Patents

Literature

32results about How to "Reduce printing and dyeing costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

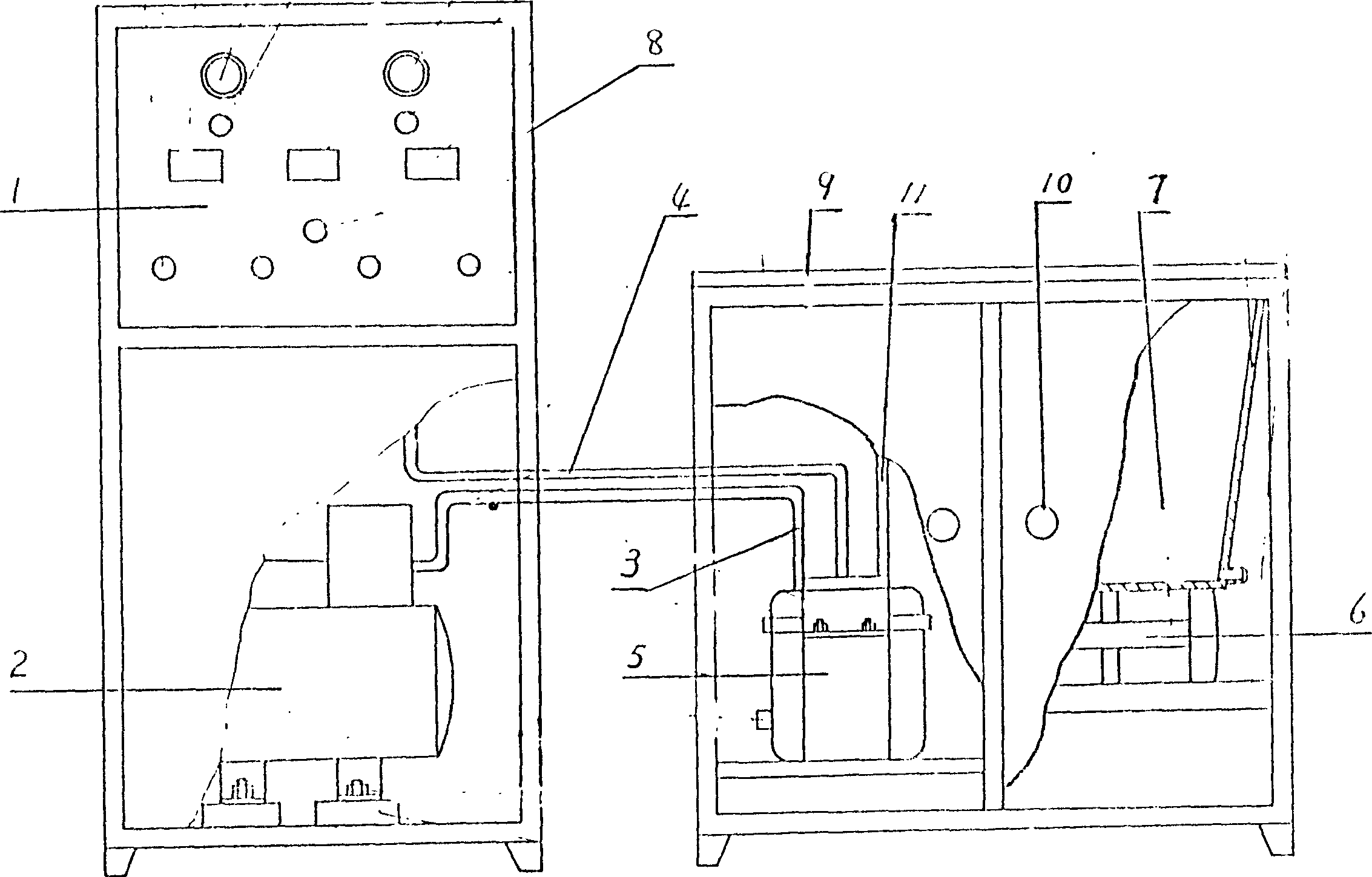

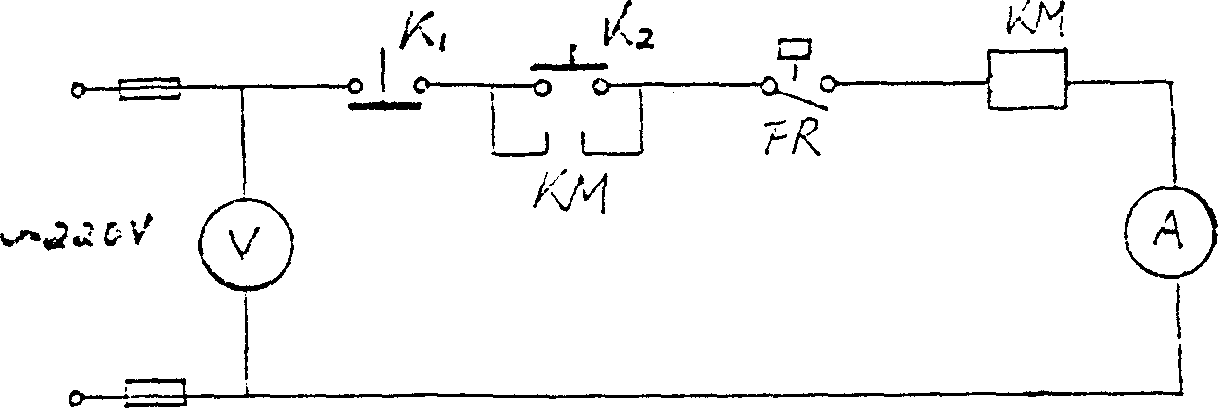

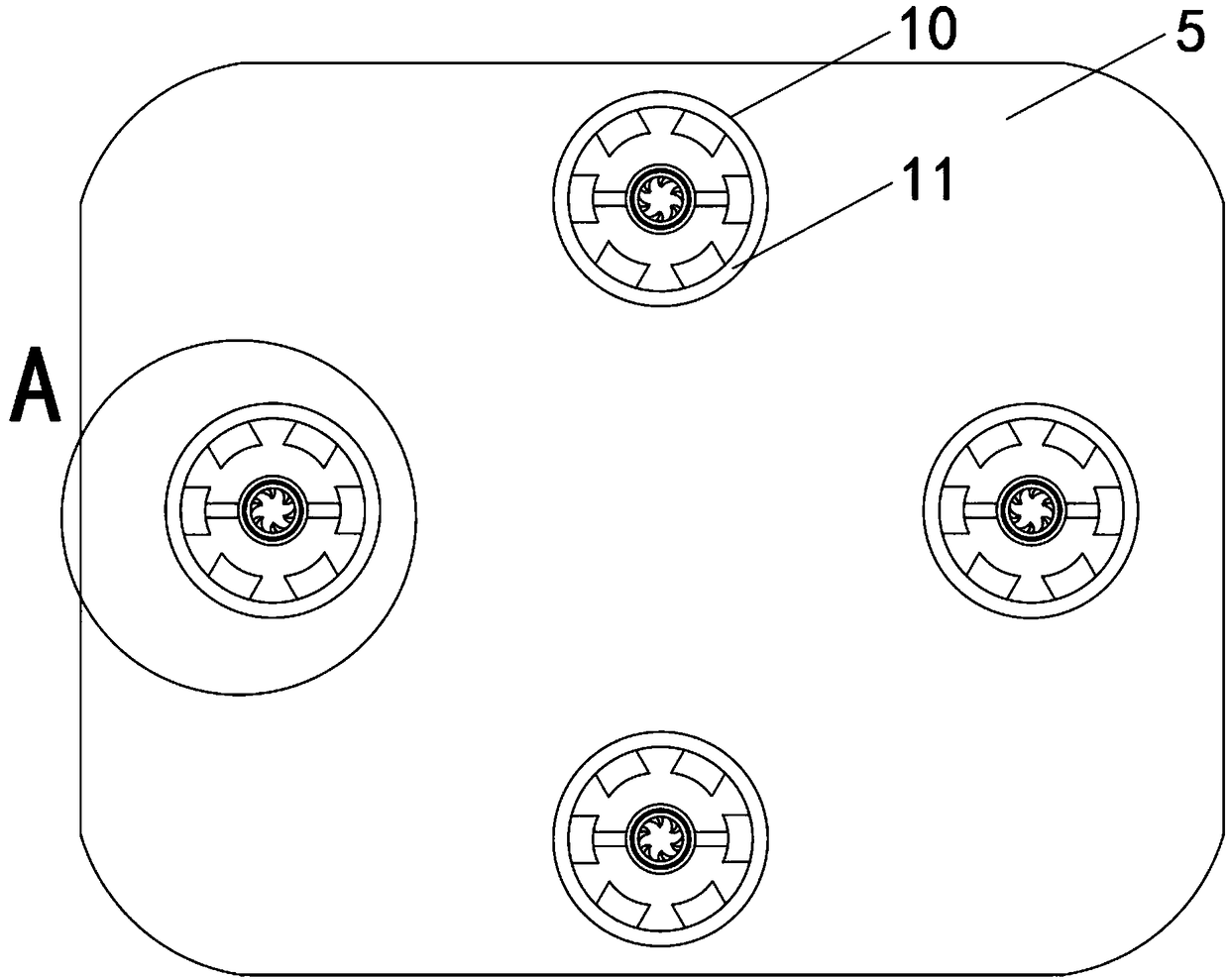

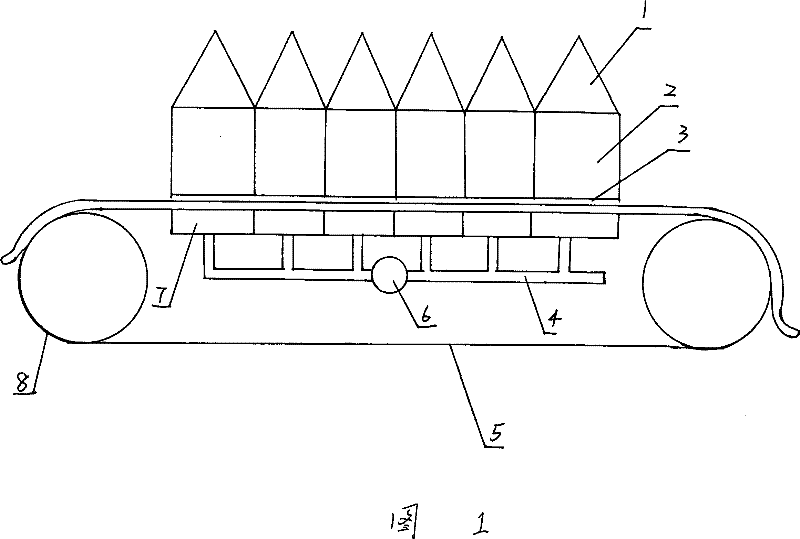

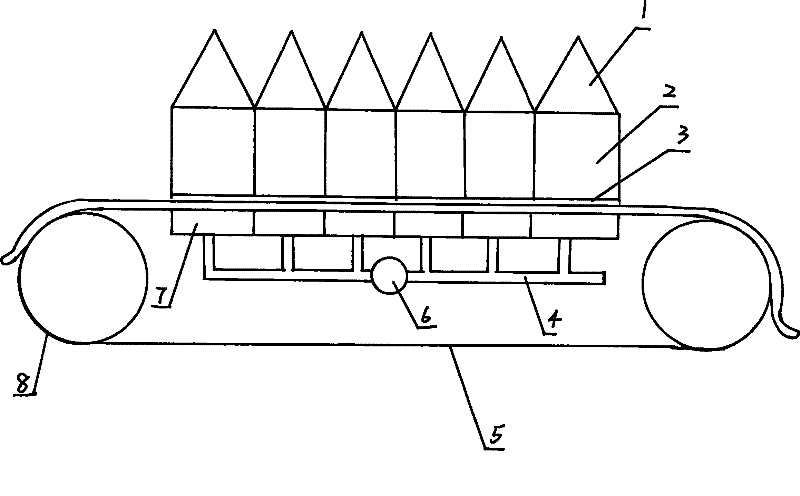

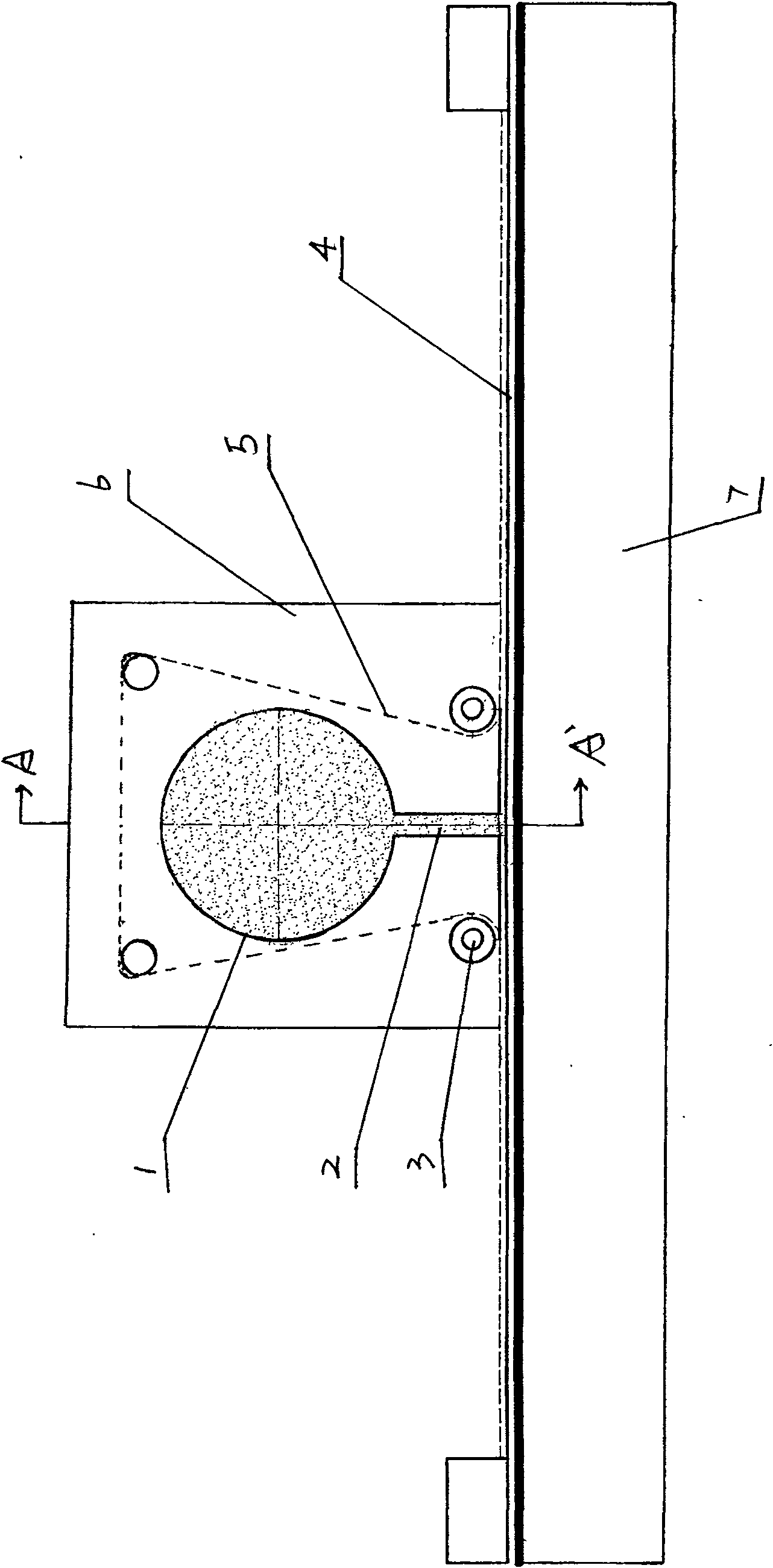

