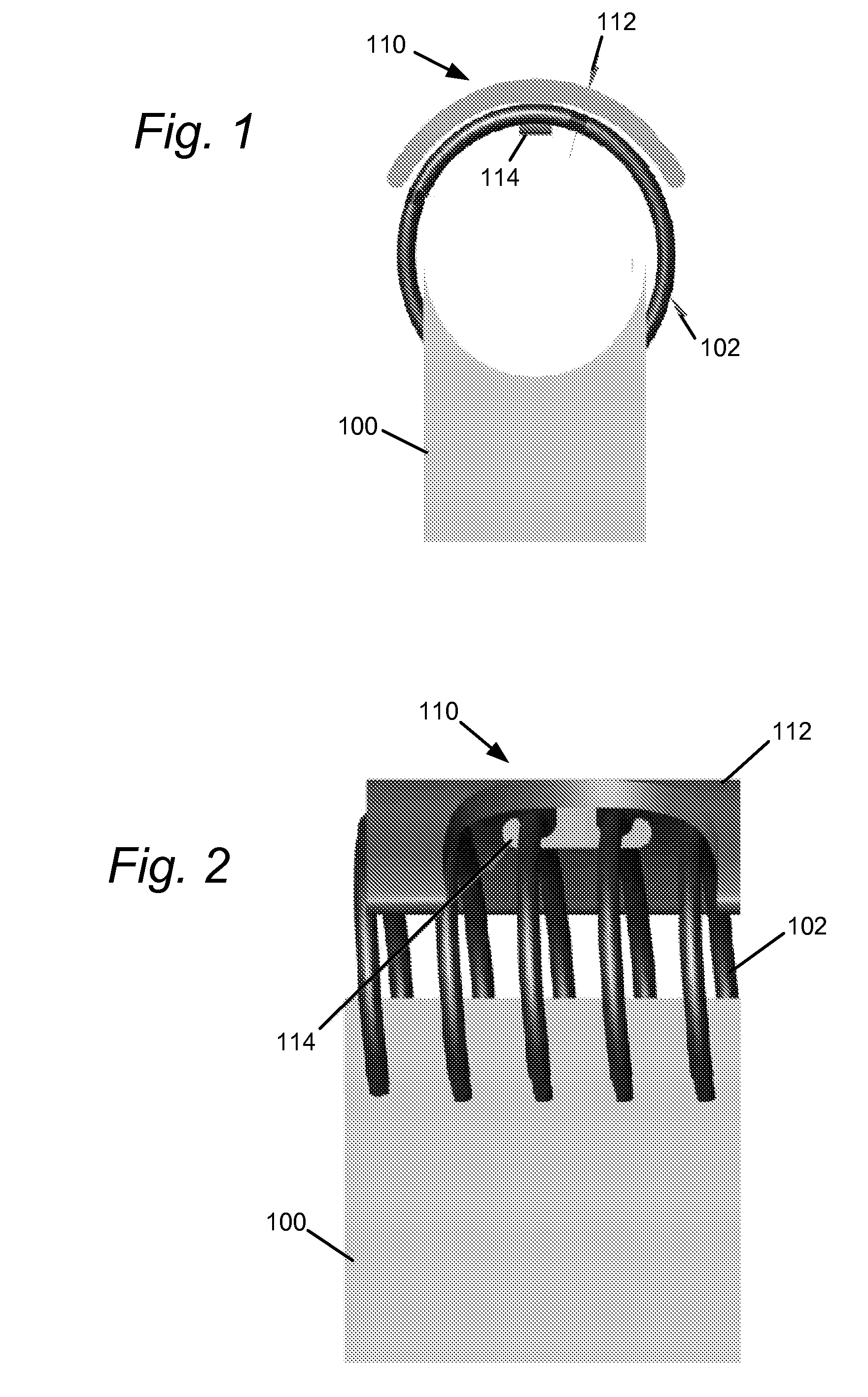

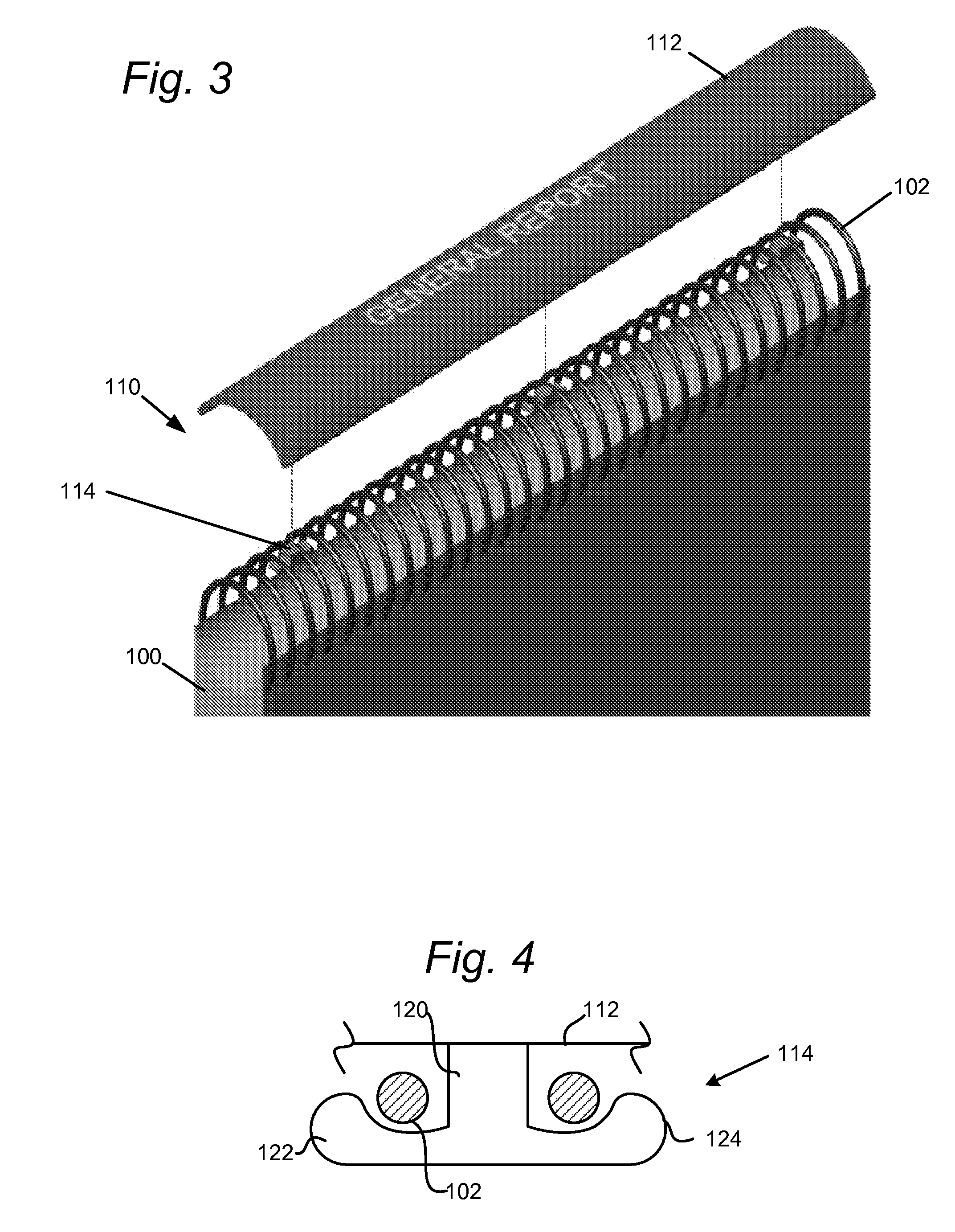

Labeling system for coil binders

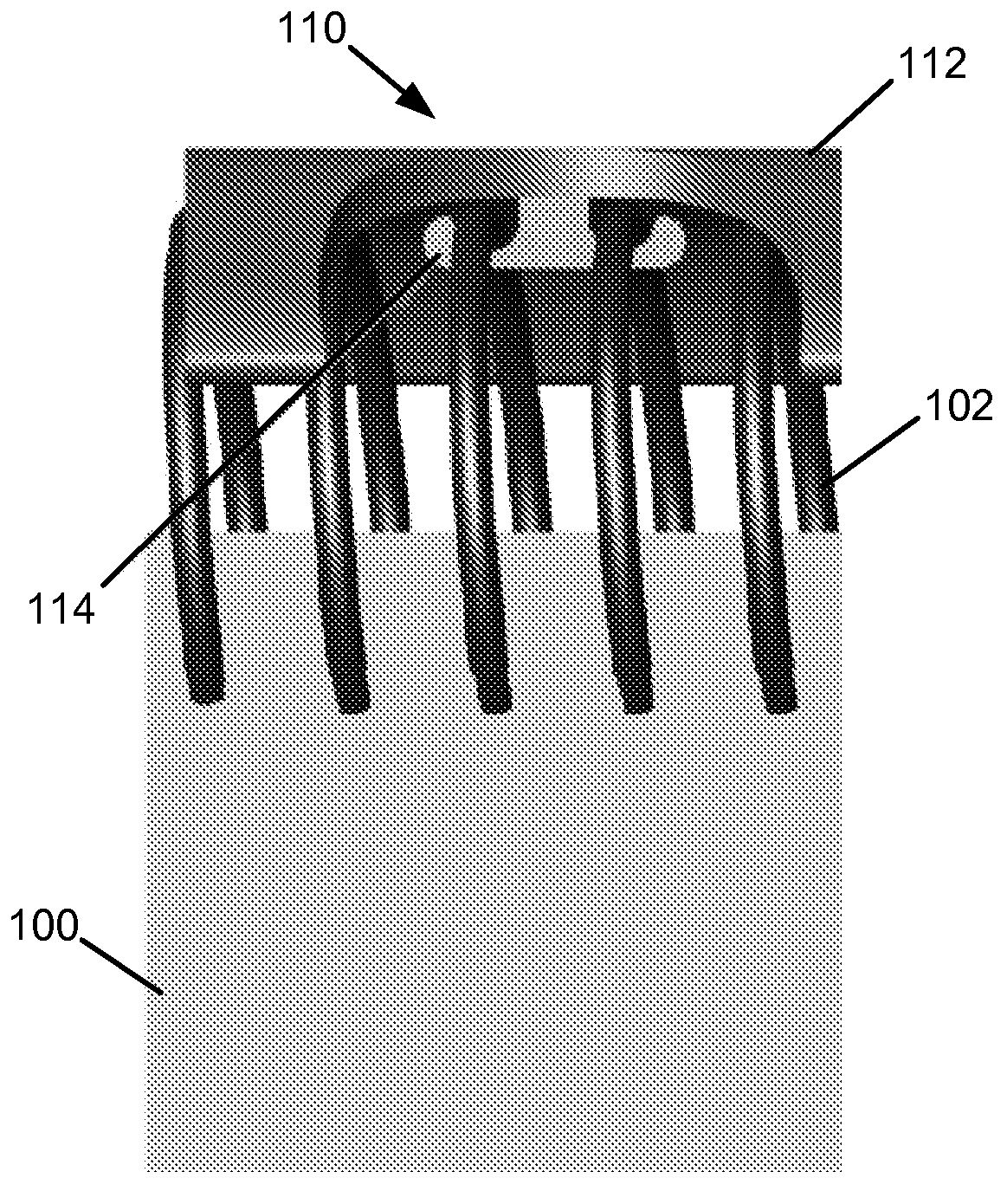

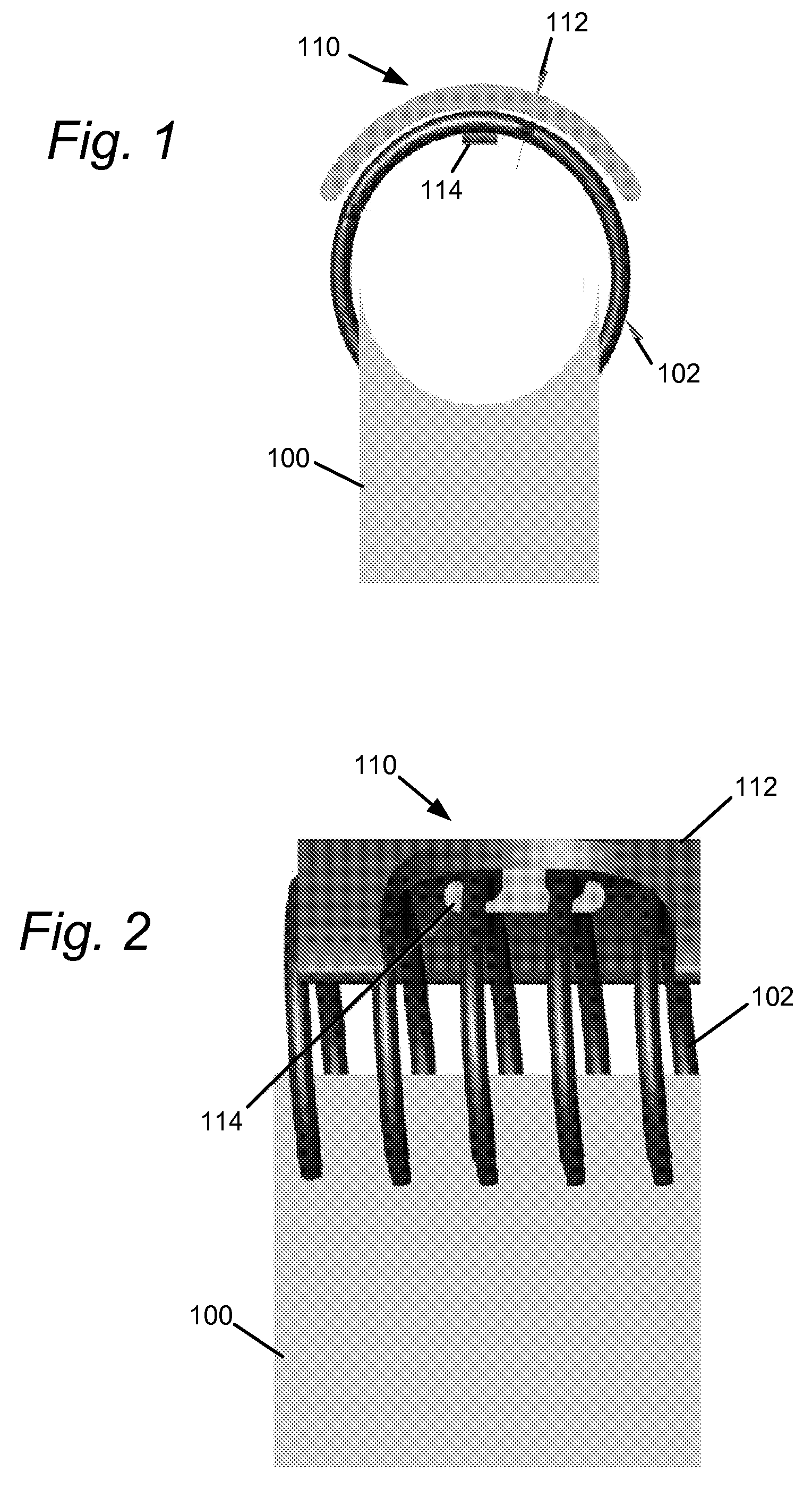

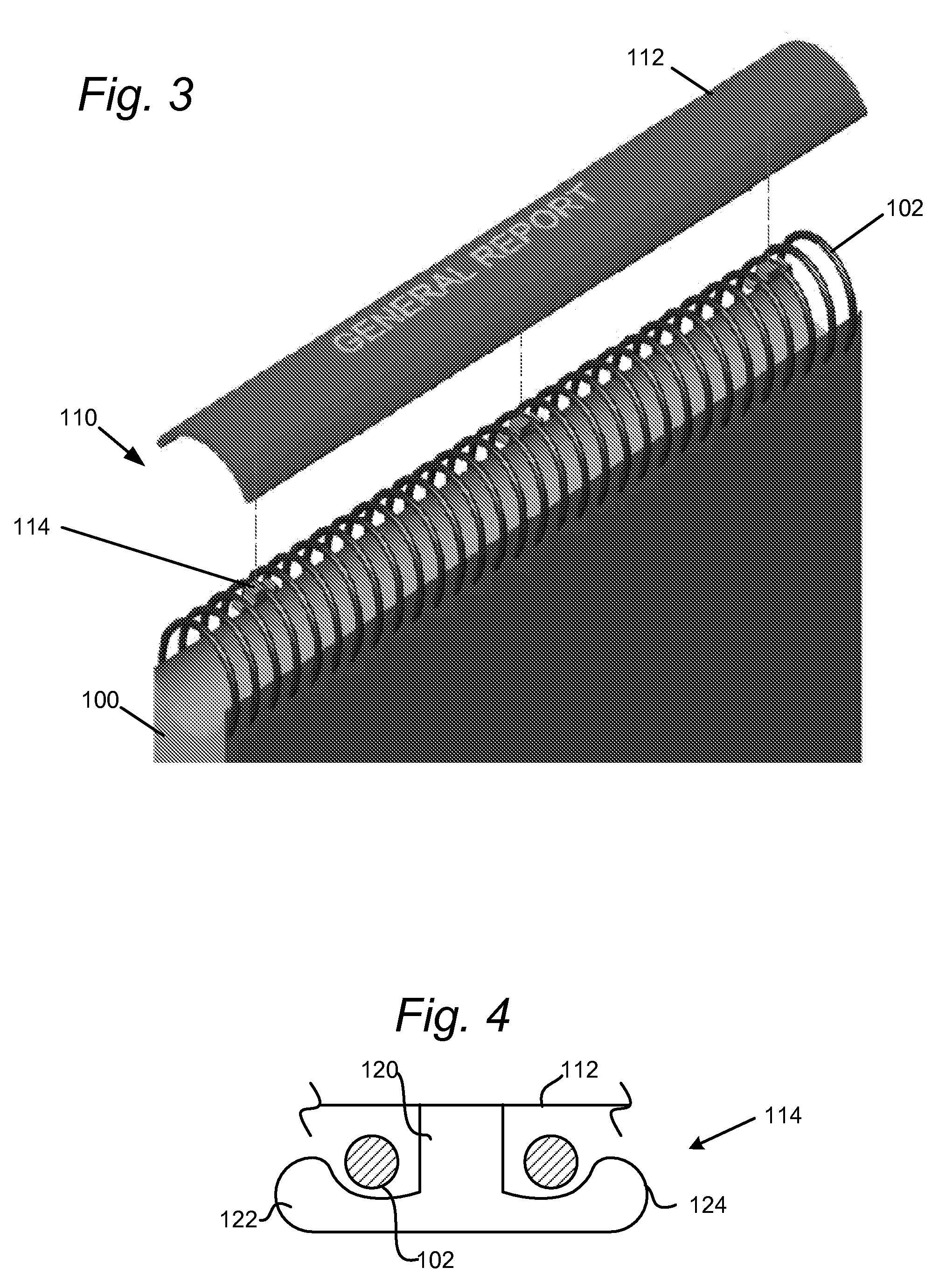

InactiveUS20080141573A1Improve structural rigidityMore rigidStampsFiling appliancesCoil bindSpiral binding

A labeling member is disclosed which attaches to the coil used for the coil binding of documents. The member may be affixed as an aftermarket upgrade to existing coil binding products. In embodiments, the member serves at least two functions. First, the member presents a face along the edge of a coil which may be marked or labeled to allow identification of the coil bound document when shelved or stacked. Second, the member adds structural rigidity to the bound document when placed vertically on a shelf by making the coil more rigid.

