Binding device for roll-dividing machine and binding method

A technology of a coiler and a rotating device, which is applied to the parts of the binding machine, can solve the problems of low binding efficiency and finger scratches, and achieve the effects of improving binding efficiency, reducing labor intensity, and avoiding scratches on binding wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

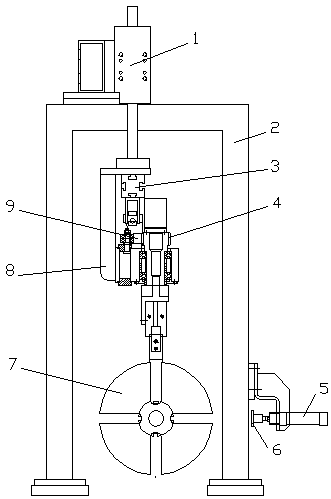

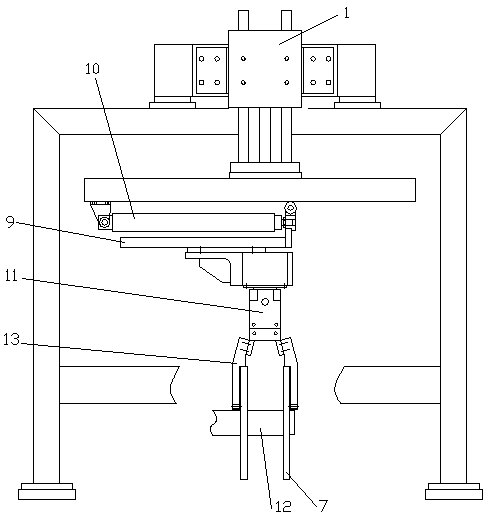

[0025] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

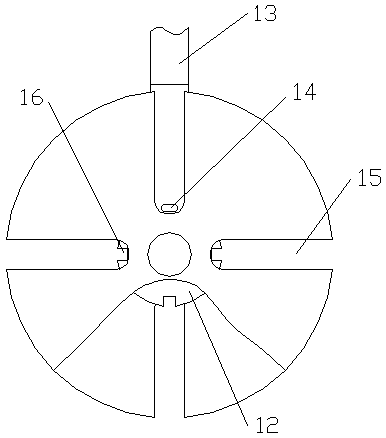

[0026] A rope reel for a winding machine, comprising a horizontally placed mandrel 12 driven by a driving motor and baffles 7 located at both ends of the mandrel, wherein one end of the baffle is fixedly connected to the mandrel, and the other end of the baffle is connected to the mandrel. Detachable connection, the detachable connection can be a key connection, or the baffle can be pressed on the end of the mandrel, as long as the two baffles and the mandrel rotate synchronously, after the winding is completed, the other end of the baffle and the The mandrel is split for easy removal of the coil. On the surface of the mandrel 12, there are several threading grooves 16 distributed in the circumferential direction and penetrating in the axial direction. Threading gap 15, after the small rope winding system is completed, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com