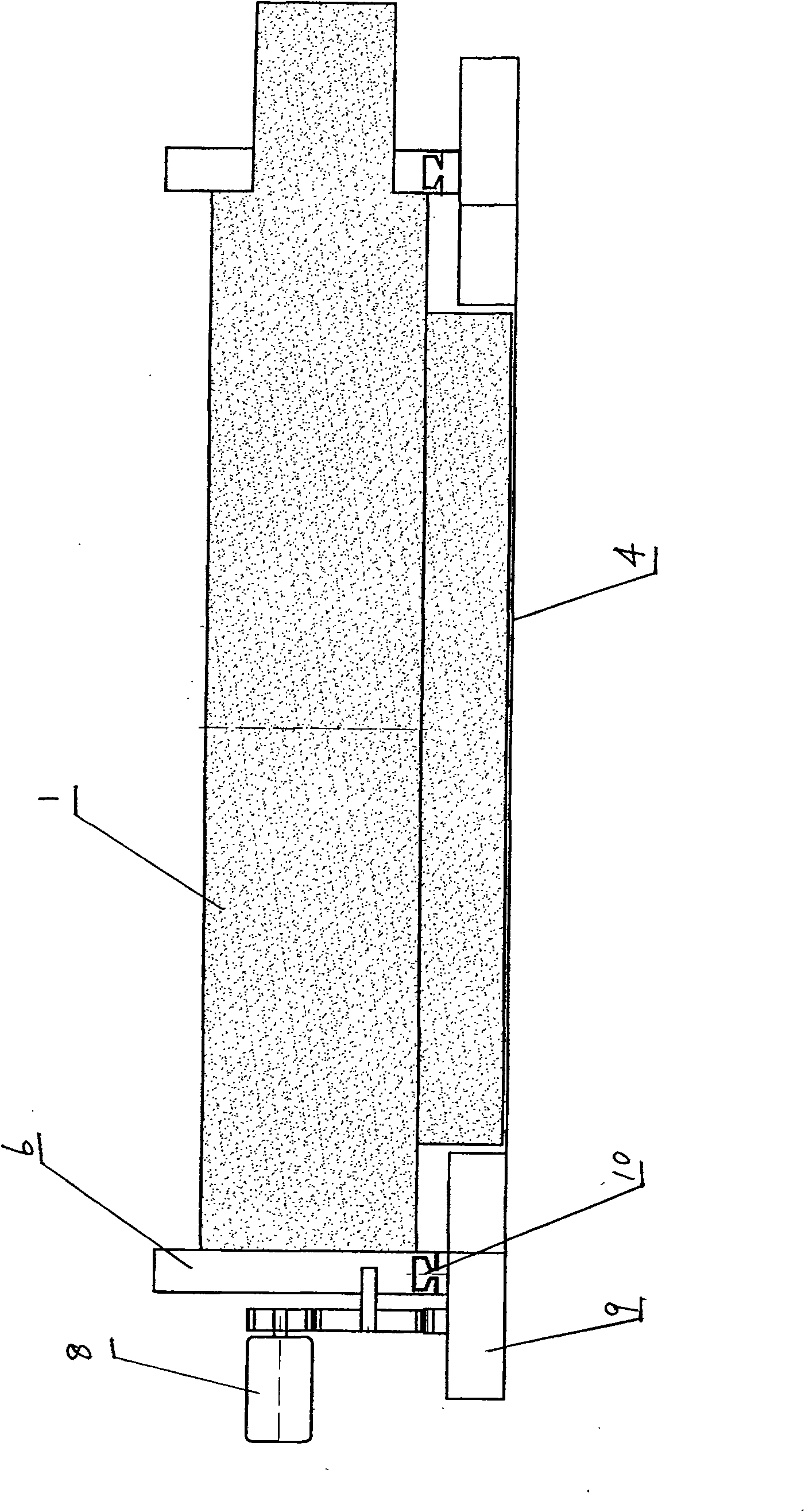

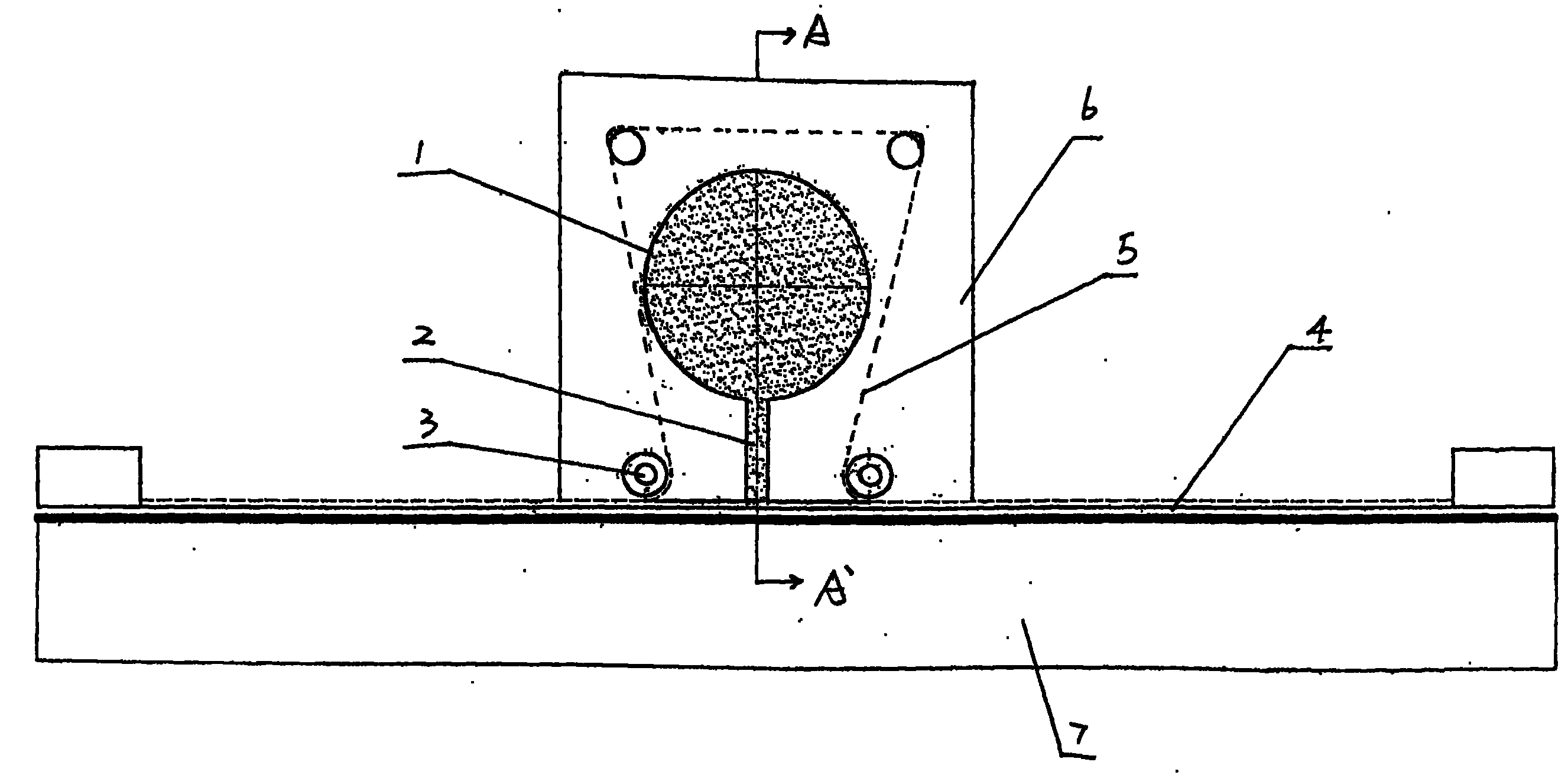

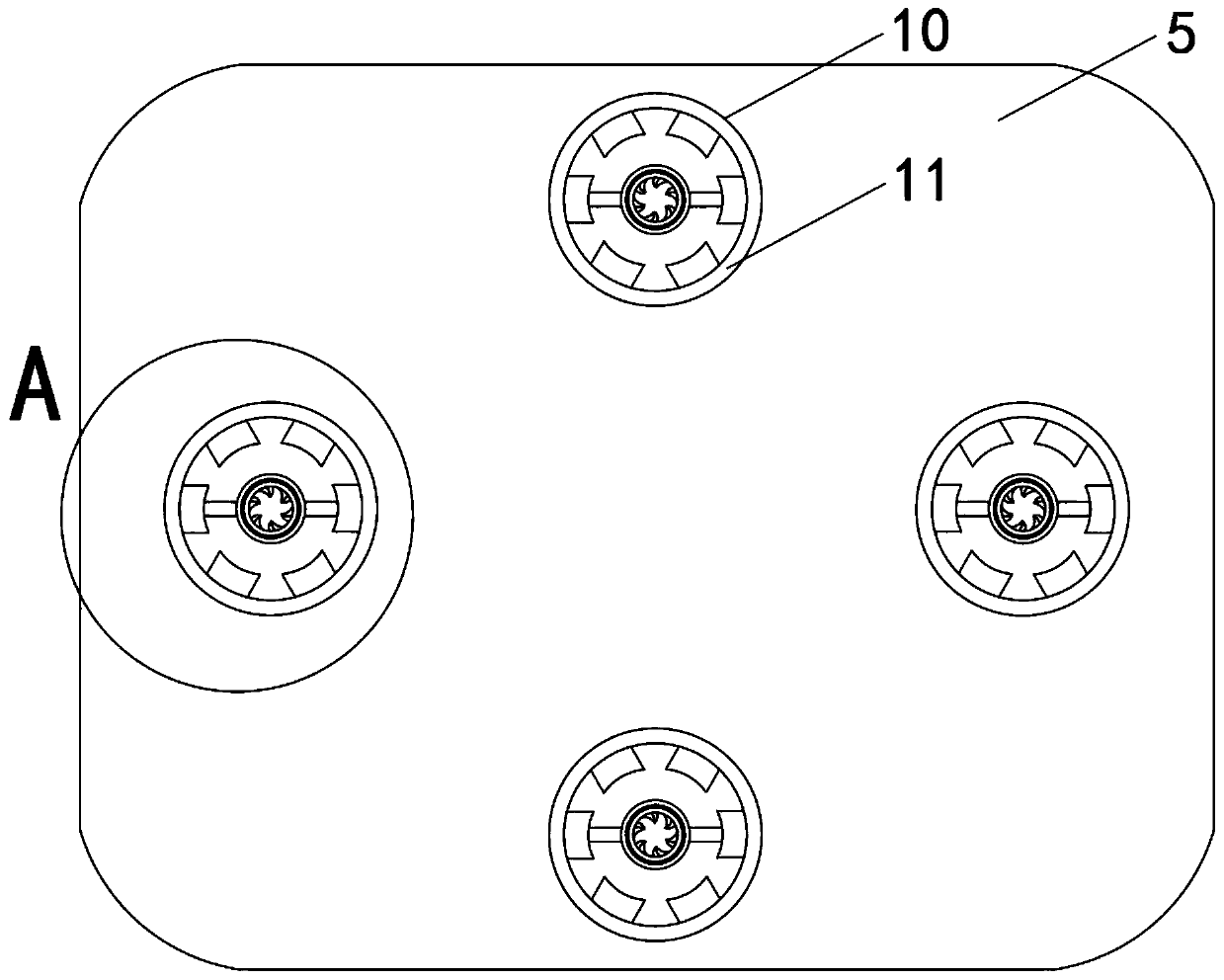

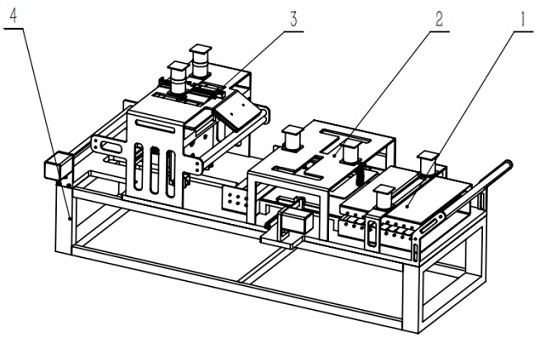

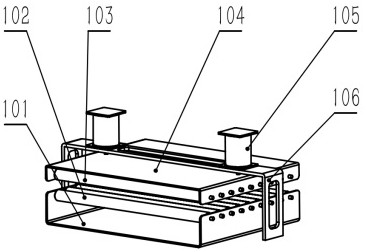

Fabric dyeing and printing device

InactiveCN101245537AImprove printing and dyeing effectUniform and beautiful colorTextile treatment by spraying/projectingTextile treatment carriersEngineeringControllability