Owner:GNESA ARIC M

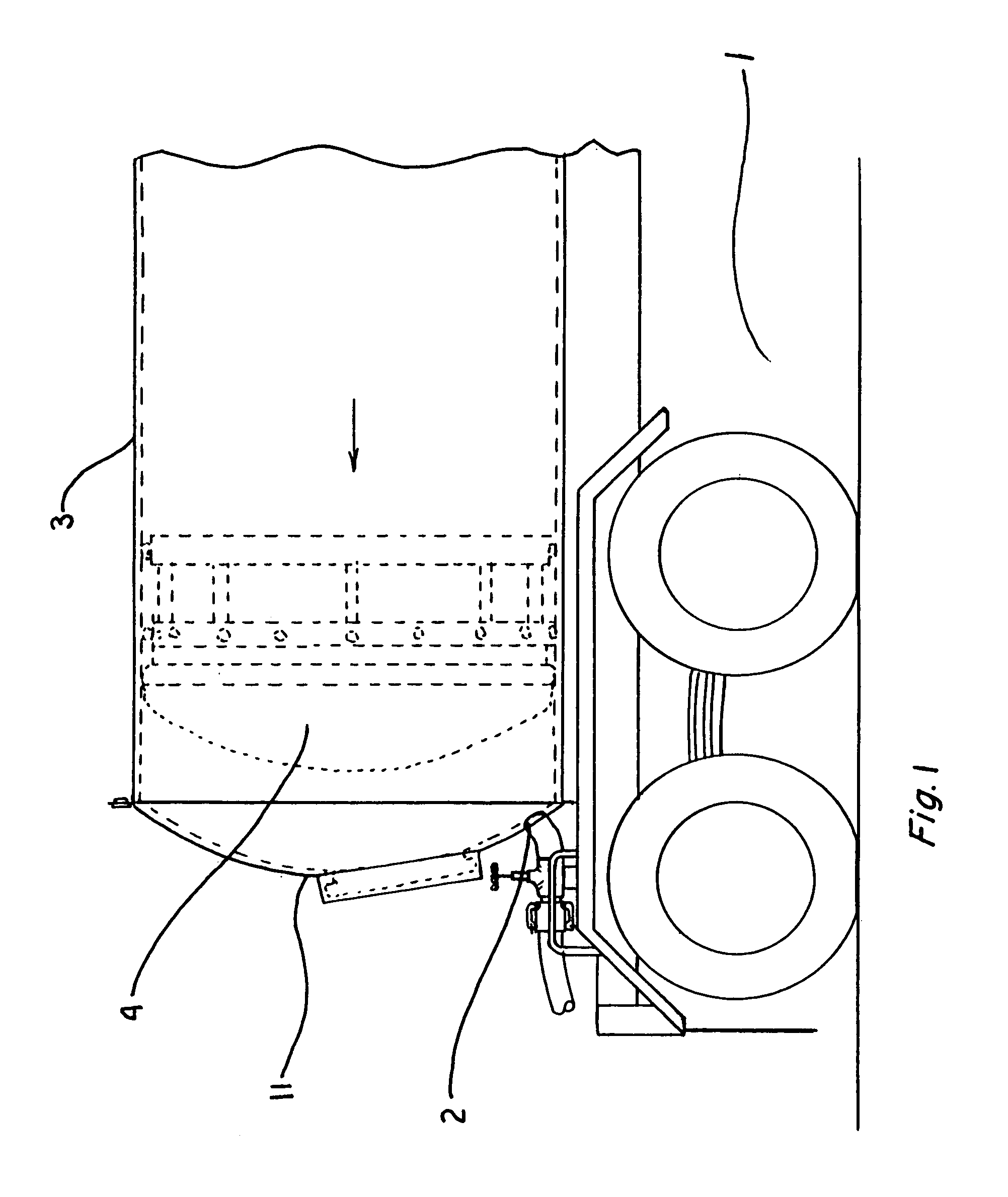

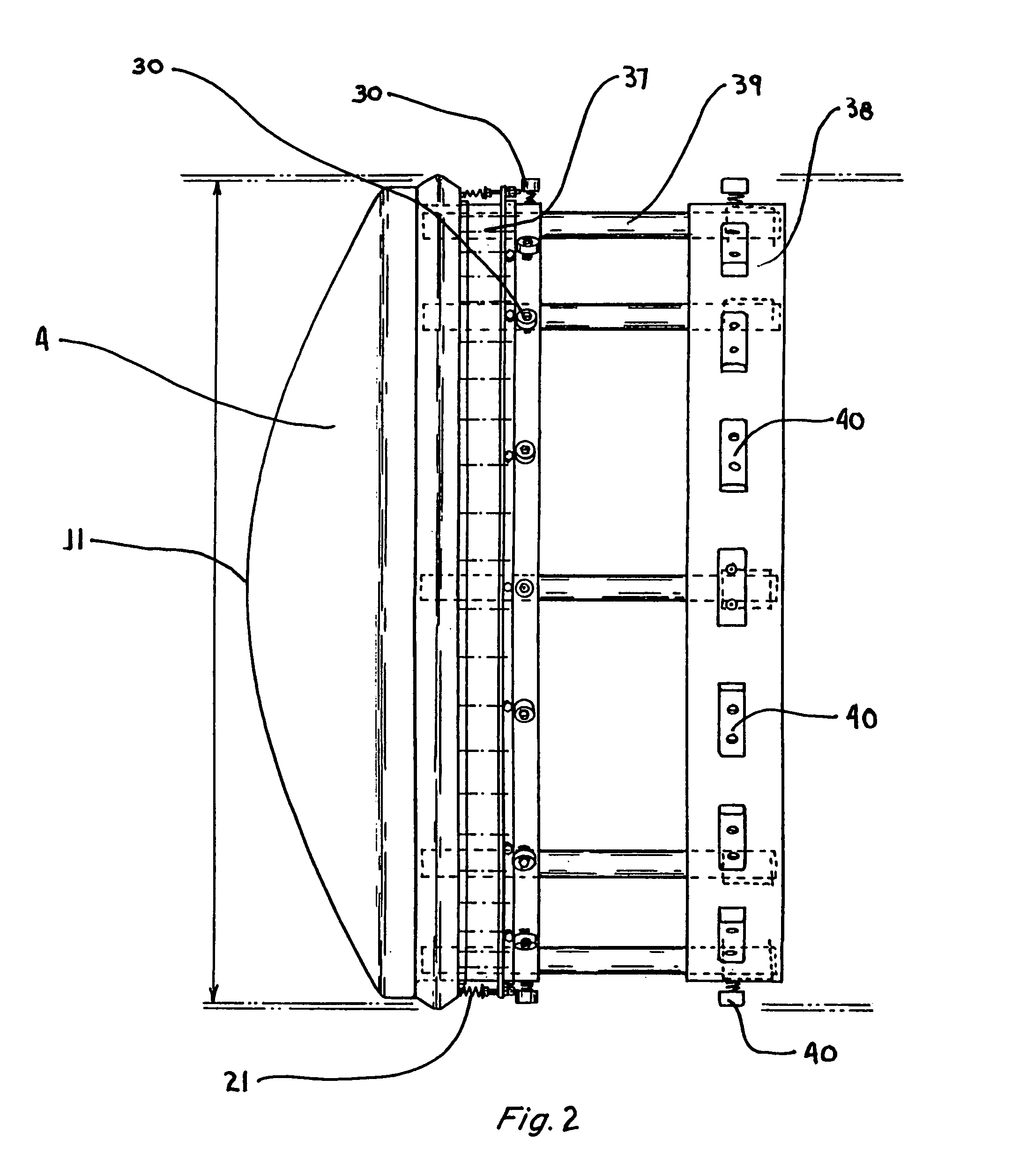

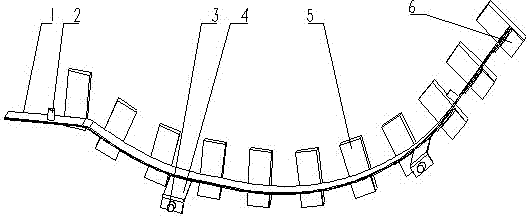

Method and device for producing books with wire or spiral bindings or other comparable bindings

The invention relates to the production of books with wire or spiral bindings or other comparable bindings, wherein sub-layers (2) made of punched sheets are collected one over the other in a successive manner into a book (5) at a collecting station (3), and the book is subsequently bound. According to the invention, a sub-layer (2) is held in a clamped manner by at least one lateral clamping device (12) which moves together with the sub-layer while the sub-layer is transported into the collecting position, while the sub-layers (10) already collected at the collecting station (3) are held in a fixed manner by means of at least one needle (13) which is moved upwards through the punched holes (4) from below. The clamping of the pliers is released only when the needles (13) are also located in the punched holes (4) of the newly conveyed sub-layers (2) as a result of the needles being moved upwards.

Owner:BIELOMATIK LEUZE GMBH & CO

Device for spot welding on wheel housing

InactiveCN103537786AGuarantee welding qualityReasonable designVehicle componentsMetal working apparatusSpiral bindingSpot welding

The invention relates to a device for spot welding on a wheel housing. The device comprises an arc-shaped connecting plate, powerful magnets and a plurality of red copper base plates, and is characterized in that the appearance of the arc-shaped connecting plate which is made of two steel coil binding straps is matched with that of a front wheel housing; the red copper base plates are uniformly distributed on a side surface of the arc-shaped connecting plate; connecting plates on the red copper base plates are fixed on the arc-shaped connecting plate; the powerful magnets (A) are arranged at two ends of the arc-shaped connecting plate; and the powerful magnet (B) is fixed on a positioning connecting plate on the other side surface of the arc-shaped connecting plate. The device is reasonable in design, simple in structure, easy to manufacture and low in cost. Because the appearance of the arc-shaped connecting plate is matched with that of the wheel housing, and the red copper base plates and the powerful magnets are fixedly connected to the arc-shaped connecting plate, the red copper base plates can be accurately and firmly adhered to positions required to be in spot welding under the action of the attraction force of the powerful magnets, the surface of the wheel housing is protected and isolated by using the red copper base plates, an electrode head is not in contact with a spot welding surface directly, the welding quality of the wheel housing can be guaranteed, and the welding efficiency is high.

Owner:ZHONGHANG HEIBAO

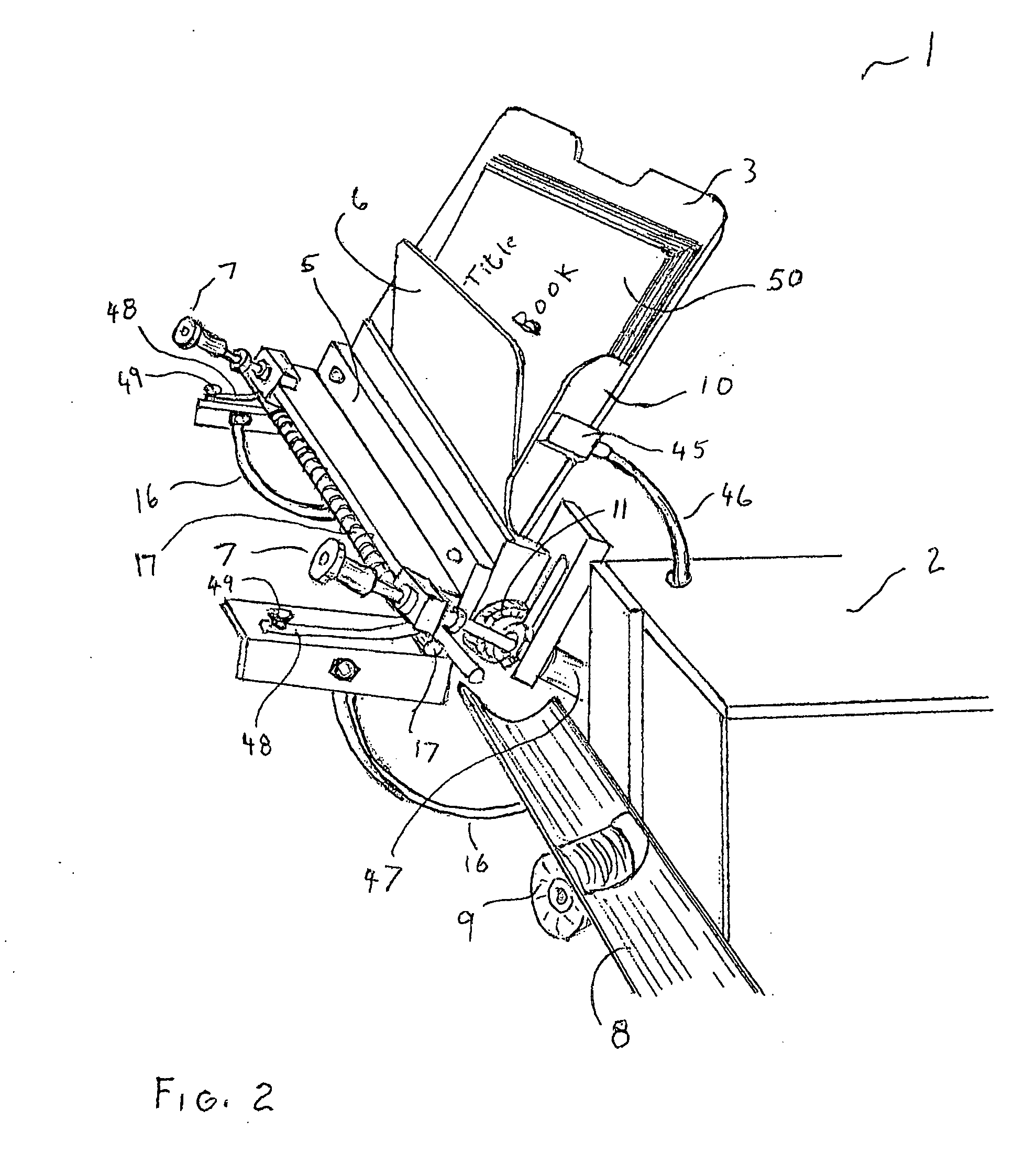

Semi-automatic plastic spiral binding machine

InactiveUS20080095596A1Minimize clingSmall and compactAlbumsSheet bindingSpiral bindingSemi automatic

A book binding machine has a page-forming mode and a spiral-binding mode, where a curved inexpensive piece of binding spiral coil or a convex member form a collection of pages being bound into a concavity on the spine of the pages to be bound with a proper pitch angle to accept insertion of a plastic spiral binding coil. An optional pivoting page-forming carriage and an optional pivoting cutter / crimper are respectively movable between engaged and disengaged positions. The book forming bar is optionally moved out of the way in an intermediate position while the spiral is spun into the perforations. Then the brackets place the cutter bar in position. Pulsed air is preferably used to operate the vibrator and the exhaust pulsed air is fed to a page aerating manifold to keep pages from clinging to each other prior to the sheets being clamped before insertion of the plastic spiral coil.

