Dyeing method of cotton yarn for weaving jean fabric

A dyeing method and denim fabric technology, applied in the field of machinery, can solve the problems of poor bearing capacity, laborious operation, inconvenient yarn removal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

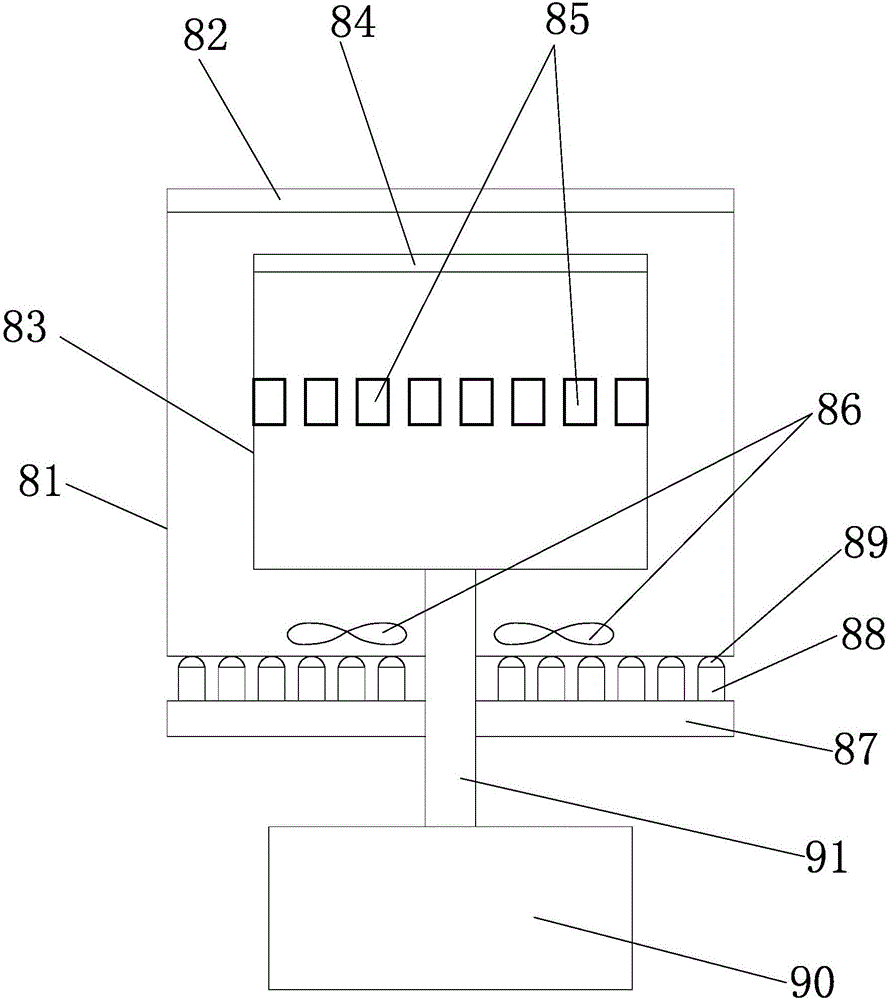

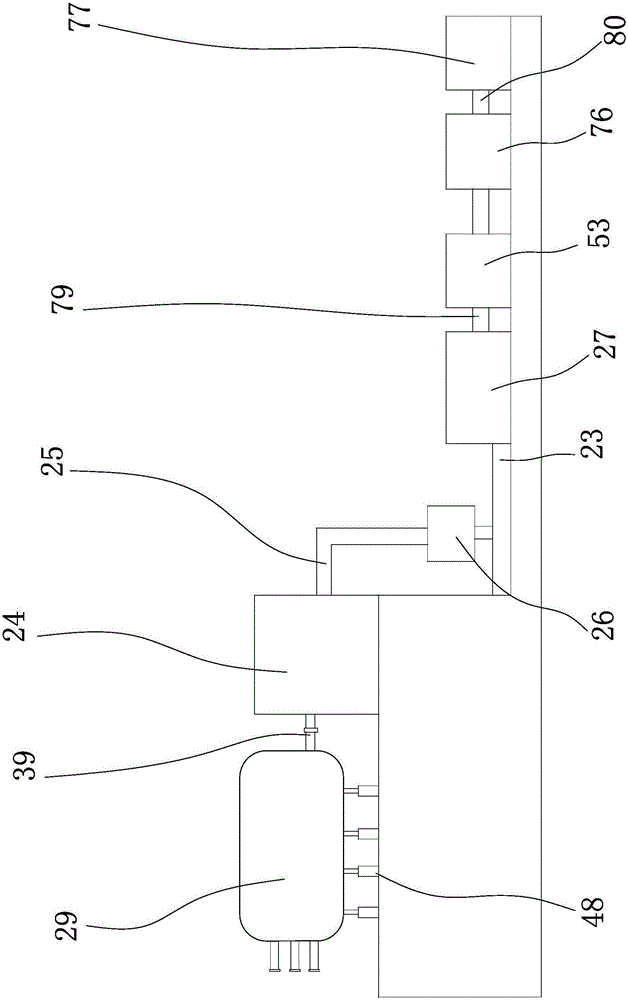

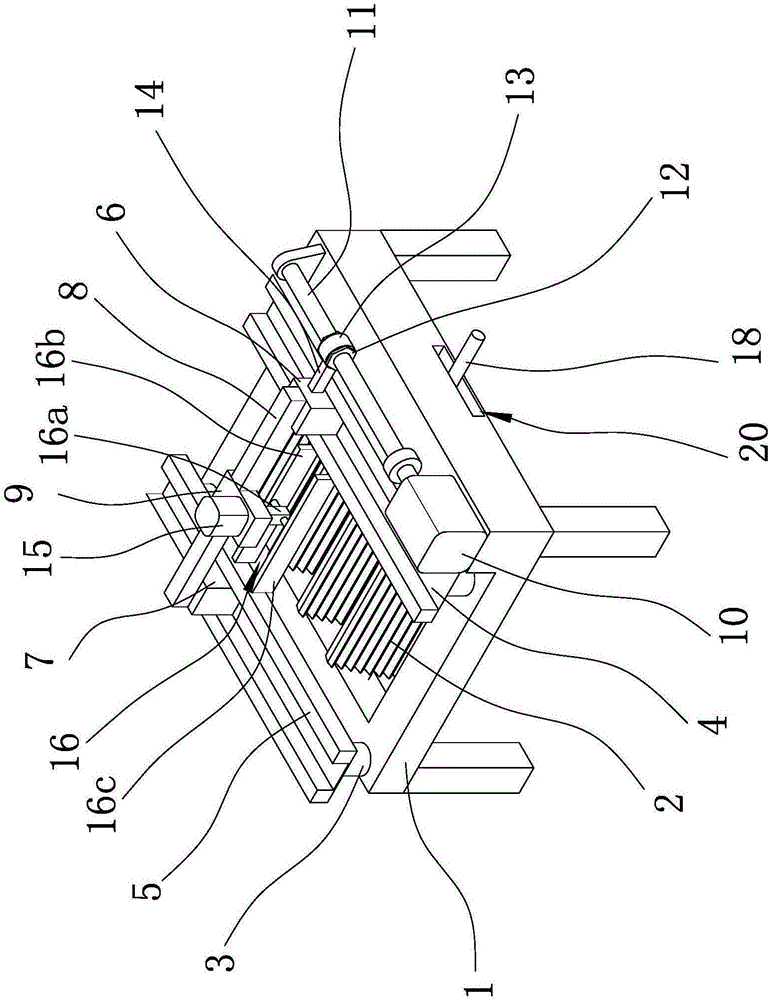

[0044] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0045] The dyeing method of the cotton yarn that is used for weaving denim fabric, this dyeing method comprises the following steps: a, prepare cotton yarn; Cotton yarn adopts the existing cotton yarn that can buy on the market as raw material; B, cotton yarn surface treatment, prepare a surface treatment cylinder, Sodium hydroxide solution is loaded into the surface treatment cylinder, and cotton yarn is passed through from sodium hydroxide solution, realizes the surface treatment of cotton yarn; c, washing for the first time; prepare the first washing cylinder, add clear water in the first washing cylinder, and The cotton yarn after the sodium hydroxide solution treatment is then cleaned with clear water in the first wash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com