Aerosol valve with defined flow paths

a technology of flow path and valve body, which is applied in the direction of liquid handling, instruments, volume metering, etc., can solve the problems of clogging flow path, affecting product formulations, and affecting the product formulation structure, so as to reduce back pressure and maximize product impingement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

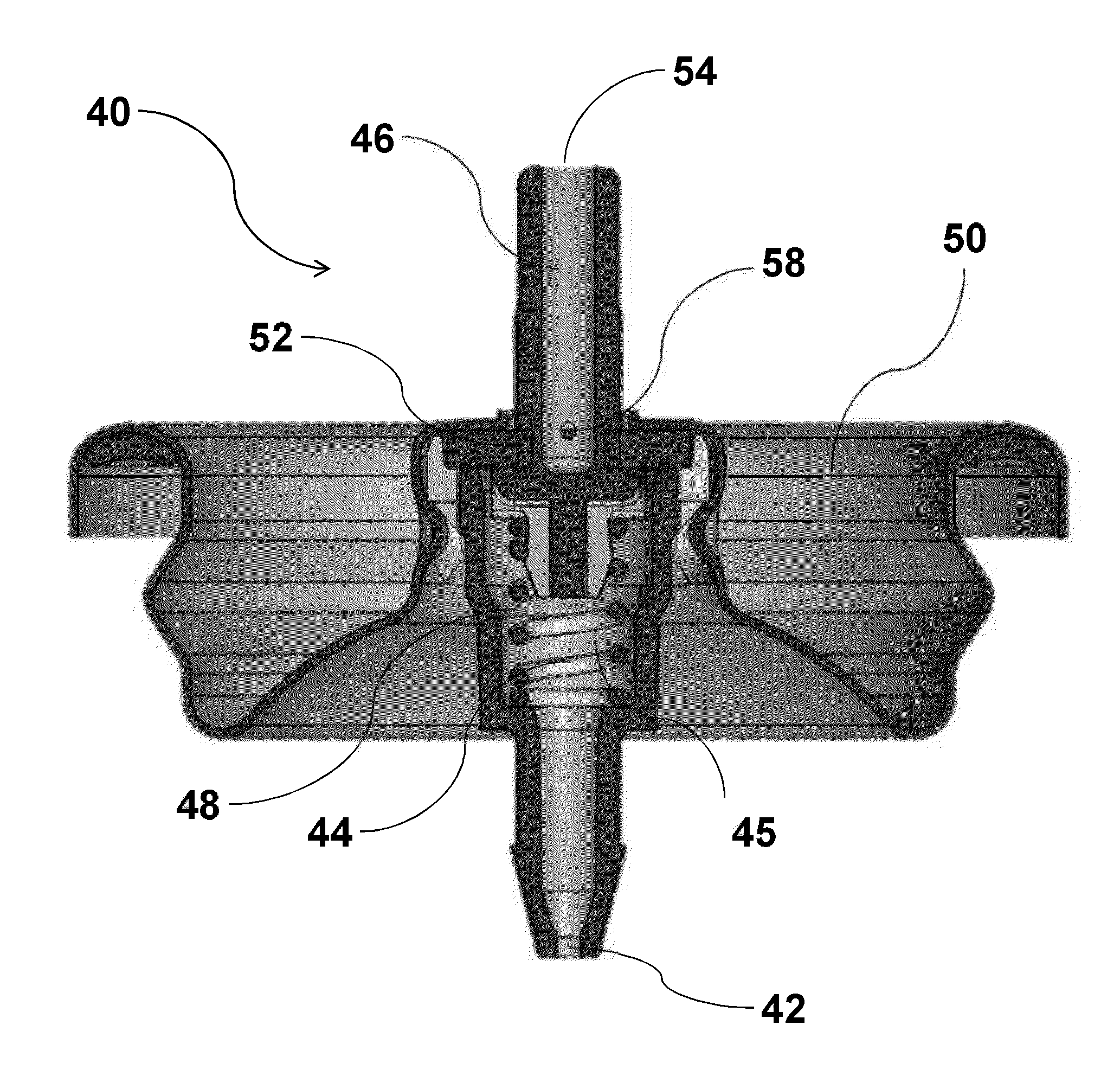

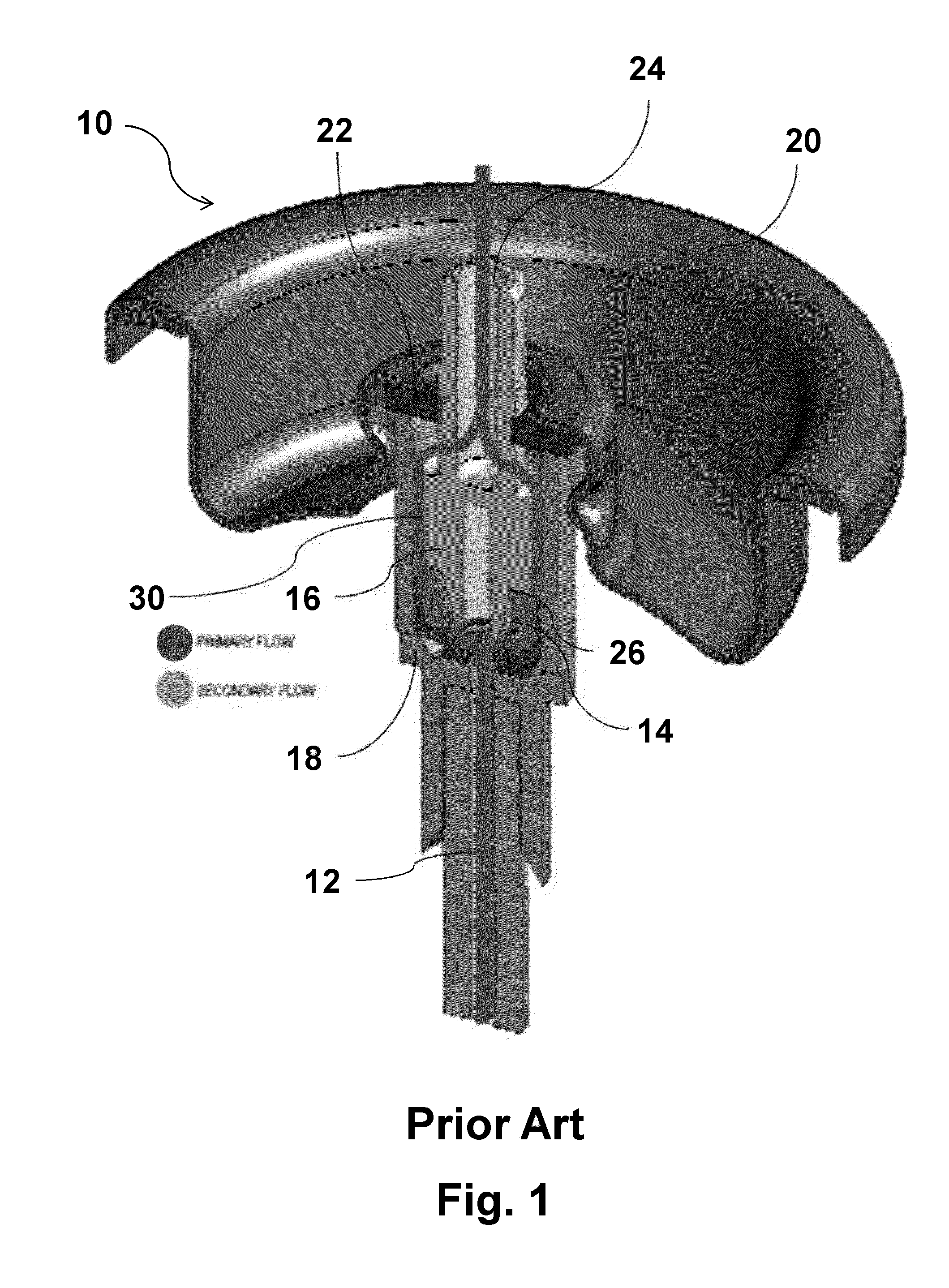

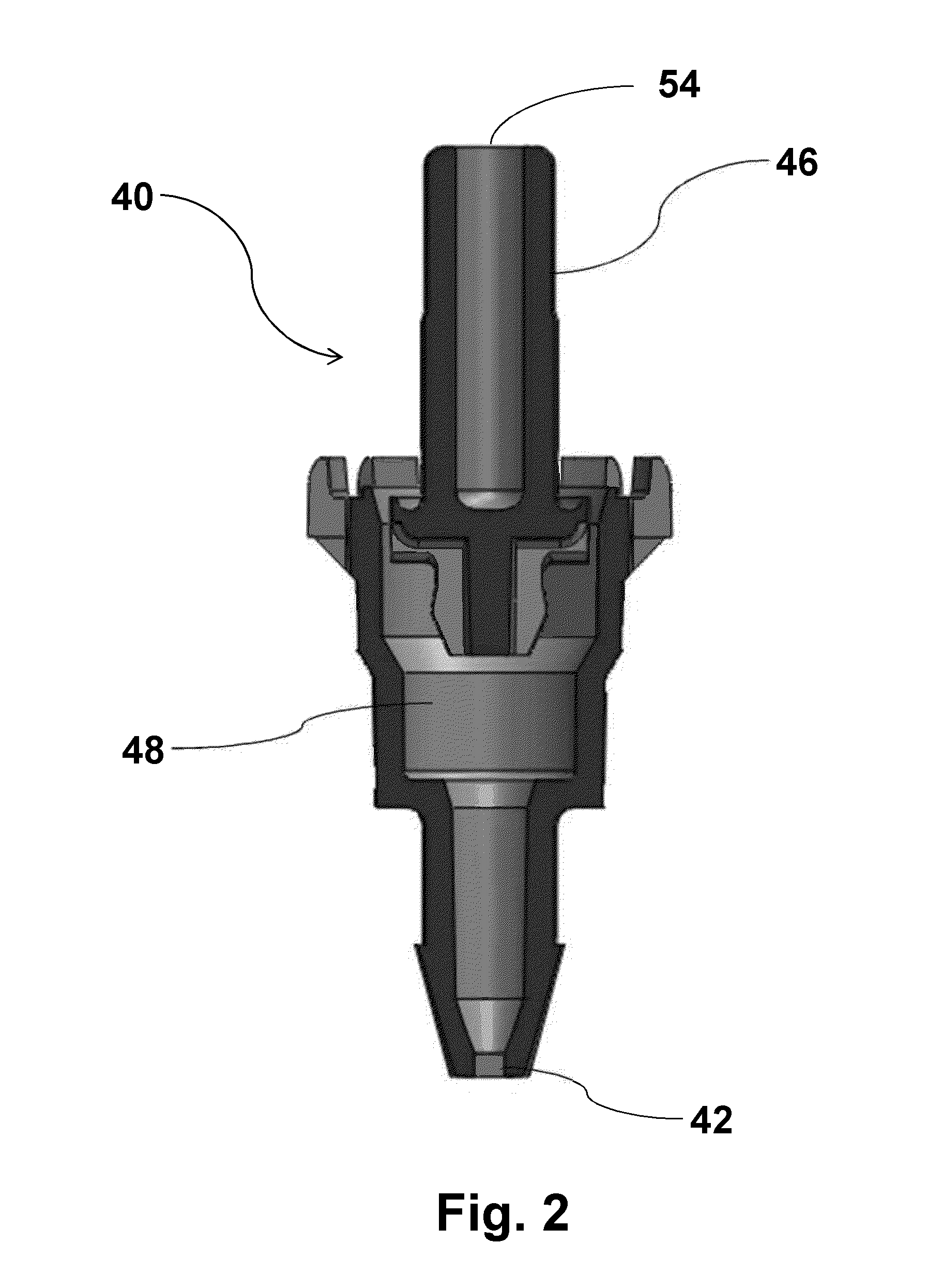

[0034]Referring to the drawings and, in particular, FIG. 1 that is a conventional or prior art aerosol valve generally represented by reference numeral 10. Valve 10, shown in FIG. 1 in full stroke, shows the flow path of the product formulation around the outside of the compression spring before the formulation is able to enter the center hole (aperture) of the valve stem.

[0035]Aerosol valve 10 includes a dip tube 12, compression spring 14, valve stem 16, valve stem housing 18, mounting cup 20, and seal 22. Valve stem 16 is enclosed in valve stem housing 18. Valve stem 16 has a pair of apertures (not shown in FIG. 1) through which a pressurized high-solids product formulation passes in order to enter center hole 24 of valve stem 16. Mounting cup 20 orients and stabilizes aerosol valve 10 in its proper position on the product. Valve stem 16 contacts compression spring 14 at contact point 26.

[0036]Compression spring 14 exerts an upward pressure on valve stem housing 18, which is press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com