Owner:SPIEL ASSOCS

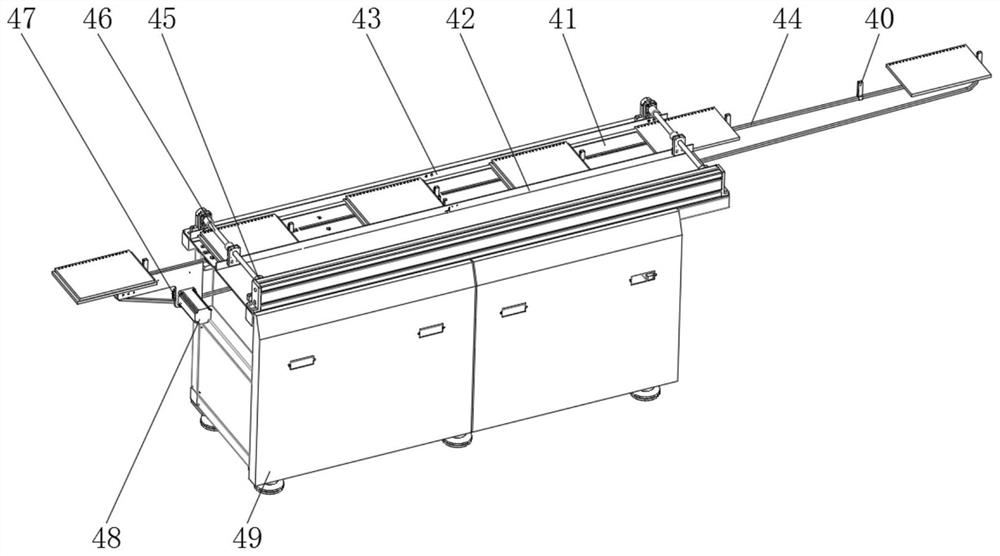

JC-520 double-coil binding machine

The invention relates to the technical field of binding machines, and discloses a JC-520 double-coil binding machine. The JC-520 double-coil binding machine comprises a cabinet body. The left upper corner of the top end of the cabinet body is movably connected with a double-coil placement frame mechanism. A feeding and coil binding mechanism is movably connected with the right side of the double-coil placement frame mechanism. A book placement platform is fixedly installed at the top end of the cabinet body. A hook feeding mechanism is fixedly installed at the top end of the feeding and coil binding mechanism. According to the JC-520 double-coil binding machine, a motor is controlled to feed materials by a double-coil detection proximity switch, an output shaft of the motor can rotate anddrive a driving chain wheel to rotate, the driving chain wheel can rotate to drive a driven chain wheel to rotate, the driven chain wheel can rotate to drive a double-coil placement optical shaft to rotate clockwise, then double coils are taken down from the interior of a packaging box and installed on the double-coil placement optical shaft, and therefore the double coils are inputted from a detection point and arrive at a wire die, and the effects of convenient conveying, labor saving, automatic press fit and automatic adjustment are achieved.

Owner:张杰

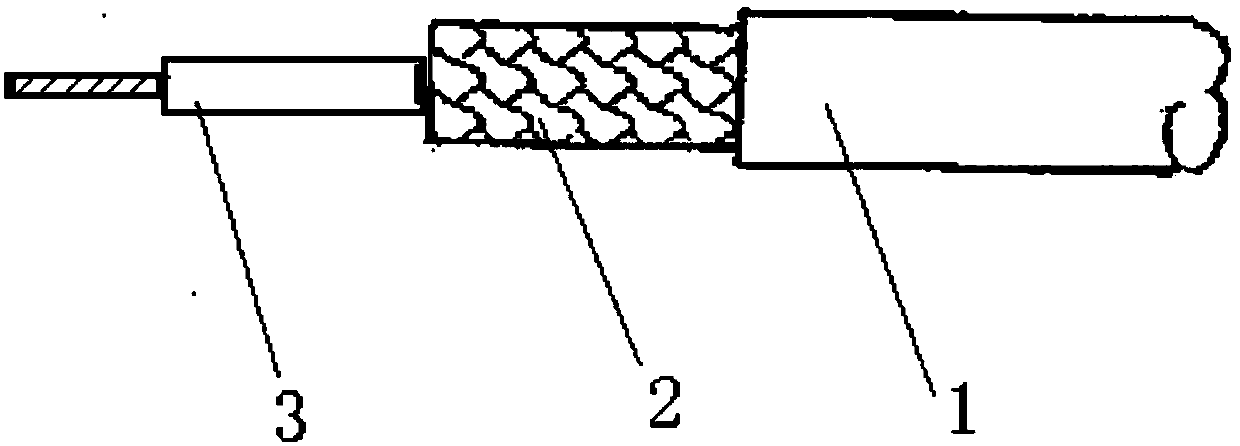

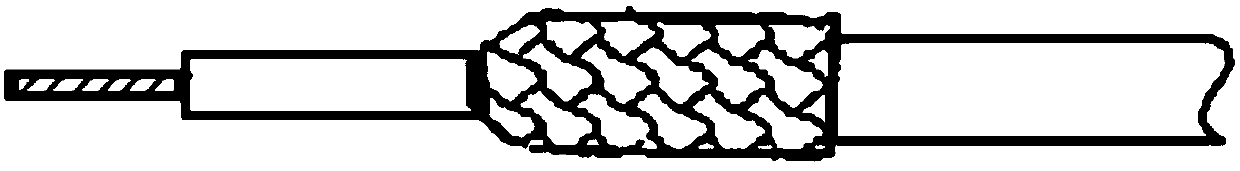

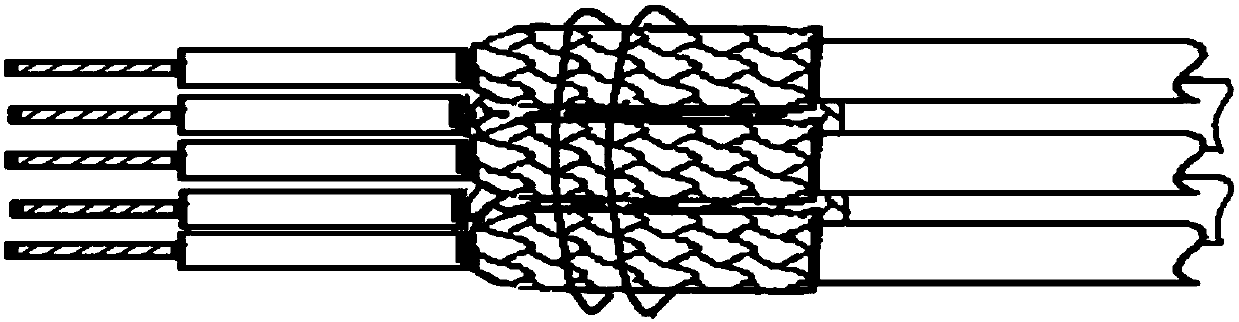

Processing method of shielding layer of shielding wire

InactiveCN107634440AReduce mutual frictionReduce solder jointsLine/current collector detailsCoil bindInsulation layer

The invention relates to a processing method of a shielding layer of a shielding wire. The method comprises steps that step 1, an outer insulation layer at one end of each single core shielding wire is stripped, and the shielding layer is overturned to the outer insulation layer; step 2, all the single core shielding wires are gathered together to be a wire harness, all the overturned shielding layers of all the shielding wires are gathered together, and a binding coil is utilized to wind the overturned shielding layers; step 3, the coil binding portion of the overturned shielding layers is coated with tin, and the coil binding portion is welded with a ground lead; and step 4, a thermal shrinkage casing is sleeved at the overturned shielding layers, and the whole overturned shielding layers are covered by the thermal shrinkage casing. The method is advantaged in that assembling difficulties including an acute angle in a cable bending type rear accessory and small assembling space are solved, a cable harness and a cable clamp manufactured through the method have relatively large gaps, extrusion and wear are reduced, and product reliability is improved.

Owner:SHAANXI QIANSHAN AVIONICS

Dry-type transformer

InactiveCN104575978AReduce distanceLow costTransformers/inductances coils/windings/connectionsCoil bindSpiral binding

The invention provides a dry-type transformer which comprises a cabinet body, a transformer body and a base, wherein the transformer body is arranged on the base in the cabinet body; the transformer body is provided with a high-voltage incoming end and a coil binding post; a connecting line between the end part of the high-voltage incoming end and the end part of the binding post is vertical. The dry-type transformer has the advantages of long service life, material-saving property and the like.

Owner:WUHU JINNIU ELECTRIC

Book Coil Binding Machine

InactiveUS20140093333A1Improve efficiencyIncrease productionSheet bindingBookbinding pressesCoil bindSpiral binding

A book coil binding machine includes a housing, a coil guiding block, a conveying device, a clamping device, a supporting apparatus and a cutting apparatus. The coil guiding block is removably disposed on the housing. The conveying device drives a coil moving forwards along the coil guiding block. The clamping device clamps the book in the book clamping space for the coil being guided into the holes of the book when the clamping device is at the clamping position. The clamping device releases the book when the clamping device is at the releasing position. The supporting apparatus is provided for the book in the book clamping space being abutted thereto when the supporting apparatus is at a supporting position, whereas the supporting apparatus is departed from the book when the supporting apparatus is at a loosening position. The cutting apparatus cuts off the two ends of the coil which are extended out of the book when the cutting apparatus is at a cutting position.

Owner:CHUNG SHEEN TECH

Labeling system for coil binders

InactiveUS7406790B2Improve structural rigidityMore rigidStampsFiling appliancesCoil bindSpiral binding

A labeling member is disclosed which attaches to the coil used for the coil binding of documents. The member may be affixed as an aftermarket upgrade to existing coil binding products. In embodiments, the member serves at least two functions. First, the member presents a face along the edge of a coil which may be marked or labeled to allow identification of the coil bound document when shelved or stacked. Second, the member adds structural rigidity to the bound document when placed vertically on a shelf by making the coil more rigid.

Owner:GNESA ARIC M

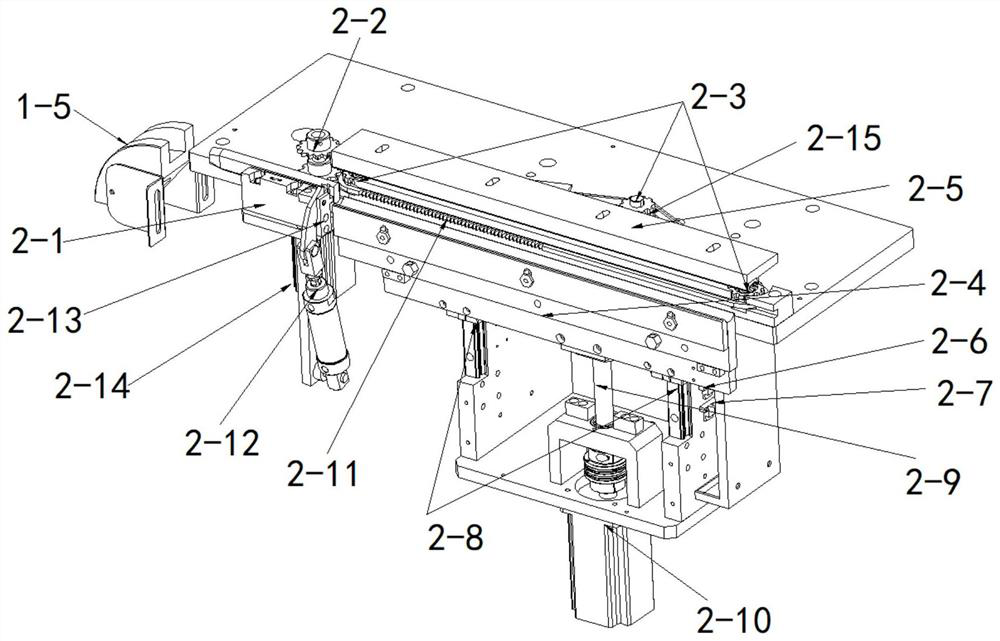

Multi-coil binding machine for hot-rolled narrow strip steel

PendingCN112357178AAvoid loose rollsSmooth liftPaper article packagingBinding material applicationHydraulic cylinderCoil bind

The invention provides a multi-coil binding machine for hot-rolled narrow strip steel. The multi-coil binding machine comprises a platform and a transverse track arranged on the platform, wherein an uncoiler is arranged on the right side of the platform; a coil conveying trolley on which steel coil carrier rollers are arranged is arranged on a longitudinal track configured with the platform; a coil penetrating trolley positioned on the left side and a trolley positioned on the right side are arranged on the transverse track; the coil penetrating trolley is provided with a coil penetrating trolley driving mechanism; the trolley is provided with a trolley positioning hydraulic cylinder; a binding belt bending mechanism, a binding belt head clamping and pulling mechanism and a follow-up chassis are arranged on the trolley; and a two-roller clamping and conveying mechanism, a clamping roller straightening mechanism, a binding belt shearing and bending mechanism, an electromechanical limiting switch and a welding machine are arranged on the follow-up chassis. The multi-coil binding machine can replace manual binding, and the automation degree of binding, the safety and reliability of work, the binding quality and the binding speed are greatly improved.

