Radial double split foil winding and winding method thereof

A winding method and double-split technology, which are applied in coil manufacturing, transformer/inductor coil/winding/connection, inductor/transformer/magnet manufacturing, etc., can solve the problems of foil coil structure and winding method that cannot be completed, etc. Achieve the effect of less magnetic flux leakage, increased stability and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

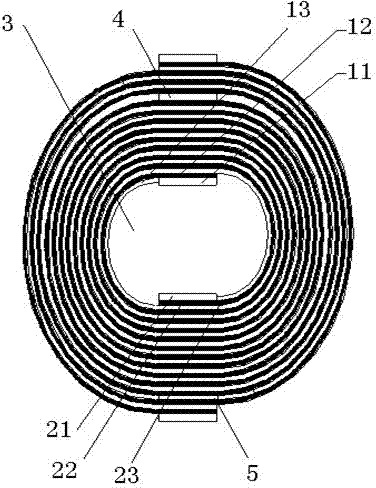

[0016] A radially double-split foil coil, see figure 1 , the coil includes a first outgoing copper bar 11 , a first layer of copper foil 12 , a first layer of insulating material 13 , a second outgoing copper bar 21 , a second layer of copper foil 22 and a second layer of insulating material 23 . Both the first outgoing copper bar 11 and the second outgoing copper bar 21 are located inside the coil, with a difference of half the inner diameter and circumference of the coil. The first layer of copper foil 12 is welded on the first outgoing copper bar 11 , and the first layer of insulating material 13 is wrapped inside the first layer of copper foil 12 . The second layer of copper foil 22 is welded on the second outgoing copper bar 21 , and the second layer of insulating material 23 is wrapped inside the second layer of copper foil 22 . The first layer of copper foil 12 and the second layer of copper foil 22 are arranged at intervals, and the second layer of copper foil 22 cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com