Method for preparing coagulant from potassium-rich slate solid slag as raw material

A technology of potassium-rich slate and solid slag, which is applied in the field of resource utilization of industrial waste, can solve the problems of increasing operational difficulty and production costs, complex and cumbersome processes, and harsh preparation conditions, and achieves optimized preparation process steps, conditions, and processes The effect of simple and optimized preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

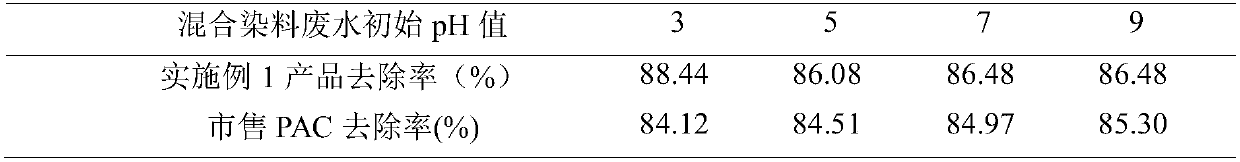

Embodiment 1

[0066] Embodiment 1, the preparation of polyaluminum chloride ferric coagulant

[0067] Put 10 g of potassium-rich slate solid slag into a closed reaction kettle lined with polytetrafluoroethylene, add 30 mL of 20% HCl solution and mix evenly, and place the closed reaction kettle in an oven at 105°C for 2 hours to obtain a solid-liquid mixed reaction solution. After the reaction was completed, the temperature of the solid-liquid mixed reaction solution was lowered and 80 mL of water was added, stirred thoroughly, filtered and the filtrate was collected. Wash the filter cake with water 3 times, 25 mL each time, combine the washing liquid with the previous filtrate, add sodium hydroxide solution to adjust the pH to 3.5 at a controlled temperature of 10°C, and filter to remove the solid precipitate. The filtrate was heated up to 100°C for evaporation and concentration, and at the same time, the hydrolysis polymerization reaction was carried out for 10 hours. Then the material wa...

Embodiment 2

[0068] Embodiment 2, the preparation of polyaluminum chloride ferric coagulant

[0069] Put 10g of potassium-rich slate solid slag into a closed reaction kettle lined with polytetrafluoroethylene, add 40mL of 15% HCl solution and mix evenly, and place the closed reaction kettle in an oven at 80°C for 3 hours to obtain a solid-liquid mixed reaction solution. After the reaction is finished, cool down the solid-liquid mixed reaction solution and add 100 mL of water, stir well, filter and collect the filtrate. The filter cake was washed with 75mL of water, and the washing liquid was combined with the previous filtrate. Potassium hydroxide solution was added to adjust the pH to 4.0 at a controlled temperature of 18°C, and the solid precipitate was removed by filtration. The filtrate was heated to 90°C for evaporation and concentration, and at the same time, the hydrolysis polymerization reaction was carried out for 12 hours. Then the material was cooled and transferred to an oven ...

Embodiment 3

[0070] Embodiment 3, the preparation of polyaluminum chloride ferric coagulant

[0071] Put 10 g of potassium-rich slate solid slag into a closed reaction kettle lined with polytetrafluoroethylene, add 60 mL of 10% HCl solution and mix evenly, and place the closed reaction kettle in a 60°C oven for 5 hours to obtain a solid-liquid mixed reaction solution. After the reaction was completed, the temperature of the solid-liquid mixed reaction solution was lowered and 160 mL of water was added, stirred thoroughly, filtered and the filtrate was collected. Wash the filter cake with water 3 times, 25 mL each time, combine the washing liquid with the previous filtrate, add sodium hydroxide solution at a controlled temperature of 15°C to adjust the pH to 5, and filter to remove the solid precipitate. The filtrate was heated to 80°C for evaporation and concentration, and at the same time, the hydrolysis polymerization reaction was carried out for 6 hours. Subsequently, the material was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com