Owner:张少壮

Binding device for roll-dividing machine and binding method

PendingCN109733658AIntertwinedReduce labor intensityBundling machine detailsSpiral bindingEngineering

The invention relates to a binding device for a roll-dividing machine and a binding method. The binding device comprises a connecting frame,a binding machine rack and a binding lifting device, whereinthe binding machine rack is fixedly arranged, the binding lifting device is mounted on the binding machine rack and drives the connecting frame to move vertically, a rotary device and a finger air cylinder are mounted on the connecting frame, the finger air cylinder is driven to rotateby the rotary device, two clamping jaws of the finger air cylinder are respectively and fixedly connected with clamping plates, the two clamping plates are respectively provided with wire threading holes, and when the finger air cylinder is loosened, the space between the two clamping plates is matched with theaxial width of a rope coil. According to the binding device for the roll-dividing machine and the binding method, the clamping plates are driven to drop and rise through the binding lifting device, lifting of the two ends of binding wires is achieved, the two binding wire heads are tightly bound through the action of the finger air cylinder, the finger air cylinder is driven to rotate through therotary device, and intertwining of the two binding wireheadsis achieved, so that manual rope coil binding is replaced, the binding efficiency is greatly improved, the labor intensity of workers is reduced, and meanwhile scratching of workers by the binding wires in the binding process is avoided.

