Processing method of shielding layer of shielding wire

A processing method and shielding layer technology, applied in the direction of line/collector components, electrical components, circuits, etc., can solve problems such as extrusion and wear, narrow space, and large solder joints in wiring harnesses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

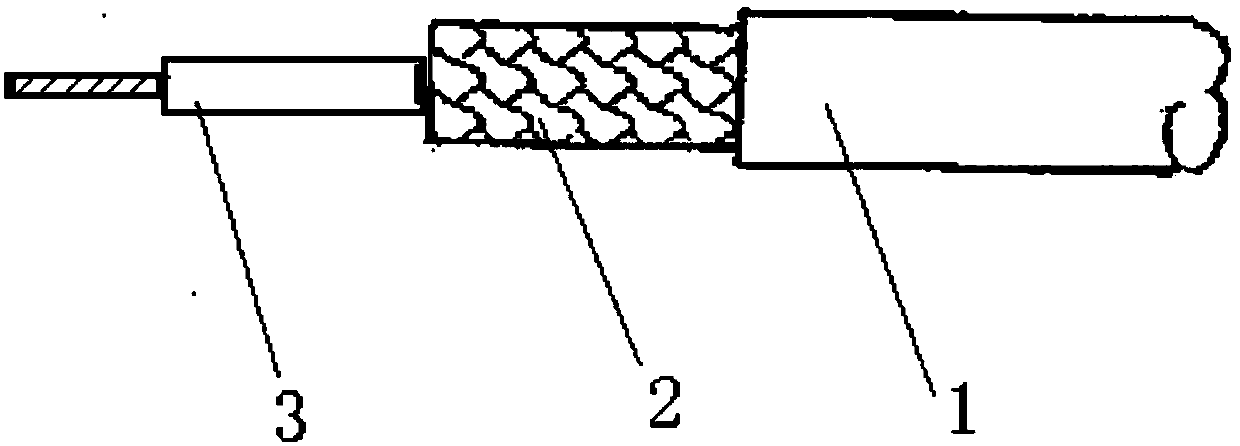

[0018] Provide a method for processing the shielding layer of shielded wires, a wire harness of multiple single-core shielded wires, wherein each single-core shielded wire at least includes an outer insulating layer 1, a shielding layer 2 and a core wire 3;

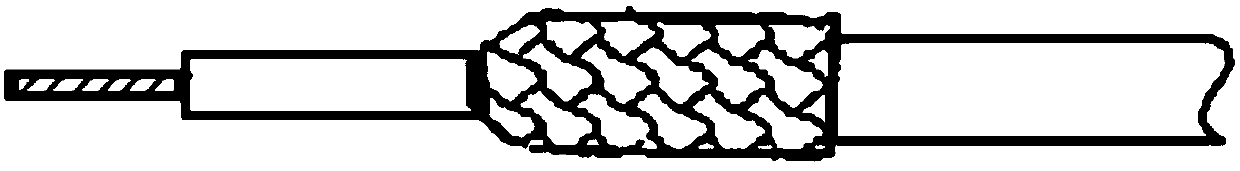

[0019] Step 1. Strip off the outer insulation layer 1 at one end of all single-core shielded wires, and turn the shielding layer 2 outward to the outer insulation layer;

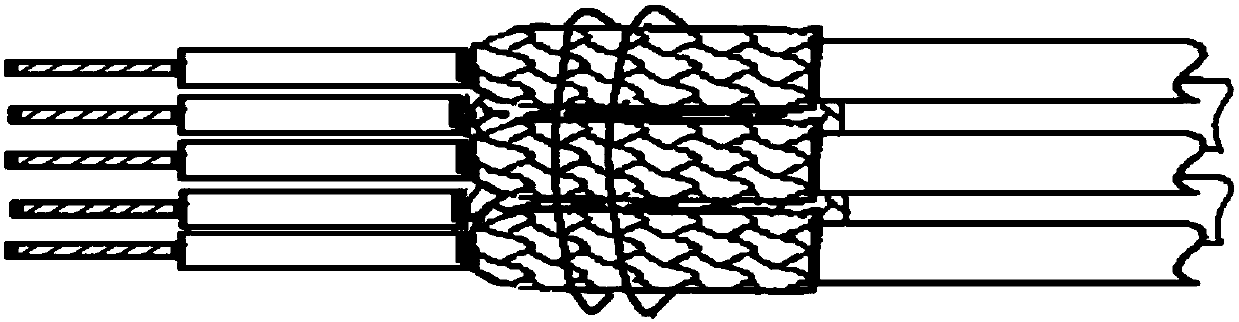

[0020] Step 2. Gather all single-core shielded wires into a wire harness, and gather the turned-out shielding layers of all shielded wires together, and wrap the turned-out shielding layer with a binding coil;

[0021] Step 3, tinning the binding coil of the outward shielding layer, and welding the grounding wire at the binding coil at the same time;

[0022] Step 4: Put a heat-shrinkable sleeve on the turned-out shielding layer so that the heat-shrinkable sleeve wraps the entire turned-out shielding layer.

[0023] Among them, in step 1, it is also ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com