Multi-coil binding machine for hot-rolled narrow strip steel

A technology for strapping machines and narrow strip steel, which is applied to the parts of strapping machines, strapping materials, and automatic control of packaging, etc. It can solve problems such as failure to achieve automation, inability to adapt, and economic losses in steel mills, so as to improve intelligent control performance and avoid High-temperature roasting ensures safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described in detail below with reference to the drawings and embodiments.

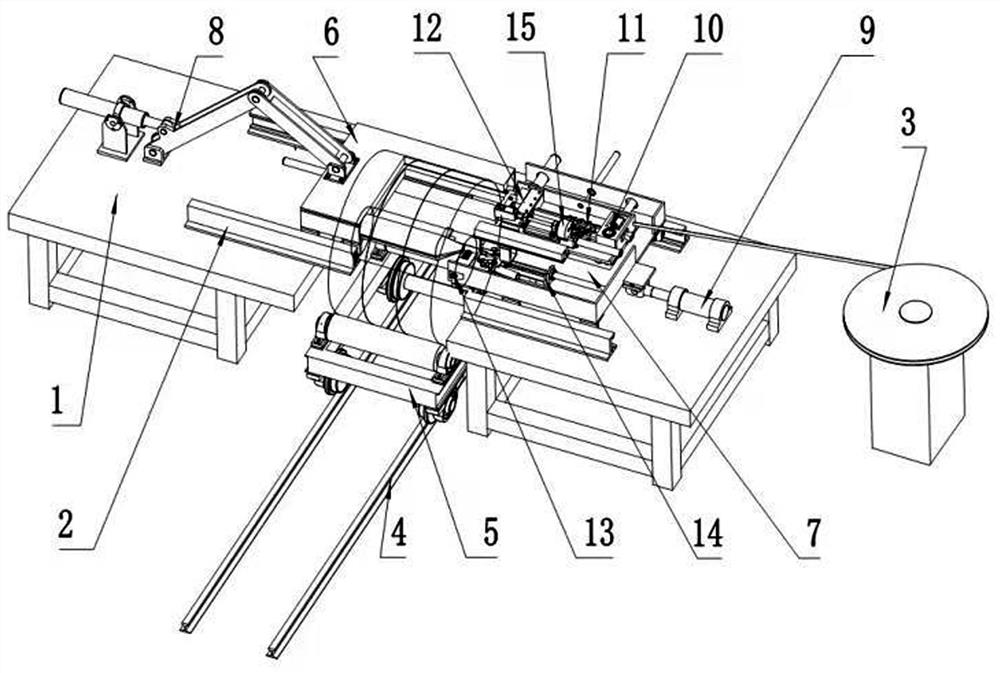

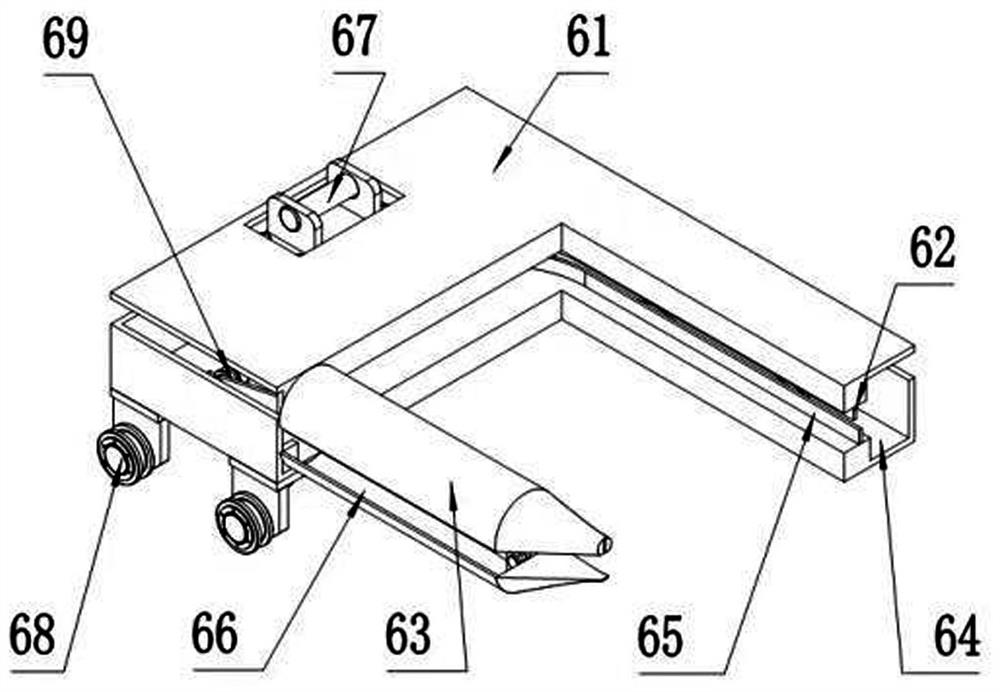

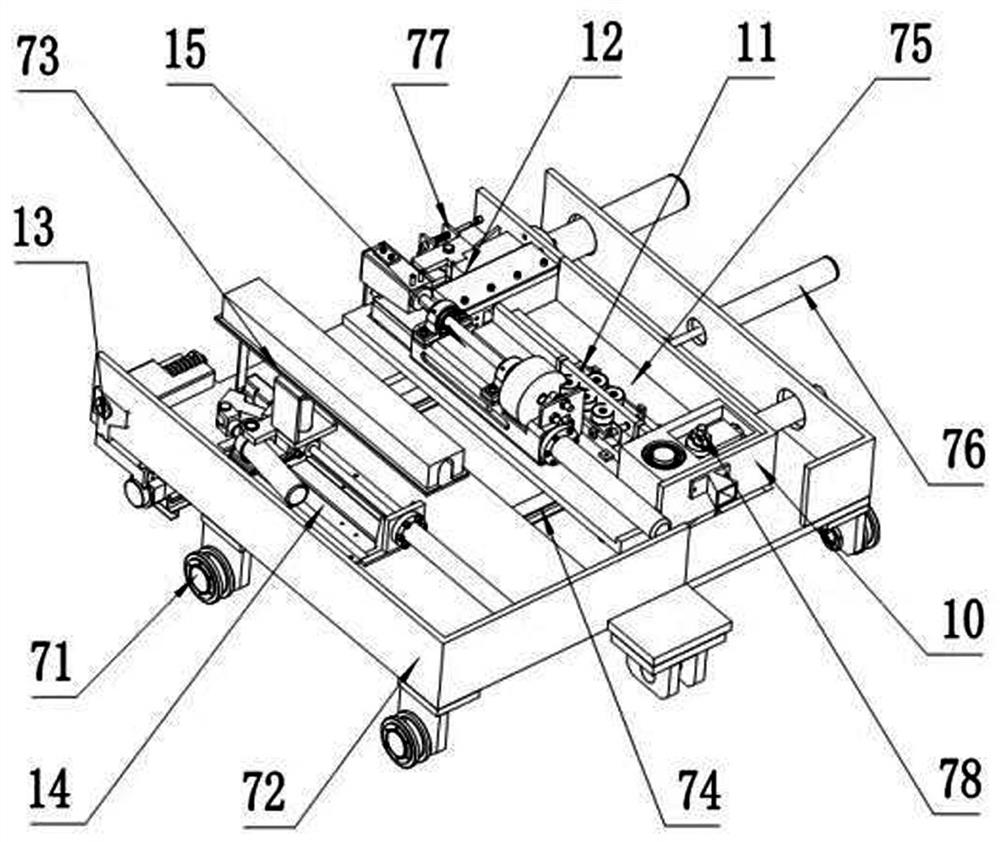

[0024] like figure 1 , the hot-rolled narrow-strip multi-volume binding machine includes a platform 1 and a transverse rail 2 arranged on the platform 1, the platform 1 is divided into left and right parts, and the transverse track 2 is a parallel track, which is also divided into left and right parts and arranged on the Corresponding above the left platform and the right platform. On the right side of the platform 1, an uncoiler 3 is arranged, and the uncoiler 3 adopts a torque motor and assembles a flat storage tape reel. A longitudinal rail 4 is arranged between the left and right two parts of the platform. On the longitudinal rail 4, a rolling trolley 5 is arranged. The rolling trolley 5 is provided with a driving mechanism, and a pair of steel coil holders are installed on the rolling trolley 5. The steel coil idler is eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com