Owner:山东鲁普耐特机械有限公司

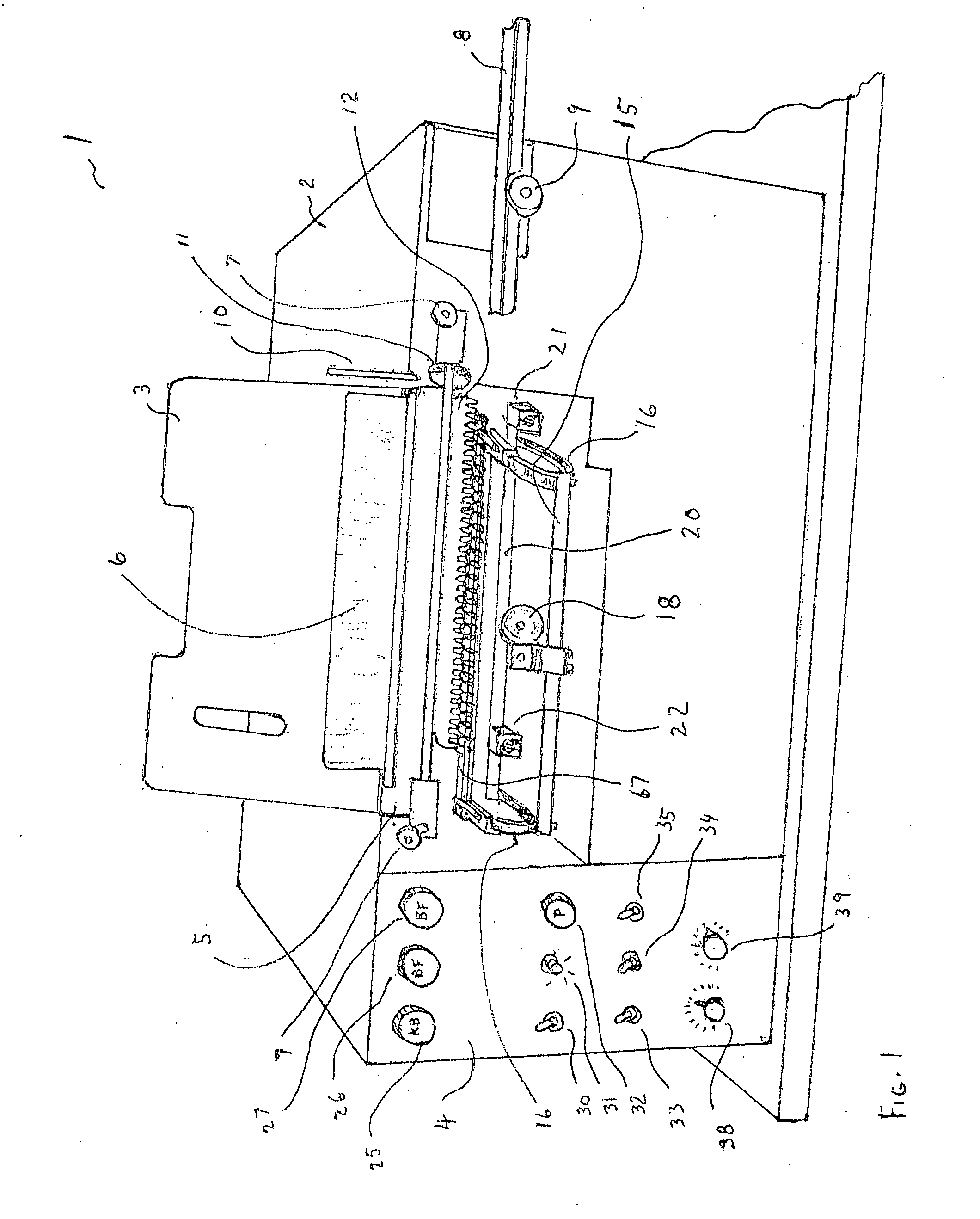

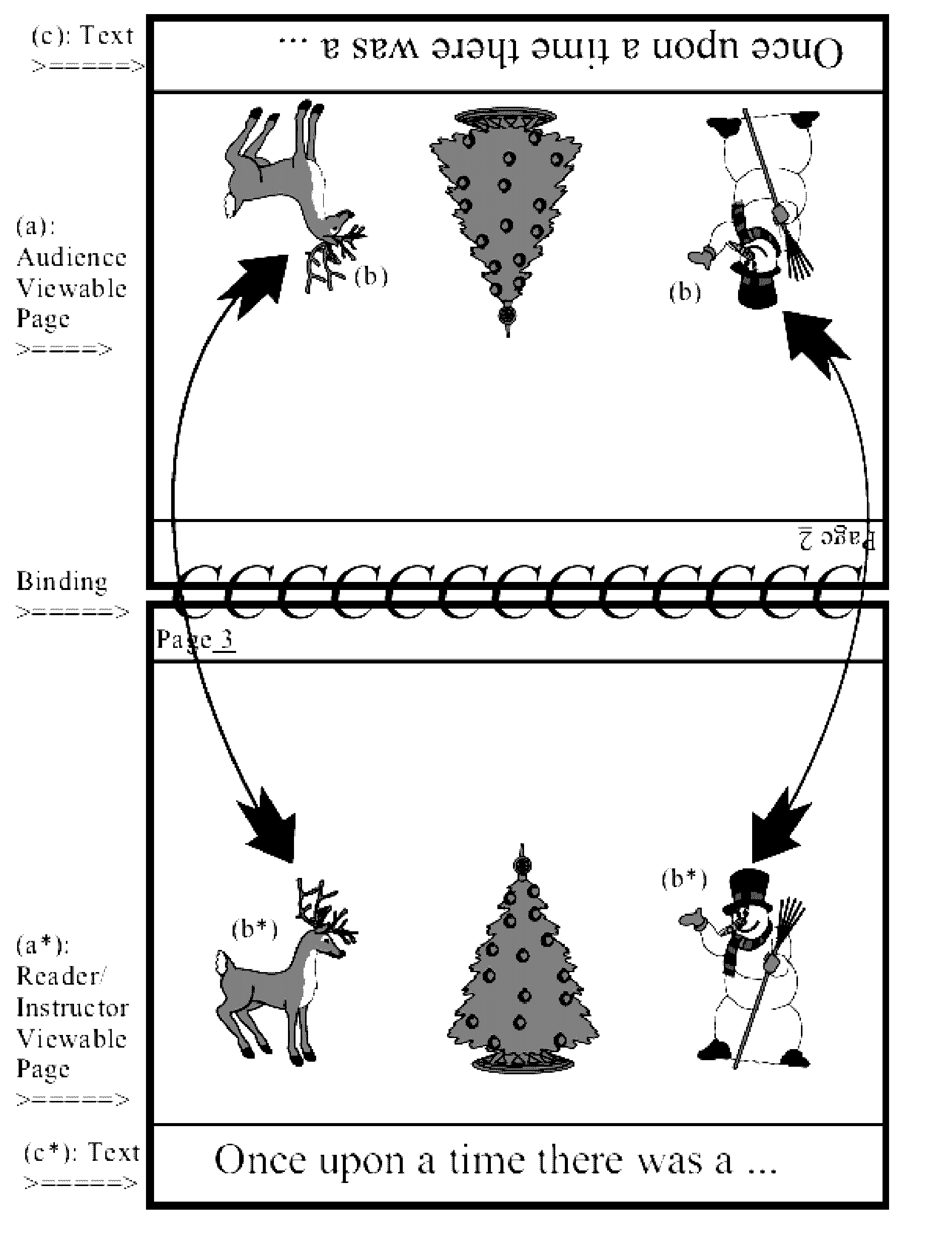

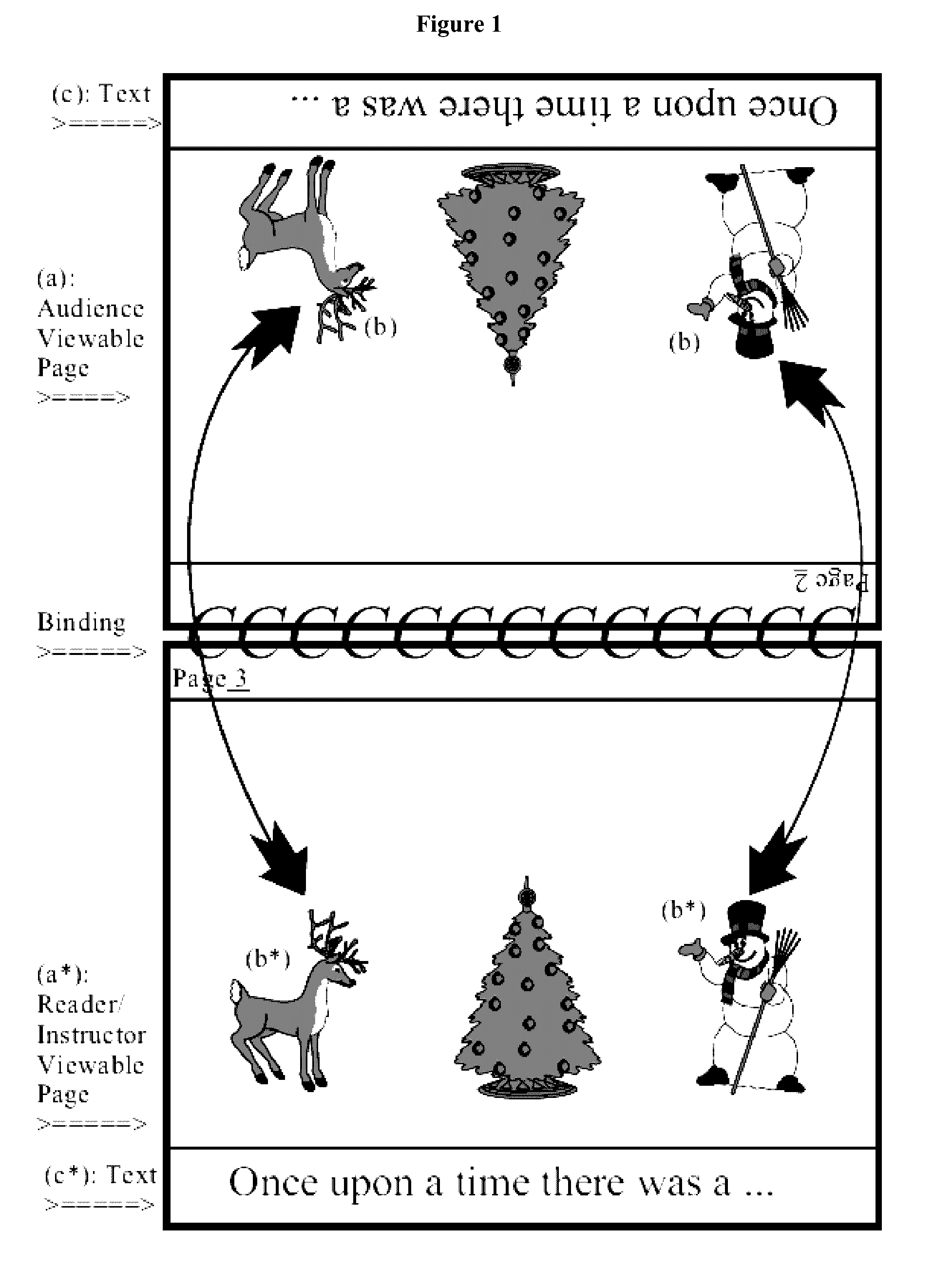

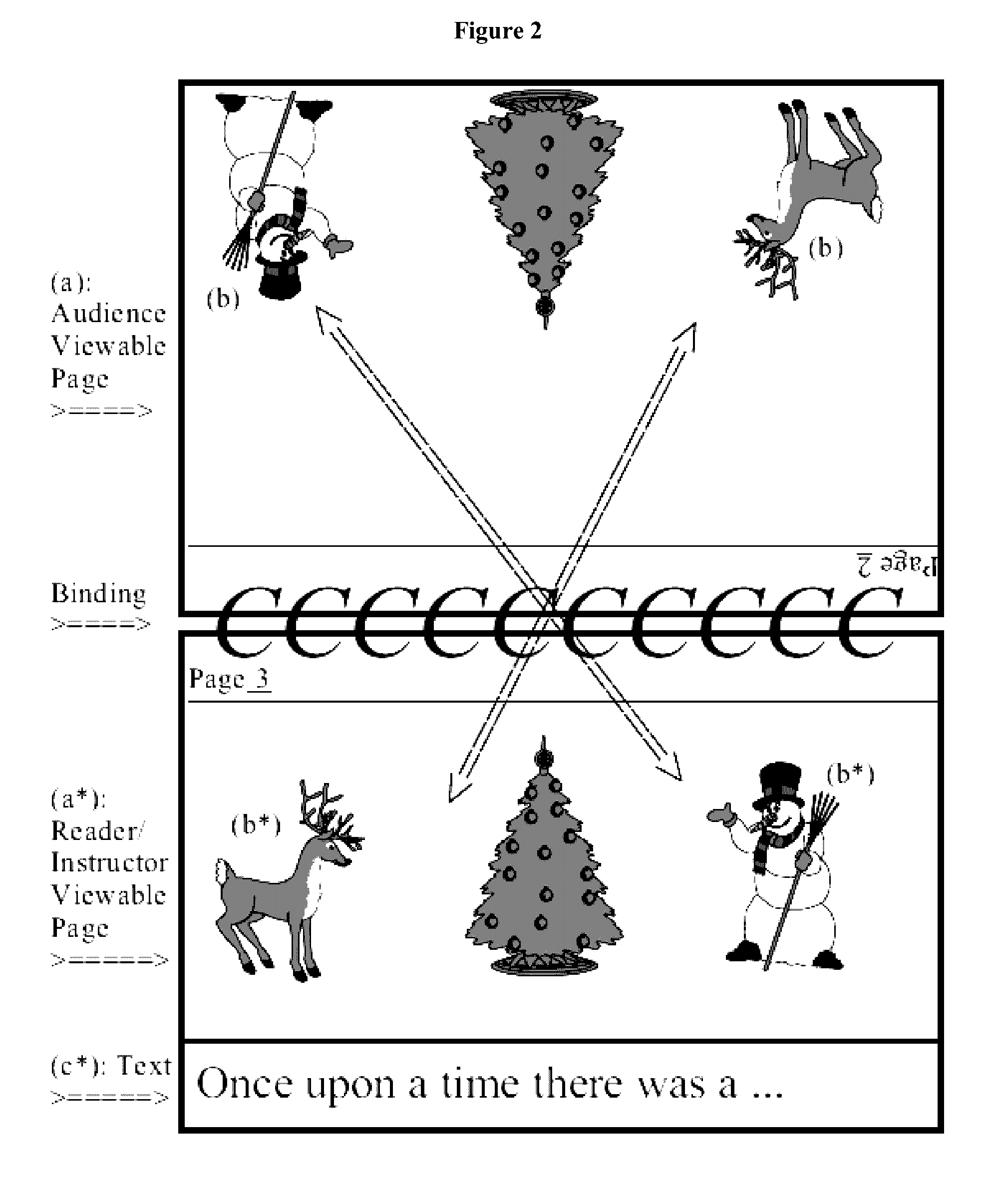

Two-Way Read-and-Show Illustrated Flip-Over Storytelling or Picture Books and Aids

A selected number of pages are arranged in book-like fashion and bound together so that the book may be displayed with one hand under the back cover held by the instructor, storyteller or reader. The other hand is free to turn the pages and make reference to objects within the illustrations facing the audience. The back cover may be approximately horizontal to the floor. The pages facing the audience may be approximately perpendicular to the floor. The first story page facing the audience carries an illustration depicting a portion of the story, while the second story page facing the reader carries a mirror image of the illustration seen on the first story page along with the text that relates a portion of the story and both first and second story pages are in diametric contraposition to each other on separate and sequential pages bound with a horizontal spiral binding within the book.

Owner:CLEMENTS JEHAN

Semi-automatic plastic spiral binding machine

A book binding machine has a page-forming mode and a spiral-binding mode, where a curved inexpensive piece of binding spiral coil or a convex member form a collection of pages being bound into a concavity on the spine of the pages to be bound with a proper pitch angle to accept insertion of a plastic spiral binding coil. An optional pivoting page-forming carriage and an optional pivoting cutter / crimper are respectively movable between engaged and disengaged positions. The book forming bar is optionally moved out of the way in an intermediate position while the spiral is spun into the perforations. Then the brackets place the cutter bar in position. Pulsed air is preferably used to operate the vibrator and the exhaust pulsed air is fed to a page aerating manifold to keep pages from clinging to each other prior to the sheets being clamped before insertion of the plastic spiral coil.

