Dry-type transformer

A dry-type transformer and transformer technology, applied in the field of transformers, can solve the problems of chaotic cable routing, high cost, and long connecting wires, and achieve the effects of standard cable routing, easy installation and maintenance, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

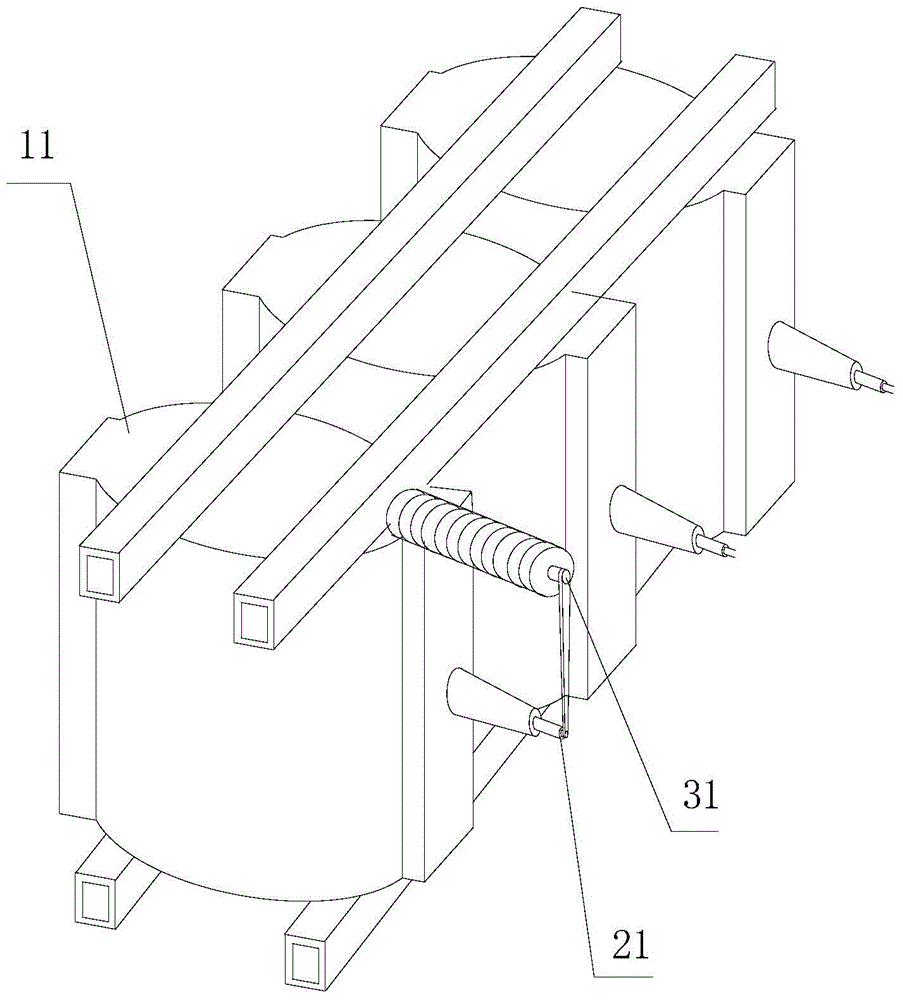

[0022] figure 1 The basic structural diagram of the dry-type transformer of the embodiment of the present invention is schematically given, as figure 1 As shown, the dry-type transformer includes:

[0023] A cabinet, a transformer body and a base, the transformer body adopts a dry-type transformer 11, which is installed on the base in the cabinet; the transformer body has a high-voltage access terminal 31 and a coil terminal 21;

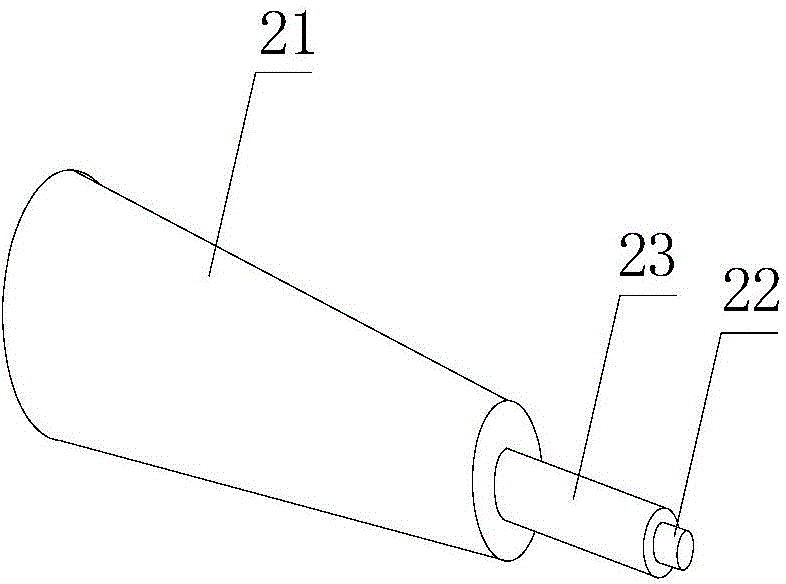

[0024] figure 2 Schematically provides the basic structural diagram of the coil terminal of the embodiment of the present invention, as figure 2 As shown, the insulating sleeve 23 is installed on the conductive post 22 inside the terminal post 21 .

[0025] The connection line between the end of the high-voltage access terminal and the terminal of the terminal is vertical, so that the distance between the high-voltage access terminal and the terminal is the shortest and the most economical.

[0026] "L"-shaped part, the "L"-shaped part is made ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com