Rotary vane based synchronous swing type double-flapping-wing aircraft

A technology of flapping-wing aircraft and synchronous swinging, which is applied to unmanned aircraft, aircraft, wings, etc., can solve the problems of restricting the popularization and application of flapping-wing aircraft, low overall efficiency of flapping-wing aircraft, and low aerodynamic efficiency. Simple structure, low production cost, good mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

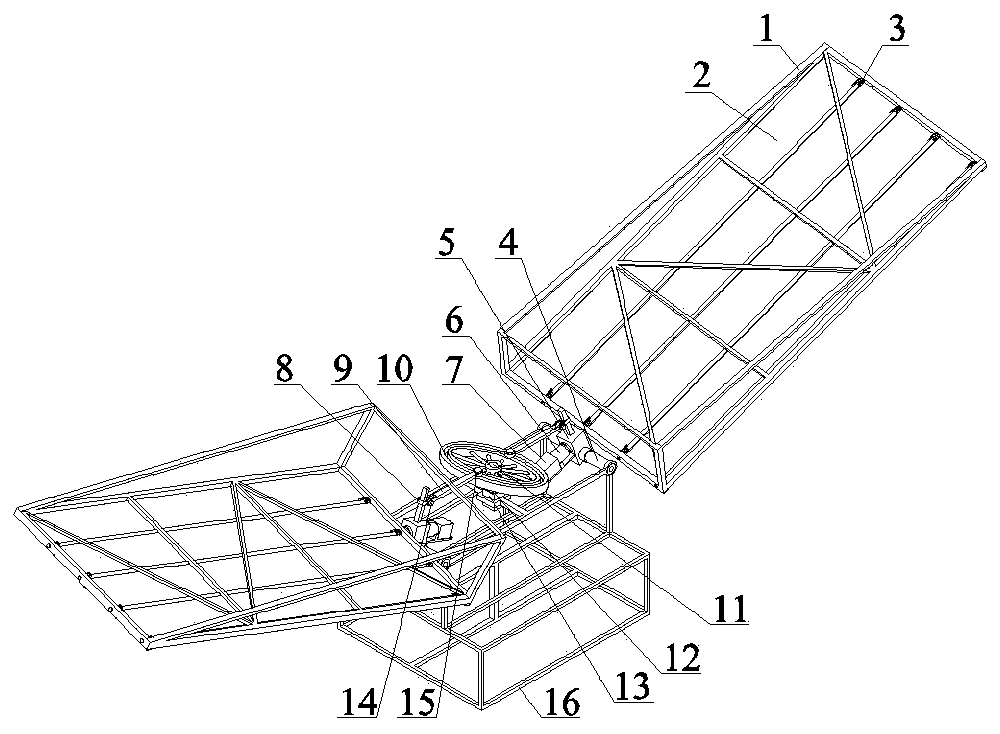

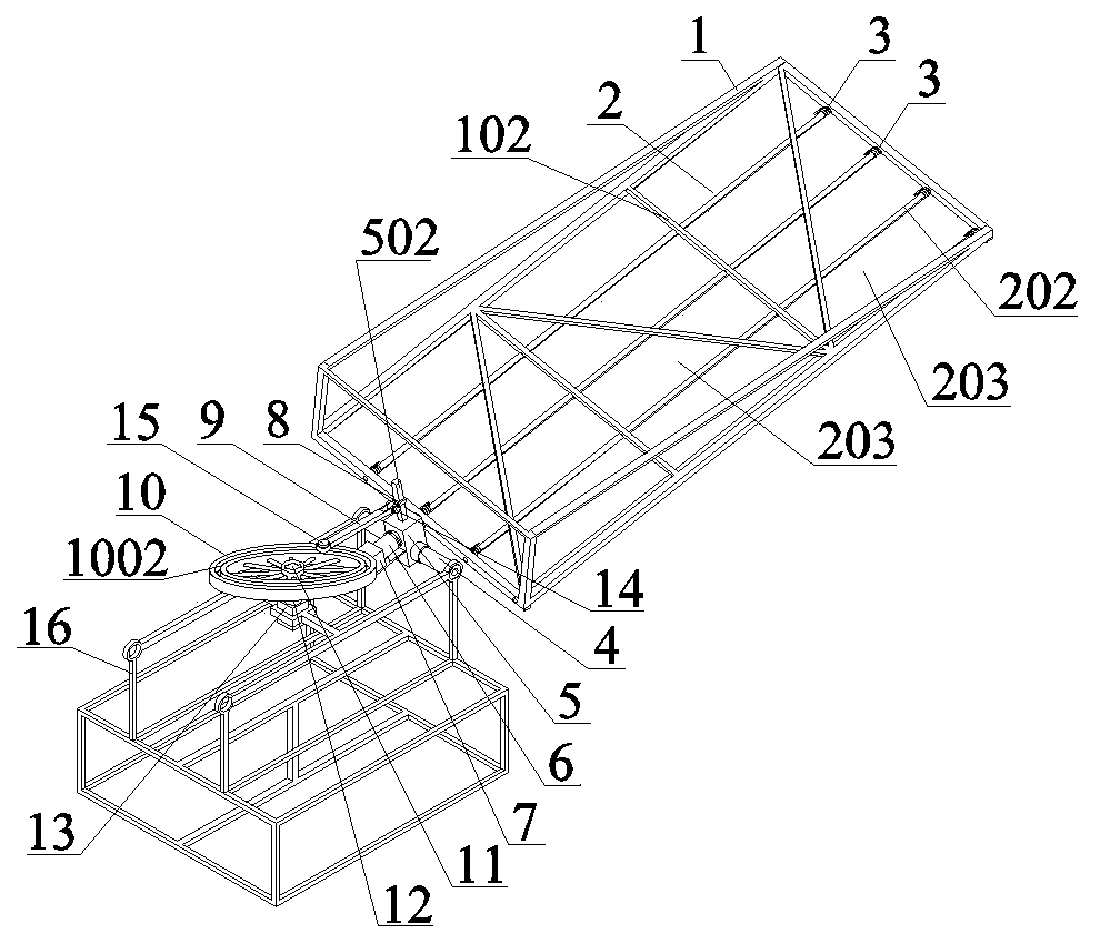

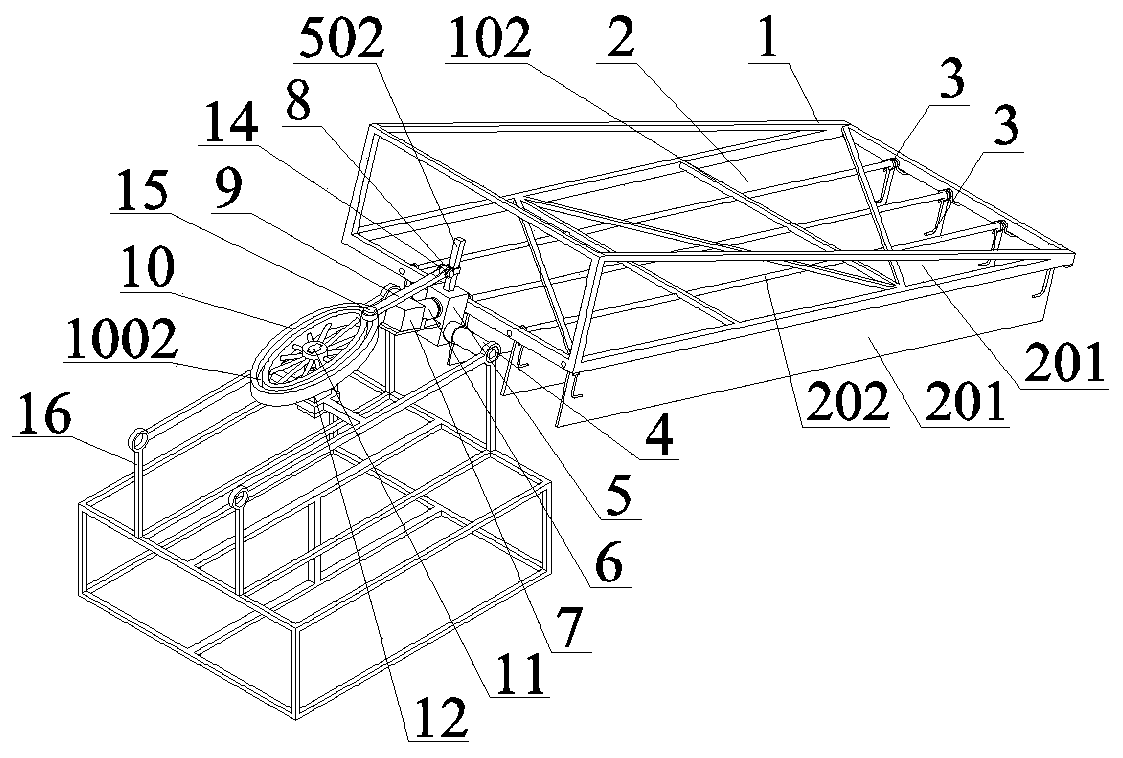

[0042] combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 with Figure 11 , a high-voltage wire inspection drone based on a synchronous swinging double flapping wing aircraft based on rotatable wings. Such as figure 1 As shown, the synchronous swing double flapping-wing aircraft based on the rotatable wings includes a flapping-wing frame 1, wings 2, torsion spring 3, swing shaft 4, connecting piece 5, first reducer 6, stepping motor 7, connecting Rod 8, push rod 9, cam 10, transmission shaft 11, second reducer 12, motor 13, first pin shaft 14, second pin shaft 15 and fuselage