Crimper for binding coil

a crimping coil and crimping technology, which is applied in the field of crimping devices, can solve the problems of undesirable crimping coil ends, aesthetically unpleasant or otherwise faulty coil ends, and achieve the effect of convenient and manual configuration and convenient interchang

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

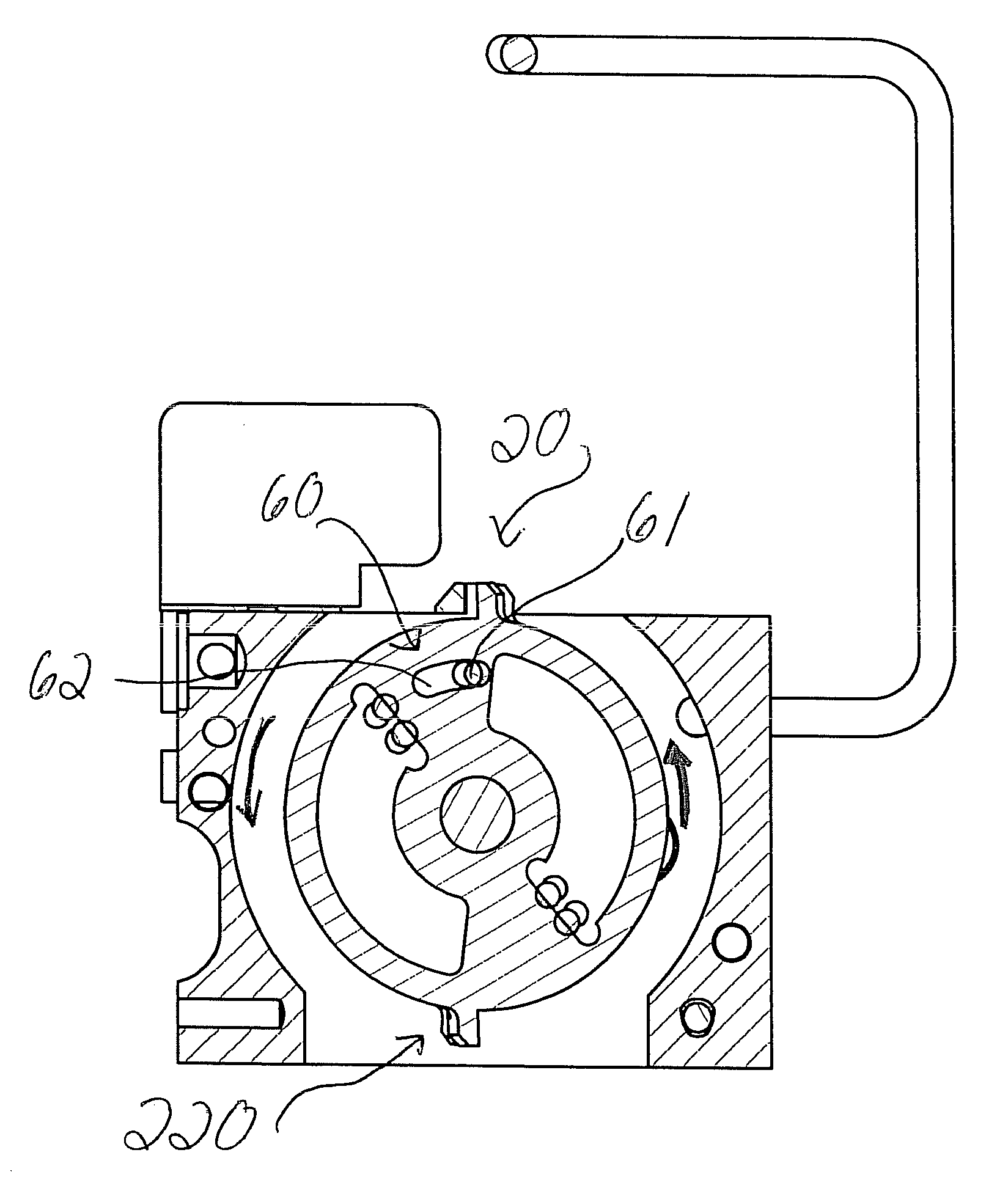

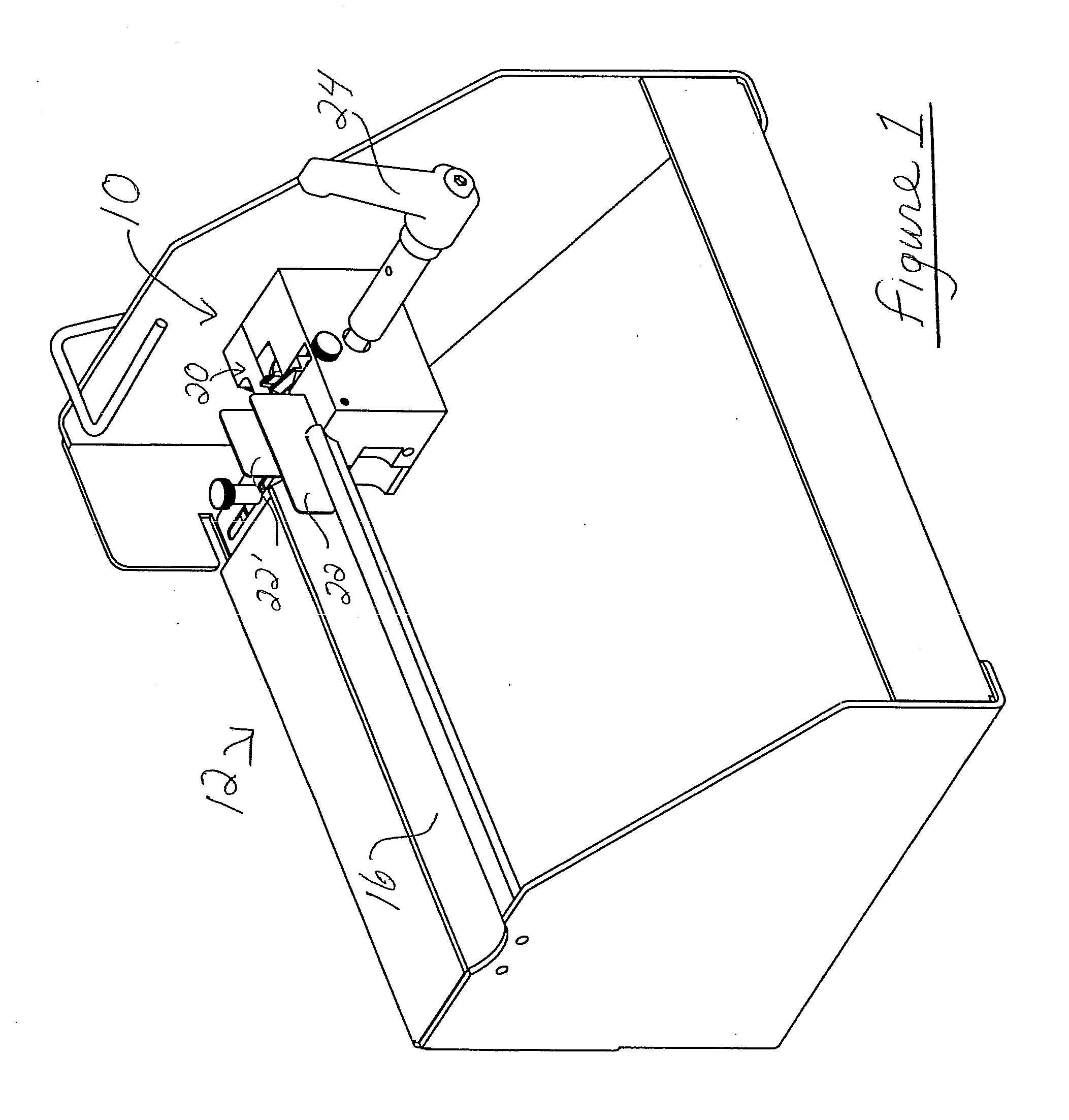

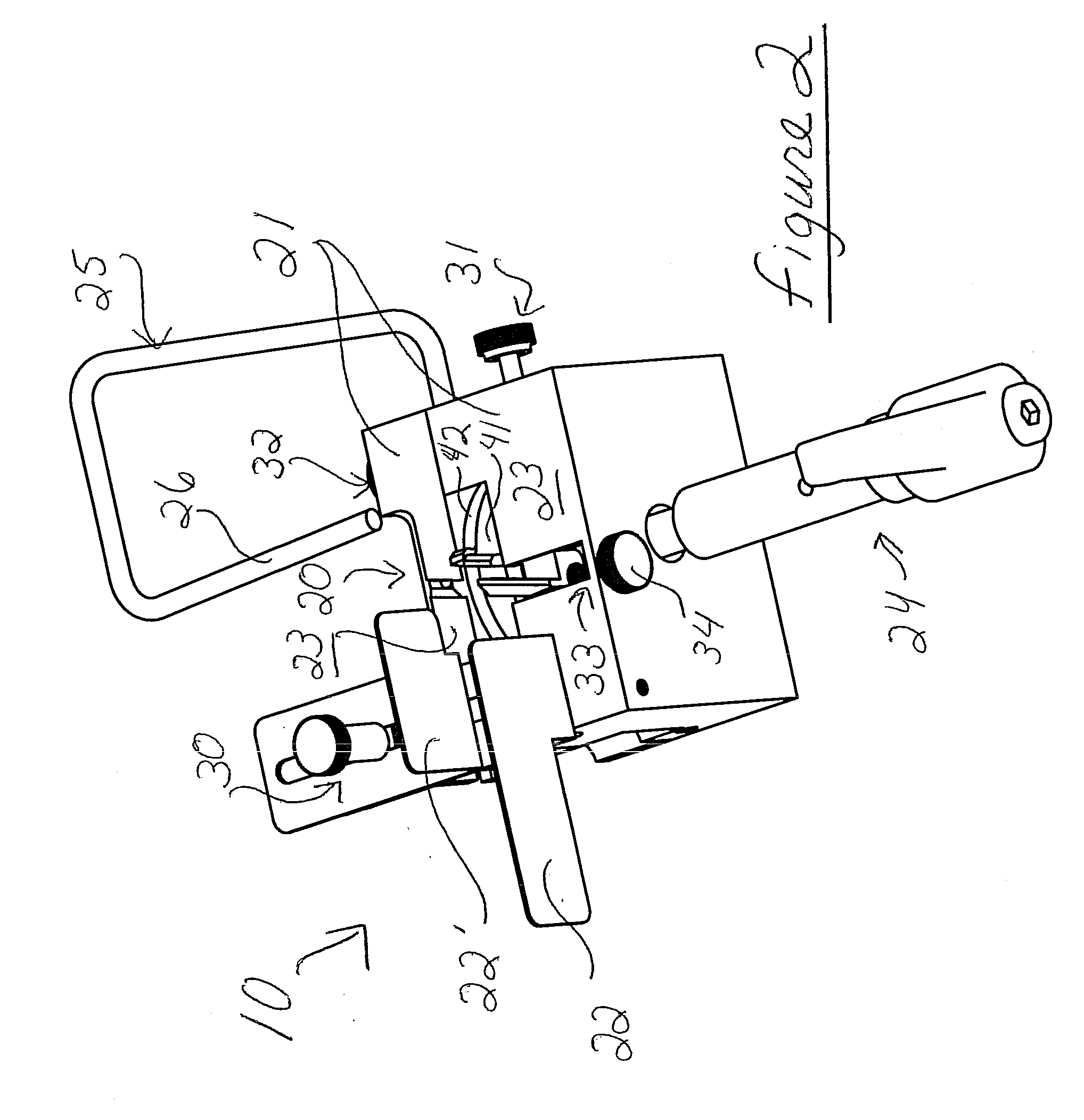

[0029]Referring to the Figures, there is shown one, but not the only, embodiments of the invented crimping device for spiral book- or pamphlet-binding coil. In most of the figures, neither the book or pamphlet, nor the coil being cut and crimped, is shown, for simplicity and to reveal the parts of the crimping set. However, it may understood, for example by viewing the embodiment of FIG. 1, that the book or pamphlet may be placed generally vertically, with the coil already inserted into the holes in the book / pamphlet sheets and received in a coil-receiving trough. This way, an end of the coil may be placed in the crimping system at one end of the trough. The book coil may be crimped on one end, and then the book and coil may be lifted up and flipped end to end to and replaced in the coil-receiving trough and crimping system for crimping of the opposite end of the coil. Alternatively, a machine may be provided with two of the invented crimpers, one for each end of the book. The prefe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com