Automatic coil binding device and stator coil winding machine with the same installed

A technology of coil device and stator coil, applied in electromechanical devices, manufacturing motor generators, electric components, etc., can solve the problem of insufficient automation and achieve the effect of improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

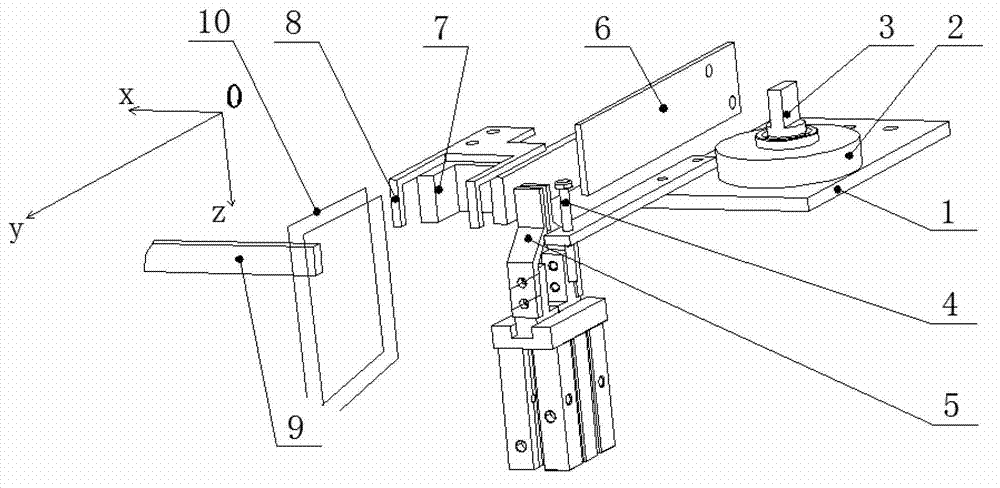

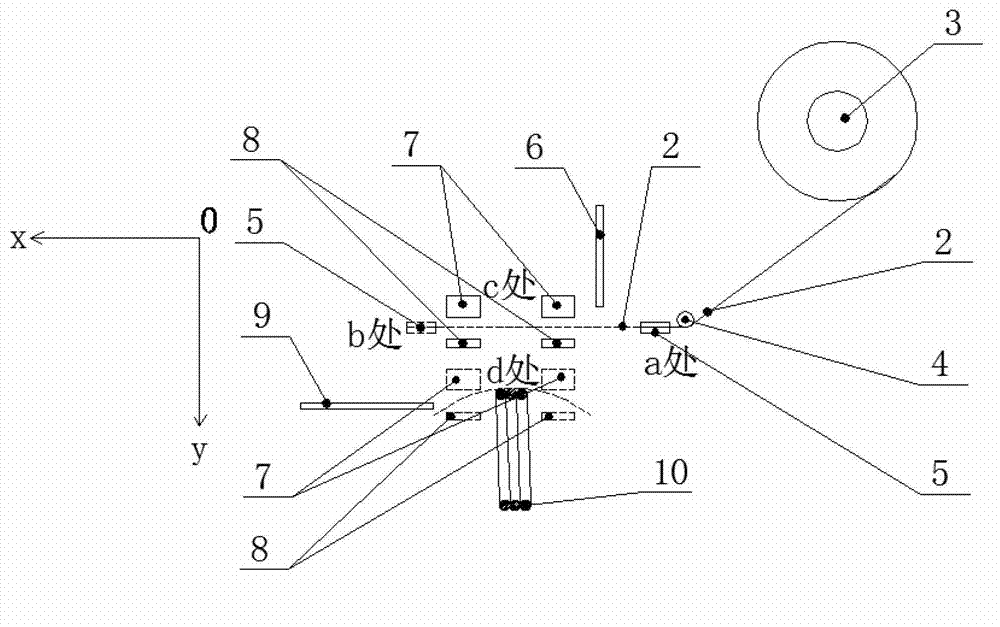

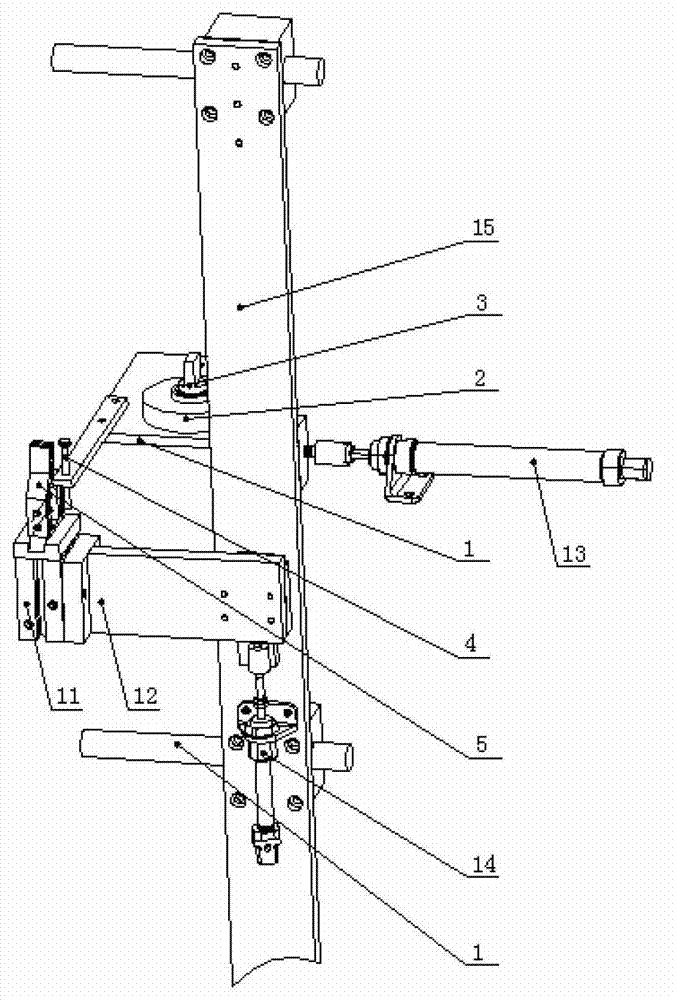

[0028] Figure 3 to Figure 6 It is a structural schematic diagram of the automatic coil binding device of the present invention. It is known from the figure that the automatic coil binding device includes a tape preparation device, a tape cutting device, a tape feeding device and a tape binding device; image 3 As we know, the adhesive tape preparation device includes frame 1, adhesive tape 2, pin shaft 3, guide rod 4, gripper 5, pneumatic gripper 11, upper and lower gripper moving frame 12, left and right cylinders 13, upper and lower cylinders 14 and left and right grippers. Hand mobile frame 15; described bearing pin 3 is fixedly connected on the frame 1, and adhesive plaster 2 is sheathed on the bearing pin 3; Described guide bar 4 is fixedly connected on the frame 1; Described clamping hand 5 is fixed Connected to the moving bar of the pneumatic gripper 11, the pneumatic gripper 11 is fixedly connected to the upper and lower clamping hand moving frame 12; The moving fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com