Owner:SPIEL ASSOCS

Jointing rod end protective cover with guiders

Owner:FUJI IND

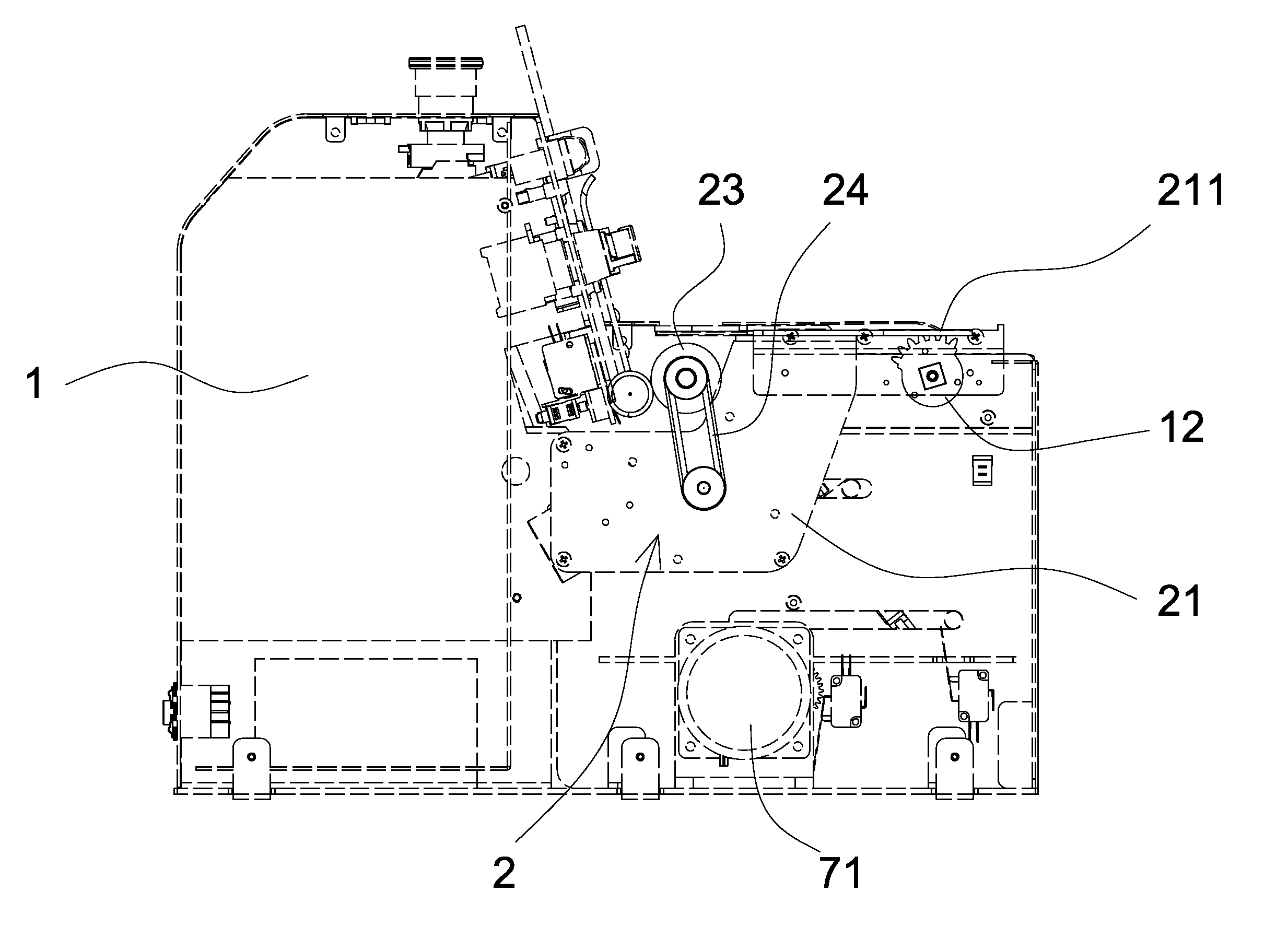

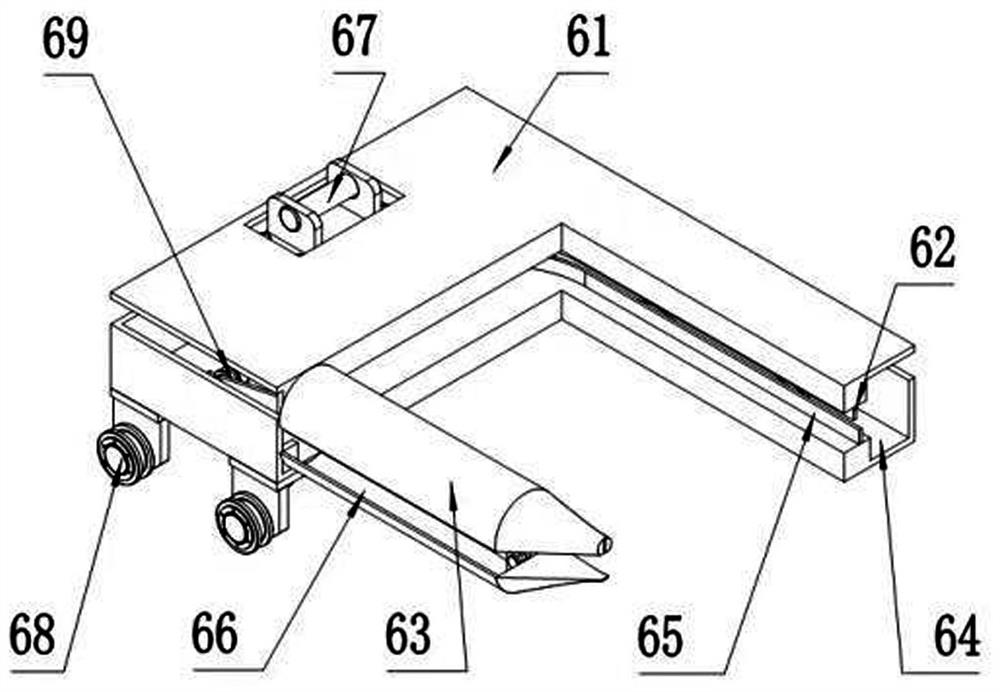

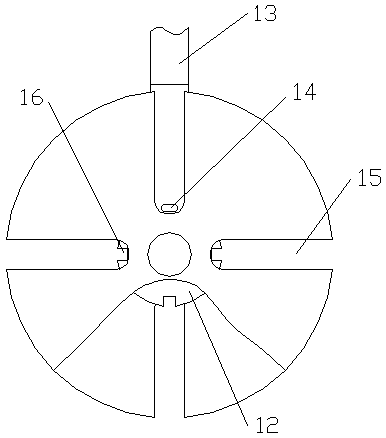

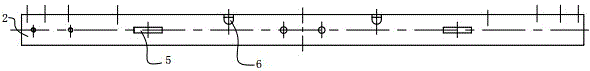

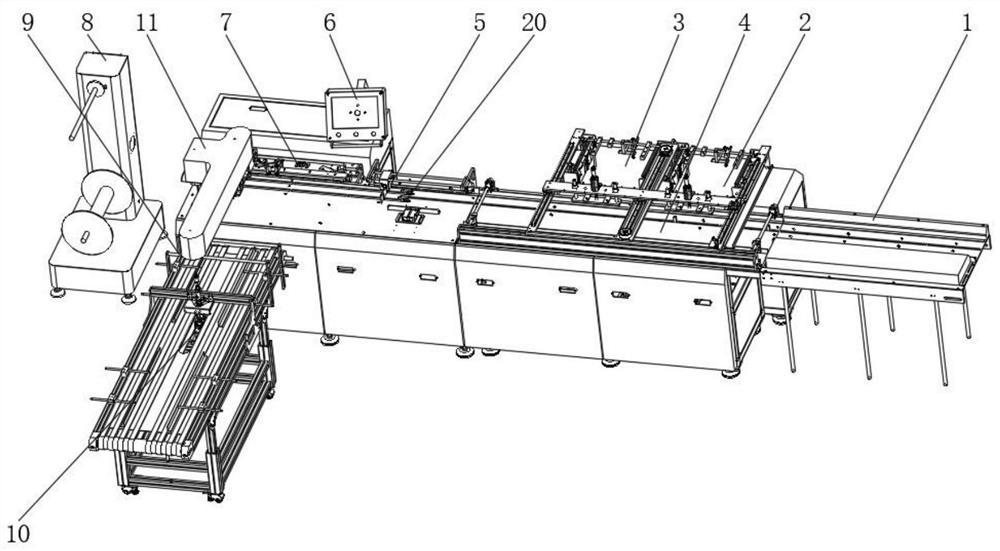

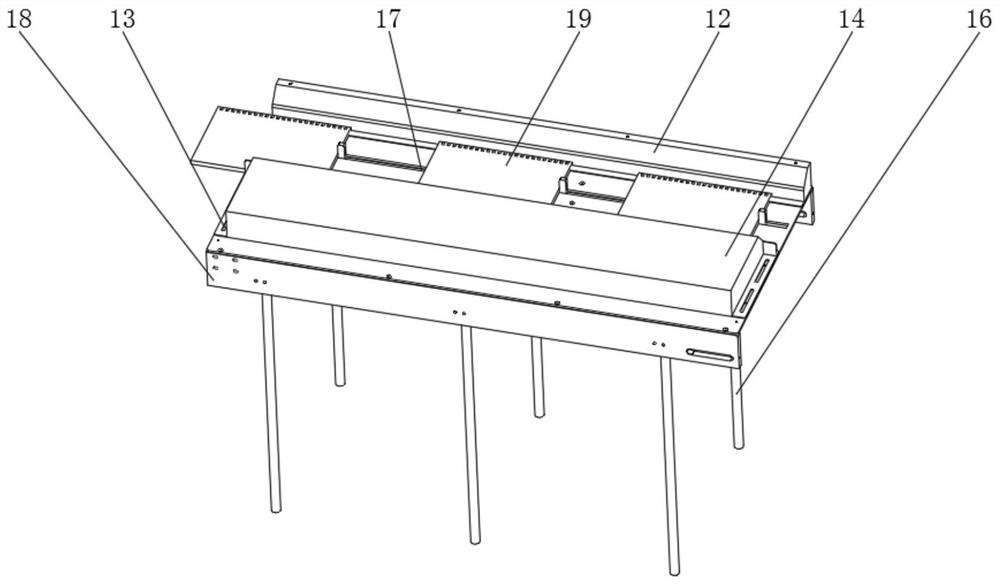

Infusion apparatus coil binding mechanism of infusion apparatus automatically-assembling machine

ActiveCN104477436AReduce the difficulty of bundlingImprove bundling efficiencyBinding material applicationPaper/cardboard containersEngineeringSpiral binding

The invention provides an infusion apparatus coil binding mechanism of an infusion apparatus automatically-assembling machine and belongs to the technical field of medical instruments. The infusion apparatus coil binding mechanism of the infusion apparatus automatically-assembling machine solves the technical problems of low automation degrees and the like of existing infusion apparatus coil binding mechanisms. The infusion apparatus coil binding mechanism of the infusion apparatus automatically-assembling machine comprises a base, the base is provided with a channel and a clamp, the clamp is provided with a clamping jaw for clamping an infusion apparatus coil, and the clamping jaw is formed above the channel; the infusion apparatus coil binding mechanism of the infusion apparatus automatically-assembling machine also comprises at least two swinging units which are arranged on both sides of the clamp, one end of every swinging unit is hinged to the base, and a driving structure capable of driving the other end of the swinging unit to stand upwards is arranged between the swinging unit and the base. When the infusion apparatus coil binding mechanism of the infusion apparatus automatically-assembling machine is in use, an operator does not need to hold the infusion apparatus coil by hand or manually stand both ends of a binding strip up, so that the infusion apparatus coil binding difficulty can be lowered, and the infusion apparatus coil binding efficiency can be improved.

Owner:MAIDER MEDICAL IND EQUIP

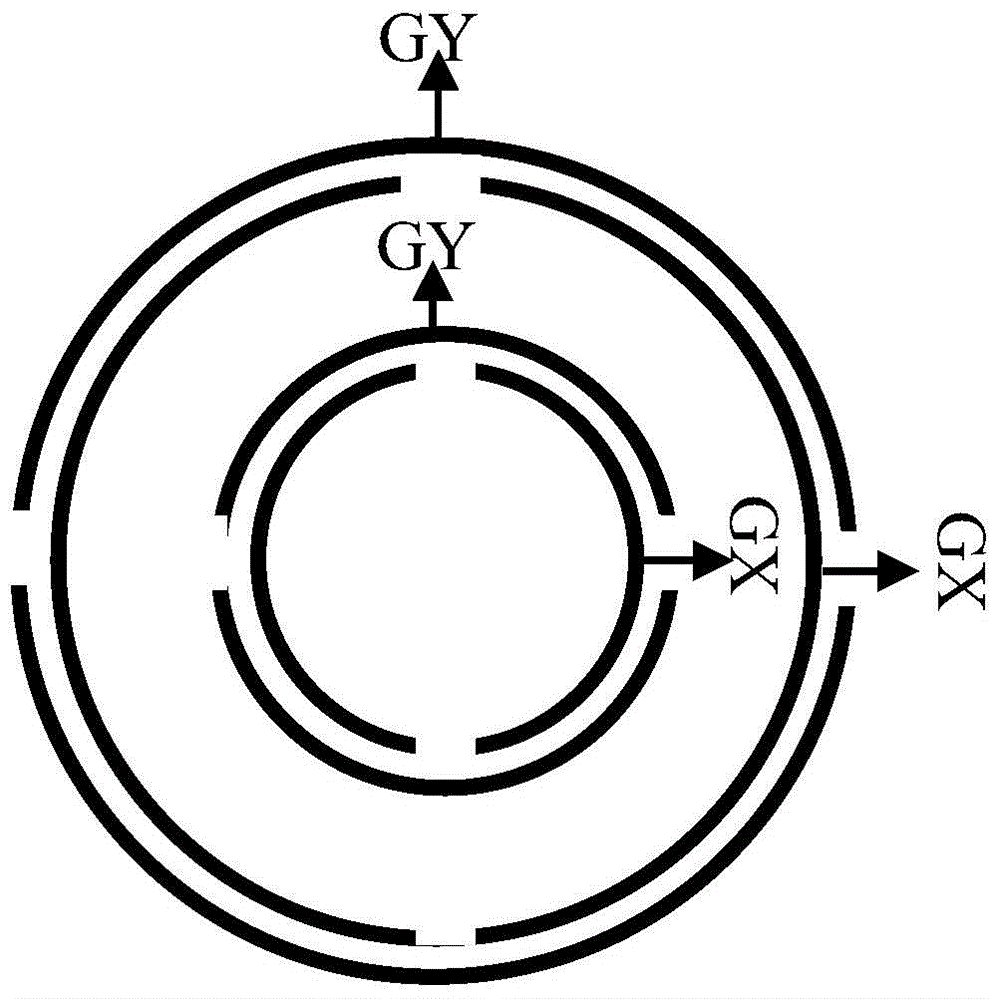

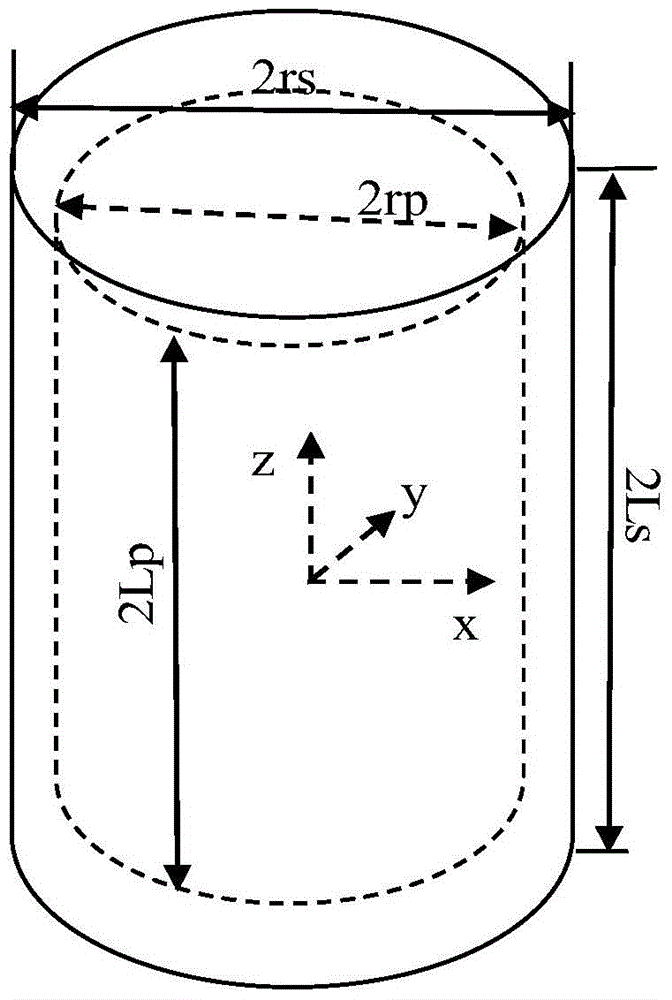

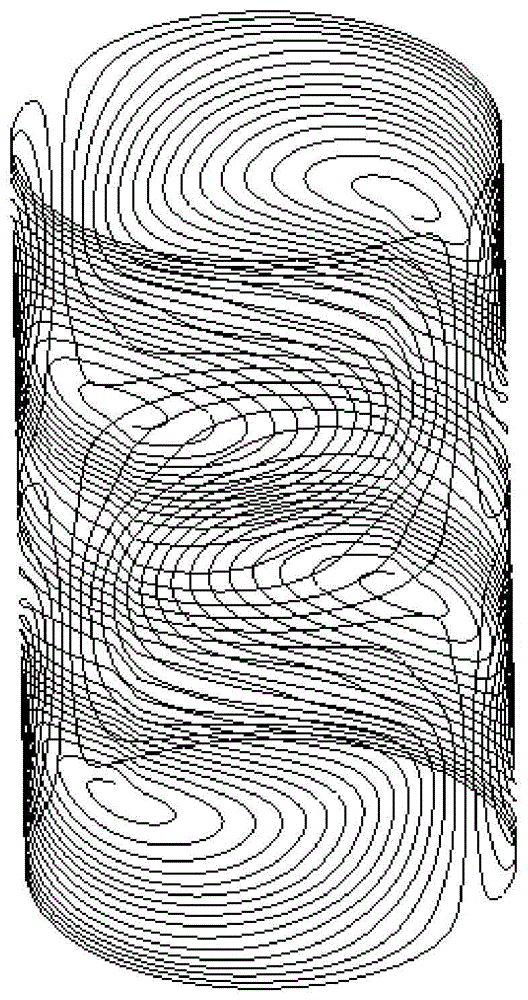

Gradient Coil Design Method Combining Functional Function and Simulated Annealing Algorithm