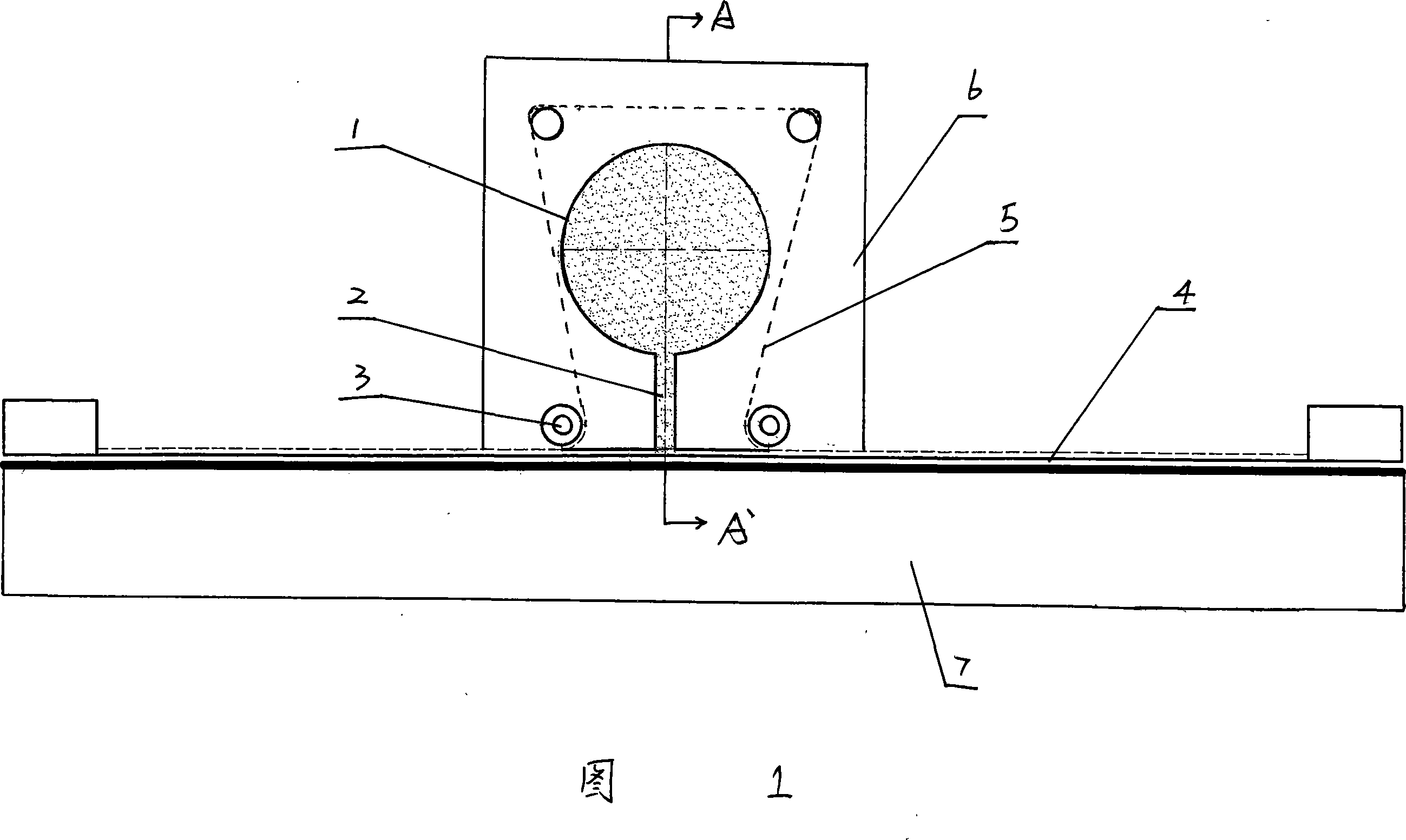

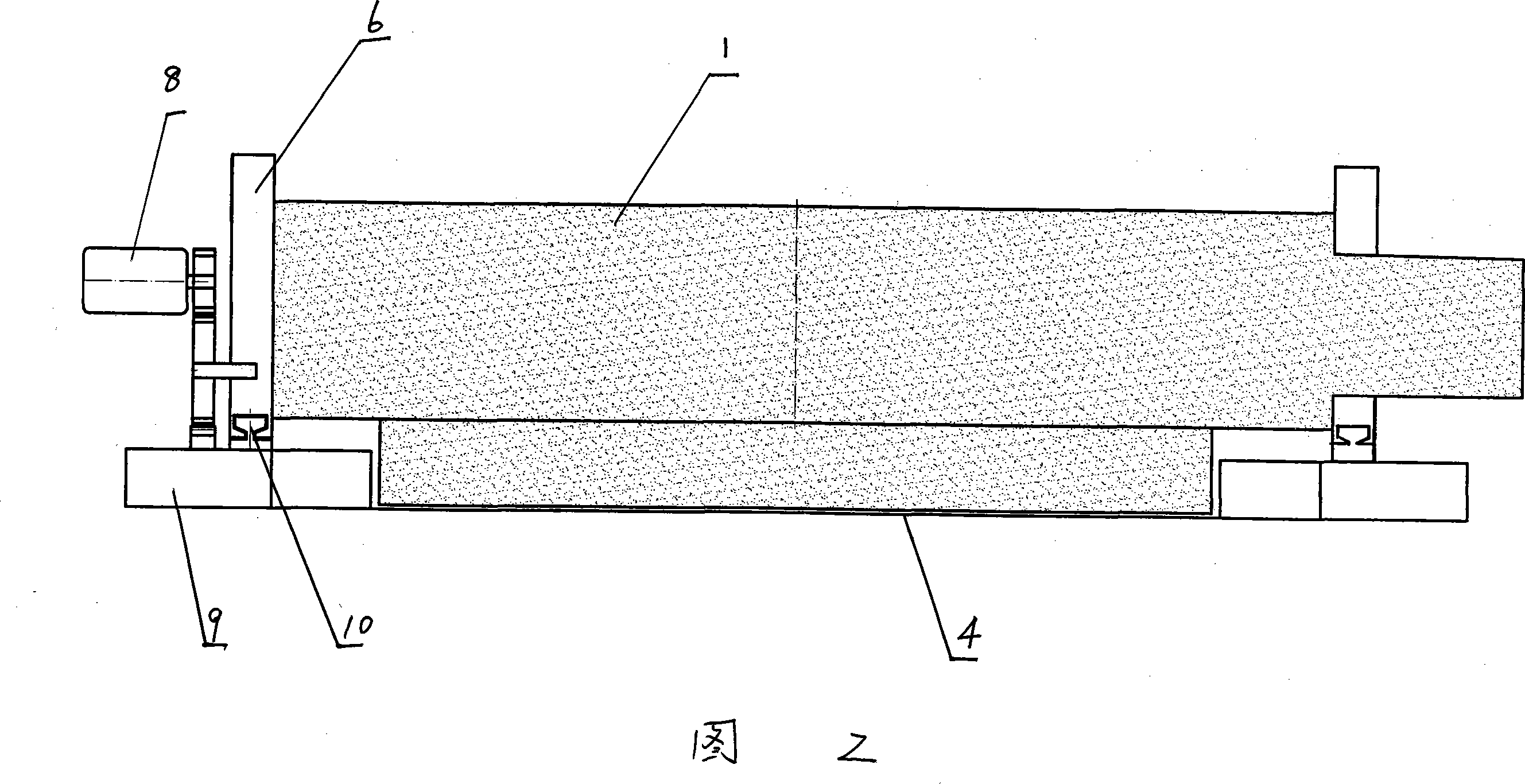

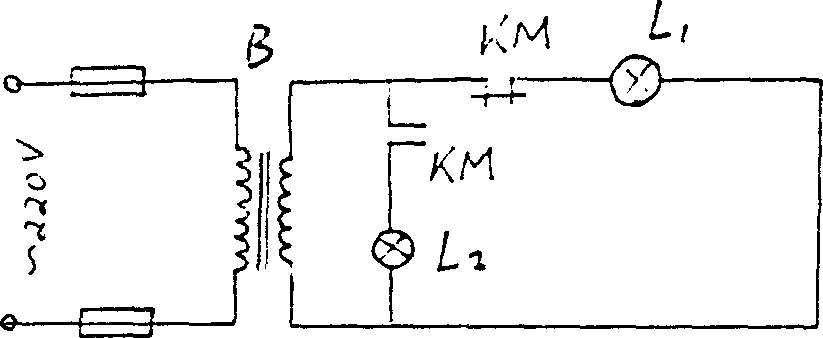

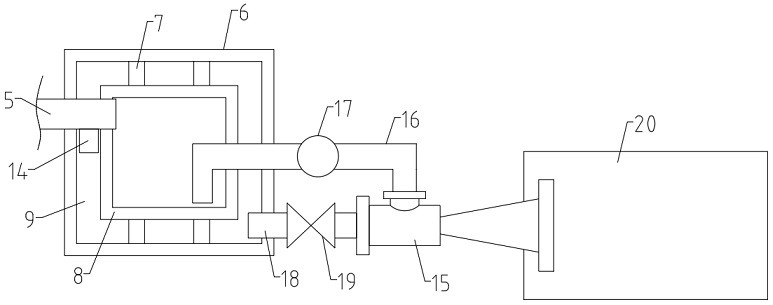

The invention relates to a fabric printing and dyeing device which includes a machine frame, a power system and a transmission system. The device is characterized in that: a fabric supporting piece is arranged on the machine frame or the transmission system. The fabric supporting piece is made by ventilating materials or is provided with a ventilating hole. The upward side and the downward side of the fabric supporting piece are respectively provided with a vacuum absorption cavity and an atomizing system. The vacuum absorption cavity is connected with a vacuum pipeline. A vacuum pump is arranged on the vacuum pipeline. The atomizing system includes an atomizer and a dye channel. A pattern templet is fixedly on the machine frame below the outlet of the dye channel. The atomizing system moves opposite to the pattern templet under the drive of the power system and the transmission system. The device of the invention utilizes vacuum subpressure absorption to print and dye atomized dyes on the fabric and has the advantages of simple and reasonable structure, low dyeing cost, high controllability on operation and high dyeing efficiency, being beneficial to improving the dyeing effect of the fabric. The color of the fabric after printing and dyeing is uniform and beautiful.

Owner:浙江宝通环保印染设备科技有限公司

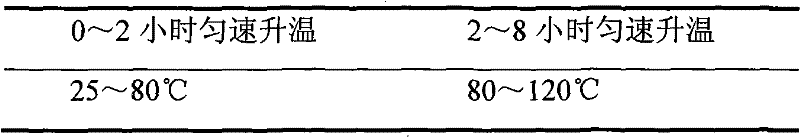

Preparation of sodium carboxymethyl cellulose

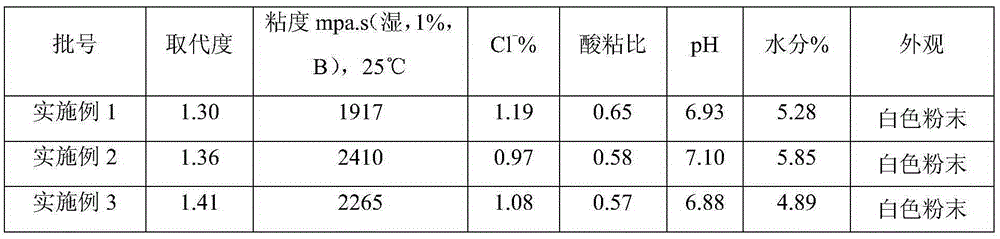

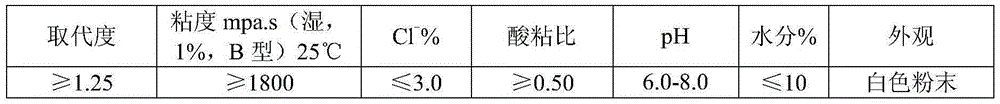

ActiveCN105330753AHigh viscosityReduce reactive hydroxyl group contentCarboxymethyl celluloseCellulose

The invention belongs to the field of polymer chemistry, and specifically relates to a method for preparing sodium carboxymethyl cellulose, the technical problem to be solved by the invention is to provide a method for preparing highly-substitution high-viscosity sodium carboxymethyl cellulosewhich with the advantage of easily accessible raw materials. The preparation method includes A, cellulose alkalization, B, cellulose etherification and C, sodium carboxymethyl cellulose preparation. The prepared sodium carboxymethyl cellulose is an excellent dye carrier, has the advantages of high substitution and viscosity and good thickening effect, and can be better used in printing / dyeing industry.

