Swing mechanism of cold-rolling pipe mill

A technology of slewing mechanism and cold rolling mill, which is applied in the direction of metal rolling, metal rolling, manufacturing tools, etc., which can solve the problems of difficult guarantee, heavy operation intensity of the operator, long operation time, etc., and achieve the effect of fast operation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the examiners of the patent office, especially the public, further understand the technical essence of the present invention, the applicant will illustrate with the examples given below, but the examples are not limitations to the scheme of the present invention. Any changes made only in form but not in substance shall be regarded as the scope of the technical solution of the present invention and shall be protected.

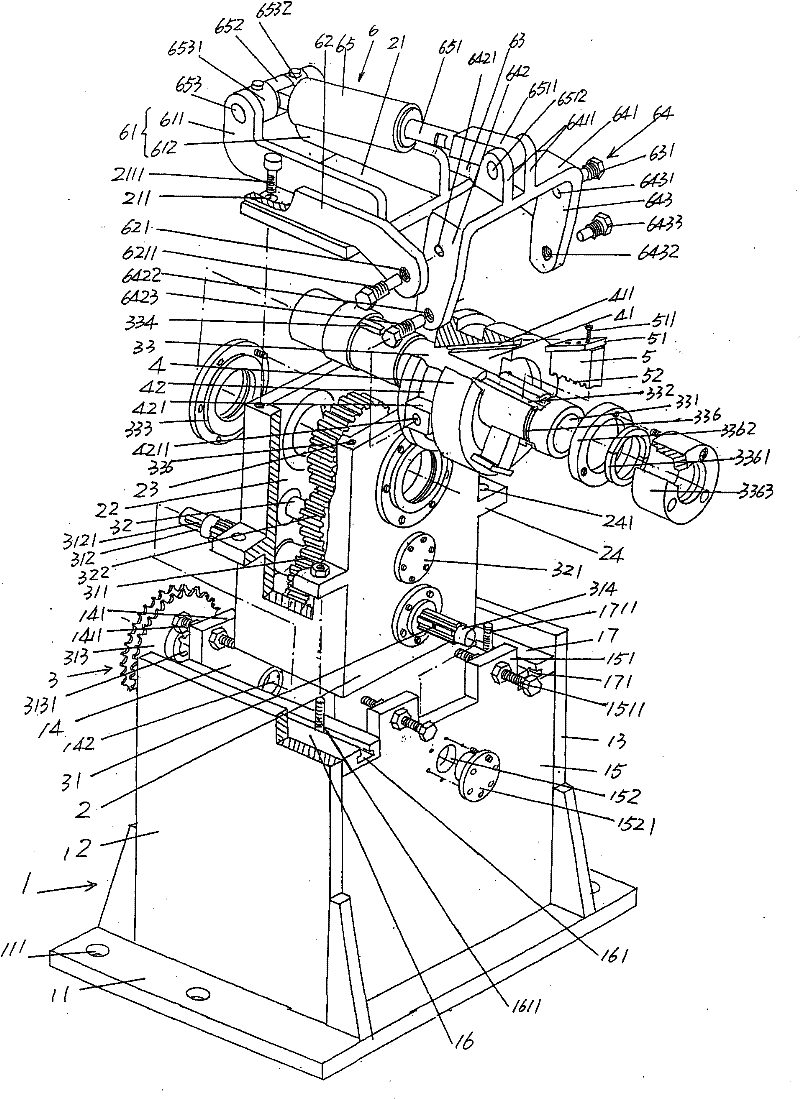

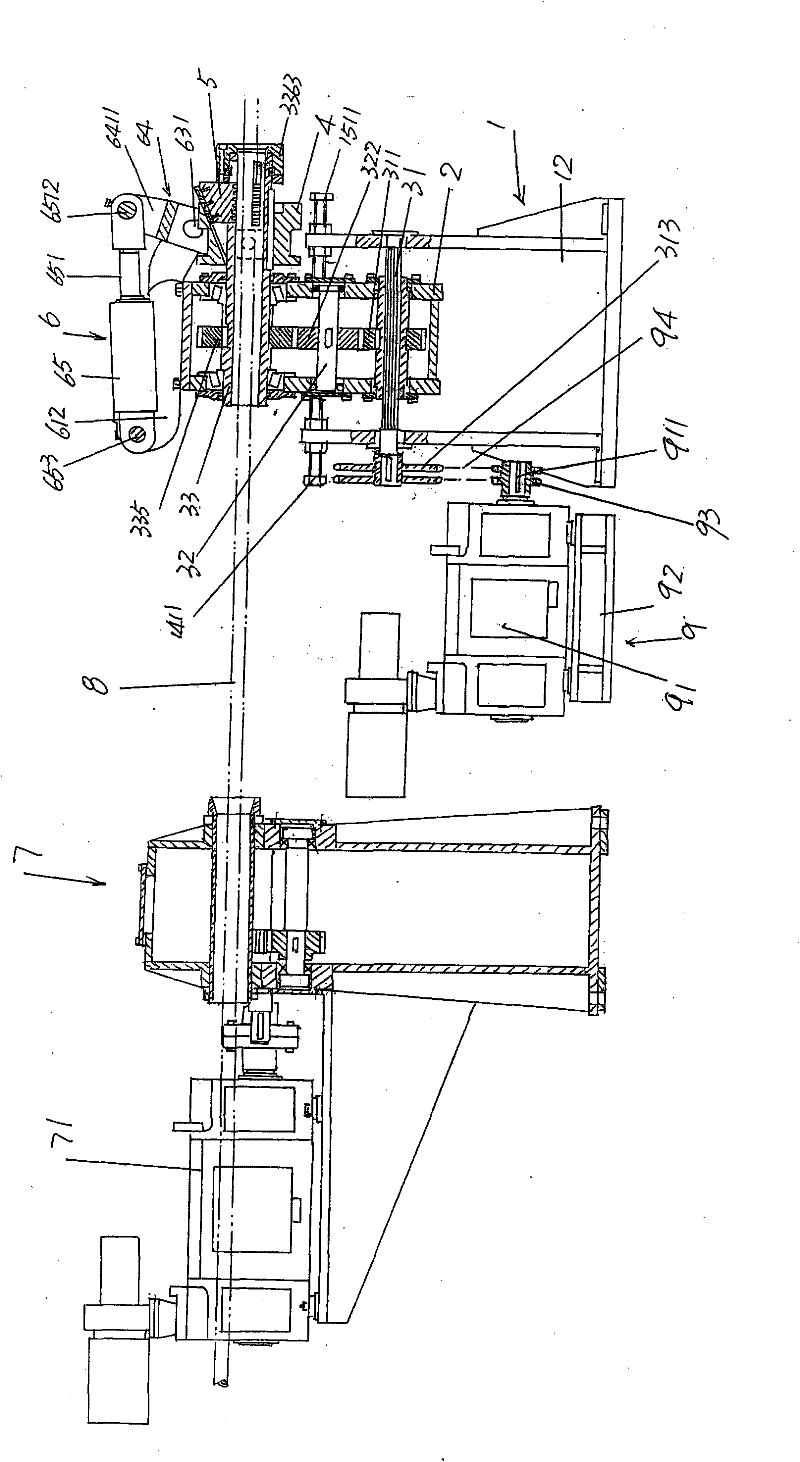

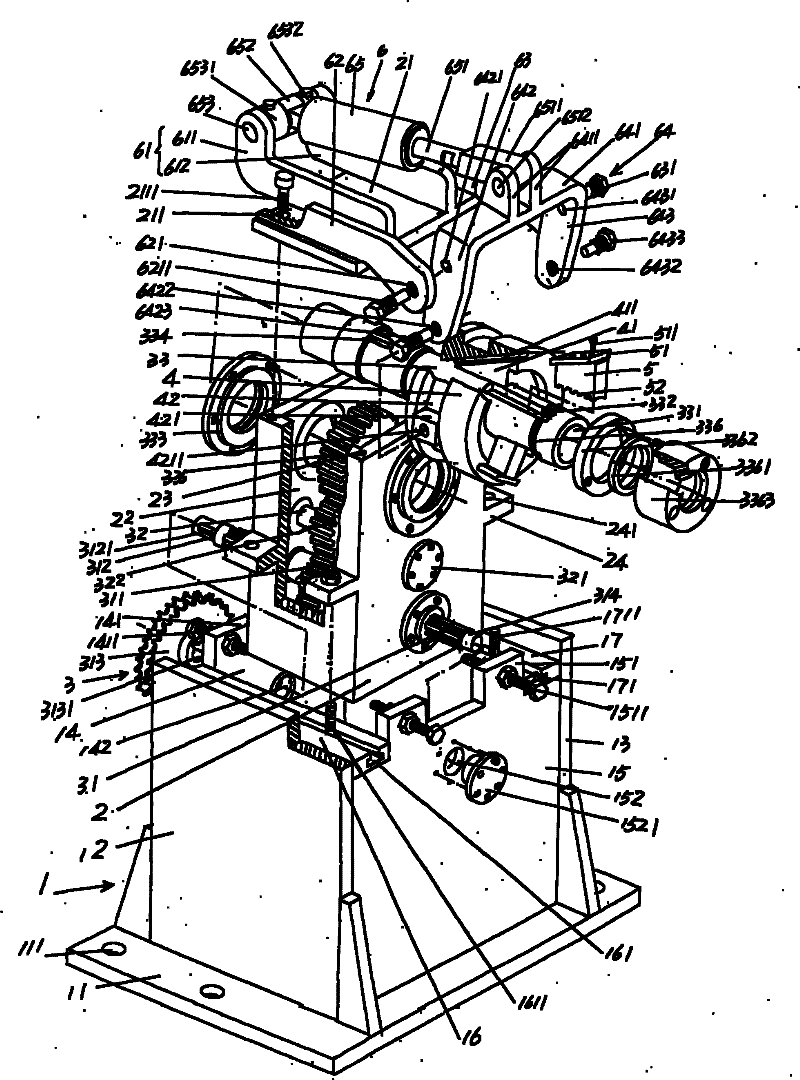

[0020] please see figure 1 , provides the mounting support seat 1 of the rotary mechanism of the cold-rolled pipe mill used alone, the meaning of the so-called used alone means: when the present invention is configured on the complete set of cold-rolled pipe mill, there is no existing technology with feeding mechanism 7( figure 2 Shown) the situation of sharing a support seat 1. The installation support base 1 has a fixed plate 11, front and rear wall panels 12, 13, a left wall panel 14, a right wall panel 15, a first box body adjustme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com