Pulse transformer and manufacturing method thereof

A pulse transformer and winding technology, applied in magnetic bias transformers, fixed transformers or mutual inductances, transformer/inductor components, etc. Simple winding method, reducing short circuit and preventing poor withstand voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

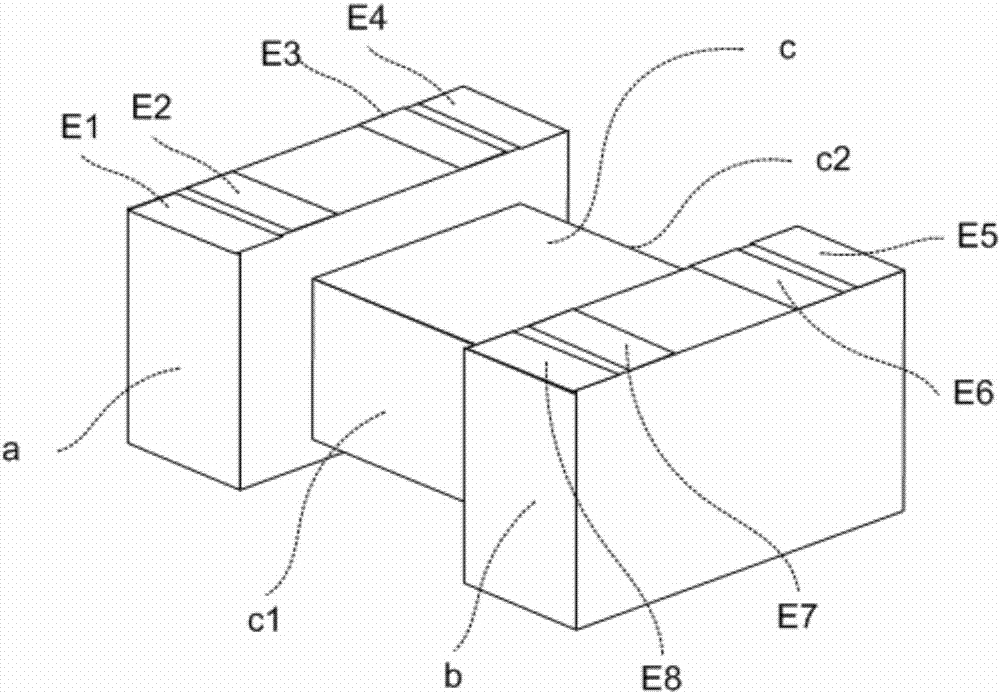

[0069] A pulse transformer combined with PCB wiring

[0070] On the first magnetic core body B1, the starting end S1a and the ending S1b of the winding S1 are respectively connected to the first electrode E1 and the seventh electrode E7, and the starting end S2a and the ending S2b of the winding S2 are respectively connected to the second electrode E2 and the eighth electrode E8 The starting end S3a and the ending S3b of the winding wire S3 are connected to the third electrode E3 and the fifth electrode E5 respectively, and the starting end S4a and the ending S4b of the winding wire S4 are connected to the fourth electrode E4 and the sixth electrode E6 respectively.

[0071] Wherein, the winding wires S1 and S3 start to wind from the first side c1 of the central column c of the first magnetic core body B1 and end from the second side c2 of the central column c. The windings S2 and S4 start from the first side c1 of the central column c and end from the second side c2 of the ce...