Owner:泸州北方纤维素有限公司

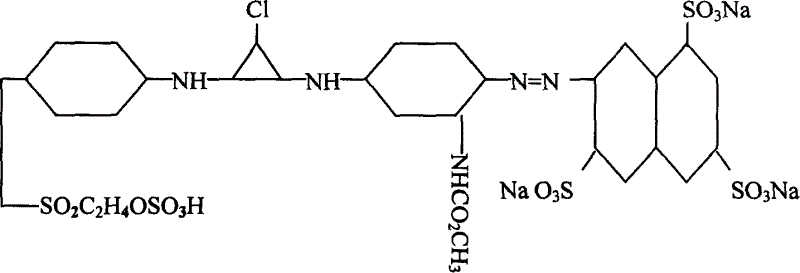

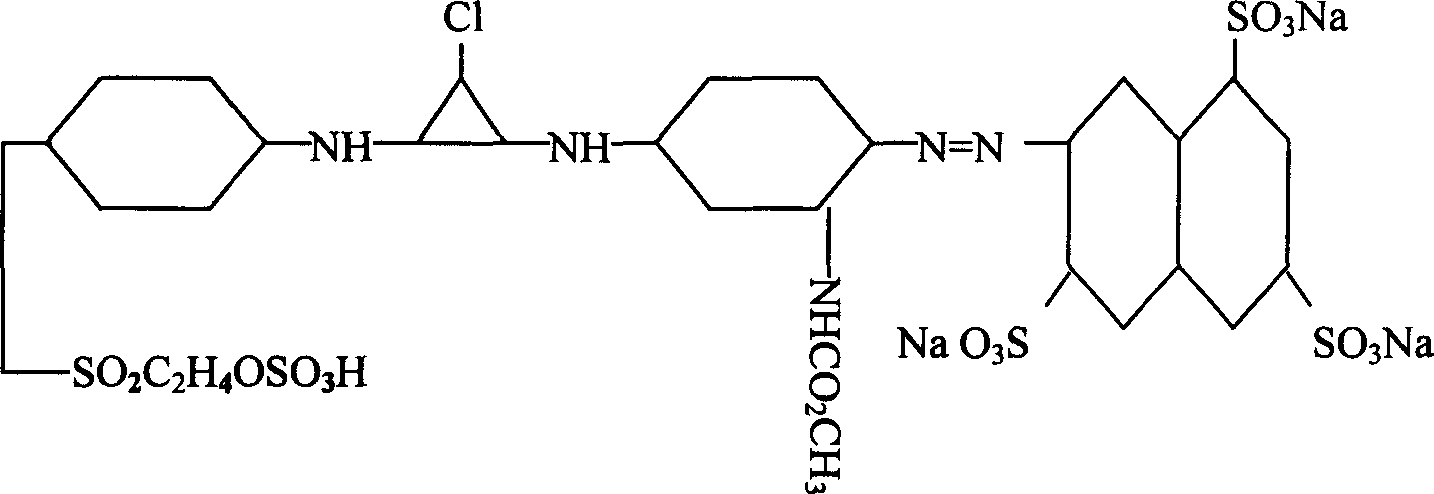

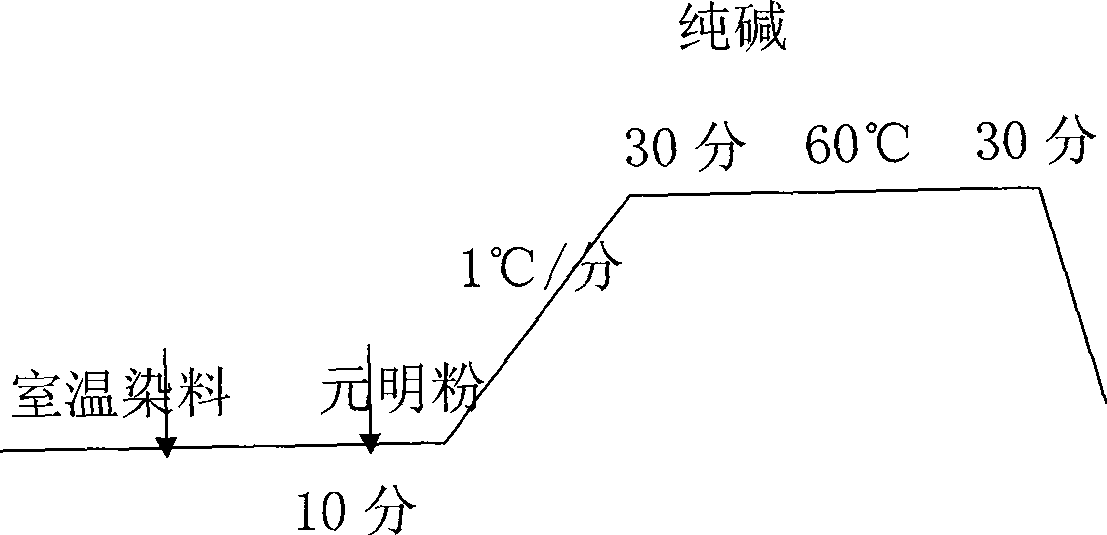

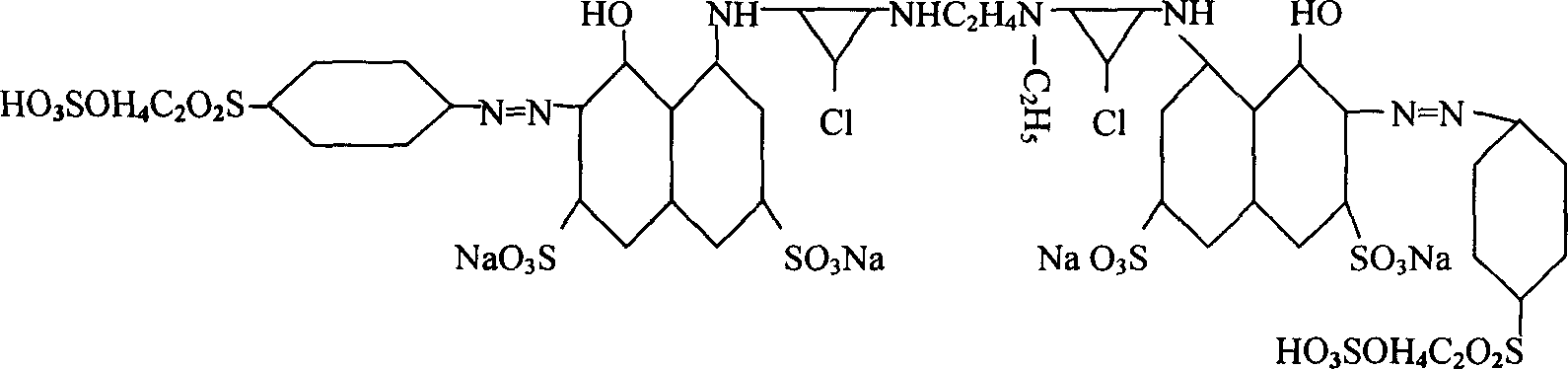

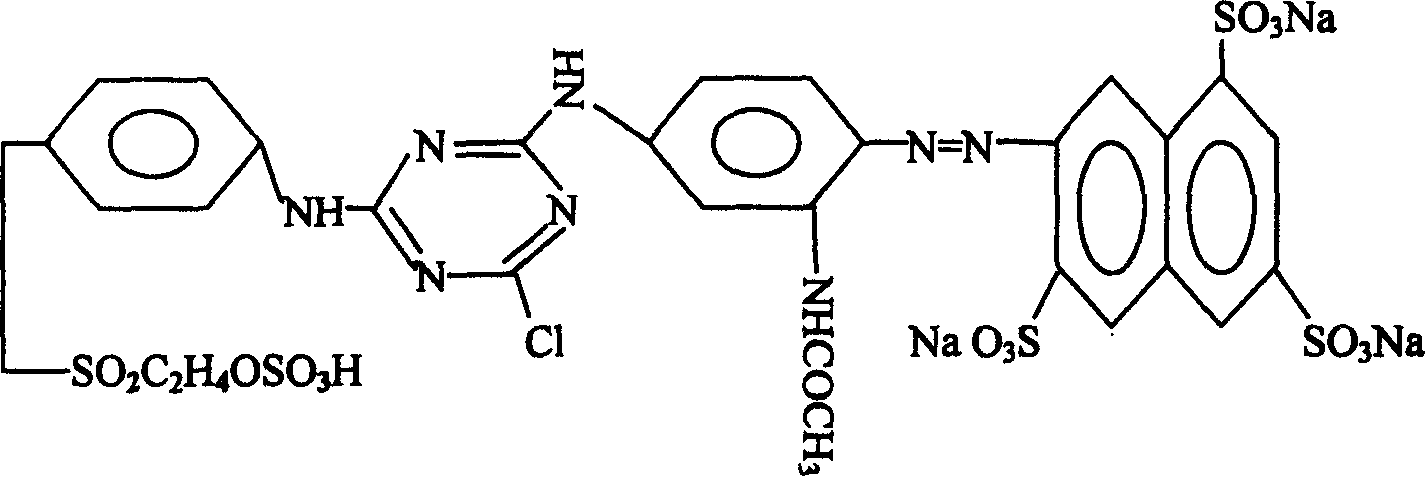

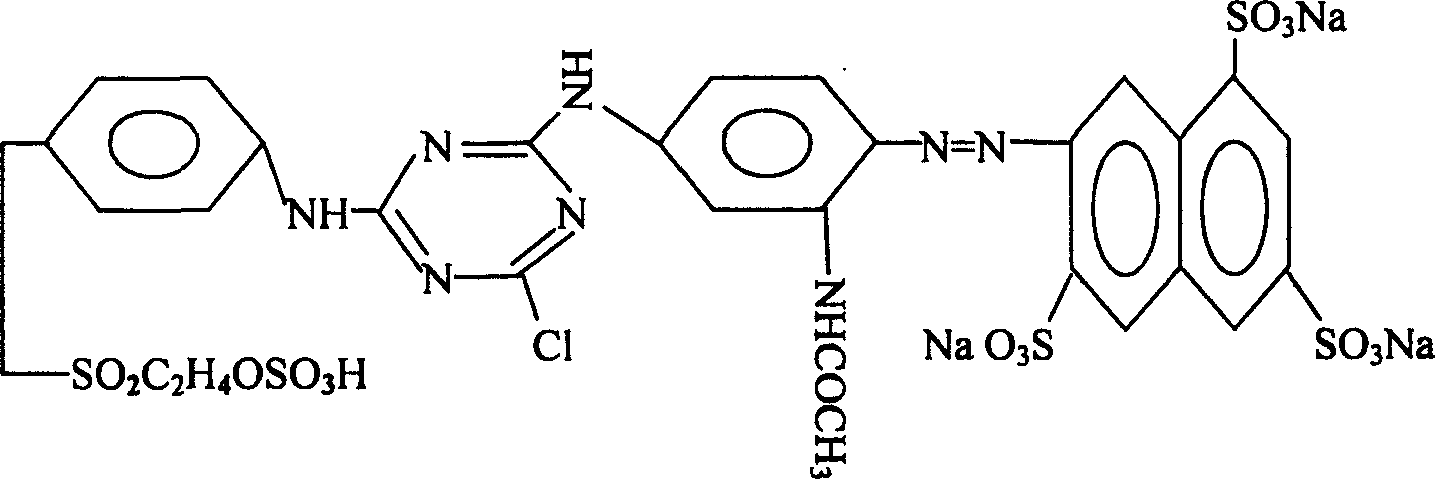

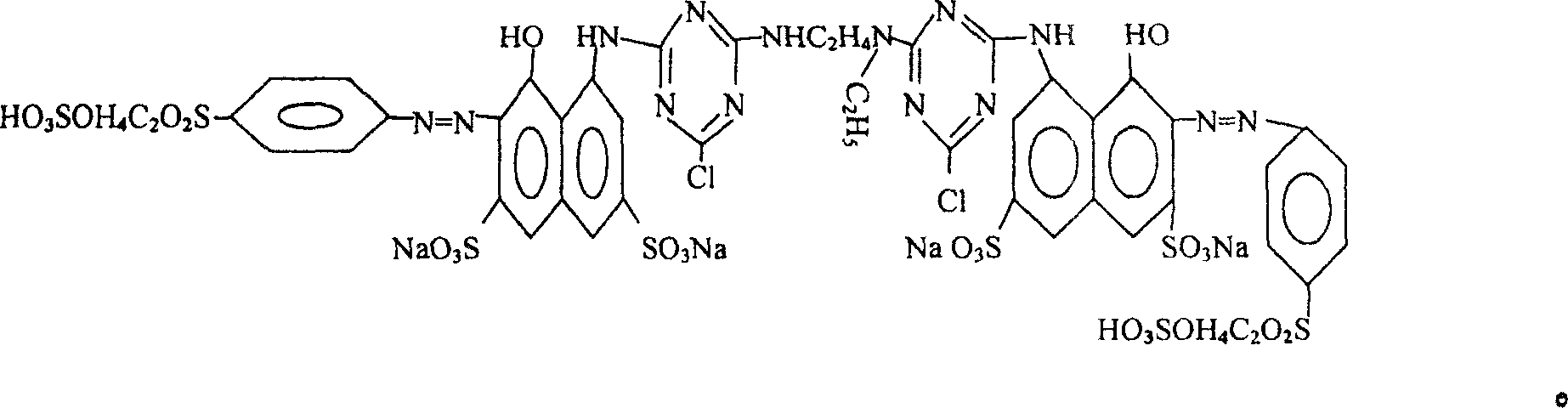

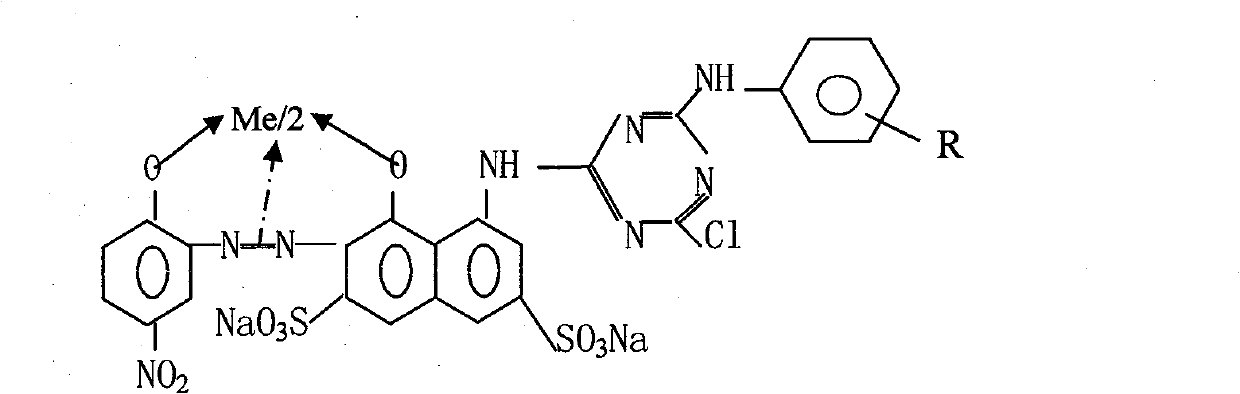

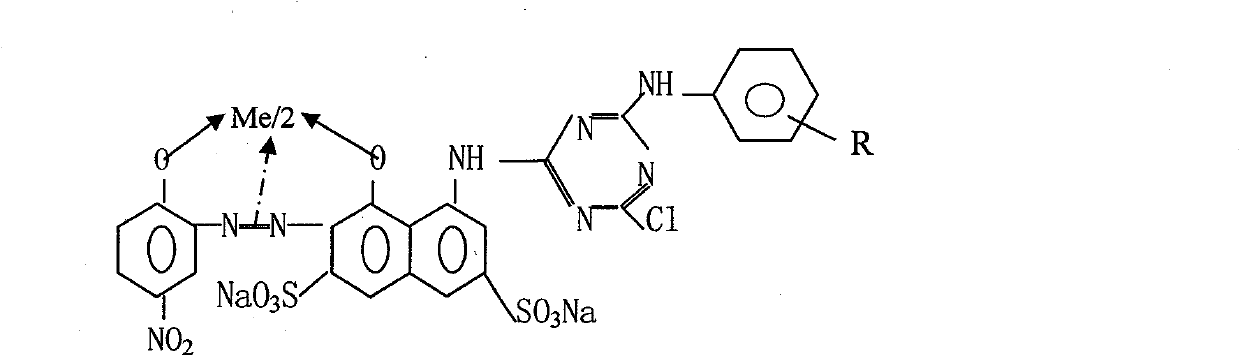

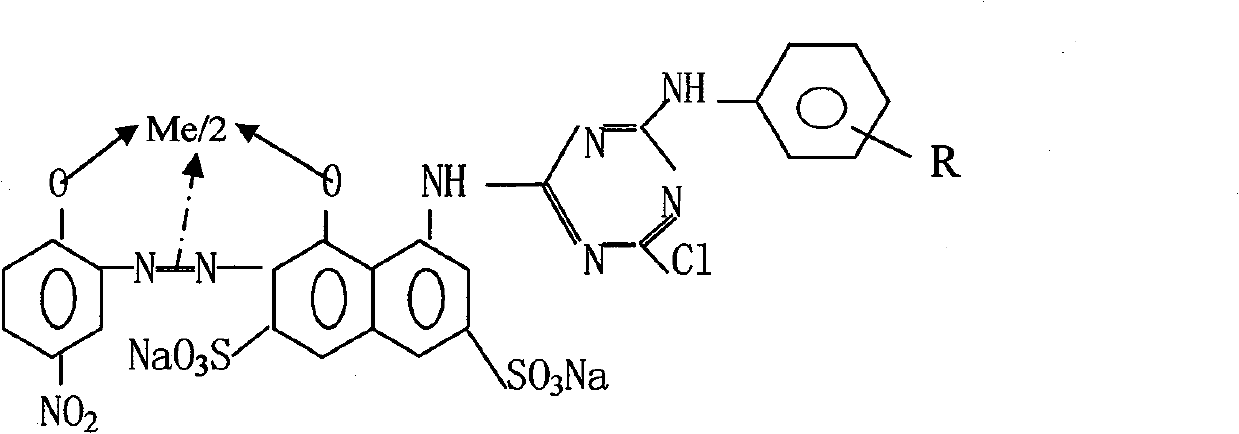

Active yellow SDE, synthetic method and its composite active yellow dye

Disclosed is a active yellow SDE monomer, which is prepared by subjecting 3,6,8-trisulfonic acid -2-naphthylamine dried substance to beating homogeneously at the presence of ice, diazotizing with hydrochloric acid, coupling the diazonium substance with metaamino-benzene amine acetylated hydrochlorate, condensing with cyanuric chloride, charging (beta-sulfate ethyl sulfone) phenylamine dried article for second condensation, and direct drying by spraying.

Owner:无锡润新染料有限公司

High temperature high pressure jet dyeing process and apparatus for color fabrics

InactiveCN1456737AImprove utilizationSave energyDyeing processTextile treatment by spraying/projectingEngineeringHigh pressure

A technology for dyeing the color fabric by high-temp and -pressure spray includes such steps as mixing dye with assistant, heating while pressurizing, spraying the mixture onto fabric, and high-temp and-pressure steaming for fixating color. Its advantages are low cost, short time, no deformation of fabric, high utilization rate of dye, and no pollution.

Owner:HENGTAI DYEING TECHNOLOGICAL SERVICE CHANGCHUN CITY

Uneasily-faded figured cloth printing process

The invention discloses an uneasily-faded figured cloth printing process. The uneasily-faded figured cloth printing process comprises the following steps: (1) whitening blank cloth and drying; (2) preparing a dye by using pigments with different colors according to needed patterns and colors, wherein the dye comprises the following components in percentage by weight: 30%-60% of the pigments, 0.1%-0.8% of a binding agent, 1%-4% of a thickening agent, 1%-5% of a leveling agent and the balance being water; (3) forming paper patterns, namely printing the patterns on a metal surface by using the prepared dye and a pattern roller; (4) sizing the blank cloth, namely rolling a modifying agent on the whitened and dried blank cloth and finishing sizing; (5) carrying out heat transferring printing on the patterns printed on the metal surface obtained in the step (3) to the blank cloth in the step (4); and (6) coiling.

