Industrial furnace capable of realizing thermal shift and atmospheric uniformity of gas flow field

An industrial furnace and heat displacement technology, applied in the direction of furnace, furnace type, lighting and heating equipment, etc., can solve the problems of energy waste, low energy saving level, unsatisfactory thermal efficiency, etc., and achieve uniform and no dead angle, reduce heat treatment energy Consumption, the effect of improving the level of cleaner production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further explained below in conjunction with the drawings and embodiments:

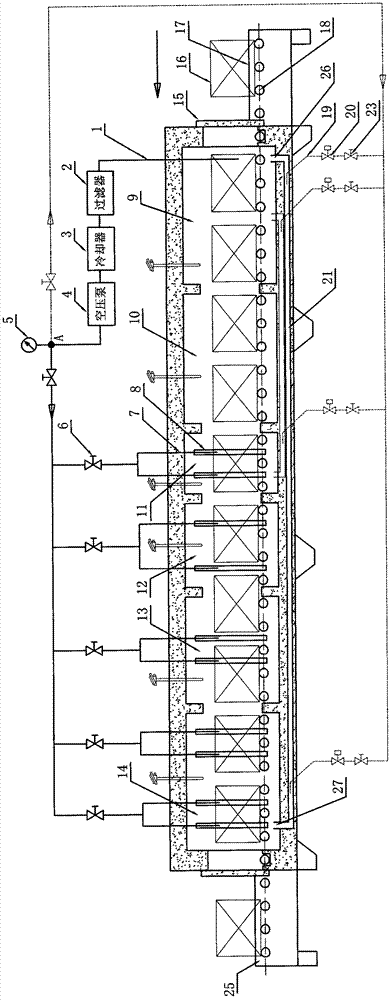

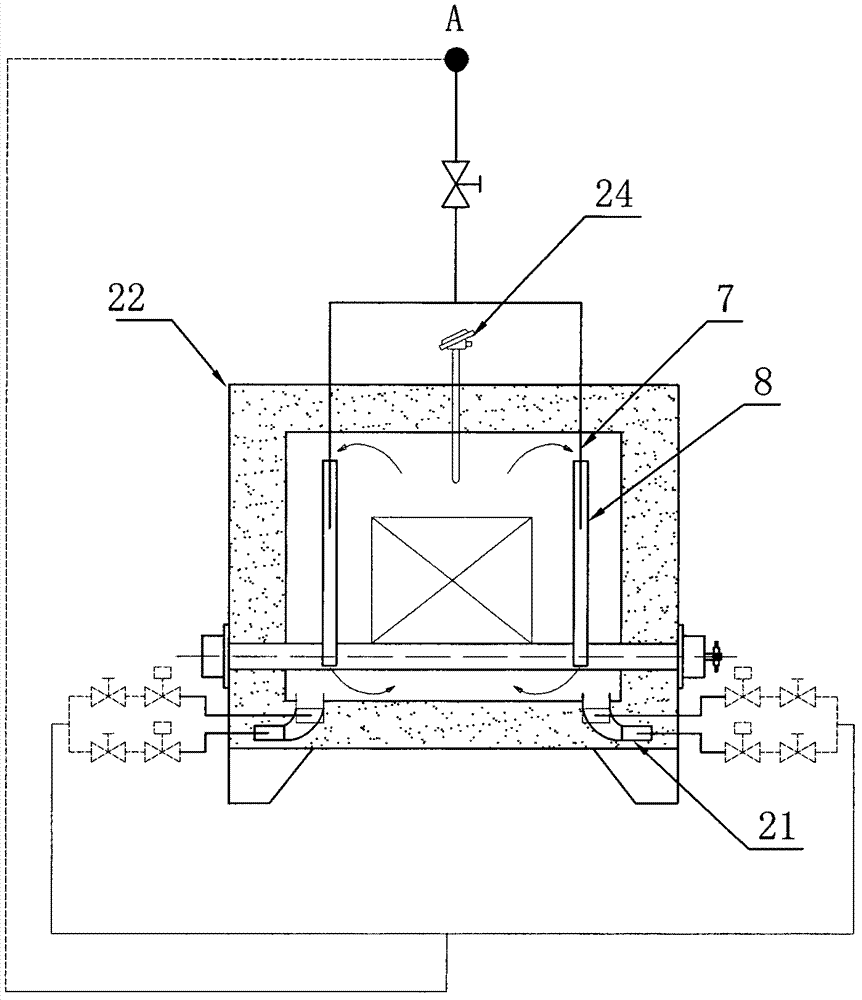

[0021] Such as figure 1 , figure 2 As shown, the industrial furnace that realizes the thermal displacement of the gas flow field and the uniform atmosphere includes a furnace body 22, a thermocouple 24, a feeding table 17, a discharging table 25, a driving roller 18 and a furnace door 15, in the front section of the furnace The preheating section 10 is connected through the suction pipe 1, the filter 2, the cooler 3, and the input end of the air pressure pump 4. The output end of the air pressure pump 4 passes through the regulating valve 6 and is connected to the cooling area at the back of the furnace. A set of upper and lower convective injection pipes 7 are connected. The output end of the air pressure pump 4 is connected with a pressure gauge 5. The upper and lower convective injection pipes 7 are installed in the corresponding upper and lower convection guide pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com