Temperature fuse and manufacturing method thereof

A temperature fuse, low temperature technology, applied in fuse manufacturing, electrical components, circuits, etc., can solve the problems of the limited working current of the thermal fuse and the melting of the thermal fuse, and achieve the effects of small size, space saving and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

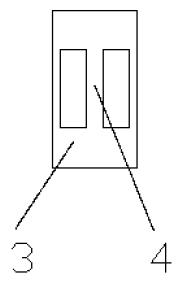

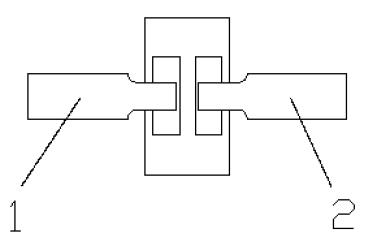

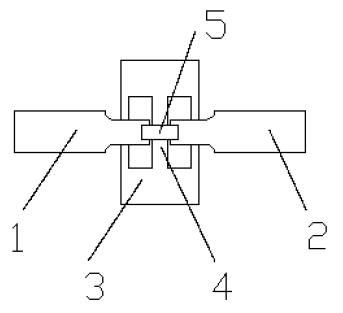

[0045] The middle insulating film 3 and the cushion layer 4 are made of PET (polyethylene terephthalate), the upper insulating film 9 and the lower insulating film 10 are made of PET (polyethylene terephthalate), and welded twice, In the first step, the upper insulating film 9 and the middle insulating film 3 are welded, and in the second step, the lower insulating film 10 and the middle insulating film 3 are welded, and samples are obtained after welding.

Embodiment 2

[0047] The middle insulating film 3 and the cushion layer 4 are made of PBT (polybutylene terephthalate), and the upper insulating film 9 and the lower insulating film 10 are made of PBT (polybutylene terephthalate). The upper insulating film 9 , the lower insulating layer 10 and the middle insulating film 3 are welded to obtain samples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com