Owner:蒋瑾

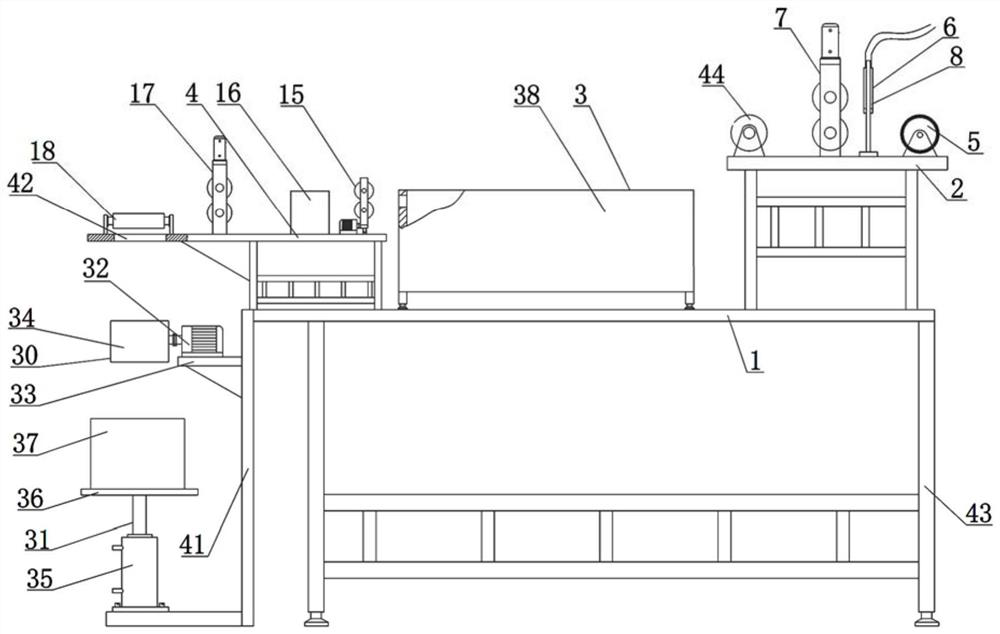

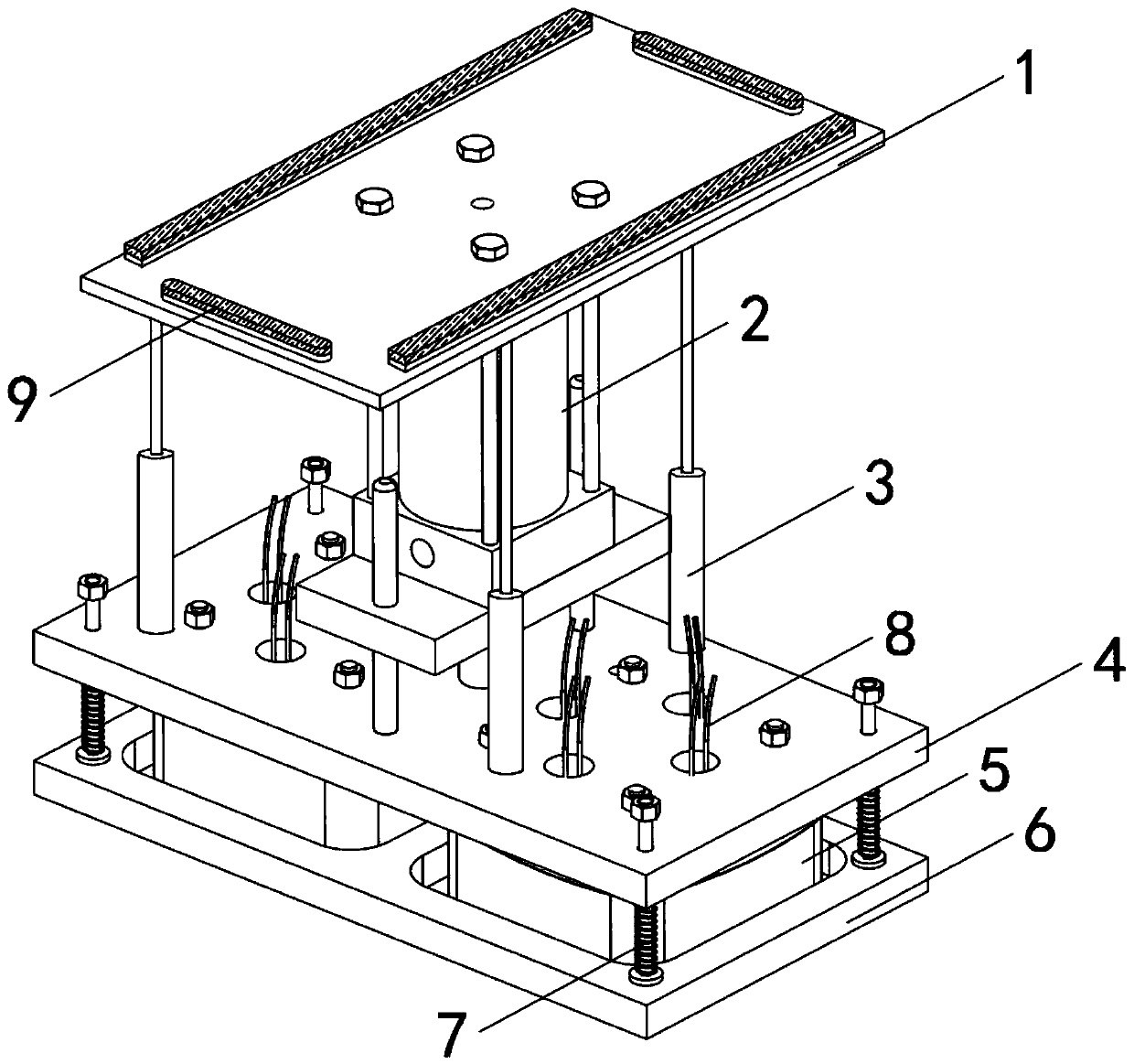

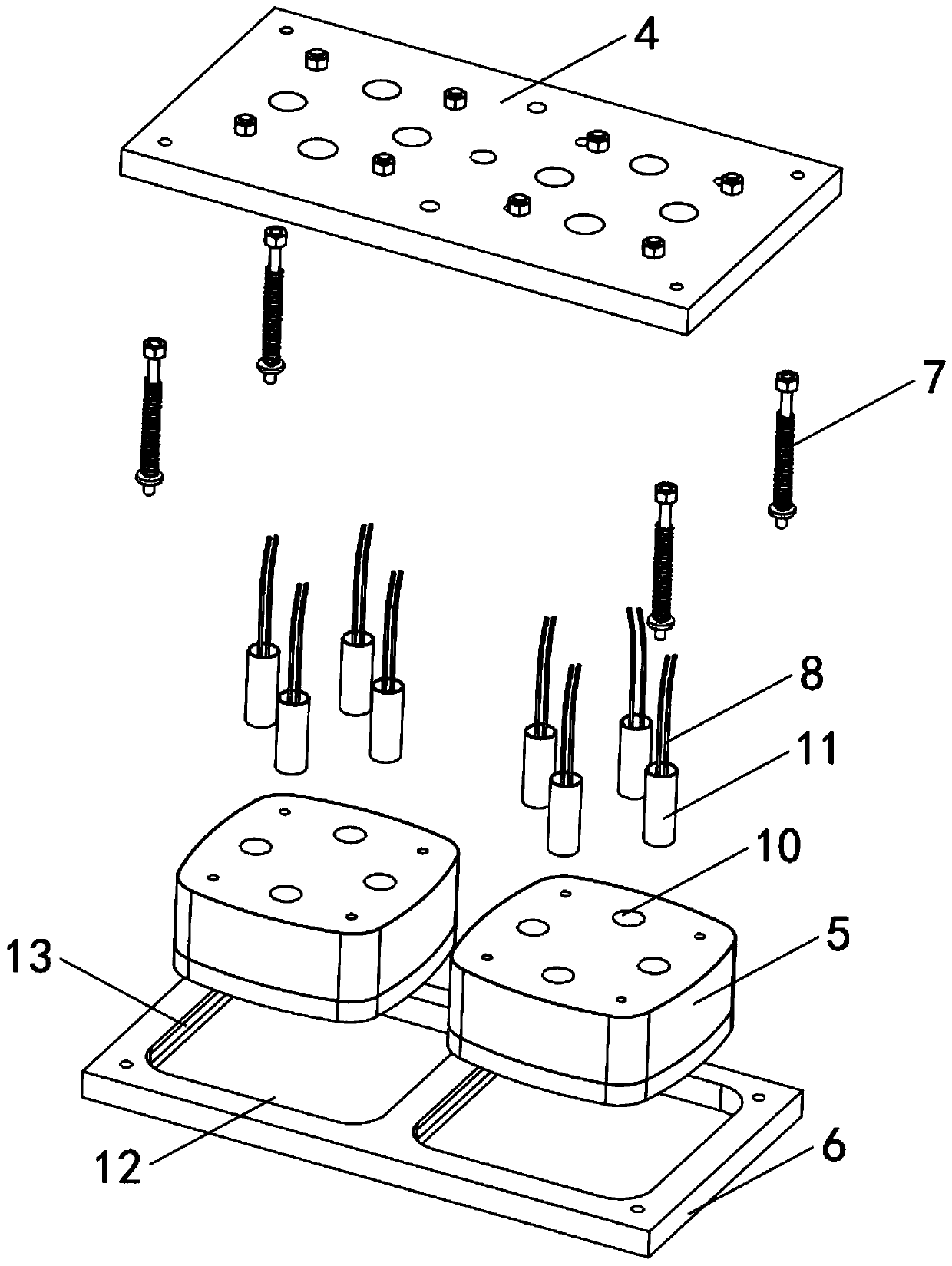

Printing and dyeing textile equipment for producing textile fabric and production method thereof

InactiveCN111332011AAvoid wastingReduce labor intensitySevering textilesRotary pressesPolymer scienceEngineering

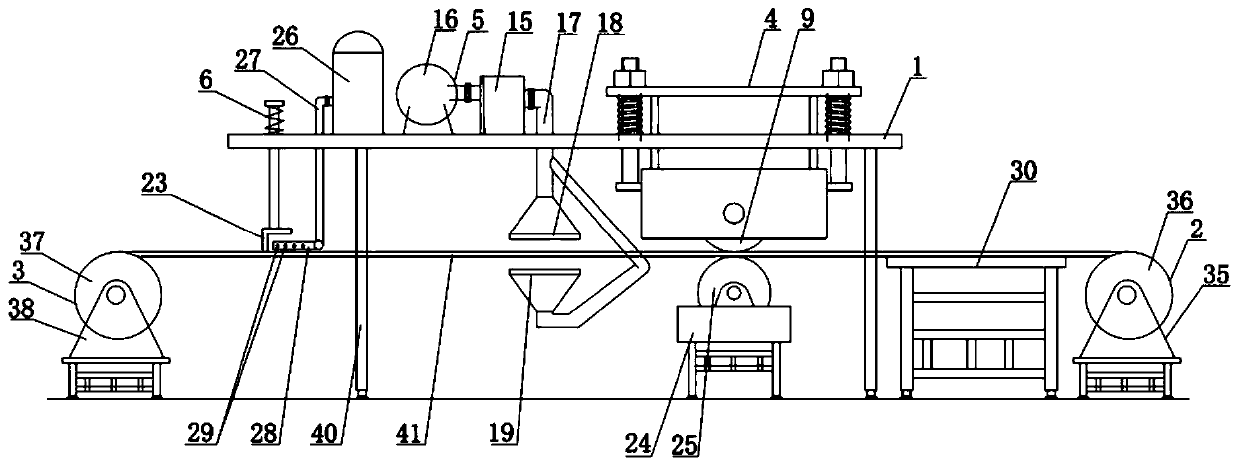

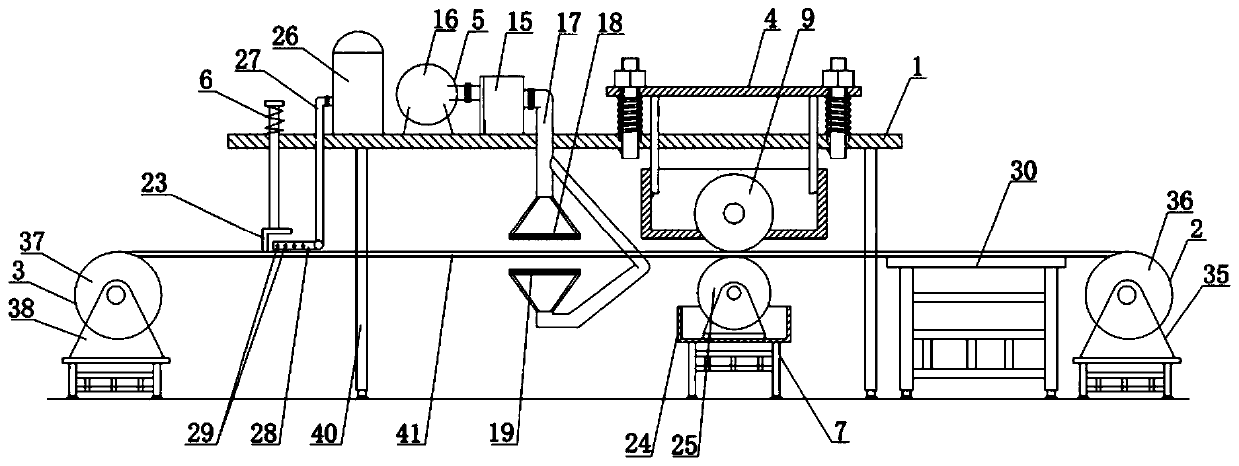

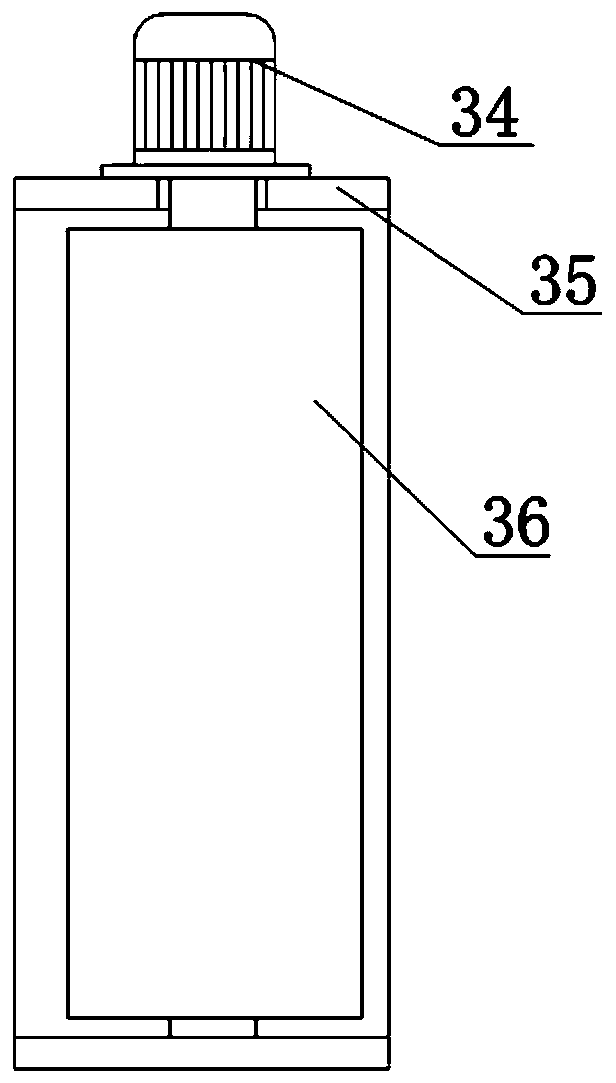

The invention discloses printing and dyeing textile equipment for producing textile fabric. The equipment comprises a worktable, a winding device and unwinding device, wherein the winding device and the unwinding device are mounted on the left side and the right side of the worktable correspondingly, an upper printing and dyeing device, a textile fabric drying device and a particle pigment scraping device are sequentially mounted on the worktable from right to left, a lower printing and dyeing device located under the upper printing and dyeing device is arranged below the worktable, the upperprinting and dyeing device comprises an upper printing and dyeing box and an upper printing and dyeing roller, the upper printing and dyeing box is located below the worktable, the upper printing anddyeing roller is longitudinally mounted in the upper printing and dyeing box, the two ends of the upper printing and dyeing roller are rotatably mounted on the front wall and the rear wall of the upper printing and dyeing box correspondingly, the lower end of the upper printing and dyeing roller penetrates through the bottom of the upper printing and dyeing box, and movable rods are welded to theleft and right inner side walls of the upper printing and dyeing box. The equipment has the beneficial effects that the printing and dyeing quality can be improved, labor intensity of a worker can bereduced, pigment waste can be avoided, production cost is reduced, and the equipment is suitable for printing and dyeing of the textile fabric of different thicknesses.

Owner:绍兴如圆纺织有限公司

Automatic picture adjusting method for online printing and dyeing yarn sheet with full-size width

ActiveCN108583040ASolve the problems in the application of digital printing technologyLow efficiencyOther printing apparatusYarnTextile printer

The invention relates to the field of textile printing and dyeing cloth, in particular to an automatic picture adjusting method for online printing and dyeing a yarn sheet with the full-size width. Inorder to solve the problems such as more sewage and low efficiency in digital printing technology application of the yarn-dyed industry in the prior art, the invention provides the automatic pictureadjusting method for online printing and dyeing the yarn sheet with the full-size width. A computer is adopted as a tool, a picture for online printing and dyeing the yarn sheet with the full-size width is automatically and quickly generated based on a target picture, no picture database is needed, and the target picture is copied and moved and a slice picture is reconstructed to a target area, sothat the picture for online printing and dyeing the yarn sheet with the full-size width can be generated.

