Method and device for producing books with wire or spiral bindings or other comparable bindings

A technology of binding pieces and metal wires, applied in the direction of binding, book binding, stack receiving device, etc., can solve complex and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

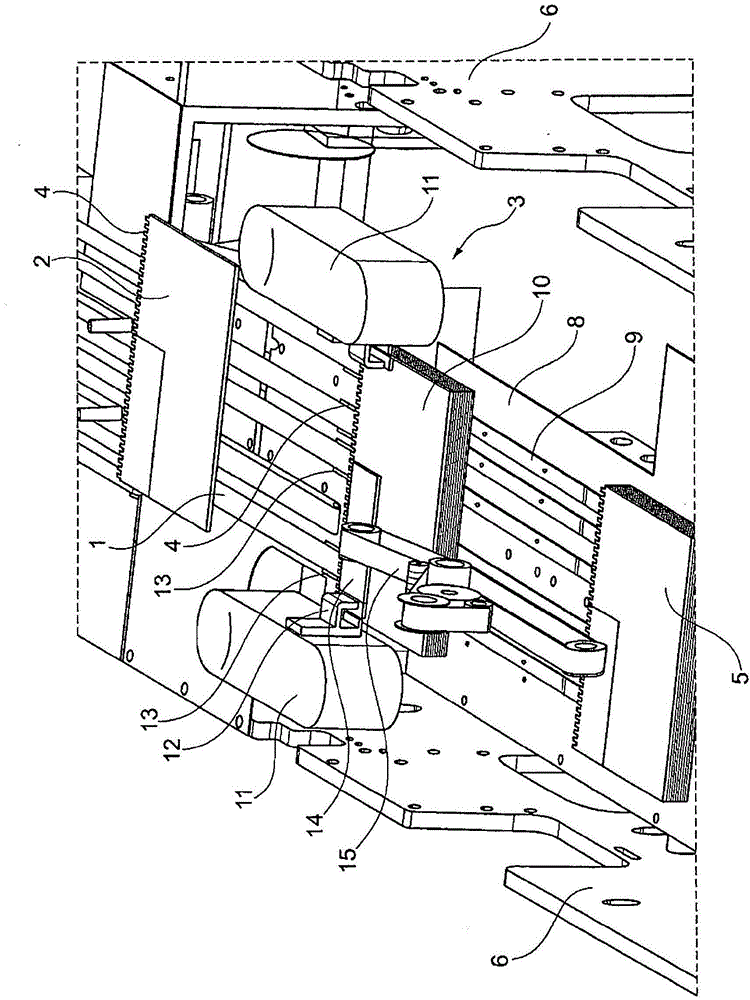

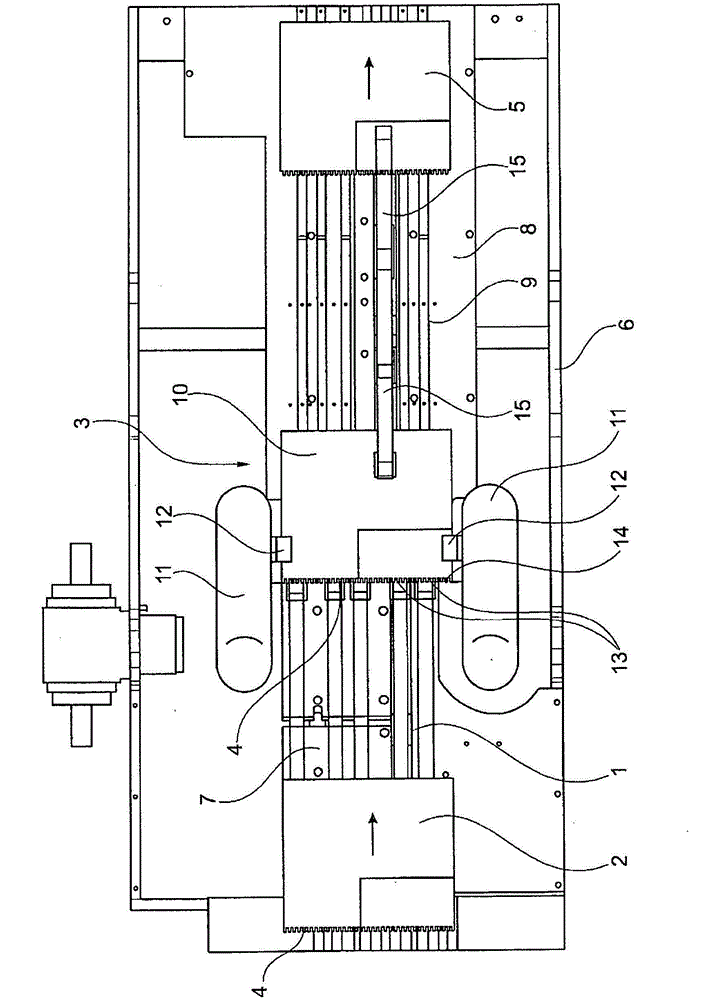

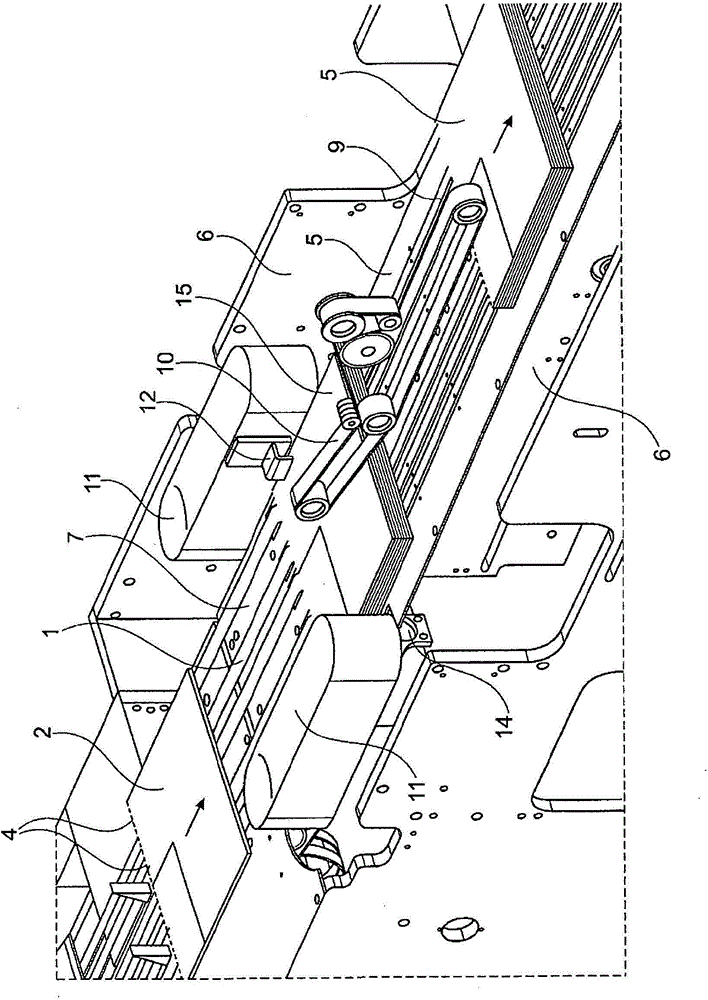

[0015] The device partially shown in the figures is part of a plant which manufactures booklets bound with wire comb or spiral binders from paper rolls. In said apparatus the sheets are produced from the paper strip by cutting transversely and longitudinally, which are then collected into volumes and provided with a row of holes by punching through which a spiral or wire-comb binder can be guided. hole.

[0016] The partial volumes are separated from one another by the laid-down intermediate pages and are subsequently collected into the volume, wherein the volume cover and the spine of the volume are additionally conveyed. The subvolumes of the original volume are then collected precisely at the binding location by guiding the spiral binding or the wire comb binding through the perforations in a known manner in the binding drum.

[0017] exist Figures 1 to 3 2 shows a collection location 3 in which the individual volumes 2 brought in on the conveyor belt 1 are collected int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com