Process for producing calcium sulfate whiskers from chlorine-containing wastewater from titanium white by chlorination

A technology of calcium sulfate whisker and chloride method, which is applied in chemical instruments and methods, calcium/strontium/barium sulfate, single crystal growth, etc., can solve the problem that titanium white chlorine-containing wastewater is not economically feasible and has economic benefits Deal with technology and other issues to achieve the effect of improving the level of clean production, low cost and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

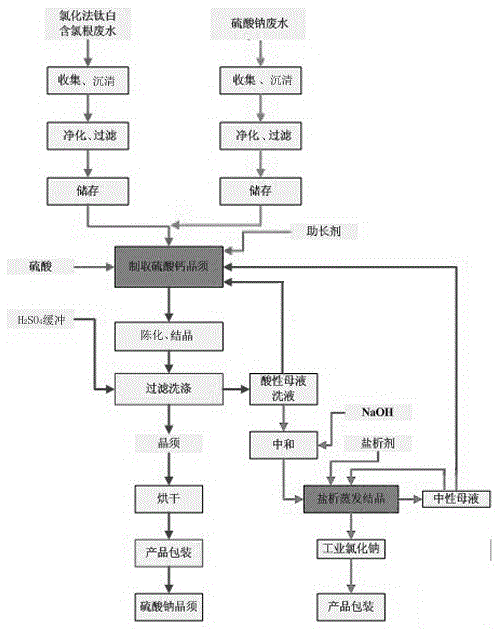

Method used

Image

Examples

Embodiment 1

[0022] ①. Collect, settle, purify and filter the wastewater containing calcium chloride (mainly calcium chloride and sodium chloride) from chlorinated titanium white to make the Ca in the wastewater 2+ content ≥ 50g / L, Cl - content of ≥100g / L, content of ΣFe≤20ppm, Pb 2+ 、 Bi 3+ 、Cd 2+ content of ≤5ppm, store for future use;

[0023] ②, will produce vanadium pentoxide containing Na 2 SO 4 After the waste water is collected, settled, purified and filtered, the SO in the waste water 4 2- The content of ≥50g / L, the content of ΣFe≤20ppm, Cr 6+ content of ≤5ppm, store for future use;

[0024] ③. Ca in the solution obtained according to step ① 2+ and SO in the solution obtained in step ② 4 2- Molar ratio 1:1.5 Mix step ① and step ② solution to react, stir, heat to 80°C, add sulfuric acid to adjust to pH = 4; add magnesium chloride simultaneously and make accelerator, the add-on of described magnesium chloride is 3% of product calcium sulfate theoretical weight, and the r...

Embodiment 2

[0031] ①. Collect, settle, purify and filter the wastewater containing calcium chloride (mainly calcium chloride and sodium chloride) from chlorinated titanium white to make the Ca in the wastewater 2+ content ≥ 50g / L, Cl - content of ≥100g / L, content of ΣFe≤20ppm, Pb 2+ 、 Bi 3+ 、Cd 2+ content of ≤5ppm, store for future use;

[0032] ②. Dissolve Glauber's salt, a by-product of the production of red alum sodium, in vanadium pentoxide wastewater, settle, purify, and Cr 6+ After reduction to chromium hydroxide and filtration, the SO in the wastewater 4 2- The content of ≥100g / L, the content of ΣFe≤20ppm, Cr 6+ content of ≤5ppm, store for future use;

[0033] ③. Ca in the solution obtained according to step ① 2+and SO in the solution obtained in step ② 4 2- Molar ratio 1:1.15 Mix step ① and step ② solution to react, stir, heat to 60°C, add sulfuric acid to adjust to pH = 2; adding magnesium chloride simultaneously is made accelerator, and the add-on of described magnesi...

Embodiment 3

[0040] ①. Collect, settle, purify and filter the wastewater containing calcium chloride (mainly calcium chloride and sodium chloride) from chlorinated titanium white to make the Ca in the wastewater 2+ content ≥ 50g / L, Cl - content of ≥100g / L, content of ΣFe≤20ppm, Pb 2+ 、 Bi 3+ 、Cd 2+ content of ≤5ppm, store for future use;

[0041] ②. The subsidence waste liquid from the production of Haibo contains the main amount of Na 2 SO 4 , the rest Na 2 S 2 o 3 、Na 2 SO 3 , first put S 2 o 3 -2 , SO 3 -2 Oxidation to SO 4 2- Finally, after collecting, settling, purifying and filtering, the SO in the wastewater 4 2- The content of ≥200g / L, the content of ΣFe≤20ppm, Cr 6+ content of ≤5ppm, store for future use;

[0042] ③. Ca in the solution obtained according to step ① 2+ and SO in the solution obtained in step ② 4 2- The molar ratio is 1:1.25. Mix the solution of step ① and step ② for reaction, stir, heat to 100°C, add sulfuric acid to adjust the pH = 5; add ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com