Jointing rod end protective cover with guiders

A technology of a guide and a protective cover, which is applied in the directions of fishing rods, fishing, and applications, can solve the problems such as the unsolved interference problem of the binding belt 109, and achieve the effect of easy installation work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The jointed rod end protective cover 1 with a guide according to the first embodiment of the present invention will be described with reference to the drawings.

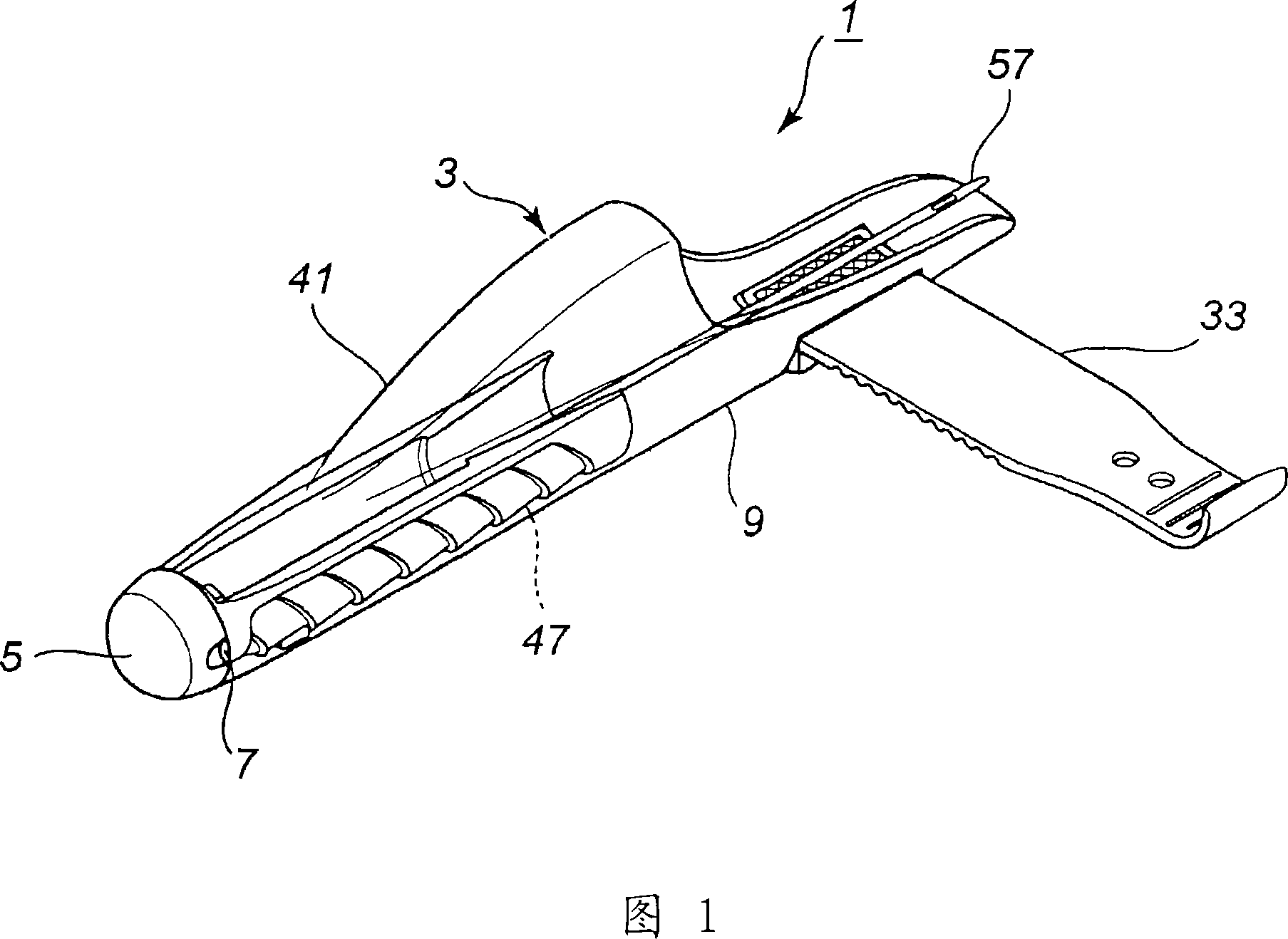

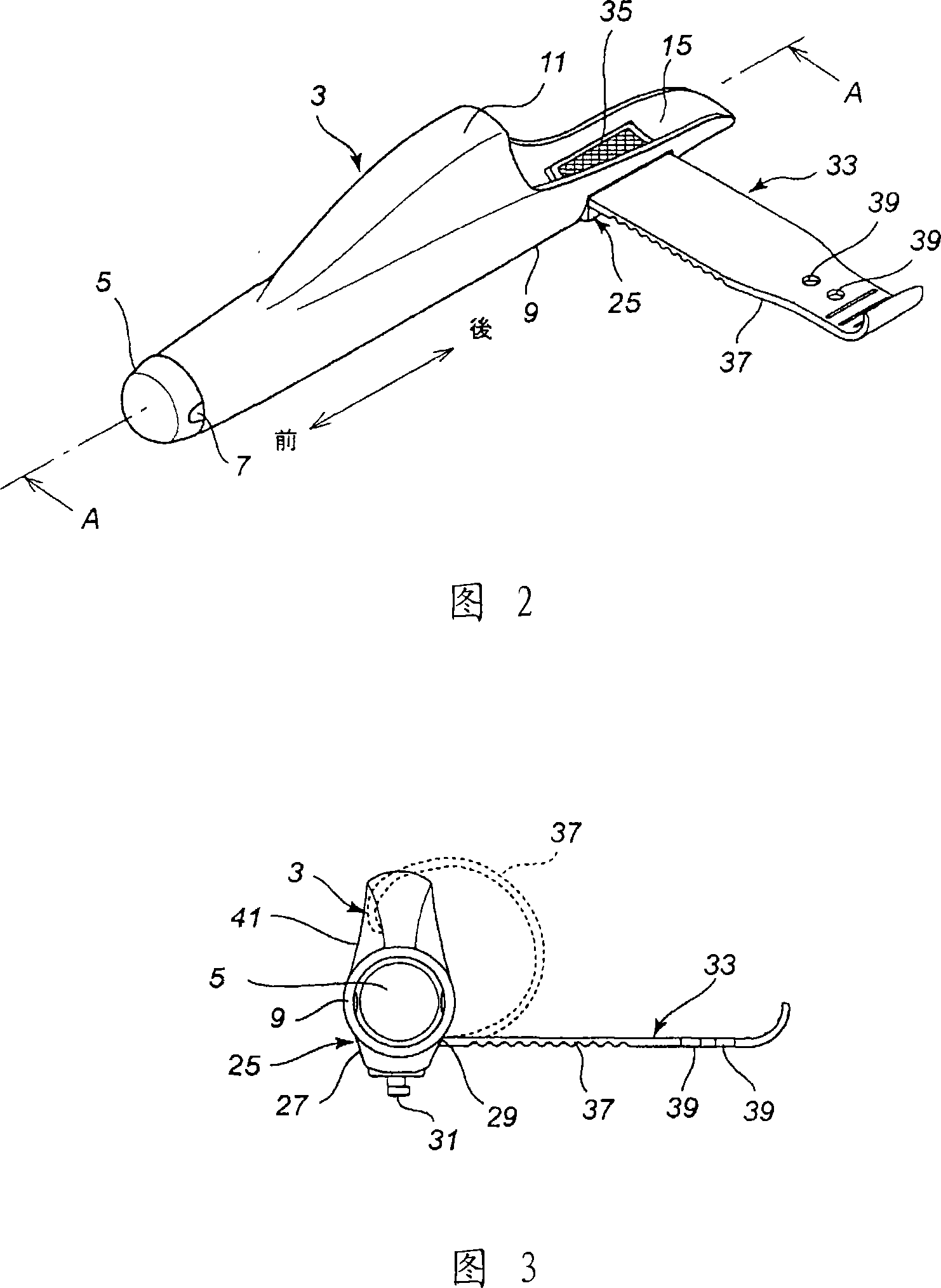

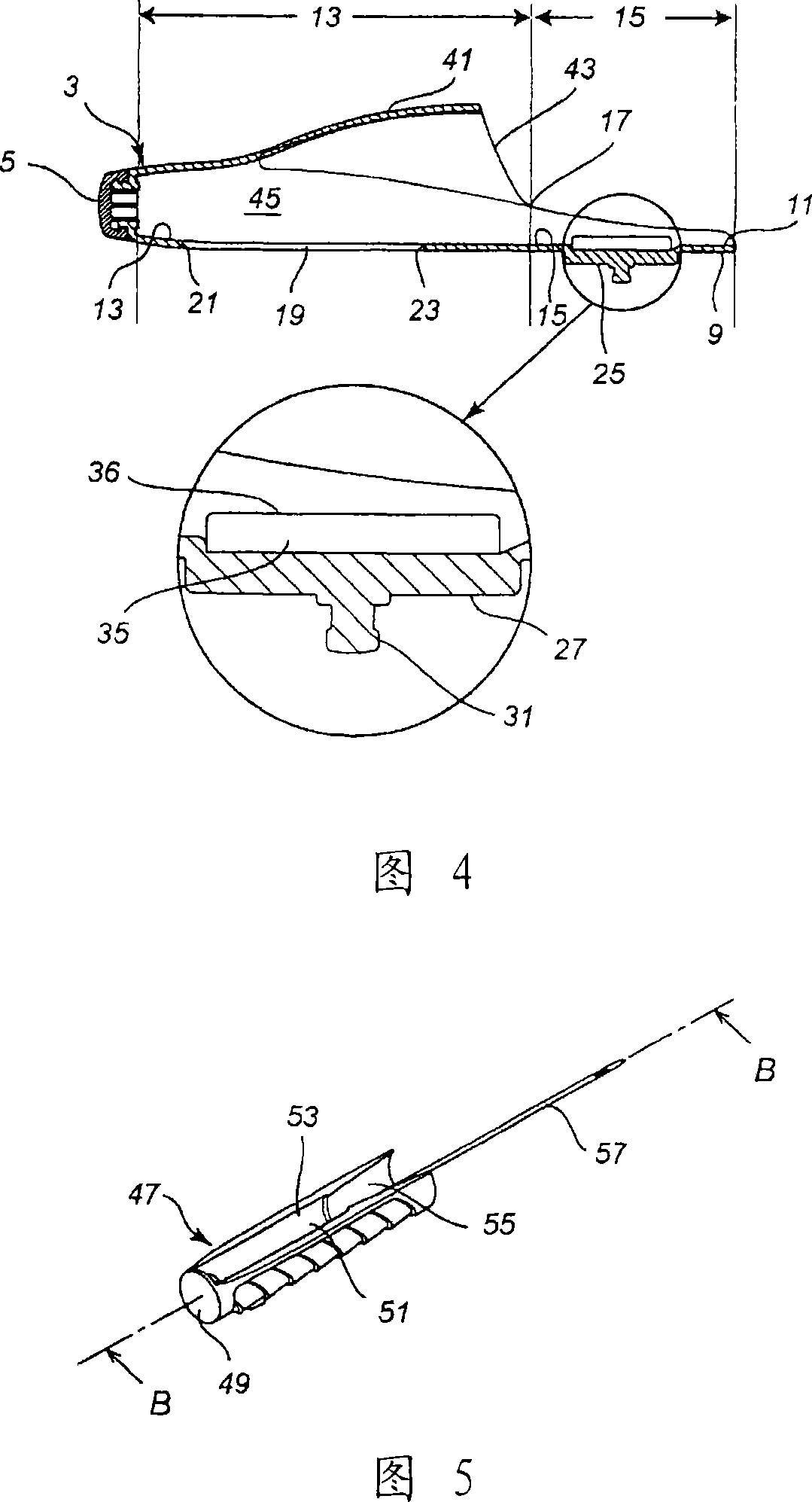

[0049] FIG. 1 shows a perspective view of a pole end protective sleeve 1 .

[0050] Reference numeral 3 denotes a transparent cylindrical sleeve body, the front port of which is plugged by being inserted with a cap 5 . Two vent holes 7 are formed on the cap 5 facing each other. The vent hole 7 communicates with the inner space of the sleeve body 3, and prevents corrosion of the guide and deterioration of the surface coating of the rod material due to moisture in the sleeve body 3.

[0051] The cover body 3 is composed of a base part 9 and a cover part 41, and the base part 9 and the cover part 41 are integrally formed into a cylindrical shape by resin molding of a single part.

[0052] Reference numeral 47 denotes a locking block, and the locking block 47 is inserted and accommodated in the case body 3 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com