An adjustable uncoiler material head feeding device that can effectively compress the strip

A technology of feeding device and pressing belt, which is applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems of low production efficiency, easy loosening of steel coils, waste of time, etc., so as to improve feeding and pressing. Efficiency, reducing head damage, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

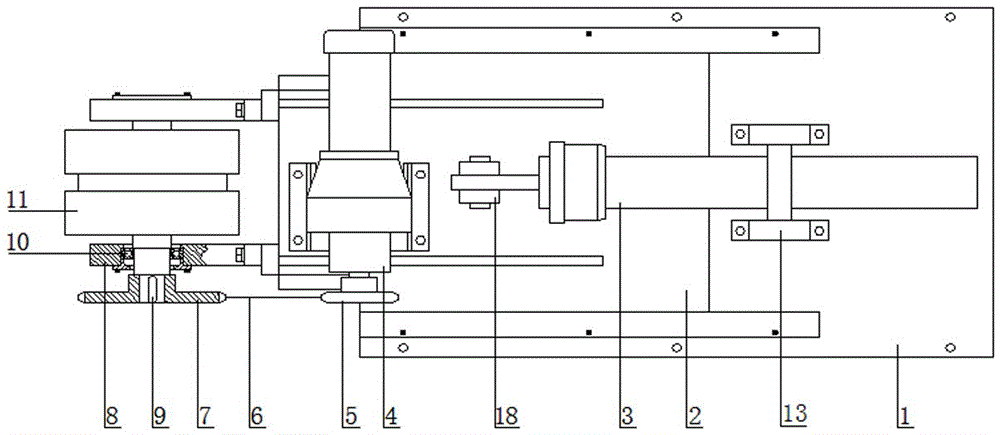

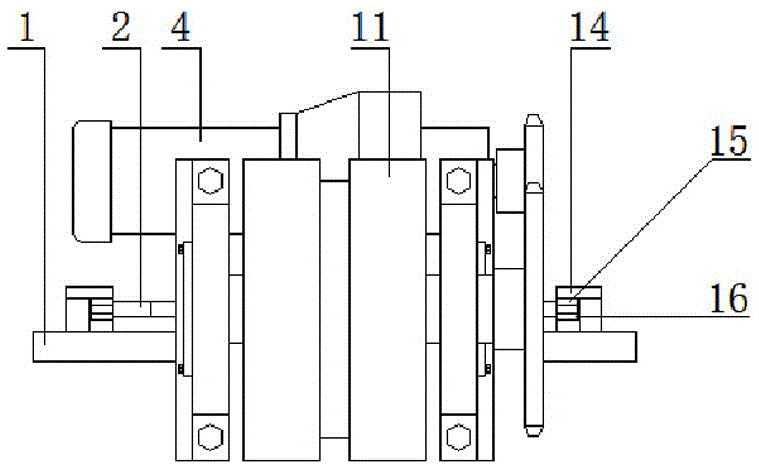

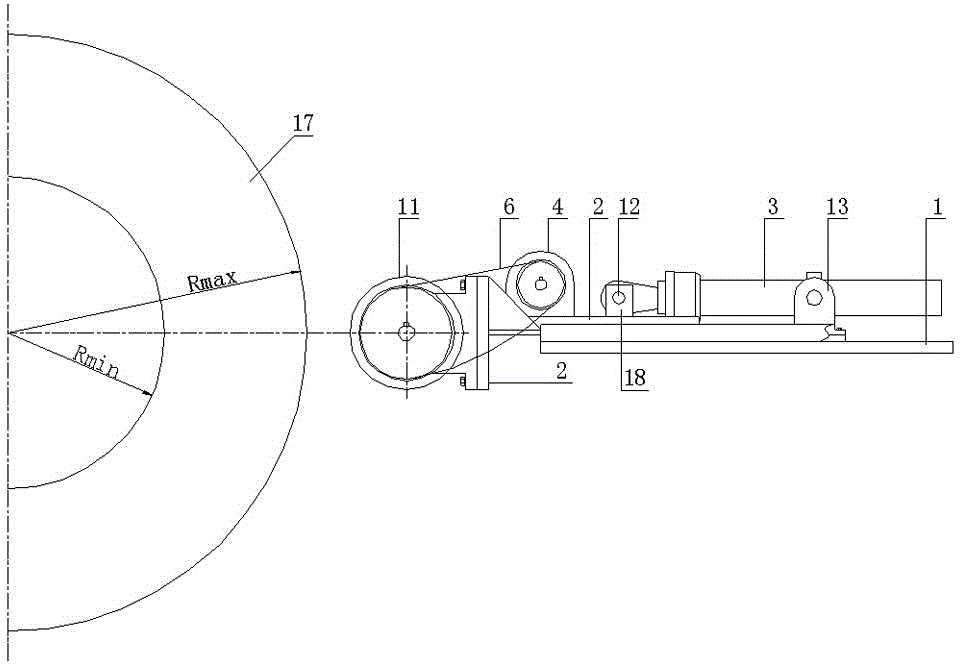

[0012] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way, and any transformation made based on the teaching of the present invention falls within the protection scope of the present invention.

[0013] Such as Figure 1~3 As shown, the present invention includes a base 1, a sliding seat 2, an oil cylinder 3, a feeding roller 11 and a driving device for the feeding roller, and positioning chute 14 is arranged on both sides of the upper part of the base 1, and the described sliding seat 2 passes through the positioning chute 14 Slidingly fit with the base 1; the outer side of the upper part of the base 1 is consolidated with an oil cylinder frame 13, and an oil cylinder 3 is arranged on it; the piston rod of the oil cylinder 3 is hinged to the ear seat 18 on the upper part of the slide seat 2 through a pin 12; The feeding roller 11 is arranged on the end of the tape coil 17, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com