Transformer abnormal-shape clamp member

A transformer and special-shaped technology, applied in the direction of transformer/inductor magnetic core, etc., can solve problems such as processing difficulties, and achieve the effect of increasing the scope of application, simple operation, and saving processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below by means of specific embodiments:

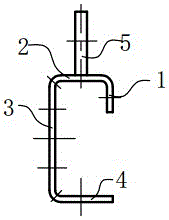

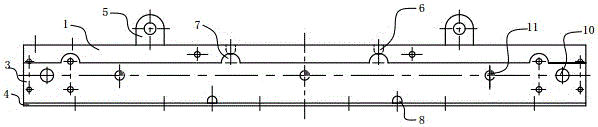

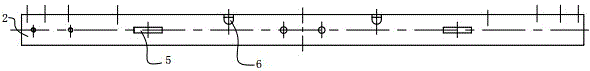

[0024] The reference signs in the drawings of the specification include: front plate 1, top plate 2, back plate 3, bottom plate 4, lifting lug 5, upper cable tie hole 6, terminal connection hole 7, lower cable tie hole 8, installation hole 9, the A bolt hole 10 and a second bolt hole 11.

[0025] like figure 1 As shown, the transformer special-shaped clamp is integrally formed by a steel plate, including a front plate 1, a top plate 2 vertically connected to the front plate 1, a back plate 3 vertically connected to the top plate 2 and on the same side as the front plate 1, and a back plate connected to the back plate 3 Bottom plate 4 connected vertically and on the same side as top plate 2; lifting lugs 5 for coil installation are welded on the top surface of top plate 2; holes are opened on front plate 1, top plate 2, back plate 3 and bottom plate 4. like Figure 5 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com