Synchronizer and gearbox

A synchronizer and synchronizing ring technology, which is applied in the field of gearboxes, can solve the problems such as the reduction of transmission shifting efficiency, the reduction of transmission transmission efficiency, and the aggravation of 1' wear of the synchronizing ring, and the effects of easy processing, reasonable structure and cost control are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

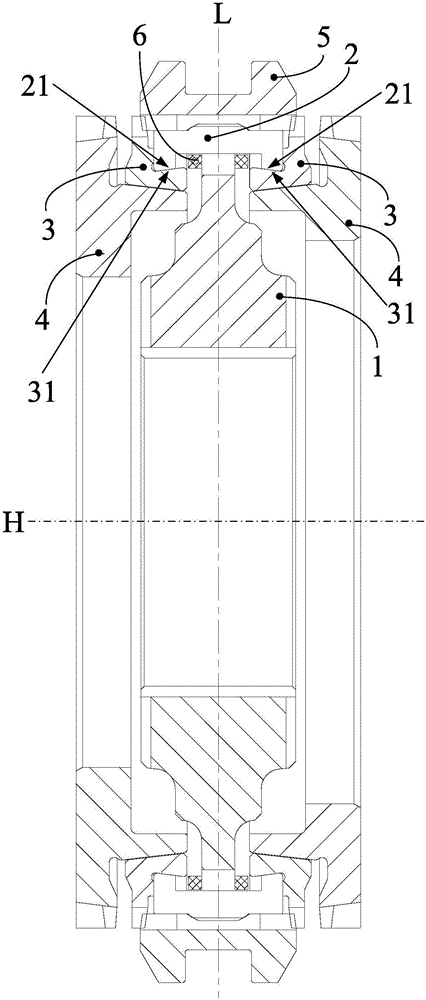

[0041] The accommodating groove includes a side wall arranged along the circumference of the synchronization ring 3 and a top wall facing the axial center of the synchronizer, such as figure 2As shown, L is the axial centerline of the synchronizer, the slider 2 is in conflict with the top wall and the side wall of the housing groove, and the slider 2 and the side wall of the housing groove are axially limited through taper fit; wherein, the first limit One of the position part 21 and the second limit part 31 is an outwardly convex conical arc surface, and the other is an inner concave conical arc surface, and the outer convex conical arc surface and the inner concave conical arc surface reach the axis H of the synchronizer The distance from the end close to the axial center of the synchronizer gradually decreases to the end far away from the axial center of the synchronizer.

[0042] In this solution, the slider 2 is in conflict with the top wall of the housing groove, the sl...

Embodiment 2

[0045] Embodiment two: (not shown in the figure)

[0046] One of the first limiting part and the second limiting part is a bar-shaped chute arranged along the circumference of the synchronous ring, and the other is a limiting slider. The limiting slider is inserted into the bar-shaped chute and can slide relative to the bar. The groove slides along the circumferential direction of the synchronizer, and the width of the limit slider is equal to or close to the width of the bar slide groove.

[0047] In this scheme, one of the side walls of the slider and the receiving groove is provided with a bar-shaped chute, and the other is provided with a limit slider. The limit slider can slide relative to the bar-shaped chute along the circumferential direction of the synchronizer to ensure synchronization. The device can work normally, and the width of the limit slider is equal to or close to the width of the bar chute, which eliminates the free space for the axial movement of the synch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com