Rotor coil binding machine of wind power generator

A wind power generator and rotor coil technology, applied in the direction of wind power generation, manufacturing motor generators, electrical components, etc., can solve the problems of high labor intensity, unsuitable quality control, low efficiency, etc., achieve good results, ensure coil insulation structure, The effect of guaranteeing the mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

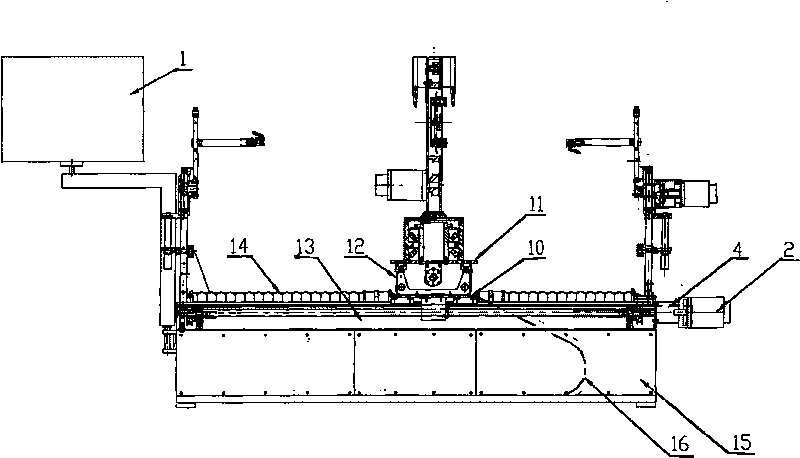

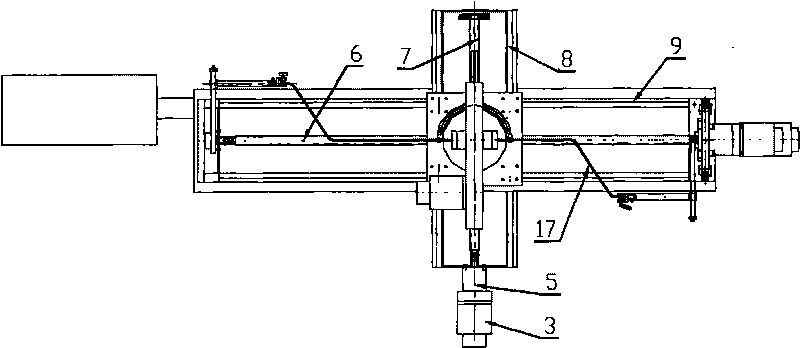

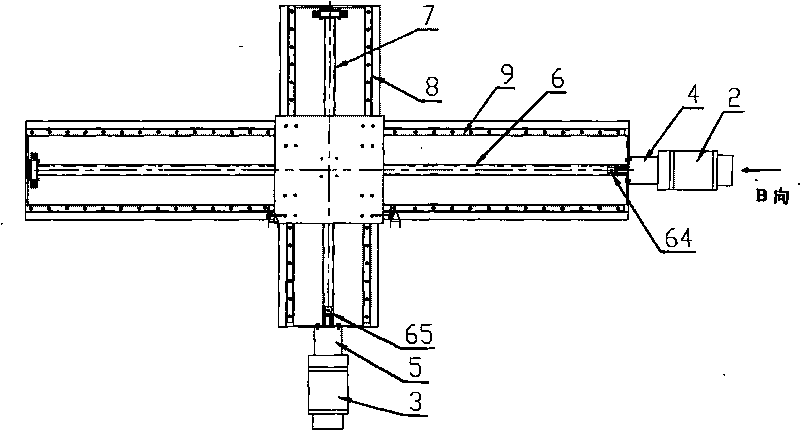

[0042] Wind power generator rotor coil wrapping machine includes numerical control system 1, machine base 15, feed system fixed on machine base 15, rotor coil clamping synchronization device and wrapping head fixed on feed system;

[0043] The feed system consists of an X-direction feed device and a Y-direction feed device; the X-direction feed device includes an X-direction grooved bed 13, and an X-direction ball screw 6 is supported inside the X-direction grooved bed 13, and the X-direction One end of the ball screw 6 is connected to the servo motor 2 through the coupling 64 and the reducer 4, and the top of the two ends of the X-direction grooved bed 13 is fixed with a linear guide rail 9, and a slider is installed on it, and an X-direction guide rail is fixed on the slider. Carrier 10, the bottom of the X-direction carriage 10 is fixed with a nut that matches the X-direction ball screw 6; the Y-direction feed device includes a Y-direction groove-shaped Bed 12, Y-direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com