Coil binding anti-scratch device

A coil and outer protection technology, which is applied to the parts of strapping machinery, etc., can solve the problems of coil scratches, waste products, and increased production costs, so as to prevent coil scratches, reduce production costs, and have a long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

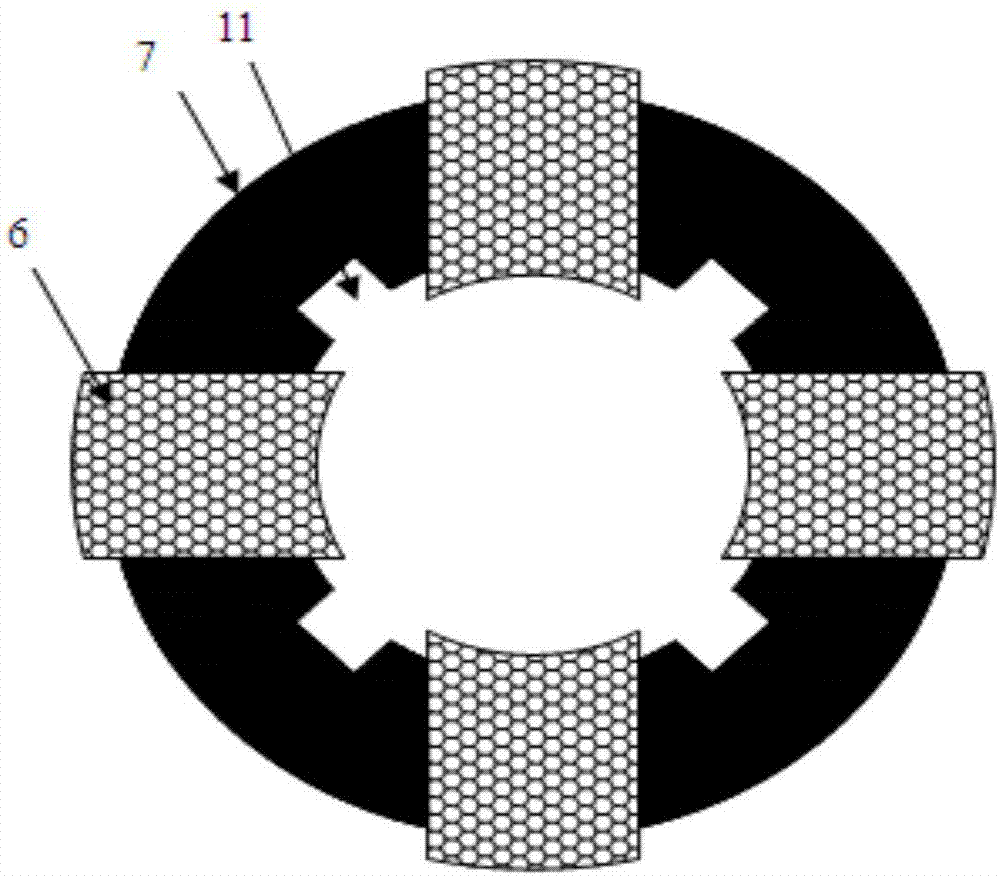

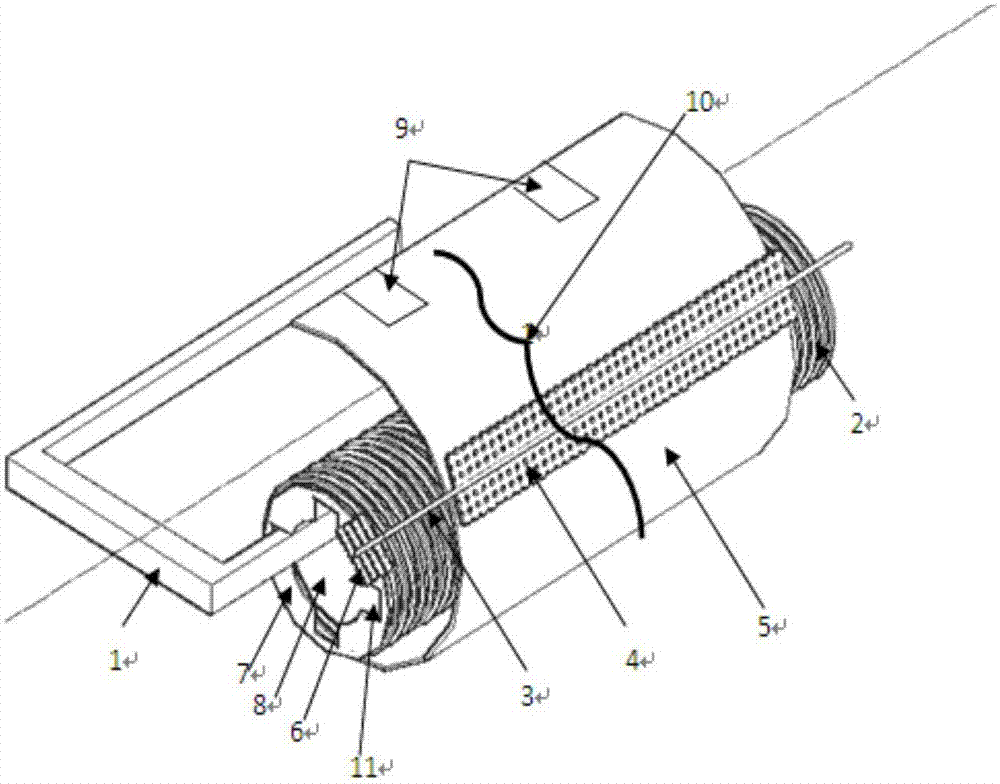

[0015] Such as Figure 1-2 As shown, the coil bundling anti-scratch device includes an inner protective plate 8, an outer protective plate 5 and an end protective plate, the inner protective plate 8 is closely attached to the inner wall of the coil 2, and the outer protective plate 5 is wrapped outside the coil 2 , the inner protective plate 8 and the outer protective plate 5 that the binding line 3 passes through are all provided with a plastic mesh belt 4 through the lock, and the inner protective plate 8 and the outer protective plate 5 are all composed of two layers of cardboard and the two layers of cardboard There is a layer of nylon weaving net in the middle, and multi-layer nylon weaving net can be arranged according to actual needs. The joints of both ends of the inner and outer protective plates are provided with master rubber blocks 9, and the outer protective plate 5 is also provided with a tightening belt 10. The upper protective plate includes an annular collar 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com