Device and method for uncoiling diamond frame sawbladesteel belt coils

An uncoiling device, diamond technology, applied in the direction of coiling strips, transportation and packaging, thin material handling, etc., can solve the problems of uneven unloading, loose coils, etc., to avoid potential safety hazards, easy to load and unload, and simplify the system structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

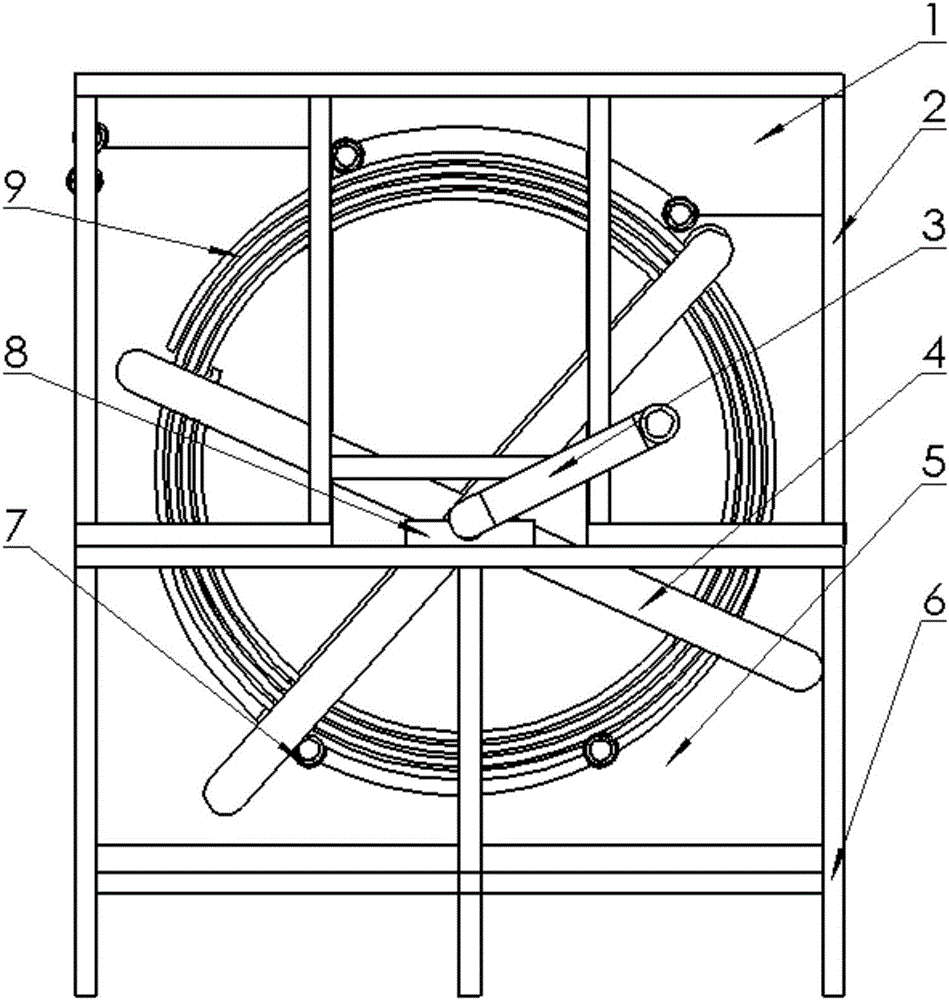

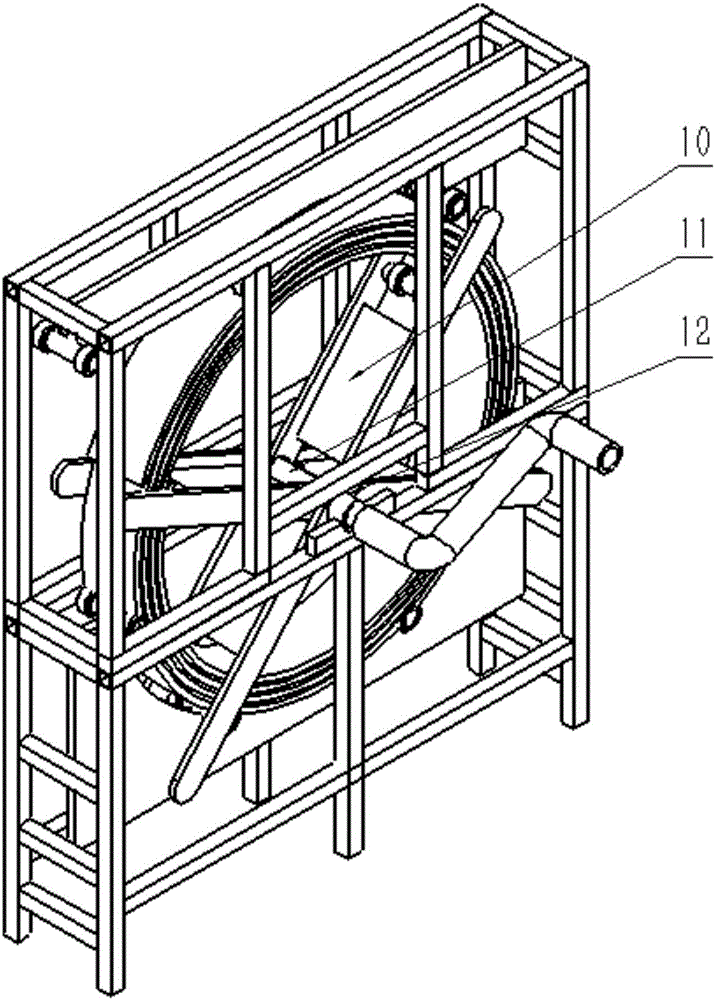

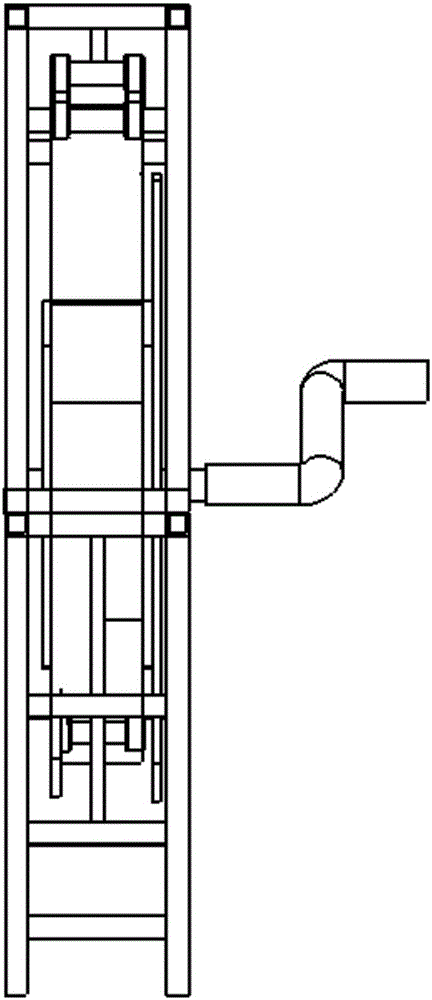

[0039] Embodiment: a kind of diamond frame saw saw blade strip coil uncoiling device, its structure is as follows Figure 1-3 As shown, it mainly includes a supporting mechanism 14 , a driving mechanism 15 and a positioning mechanism 13 .

[0040] The driving mechanism 13 drives some parts of the supporting mechanism 14 to rotate, and some parts of the supporting mechanism 14 are used to fix the steel strip coil 9 . The support mechanism 14 includes a positioning block 10 , a central shaft 11 , a roller 7 , an upper frame 2 , a lower frame 6 , an upper baffle 1 and a lower baffle 5 . The positioning mechanism 13 includes a shaft sleeve 12 , a long plate 4 and a spacer 8 , and the driving mechanism 15 includes a rocker arm 3 .

[0041] The relative positions of the above-mentioned components are:

[0042] The upper frame 2 is detachably connected with the lower frame 6, and an upper baffle plate 1 is installed on the upper frame 2, and 4 rollers 7 for positioning are installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com