Fabric dyeing and printing device

A fabric and atomization system technology, applied in the processing of textile materials, local processing of textile materials, textiles and papermaking, etc., can solve the problems of high production cost, high labor intensity of workers, low degree of automation, etc., and achieve the cost of printing and dyeing Low, improve printing and dyeing effect, high printing and dyeing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

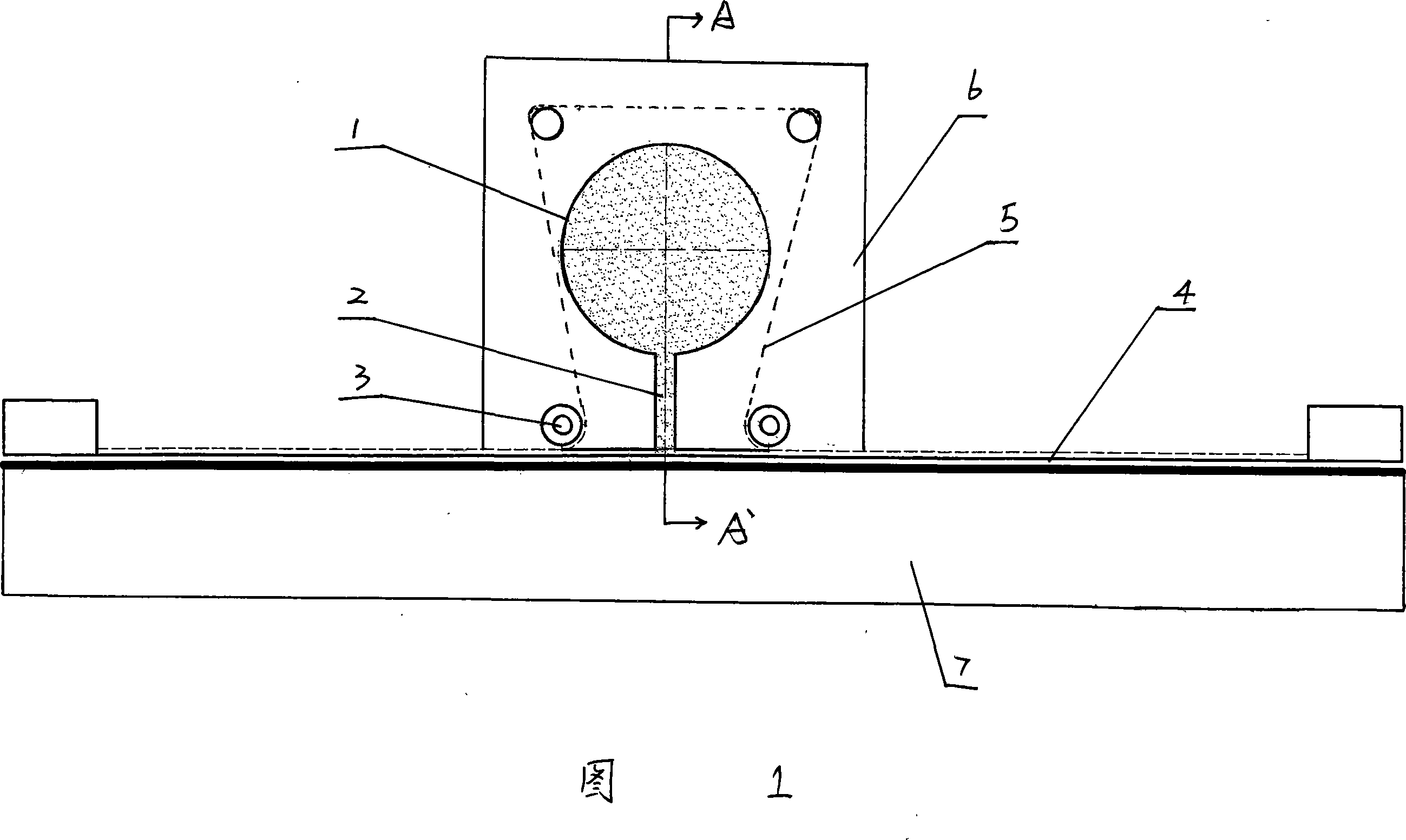

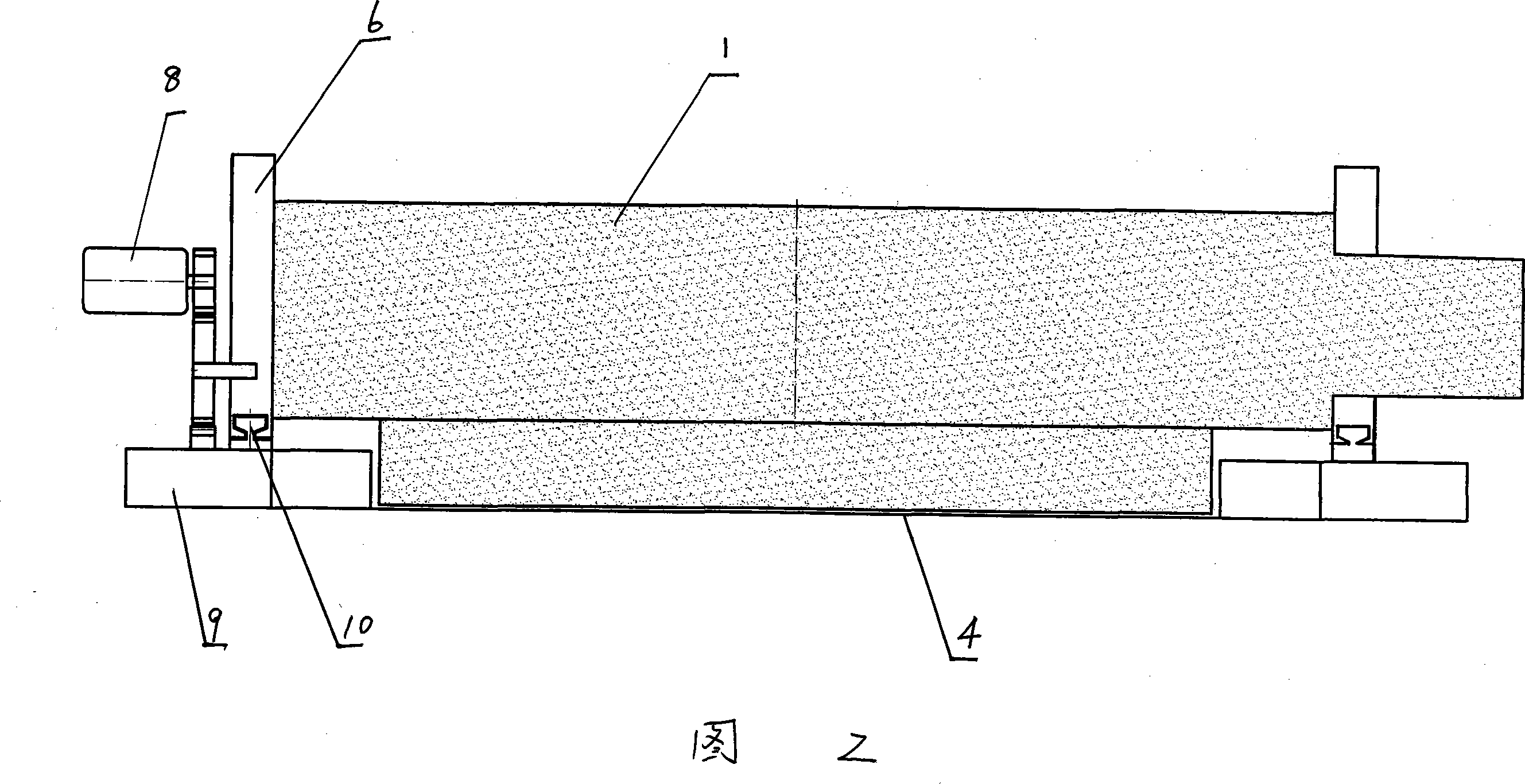

[0015] Example 1. Refer to Figure 1 and Figure 2. A fabric printing and dyeing device, comprising a frame 9, a power system and a transmission system, a fabric support is provided on the frame 1 or the transmission system, and the fabric support is made of a breathable material or is provided with air holes , the top and bottom of the fabric support are respectively provided with a vacuum adsorption chamber 7 and an atomization system; the vacuum adsorption chamber 7 is connected to a vacuum pipeline, and a vacuum pump is arranged on the vacuum pipeline; the atomization system includes an atomizer 1 and Dye channel 2; a pattern plate 4 is fixed on the frame 1 below the outlet of the dye channel 2, and the atomization system moves relative to the pattern plate 4 under the drive of the power system and transmission system.

Embodiment 2

[0016] Example 2. In the fabric printing and dyeing device described in Embodiment 1, a supporting wallboard 6 is also provided on the frame 9, and the supporting wallboard 6 slides on the frame 9 through the chute 10; There is a closed isolation film 5, and a pressure roller 3 is pressed on the closed isolation film 5. The atomization system is fixed on the support wallboard 6, and the pressure roller 3 is connected to the support wallboard 6 through a connecting shaft; The supporting wallboard 6, the atomization system and the pressure roller 3 move relative to the pattern plate 4 under the drive of the transmission system and the power system, and the pressure roller 3 cooperates with the atomization system to press the closed isolation film 5 during the movement.

Embodiment 3

[0017] Example 3. In the fabric printing and dyeing device described in Example 2, there are two pressure rollers 3, which are respectively symmetrically pressed on the closed isolation membranes 5 on the left and right sides of the atomization system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com