Gear shifting manipulator

A manipulator and shift shaft technology, which is applied in the field of auto parts, can solve the problems that the deflection angle cannot be effectively excessive, affects the shifting efficiency and shifting feeling, and wears the locking area, so as to solve interference or abnormal friction, The effect of avoiding interference and facilitating effective return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

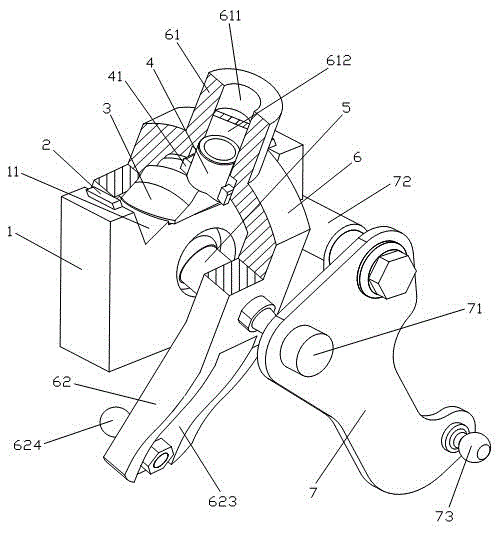

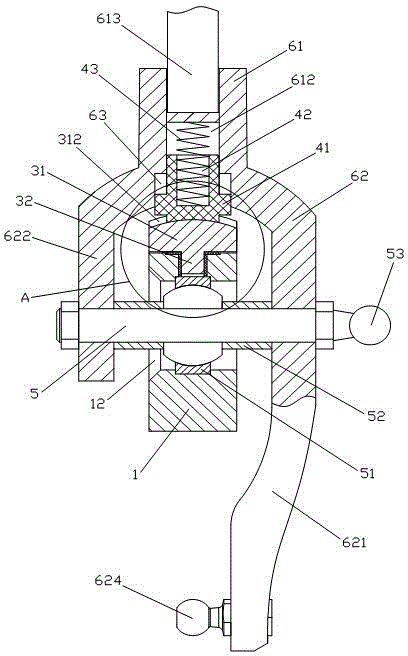

[0026] Such as Figures 1 to 6 As shown, the shift manipulator of the present invention includes a manipulator support 1, a shift limit pad 2, a shift limit block 3, a limit lock tongue 4, a shift shaft 5, a shift rocker arm 6 and a selector Gear rocker arm 7.

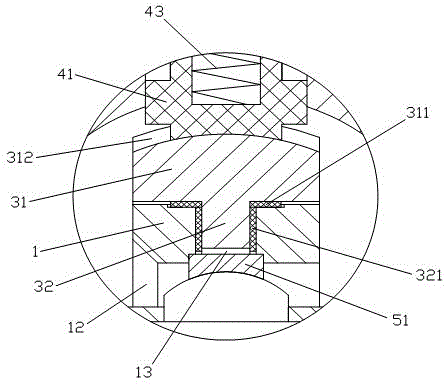

[0027] The manipulator support 1 has a block structure, and a pair of V-shaped grooves 11 are provided on the top. At the same time, the manipulator support 1 is horizontally provided with a bearing hole 12 from the middle of one side to the opposite side. The radial direction of the bearing hole 12 is provided with a limiting shaft hole 13, and one end of the bearing hole 12 has a slope; the pair of V-shaped grooves 11 are symmetrically located on both sides of the limiting shaft hole 13 and are close to the limiting shaft. One side of the hole 13 is provided with an elastic shift limit pad 2 .

[0028]The shift limit block 3 is movably installed on the top of the manipulator support 1, and it is composed of a trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com