Full-automatic coil binding machine

A binding machine, fully automatic technology, applied in the direction of binding, etc., can solve the problems of many defective products, decline in the output and quality of this book, complicated procedures, etc., and achieve the goal of increasing production efficiency, simplifying and stabilizing processes, and improving product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

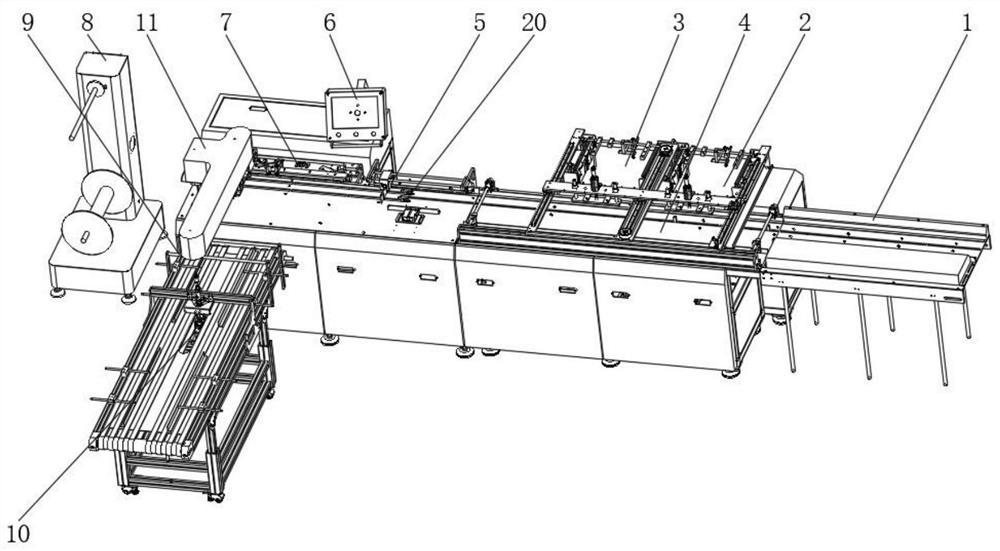

[0035] see Figure 1-11 As shown, a fully automatic coil binding machine includes: an inner core placement table 1, an automatic bottom cover assembly mechanism 2, a chain indirect transmission mechanism 4, a calibration mechanism 5, a cover flip mechanism 11 and a finished product U-turn storage mechanism 10, and the inner core is placed One side of platform 1 and one side of chain indirect transmission mechanism 4 are fixedly installed.

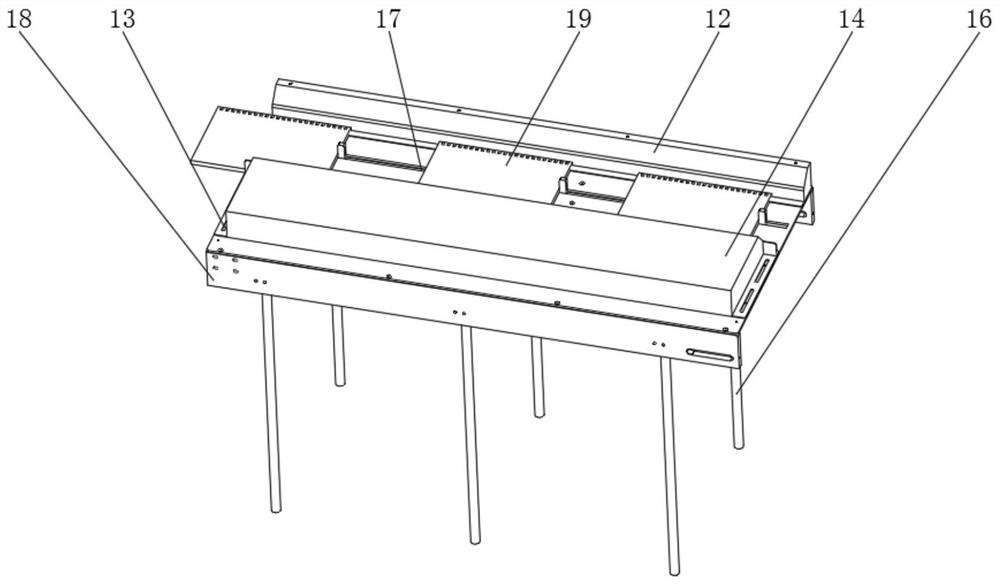

[0036] Such as Figure 1-3As shown: one end of the rear side of the chain indirect transmission mechanism 4 is movably installed with the front end of the back cover automatic assembly mechanism 2, and the other end of the rear side of the chain indirect transmission mechanism 4 is movably installed with a cover automatic assembly mechanism 3, and the inner core placement table 1 includes Place plate 18, rear adjustable baffle 14, front fixed baffle 12 and inner core 19, the bottom of place plate 18 is fixedly connected with support frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com