Owner:ZHONGYUAN ENGINEERING COLLEGE

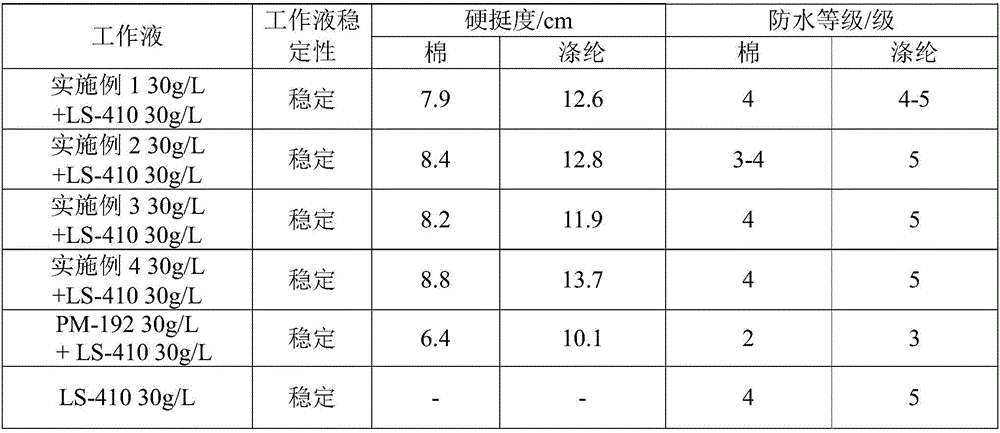

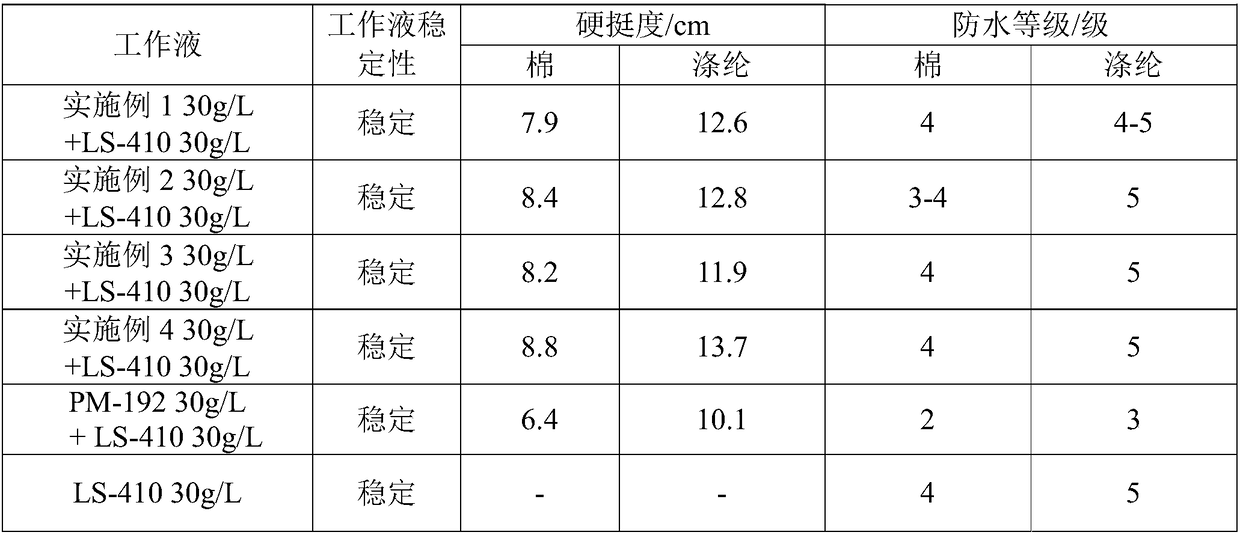

Hydrophobic stiffening agent and preparation method and use method thereof

ActiveCN106758236AWill not affect the waterproof effectPoor hydrophilicityLiquid repellent fibresMonomerChemistry

The invention relates to a hydrophobic stiffening agent and a preparation method and a use method thereof. The hydrophobic stiffening agent is prepared from the following raw materials and components in percentage by weight: 2 to 5% of dispersive stabilizer, 45 to 50% of comonomer, 0.05 to 0.3% of initiator, 0.4 to 1% of adjusting acid, 0.1 to 0.6% of neutralizing alkaline, and 43 to 53% of deionized water.

Owner:苏州联胜化学有限公司

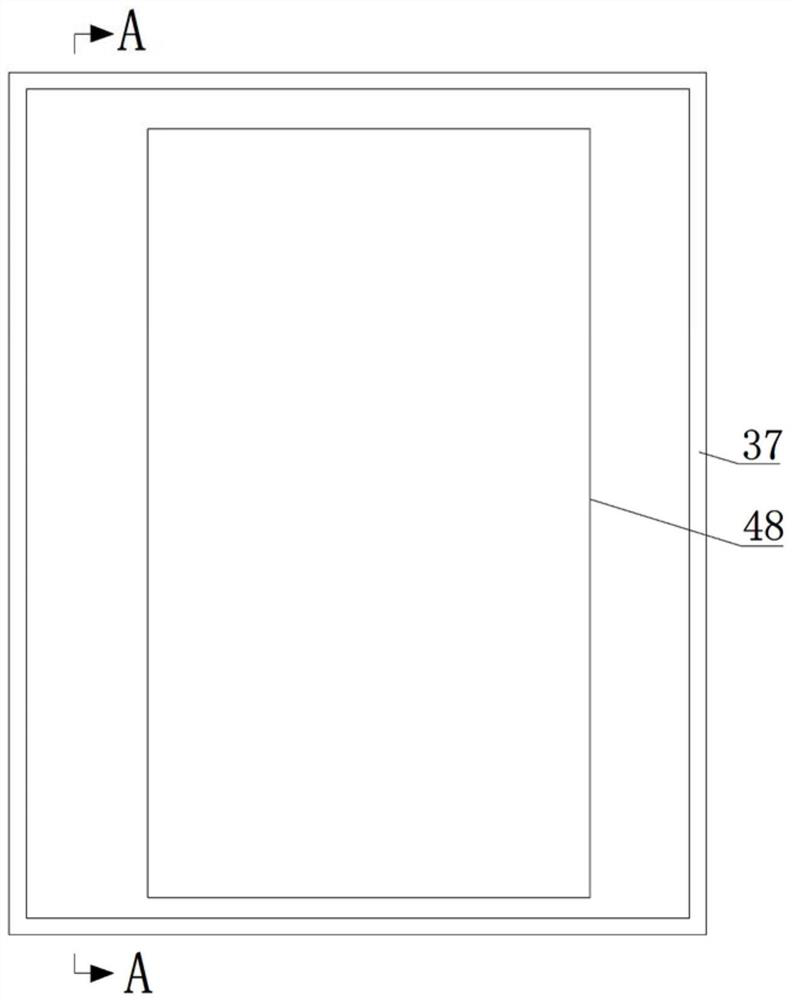

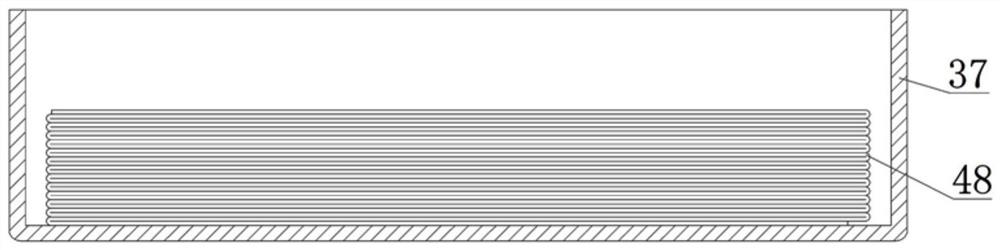

Textile fabric printing and dyeing and stacking device and method thereof

InactiveCN111636159AImprove appearance qualityAchieve levelingTextile treatment machine arrangementsFolding thin materialsDrive motorDyeing

The invention discloses a textile fabric printing and dyeing and stacking device. The textile fabric printing and dyeing and stacking device comprises a workbench, a right platform, a printing and dyeing device and a left platform, wherein the right platform, the printing and dyeing device and the left platform are arranged on the workbench and are sequentially arranged from right to left; a swinging device, a drying oven, a driving device and a guide wheel set are sequentially arranged on the left platform from right to left; the swinging device comprises a swinging motor A, a frame and two rollers rotationally arranged in the frame; the driving device comprises a second portal frame, a second air cylinder, a second support, a rolling cylinder, a driving motor and a driving wheel; a fabric stacking device and a material collecting device are sequentially arranged under the guide wheel set from top to bottom; the fabric stacking device comprises a swinging motor B, a supporting table and a square pipe; the material collecting device comprises a vertical air cylinder, a fixing plate and a material basket; the fixing plate is positioned under the square pipe; and the material basketis placed on the fixing plate. The textile fabric printing and dyeing and stacking device has the beneficial effects that the appearance quality of finished textile fabrics is improved, pigment wasteis avoided, the printing and dyeing cost is saved, and the finished textile fabrics can be stacked in an S shape.

Owner:绍兴柯桥兴旺印纸印花有限公司

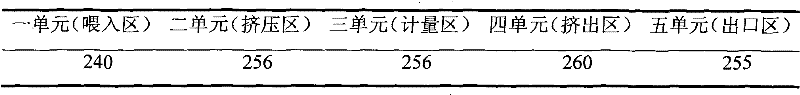

Anion terylene colored fiber and preparation and application thereof

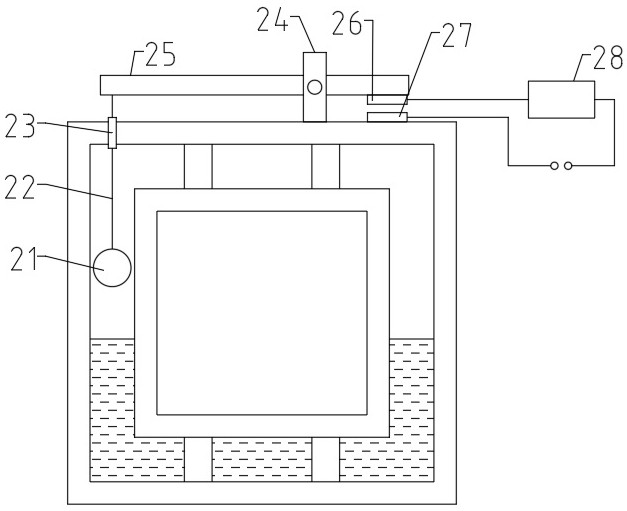

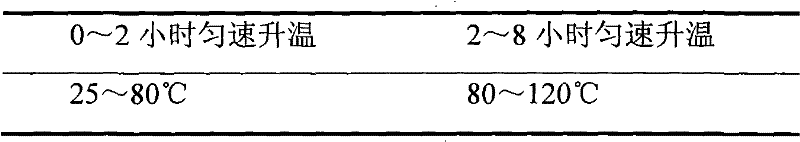

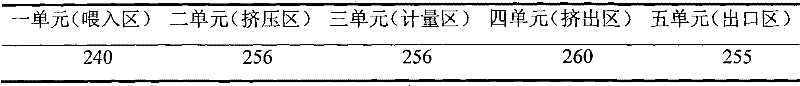

ActiveCN101545153BHigh emissivityImprove performanceMelt spinning methodsMonocomponent polyesters artificial filamentPolyesterFiber

The invention relates to an anion terylene colored fiber and preparation and preparation and application thereof. The fiber comprises the following components: a terylene anion master batch, a terylene colored master batch and a terylene fiber-forming polyester chip, and the weight ratio is 1-10:1-10: 80-98. The preparation comprises the following steps that: (1) the terylene fiber-forming polyester chip is dried in vacuum, the anion powder is mixed with the chip, and the obtained mixture is subjected to melt extrusion, cooling and granulation; (2) the terylene anion master batch, the terylene colored master batch and the terylene fiber-forming polyester chip are vacuumized, heated and subjected to heat preservation; (3) the raw materials are put in an extruder and heated, melted and compressed; and (4) the obtained product is sent to a distributing pipe, a static mixer and a metering pump respectively to form a melting current, and the melting current is cooled, coated and spun to obtain the finished product. The anion terylene colored fiber is flexible and elastic, resembles the wool fabric in style, maintains the characteristics of lightness and smoothness of terylene, can transmit anions and has different colors; moreover, the preparation method has the advantages of simple operation, easy realization of production process, low dyeing cost and the suitability for industrialized production.

Owner:ZHEJIANG JINXIA NEW MATERIAL TECH CO LTD

Water-saving and energy-saving processing technology of polyester fabric

ActiveCN109487465AReduce tensionReduce dosageChemical fixing of textilesLiquid/gas/vapor removalPolyesterWater saving

The invention discloses a water-saving and energy-saving processing technology of a polyester fabric, which comprises the steps of selecting raw materials of polyester yarns - dyeing yarns - winding yarns - weaving and cutting, and selecting high-density NC polyester yarns as raw materials of the polyester fabric. By means of the technology, the beneficial effects comprises: compared with the traditional method for integrally printing and dyeing the polyester fabric, the method of printing and dyeing is more comprehensive for polyester fabric , the polyester fabric is dyed by the dye solution,the process flow of dyeing the polyester fabric is reduced, the printing and dyeing efficiency is improved, by printing and dyeing a plurality of polyester yarns respectively, the dyeing solution consumption of the mechanism is less, so that the process is more energy-saving, water-saving and cost-saving when dyeing the polyester yarns; and the dye solution used for spraying and dyeing can flow into the packing groove by improving the sleeve groove, and the packing groove guides the dye solution into the dye solution refilling bucket, so that people can conveniently collect and process the dye solution which is not attached and dyed with the polyester yarns filament, thereby ensuring the environmental protection and saving printing and dyeing cost.

Owner:JIANGSU HUAYI GARMENT CO LTD

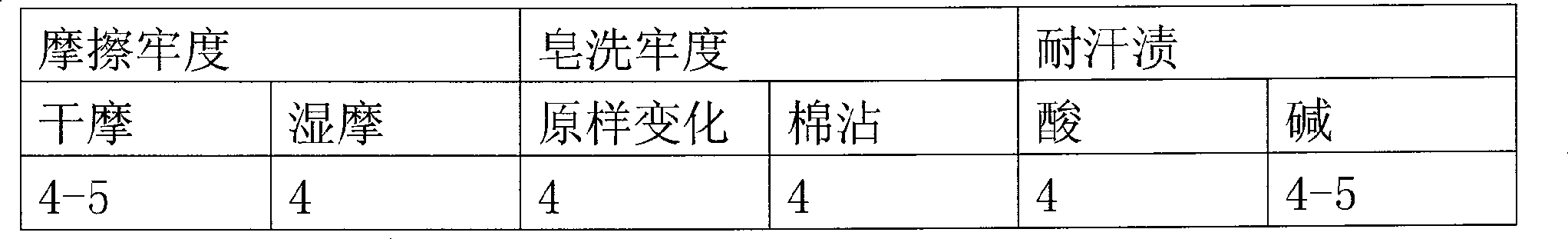

Ecological nano dye and use method thereof

InactiveCN101503576AIncrease profitHigh color fastnessOrganic dyesDyeing processColour fastnessSewage

The invention relates to an ecological nano dye for textile dye printing. The ecological nano dye consists of nano-level ecological paint color paste and liquidized ecological activated dye. The weight ratio of the nano-level ecological paint color paste to the liquidized ecological activated dye is 1:1-9. Before the ecological nano dye is used for dye printing, the textile is modified by cations; and after the dye printing, a wet rubbing fastness reinforcing agent is used to treat the textile. The textile dyed by the ecological nano dye has bright color and greatly improved color yield percentage, does not need high temperature soaping, does not discharge sewage during the dye printing, shortens the technical process, saves the energy source, reduces the production cost and improves the color fastness of the textile.

Owner:吴江桃源染料有限公司

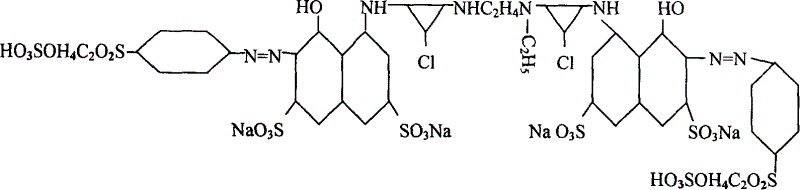

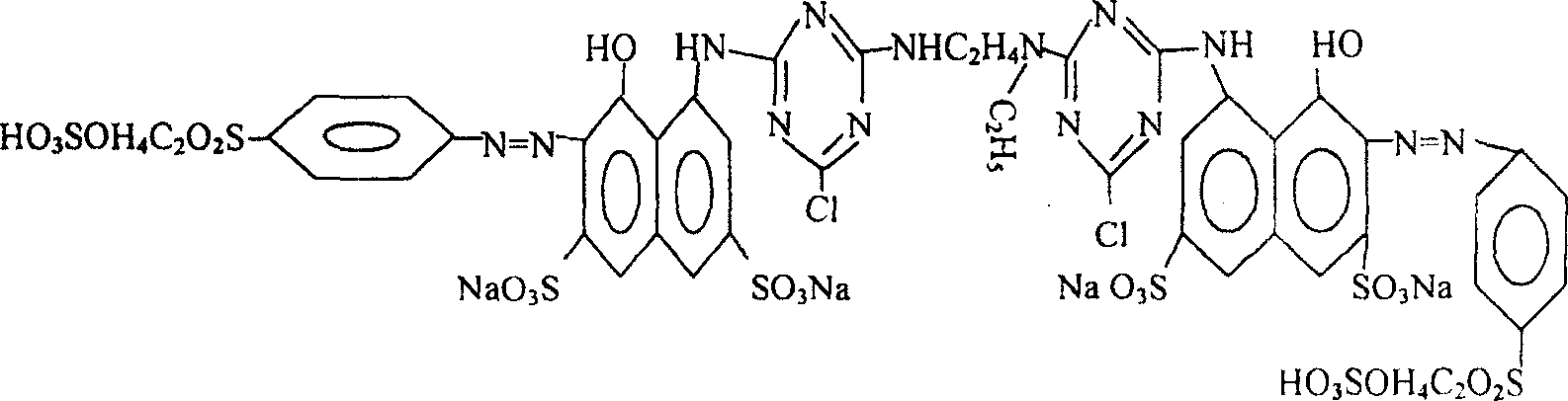

Active red SHE, synthetic method and its composite active red dye

InactiveCN1569966AReduce generationTo achieve the purpose of clean productionMonoazo dyesEthylenediamineSulfate

Disclosed is active red SHE monomer which is prepared through coupling (beta-sulfate ethyl sulfone) phenylamine with hydrochloric acid, carrying out diazonium at 0-5 deg. C, condensing with cyanuric chloride, then carrying out second condensation with N-ethyl ethylenediamine.