Embodiment 2

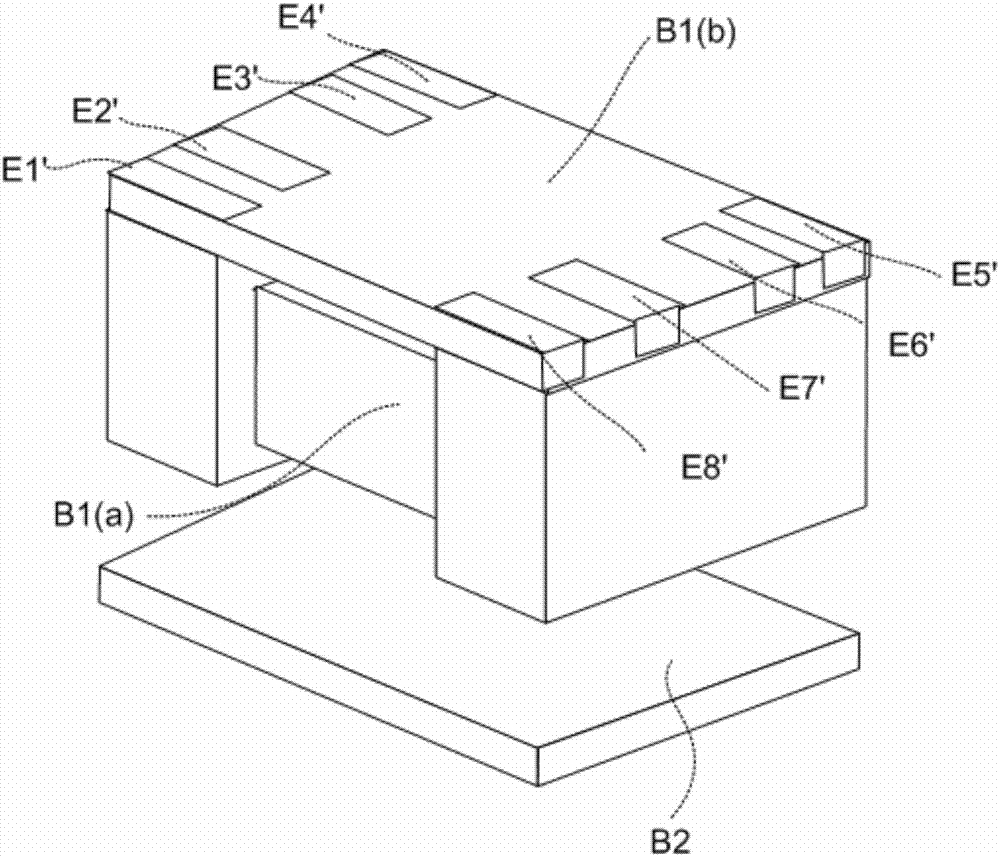

[0088] A pulse transformer combined with PCB wiring

[0089] On the first magnetic core body, the starting end S1a and the ending S1b of the winding S1 are respectively connected to the first electrode E1 and the eighth electrode E8, and the starting end S2a and the ending S2b of the winding S2 are respectively connected to the second electrode E2 and the seventh electrode E7, The starting end S3a and the ending S3b of the winding wire S3 are connected to the third electrode E3 and the sixth electrode E6 respectively, and the starting end S4a and the ending S4b of the winding wire S4 are connected to the fourth electrode E4 and the fifth electrode E5 respectively.

[0090] The windings S1 and S3 start to be wound from the first side c1 of the central column c and end from the second side c2 of the central column c. The windings S2 and S4 start to be wound from the first side c1 of the central column c and end from the second side c2 of the central column c.

[0091] The windi...

Embodiment 3

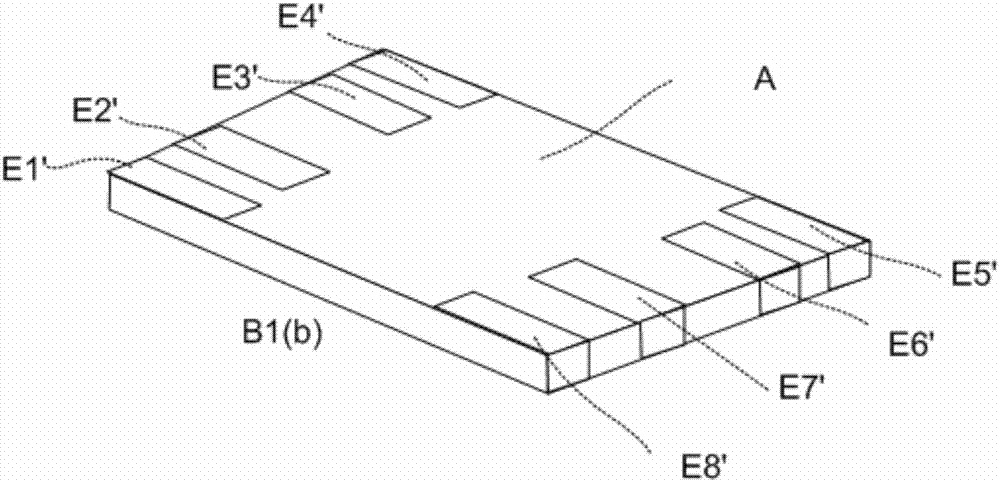

[0110] A pulse transformer combined with PCB wiring

[0111] On the first magnetic core body, the starting end S1a and the ending S1b of the winding S1 are respectively connected to the first electrode E1 and the sixth electrode E6, and the starting end S2a and the ending S2b of the winding S2 are respectively connected to the second electrode E2 and the fifth electrode E5, The start S3a and end S3b of the winding S3 are respectively connected to the third electrode E3 and the eighth electrode E8, and the start S4a and end S4b of the winding S4 are respectively connected to the fourth electrode E4 and the seventh electrode E7.

[0112] The windings S1 and S2 start to be wound from the first side c1 of the central column c, and end from the second side c2 of the central column c. The windings S3 and S4 start from the second side c2 of the central column c and end from the first side c1 of the central column c.

[0113] The windings S1 and S2 are wound on the center column c al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com