Four-drive energy adjustable continuous winged variable dip angle direct-acting aircraft

A four-drive, continuous-belt technology, applied in aircraft, motor vehicles, aircraft parts, etc., can solve the problems of inability to achieve vertical take-off and landing and hovering in the air, restricting the popular application of flapping-wing aircraft, and low overall efficiency of flapping-wing aircraft. , to achieve the effect of simple structure, low production cost and good action consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

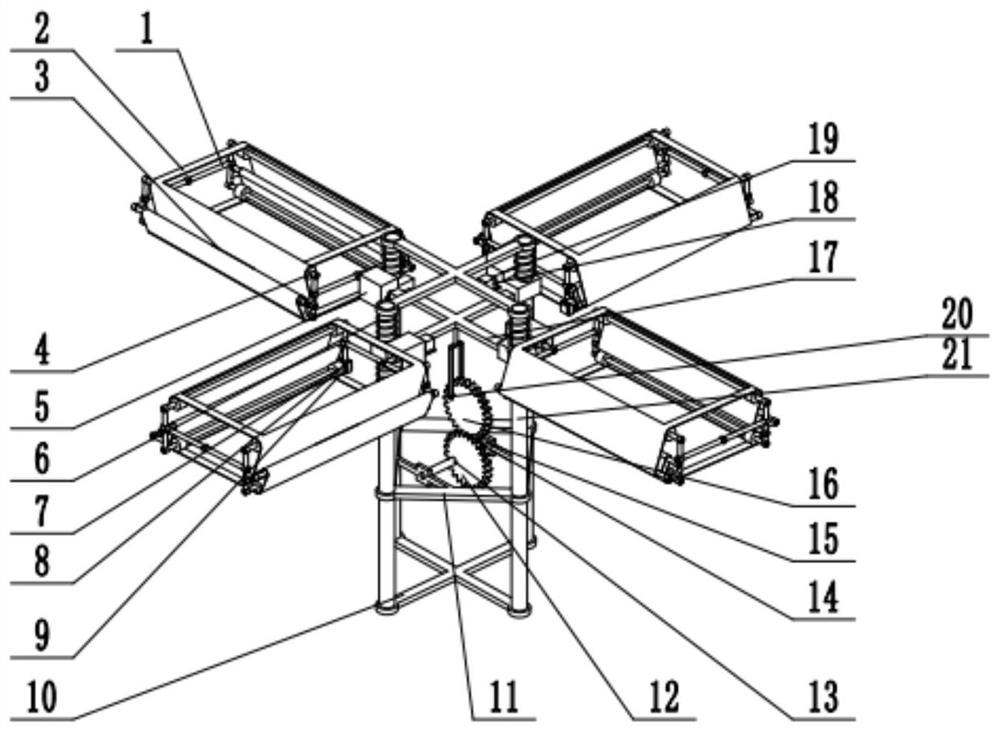

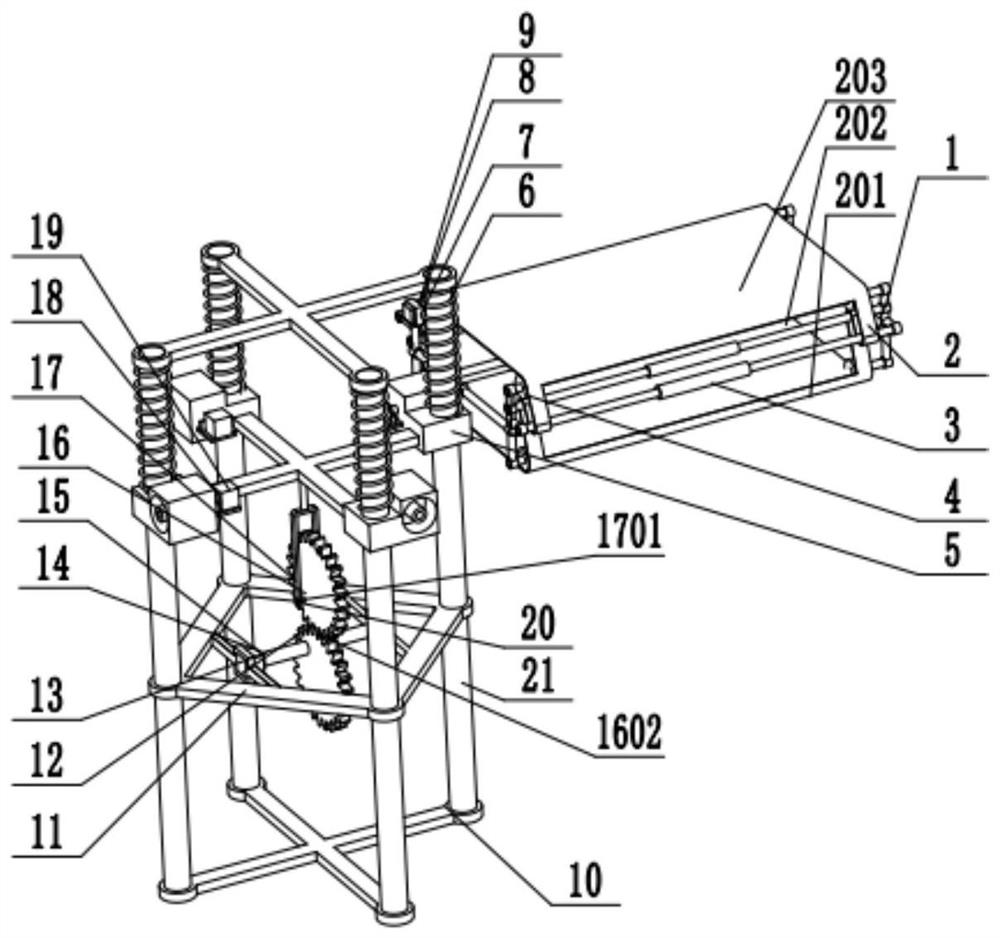

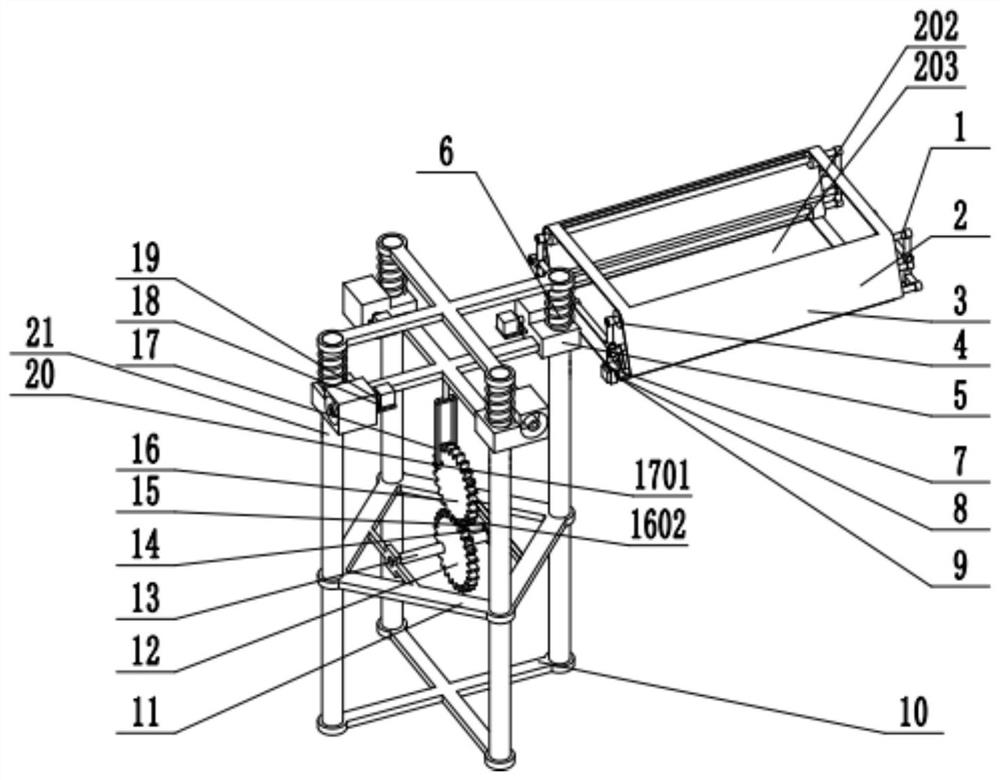

[0036] Example 1: Combining figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 11 , a high-voltage wire inspection UAV using a four-drive energy-adjustable continuous belt-wing variable-inclination direct-motion aircraft. Such as figure 1 As shown, in the present application, the four-drive energy-adjustable continuous winged variable inclination direct motion aircraft includes a winged frame 1, a soft belt 2, a tension pulley 3, a pulley 4, a connecting piece 5, a spring 6, a stepping Motor 7, first reducer 8, pulley transmission shaft 9, fuselage shell 10, fuselage frame 11, driving eccentric gear 12, transmission shaft 13, motor 14, second reducer 15, driven eccentric gear 16, push Rod 17, stepper motor 18, third reducer 19, pin shaft 20 and slideway 21. Such as Figure 6 and Figure 7 As shown, there are frame left longitudinal beam 101, frame connecting rod 102, frame right longitu...

Embodiment 2

[0037] Example 2: Combining figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 11 , a high-rise building fire-fighting drone that uses a four-drive energy-adjustable continuous belt-wing variable-inclination direct-acting aircraft. It includes a winged frame 1, a soft belt 2, a tensioning wheel 3, a pulley 4, a connecting piece 5, a spring 6, a stepping motor 7, a first reducer 8, a pulley drive shaft 9, a fuselage shell 10, a machine Body frame 11, driving eccentric gear 12, transmission shaft 13, motor 14, second reducer 15, driven eccentric gear 16, push rod 17, stepper motor 18, third reducer 19, pin shaft 20 and slideway 21 . Such as Figure 6 and Figure 7 As shown, there are frame left longitudinal beam 101, frame connecting rod 102, frame right longitudinal beam 104, motor mounting hole 105, tensioning wheel mounting rod 107, frame beam 108 and winged rotating shaft 103 on the wing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com