Owner:无锡润新染料有限公司

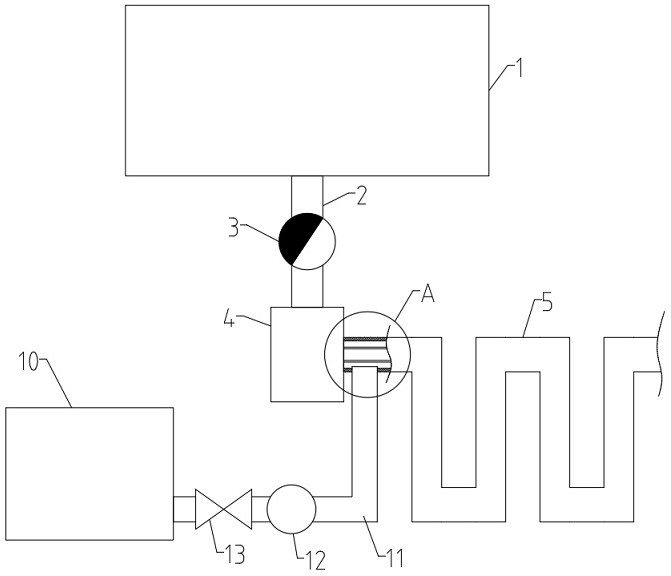

Fabric dyeing method and apparatus therefor

InactiveCN101200860BEasy to operateGuaranteed operabilityDyeing processTextile parts treatmentProcess engineeringIndustrial engineering

The present invention discloses a printing and dyeing method for fabrics, which applies the method of vacuum negative pressure to dye the atomized dye on fabrics by adsorption. The present invention also discloses the printing and dyeing equipment applied by the printing and dyeing method, which comprises a chassis, a power system and live rolls, wherein, a conveyer belt arranged on the live rolls is made of ventilating material or provided with air vents, and the upper and the lower sides of the conveyer belt are respectively provided with a vacuum adsorption system and a plurality of atomizing systems. The present invention utilizes the method of vacuum negative pressure adsorption to dye the atomized dye on fabrics, the technique is simple, the dyeing cost is low, the operability is strong, the dyeing efficiency is high, the dyeing effect is good, the colors of the dyed fabrics are uniform and beautiful, dyes and water resources can be saved, the rinsing process is not needed, so no pollution is generated. The printing and dyeing equipment disclosed by the present invention has the advantages of simple and reasonable structure and strong operability and can ensure the printing and dyeing effect of fabrics.

Owner:浙江宝通环保印染设备科技有限公司

A method for obtaining the length of the blank section that the warp and weft yarns of the fabric cover each other and its application

ActiveCN108265373BReduce dosagePrecise regional positioningDyeing processSwivel-woven fabricsTextile printerEconomic benefits

The invention provides a method for acquiring and using lengths of warp and weft mutually-covered blank sections of fabric and solves the problem that a digital printing technology cannot be applied to traditional yarn-dyed weaving all the time due to technology restrict. When the technology is applied to the digital printing technology of yarn dyed fabric, yarn is not required to be dyed in advance, and printing is performed on a loom during weaving; the covered sections are invisible on the surface of the fabric, and printing can be omitted. According to the technology, accurate area location of blank warp can be provided, the minimum printing area demand can be provided, so that the use amount of ink is reduced to be minimum, and economic benefit of an enterprise is increased; consumption of drying thermal energy is reduced while the use amount of ink is reduced. The same technology can be applied to knitted yarn-dyed fabric, and calculation is performed according to conditions of emerging segmental arc length and dry section length of a knitted fabric coil.

Owner:ZHONGYUAN ENGINEERING COLLEGE

A device for recycling condensed water of a textile printing and dyeing dryer and its application method

ActiveCN108866886BEasy dischargeRealize the alarmLiquid/gas/vapor removalTextile treatment machine arrangementsTextile printerWater storage tank

Owner:嘉兴鑫华纱线印染有限公司

A kind of normal temperature and pressure dyeable negative ion polyester fiber and its preparation method and application

ActiveCN101545154BIncrease elasticityHigh emissivityMelt spinning methodsMonocomponent polyesters artificial filamentPolyesterFiber

The invention relates to an anion polyester fiber capable of being dyed at normal temperature and normal pressure, a preparation method and application thereof. The fiber comprises the components of a polyester anion master batch and a polyester chip of which the molecular weight is between 20,000 and 30,000 and which can be dyed at normal temperature andnormal pressure, and the weight ratio is 1-10:90-99. The preparation method comprises the following steps that: (1) the polyester chip is dried and commixed; (2) the polyester anion master batch and the polyester chip are vacuumized; (3) the polyester anion master batch and the polyester chip are mixed, put in an extruder, heated, melted and compressed into a fused mass, and the fused mass is extruded by a rotary screw rod; and (4) matters obtained from the step (3) are sent to a distributing pipe, a static mixer and a metering pump respectively, and pressed in a spinneret, so that a melting current is formed, and the melting current is coated and spun. The fiber can be used for preparing fabrics of wall textile for decoration, working clothes and clothing. The fiber has the characteristics of easy dying, bright color, uniform fiber, high transmission rate of anions, good hand feeling and uniform luster.

Owner:ZHEJIANG JINXIA NEW MATERIAL TECH CO LTD

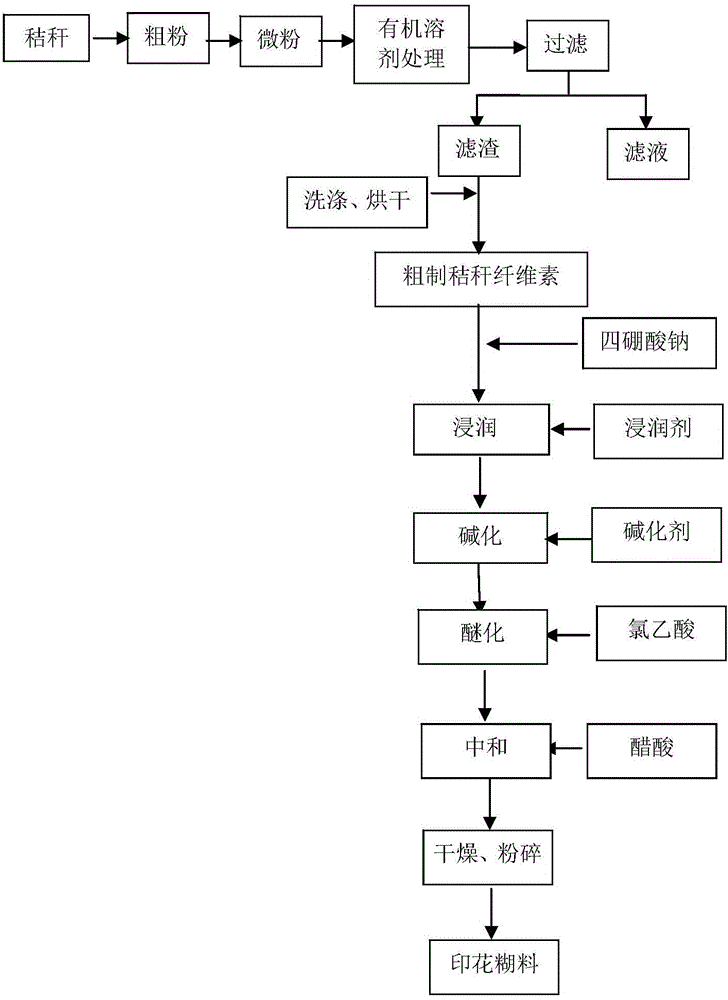

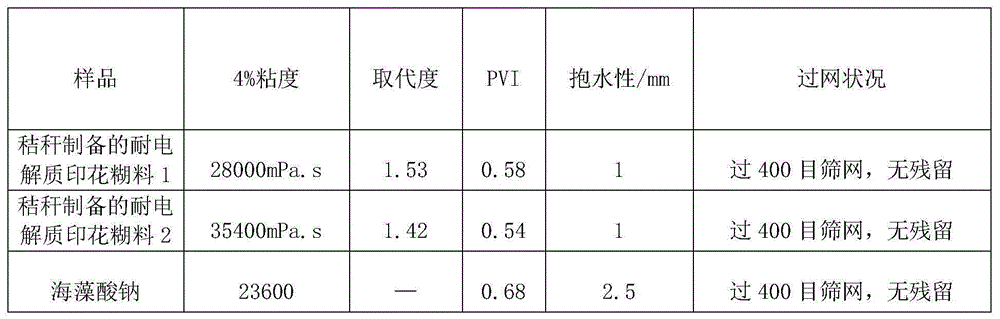

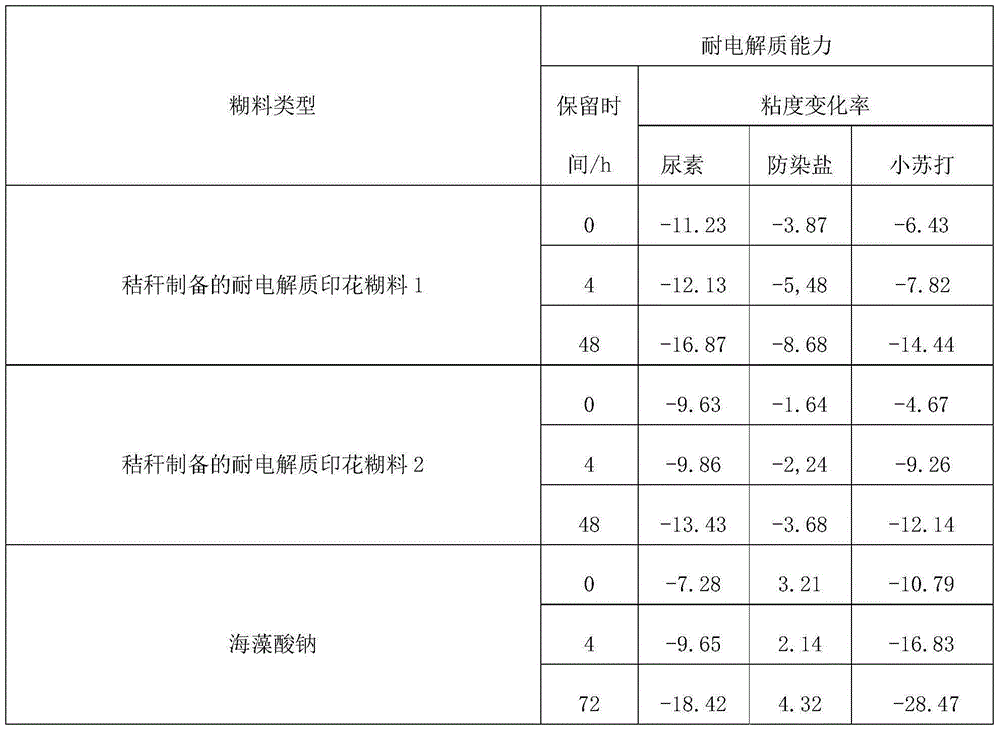

Method for preparing electrolyte-resistant printing paste with straw as raw material

The invention relates to the technical field of preparation of a gum used in a textile printing process, and particularly relates to a method for preparing an electrolyte-resistant printing gum by using straw as a raw material. A process method of pretreatment the straw by using an organic solvent, infiltration, alkalization, etherification reaction, neutralization and posttreatment is adopted, and a reaction raw material and a reaction reagent are fully mixed uniformly by high-speed stirring, so that the consumption of the organic solvent is effectively reduced, thus the production cost is lower, and the printing and dyeing cost can be effectively reduced; the reaction raw material and the reaction reagent are fully mixed uniformly by high-speed stirring, and the reaction reagent and the raw material are in full contact, thus the reaction efficiency is effectively increased, and the product substitution degree is higher; meanwhile, through adding sodium tetraborate, the homogeneity of etherification is improved, and the electrolyte-resistant performance of the printing gum is effectively improved; most of lignin and hemicellulose in the crop straw are removed by adopting an organic solvent treatment technology, thus the etherification reaction efficiency of cellulose molecules is increased, a product with high substitution degree is obtained, and the problem that a printed textile is hard in hand feel is solved.

Owner:甘肃高歌伟业新材料科技有限公司

Active yellow SDE and its synthetic method

Disclosed is a active yellow SDE monomer, which is prepared by subjecting 3,6,8-trisulfonic acid -2-naphthylamine dried substance to beating homogeneously at the presence of ice, diazotizing with hydrochloric acid, coupling the diazonium substance with metaamino-benzene amine acetylated hydrochlorate, condensing with cyanuric chloride, charging (beta-sulfate ethyl sulfone) phenylamine dried article for second condensation, and direct drying by spraying.