frame 16. Such as Image 6 As shown, the flapping wing frame 1 has a wing installation hole 101 , a wing limit beam 102 and a flapping wing shaft 103 . Such as Figure 7 As shown, the vane 2 has a vane windward surface 201 , a vane shaft 202 and a vane leeward surface 203 . Such as Figure 8 As shown, there is a swing...

Embodiment 2

[0044] This embodiment 2 provides a special drone for high-rise fire extinguishing, its structure is the same as that of embodiment 1, the difference is: the number of fins 2 is 6, the fin limit beam 102, the strengthening vertical beam 104, the strengthening beam 105 and Reinforcing inclined beam 106 all adopts engineering plastics. A high-rise fire-fighting drone that uses a synchronous swinging double flapping wing aircraft based on rotatable wings. Including flapping wing frame 1, wings 2, torsion spring 3, swing shaft 4, connector 5, first reducer 6, stepper motor 7, connecting rod 8, push rod 9, cam 10, transmission shaft 11, second Reducer 12, motor 13, first pin shaft 14, second pin shaft 15 and fuselage frame 16, wing installation hole 101, wing limit beam 102 and flapping wing rotating shaft 103 are arranged on flapping wing frame 1, and wing There are fin windward side 201, fin shaft 202 and fin leeward side 203 on 2, swing shaft hole 501, square shaft 502 and flap...

Embodiment 3

[0046]This embodiment 3 provides an agricultural plant protection unmanned aerial vehicle, its structure is the same as that of embodiment 1, the difference is: the number of fins 2 is 8, the fin limit beam 102, the reinforcement vertical beam 104, the reinforcement beam 105 and the reinforcement Slanting beam 106 all adopts engineering plastics. A high-rise fire-fighting drone that uses a synchronous swinging double flapping-wing aircraft based on rotatable wings. Including flapping wing frame 1, wings 2, torsion spring 3, swing shaft 4, connector 5, first reducer 6, stepper motor 7, connecting rod 8, push rod 9, cam 10, transmission shaft 11, second Reducer 12, motor 13, first pin shaft 14, second pin shaft 15 and fuselage frame 16, wing installation hole 101, wing limit beam 102 and flapping wing rotating shaft 103 are arranged on flapping wing frame 1, and wing There are fin windward side 201, fin shaft 202 and fin leeward side 203 on 2, swing shaft hole 501, square shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com