InactiveCN104007407BRapid designEfficient designMagnetic measurementsSpecial data processing applicationsCoil bindSpiral binding

Owner:HOHAI UNIV

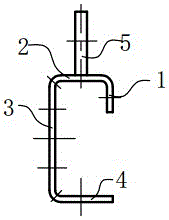

Transformer abnormal-shape clamp member

InactiveCN105118624AEasy to processEasy to installTransformers/inductances magnetic coresCoil bindSpiral binding

The invention relates to the transformer clamp member field and discloses a transformer abnormal-shape clamp member, which comprises a front plate, a top plate, a back plate and a bottom plate that are molded as a whole and sequentially connected, wherein the front plate and the back plate are respectively and vertically connected at the same side of the top plate; the bottom plate is vertically connected to the back plate and the bottom plate is located at the same side with the top plate; a top face of the top plate is connected to a lifting lug; the front plate is provided with a terminal connecting hole that is used for mounting a high-voltage connecting terminal of a transformer; the back plate is provided with a binding tie hole that is used for connecting a coil binding tie and a counter-pull bolt hole that is used for connected two abnormal-shape clamp members of the transformer; and the bottom plate is provided with a mounting hole that is used for fixing the abnormal-shape clamp members of the transformer. By adopting the transformer abnormal-shape clamp member, an iron core of the transformer is clamped more tightly; and the clamp member has the advantages of convenient processing, simple operation and easy popularization.

Owner:CHONGQING WANGBIAN ELECTRIC GRP CORP

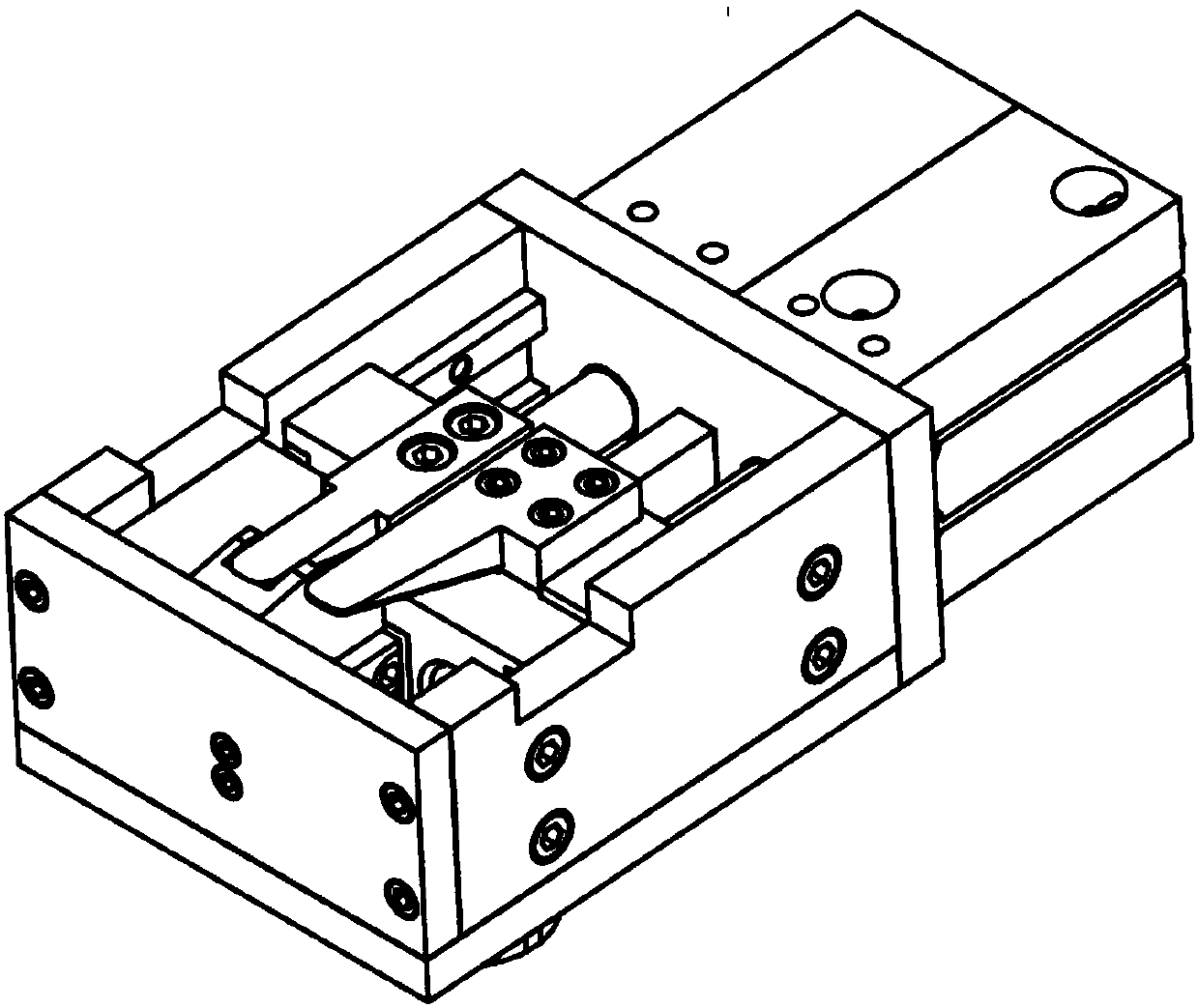

Device and method for dismounting and recovering steel coil binding belt by robot

ActiveCN112340161AEven by forceLess stringent requirementsBinding material removalCoil bindAir spring

The invention relates to a device for dismounting and recovering a steel coil binding belt by a robot. The device for dismounting and recovering the steel coil binding belt by the robot comprises a robot body, wherein a binding belt dismounting end executor is installed at one side of the robot body; a shell body fixedly connected with one end of the robot body is not included in the binding beltdismounting end executor, and a linear guide rail I is fixedly connected to one side of the inner wall of the shell body; and the linear guide rail I is fixedly connected with the an air cylinder I. According to the invention, a binding belt is located at any position between two clamps, strict requirements on locating and motion tracks of the end executor are reduced, meanwhile, when the bindingbelt is shoveled up, two sides of the binding belt are shoveled up at the same time, and the binding belt dismounting end executor is uniformly stressed and does not bear an overlarge torque; and dovetail groove designs at the end parts of the clamps can also accurately locate the position of the shoveled binding belt to adapt to the change of the tightness of the binding belt, the clamp at the side where scissors are located, adopts an air spring, the action of clamping the binding belt at first, and then shearing the binding belt can be realized, and in this way, the process of shearing after clamping can be completed by one-time action of the air cylinder, and the working efficiency is increased.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

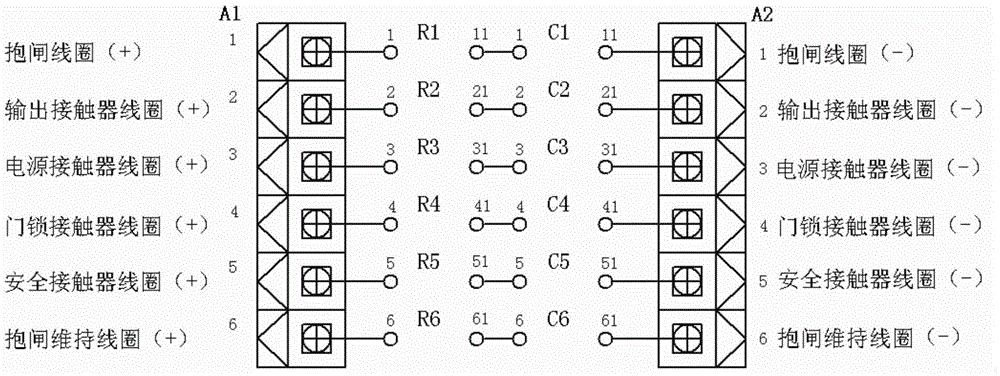

Current release circuit of elevator control cabinet

The invention provides a current release circuit of an elevator control cabinet. The current release circuit comprises a PCB, a band-type brake coil binding post, an output contactor coil binding post, a power contactor coil binding post, a door lock contactor coil binding post, a safety contactor coil binding post, a band-type brake maintaining coil binding post, resistors for absorbing contactor currents and capacitors for absorbing the contactor currents. The PCB is provided with welding positions connected to the binding posts. By arranging the band-type brake coil binding post, the output contactor coil binding post, the power contactor coil binding post, the door lock contactor coil binding post, the safety contactor coil binding post, the band-type brake maintaining coil binding post, the resistors for absorbing the contactor currents and the capacitors for absorbing the contactor currents on the PCB, modularized work is realized in the wiring process, the cost is lowered, and the assembly efficiency is improved.

Owner:TIANJIN ORAC ELEVATOR

Coil binding anti-scratch device

The invention discloses a coil binding anti-scratch device, which comprises an inner protective plate, an outer protective plate and an end protective plate, wherein the inner protective plate is arranged along the inner wall of the coil, the outer protective plate is wrapped outside the coil, a plastic mesh belt is arranged on the outer protective plate which is passed through by a bundle line, and the end protective plate includes an annular ring and end backing plates which are circumferentially arranged on the annular ring. The invention has the advantages of simple structure easy operation, high strength, good toughness, and long service lives of the inner and outer protective plates, is capable of effectively preventing coil scratch during binding, reducing production cost, and benefiting subsequent pickling process with the design of the end protective plate.

Owner:NANJING IRON & STEEL CO LTD

Full-automatic coil binding machine

The invention relates to the technical field of coil binding machines, in particular to a full-automatic coil binding machine. The full-automatic coil binding machine comprises an inner core containing table, a back cover automatic assembling mechanism, a chain indirect conveying mechanism, a calibration mechanism, a cover overturning mechanism and a finished product turning and storing mechanism, and one side of the inner core containing table and one side of the chain indirect conveying mechanism are fixedly installed. According to the full-automatic coil binding machine, inner cores are automatically and orderly conveyed, covers and back covers of the inner cores are automatically assembled into a book, and then the book is automatically conveyed to the calibration mechanism through the chain indirect conveying mechanism, so that compared with a binding machine in the market, the inner cores, the covers and the back covers are automatically conveyed, manual conveying is not needed, the labor cost is reduced, and the production efficiency is improved, the whole process is more convenient and stable, the book is automatically calibrated through the calibration mechanism, and the defects that the final product quality is affected due to the fact that holes of the book are not aligned and the number of defective products of the finally produced book is large due to the fact that the book is not calibrated before binding and the final book product quality is improved are overcome.

Owner:张杰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com