An installation device for steel coil strapping

A technology for installing devices and strapping straps, which is applied to the parts, packaging, and strapping objects of strapping machines. It can solve problems such as slow strapping speed, safety accidents, and improper operation, so as to reduce time, ensure safety, and increase reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

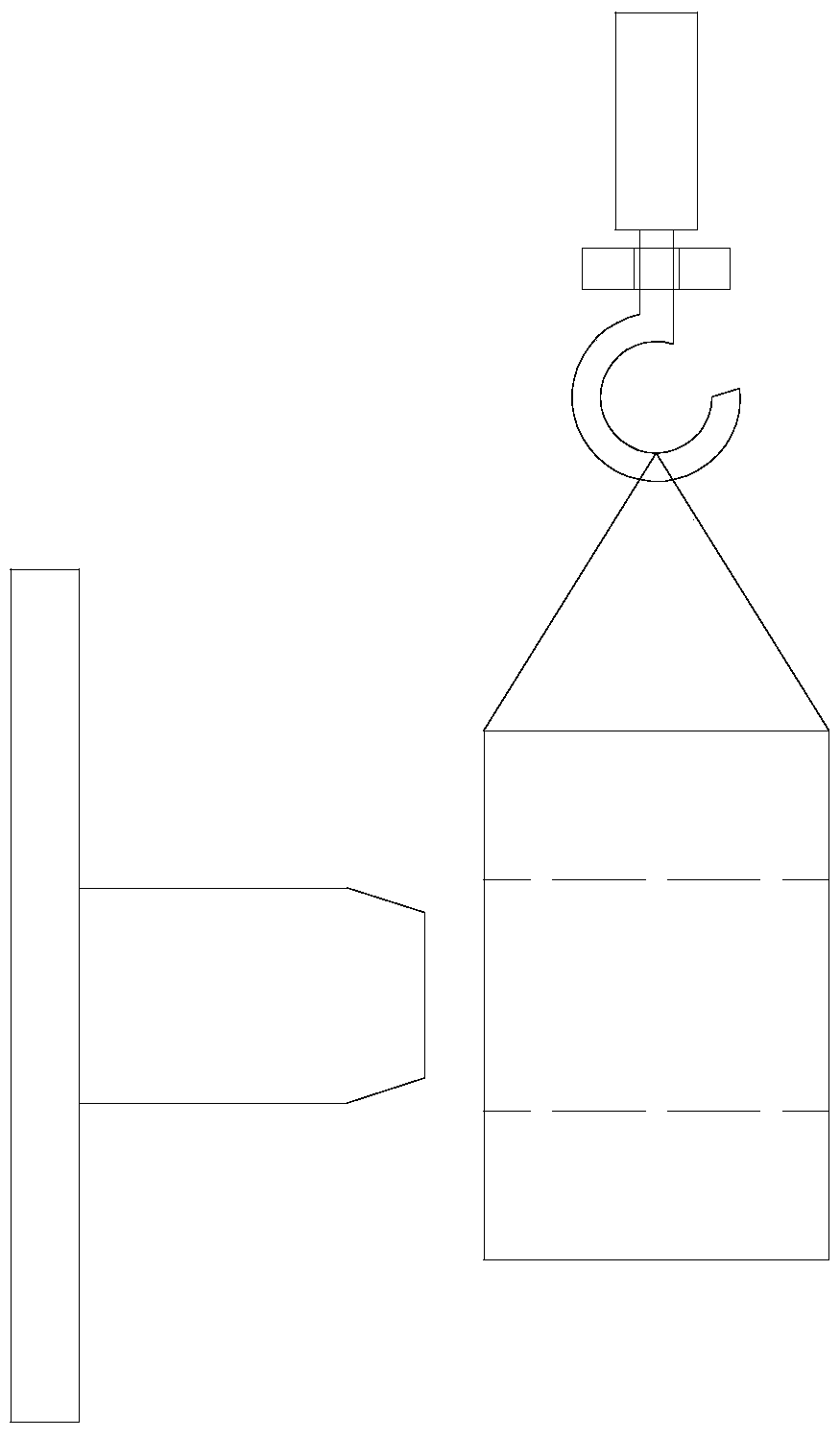

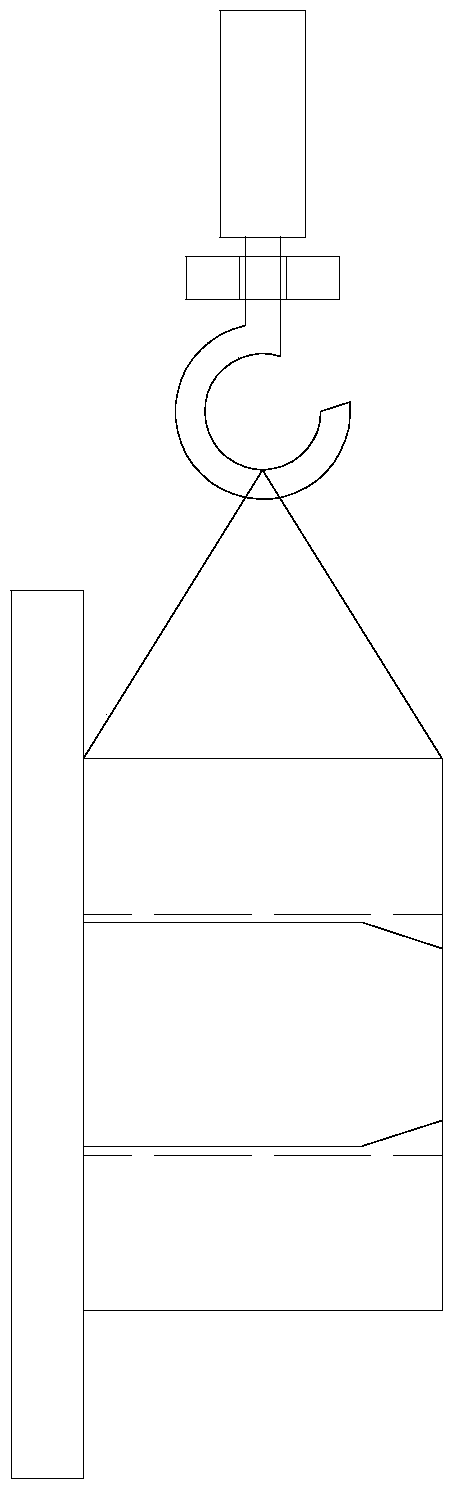

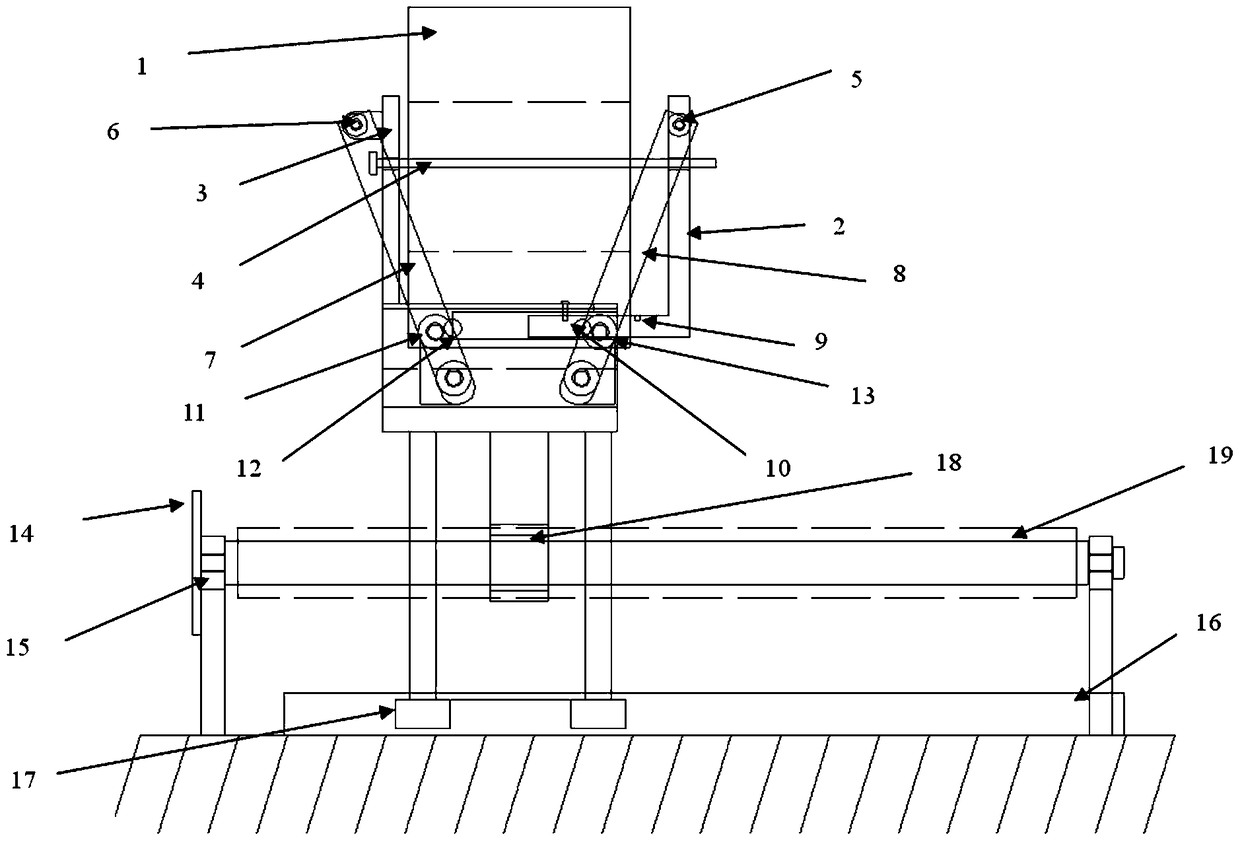

[0049] (1) Pull out the L-shaped safety rod pillar 2 first, insert the pin when the pillar positioning hole B10 is aligned with the saddle positioning hole 22, and rotate the rear rotating pillar 7 and the front rotating pillar 8 at the rear of the saddle outward at the same time And insert fixed pin, then the rear transverse safety bar 6 of front transverse safety bar 5 is inserted respectively in the jack of L-shaped pillar 2 vertical pillars 3 and rear rotating pillar 7 and rotating pillar 8 so that the saddle forms three sides and has protection.

[0050] (2), strap 1 rolls into the rear longitudinal safety bar of saddle and inserts, and rotation screw mandrel handle 14 makes whole saddle move toward strap installation inner core 21 directions along chute 16 and screw mandrel 19.

[0051] (3), the strap 1 part is set on the strap installation inner core 21, remove the front transverse safety bar 5 and continue to turn the screw handle 14 so that the strap 1 is completely se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com