Device for spot welding on wheel housing

A cover point and wheel technology is applied in the field of wheel cover spot welding devices, which can solve the problems of inability to guarantee the spot welding surface quality, deep indentation of the electrode head, increased labor intensity, etc., and achieves simple structure, high welding efficiency, and guaranteed The effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

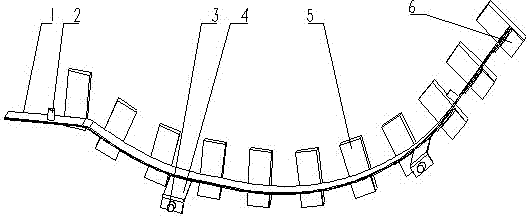

[0008] Depend on figure 1 As shown, a device for spot welding of wheel covers includes an arc-shaped connecting plate 1, powerful magnets 2, 3 and a red copper backing plate 5, and the arc-shaped connecting plate 1 made of two steel coil straps is connected with the front wheel The shape of the cover coincides with that of the arc-shaped connecting plate 1. There are a number of red copper backing plates 5 evenly distributed on one side of the arc-shaped connecting plate 1. The connecting plate 6 on the red copper backing plate 5 is fixed on the arc-shaped connecting plate 1. The end is provided with a powerful magnet A2, and a powerful magnet B is fixed on the positioning connecting plate 4 on the other side of the arc connecting plate 1, and 11 copper backing plates are evenly distributed on one side of the arc connecting plate.

[0009] The arc-shaped connecting plate made of two steel coil straps matches the shape of the wheel cover. The strong magnet A 2, strong magnet B ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com