Owner:无锡润新染料有限公司

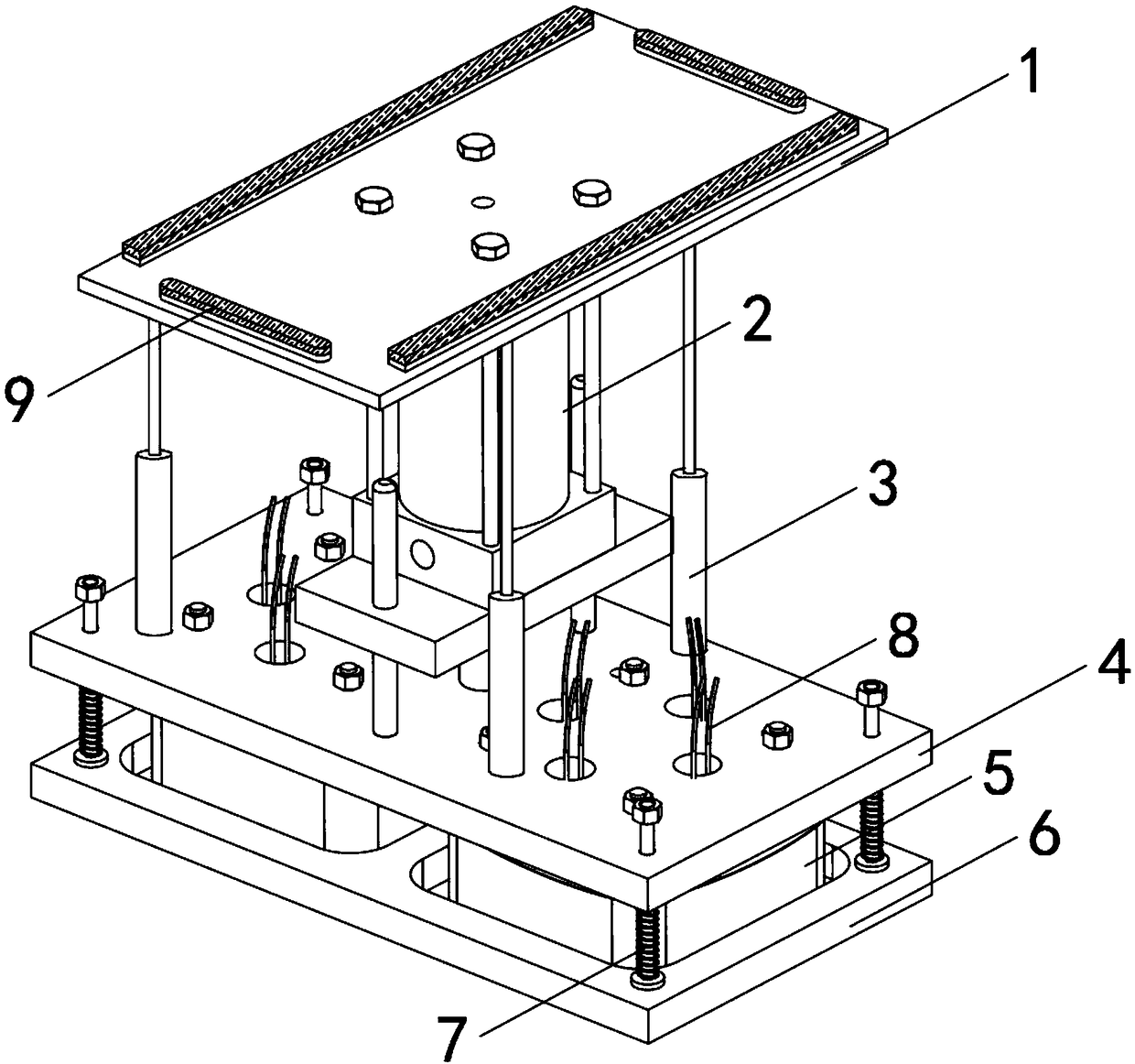

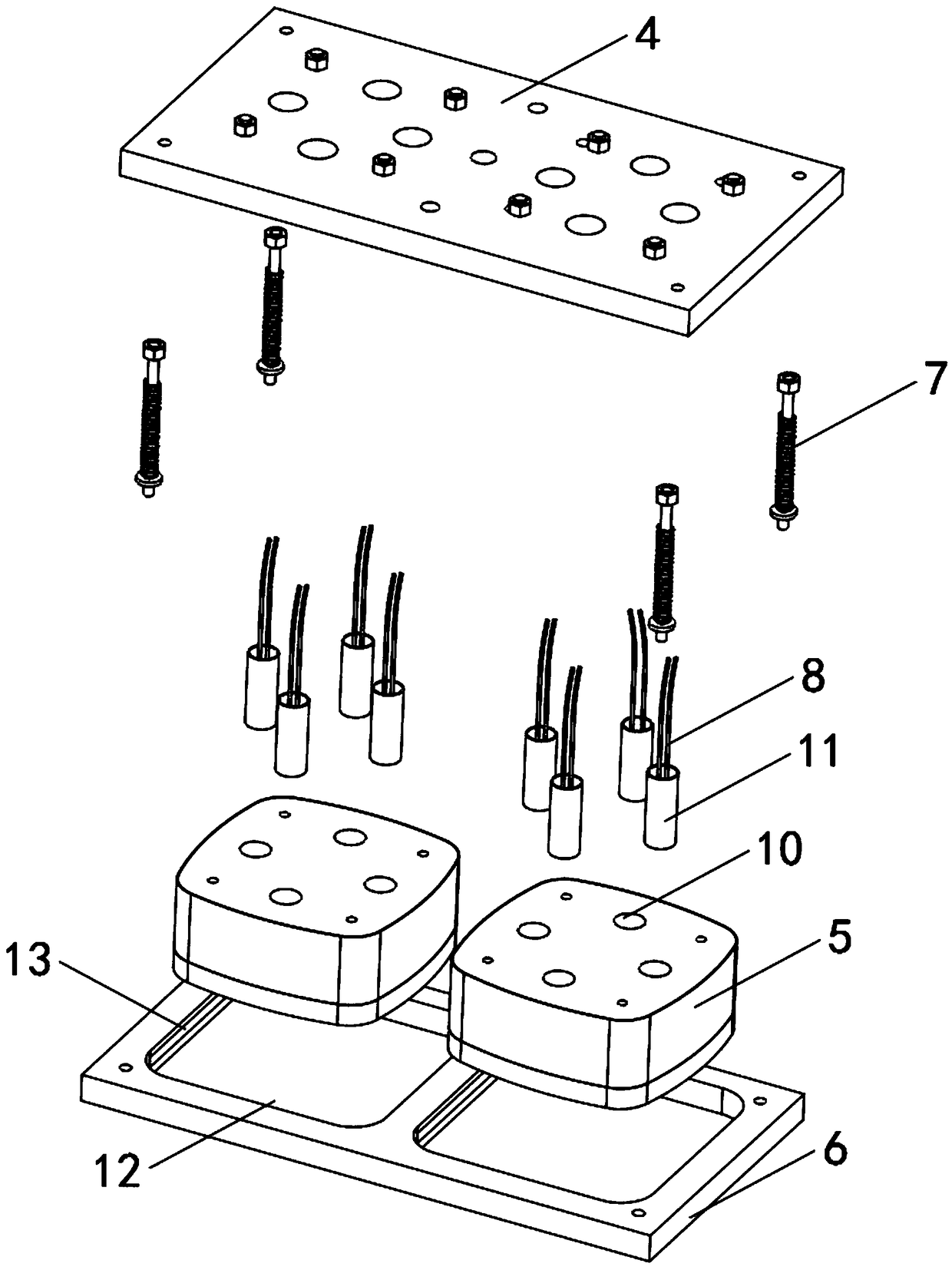

Fabric dyeing and printing device

InactiveCN101245537BImprove printing and dyeing effectUniform and beautiful colorTextile treatment by spraying/projectingTextile treatment carriersEngineeringControllability

The invention relates to a fabric printing and dyeing device which includes a machine frame, a power system and a transmission system. The device is characterized in that: a fabric supporting piece is arranged on the machine frame or the transmission system. The fabric supporting piece is made by ventilating materials or is provided with a ventilating hole. The upward side and the downward side of the fabric supporting piece are respectively provided with a vacuum absorption cavity and an atomizing system. The vacuum absorption cavity is connected with a vacuum pipeline. A vacuum pump is arranged on the vacuum pipeline. The atomizing system includes an atomizer and a dye channel. A pattern templet is fixedly on the machine frame below the outlet of the dye channel. The atomizing system moves opposite to the pattern templet under the drive of the power system and the transmission system. The device of the invention utilizes vacuum subpressure absorption to print and dye atomized dyes on the fabric and has the advantages of simple and reasonable structure, low dyeing cost, high controllability on operation and high dyeing efficiency, being beneficial to improving the dyeing effect of the fabric. The color of the fabric after printing and dyeing is uniform and beautiful.

Owner:浙江宝通环保印染设备科技有限公司

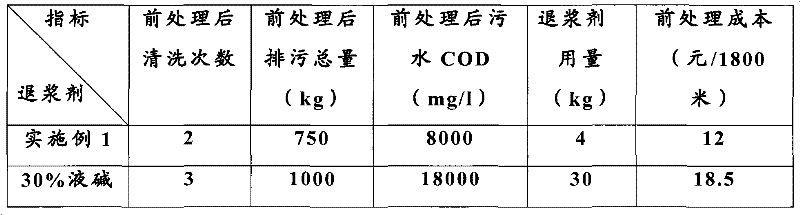

Desizing agent for production process in pretreatment of printing and dyeing and preparation method thereof

InactiveCN101831793BComplete desizingReduce usageDry-cleaning apparatus for textilesPhosphateWastewater

The invention relates to a desizing agent for a production process in pretreatment of printing and dyeing and a preparation method thereof. The desizing agent comprises the following components by weight percent: 25% to 35% of alkali metal hydroxide, 5% to 10% of alkali metal phosphate, 5% to 10% of alkali metal silicate, 2% to 6% of alkaline-resistant penetrant and the balance of water. The preparation method of the desizing agent comprises the steps of: (1) adding the alkali metal phosphate and the alkali metal silicate to the water according to a formula; stirring at the temperature of 35 DEG C to 45 DEG C; then adding the alkali metal hydroxide; keeping the temperature and stirring for 1.5 to 2.5 hours; (2) adding the alkaline-resistant penetrant to the solution obtained in the step (1); stirring for 1.5 to 2.5 hours at the temperature of 60 DEG C to 70 DEG C; and cooling to prepare the desizing agent. The desizing agent has the advantages of complete desizing, small utilization quantity (which is only arounf 15% of the utilization quantity of traditional liquid caustic soda), convenient cleaning, low wastewater yield and small pollution, and reduces the printing and dyeing cost. The preparation method has the advantages of simple preparation technology, easy acquirement of raw material and low production cost.

Owner:WUJIANG HENGMAO ENVIRONMENTAL PROTECTION TECH

Calculation method of visible segment length of fabric warp and weft yarns towards the surface

ActiveCN108803496BReduce dosageReduce utilityProgramme controlComputer controlTextile printerEngineering

Owner:ZHONGYUAN ENGINEERING COLLEGE

Active red SHE, synthetic method and its composite active red dye

InactiveCN1321158CReduce generationTo achieve the purpose of clean productionMonoazo dyesEthylenediamineSulfate

Owner:无锡润新染料有限公司

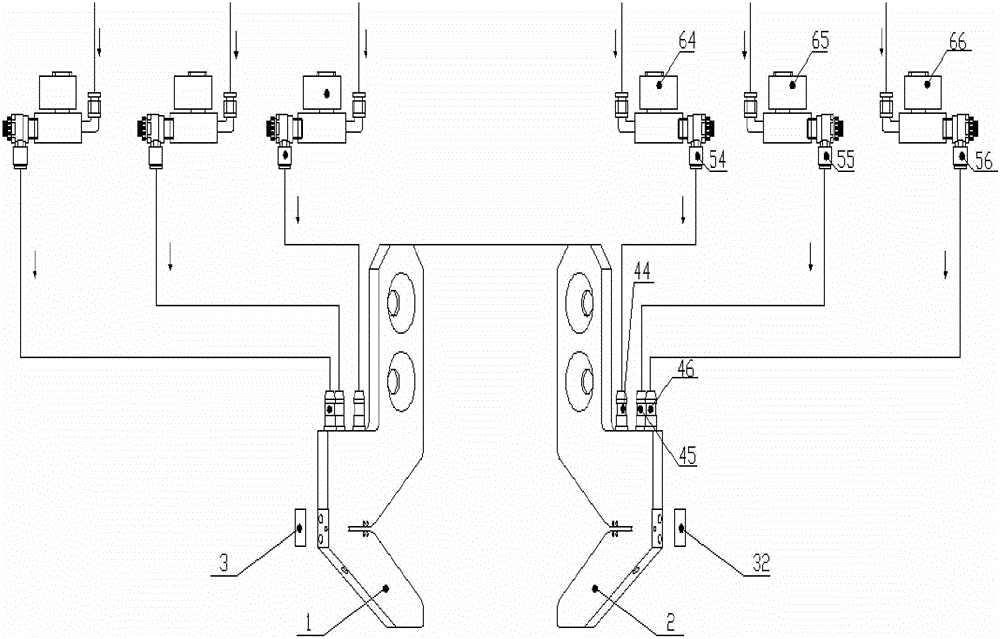

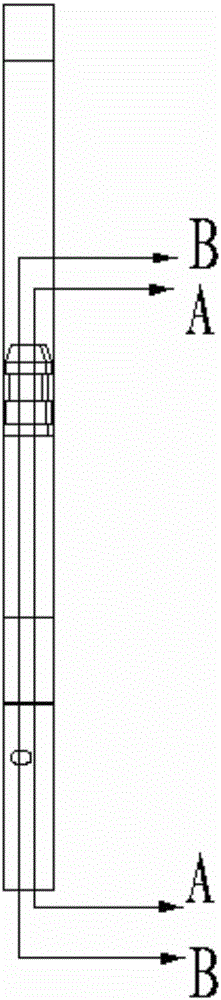

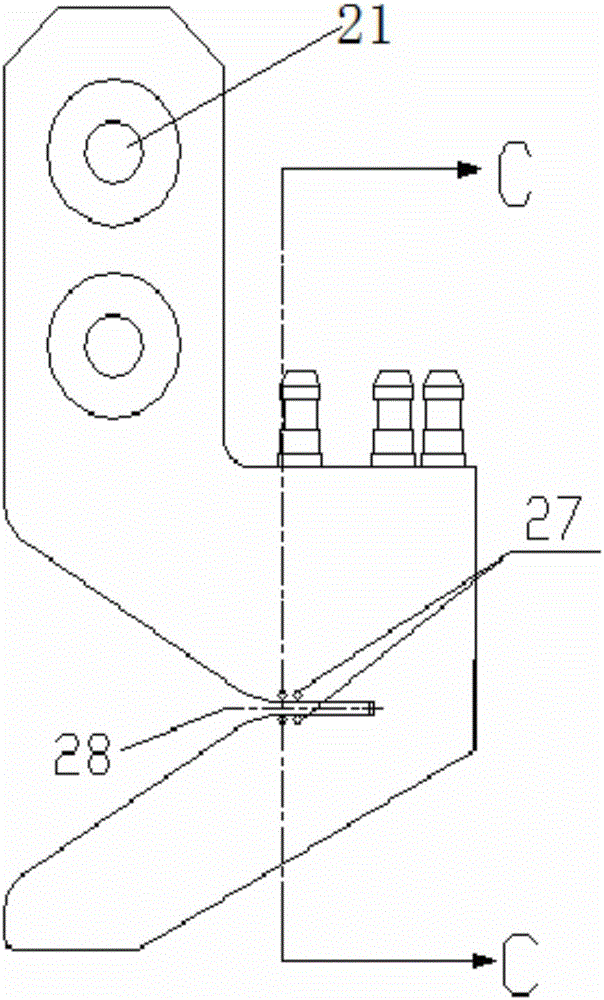

Pneumatic tuck-in device for loom

ActiveCN104988644BSolve the problem of fine adjustment of flight attitudeCompact structureLoomsYarnAgricultural engineering

The invention discloses a pneumatic fold selvage device used for a weaving machine. The device comprises a left folding block and a right folding block. The left folding block is installed on the left side of a cloth, and a right folding block is installed on the right side of the cloth. The upper parts of the left folding block and the right folding block are provided with installing holes. The middle parts of the left folding block and the right folding block are provided with holding holes. The holding holes are connected with a first high-pressure air channel. The outer side of the holding hole is provided with a first folding hole and a second folding hole in sequence. The first folding hole is connected with a second high-pressure air channel. The second folding hole is connected with a third high-pressure air channel. Both of the left folding block and the right folding block are provided with a first technical hole and a second technical hole on the outer sides of the lower parts. The first technical hole is communicated with the second folding hole. The second technical hole is communicated with the first folding hole. The outer end faces of the first technical hole and the second technical hole are sealed. The inner side of the lower part of the folding block is provided with nozzle holes. The nozzle holes are communicated with the second technical hole. The air outlets of the nozzle holes are cooperated with a side of the cloth. The device realizes refined adjustment of flight attitude when yarns are folded, and control adjustability of fold selvage width is improved.

Owner:SHANDONG RIFA TEXTILE MACHINERY

Water-saving and energy-saving processing technology of polyester fabric

ActiveCN109487465BReduce tensionReduce dosageChemical fixing of textilesLiquid/gas/vapor removalPolyesterYarn

The invention discloses a water-saving and energy-saving processing technology of a polyester fabric, which comprises the steps of selecting raw materials of polyester yarns - dyeing yarns - winding yarns - weaving and cutting, and selecting high-density NC polyester yarns as raw materials of the polyester fabric. By means of the technology, the beneficial effects comprises: compared with the traditional method for integrally printing and dyeing the polyester fabric, the method of printing and dyeing is more comprehensive for polyester fabric , the polyester fabric is dyed by the dye solution,the process flow of dyeing the polyester fabric is reduced, the printing and dyeing efficiency is improved, by printing and dyeing a plurality of polyester yarns respectively, the dyeing solution consumption of the mechanism is less, so that the process is more energy-saving, water-saving and cost-saving when dyeing the polyester yarns; and the dye solution used for spraying and dyeing can flow into the packing groove by improving the sleeve groove, and the packing groove guides the dye solution into the dye solution refilling bucket, so that people can conveniently collect and process the dye solution which is not attached and dyed with the polyester yarns filament, thereby ensuring the environmental protection and saving printing and dyeing cost.

Owner:JIANGSU HUAYI GARMENT CO LTD

Method for preventing color difference in digital printing and dyeing ageing

InactiveCN109252394AReduce dependencyReduce printing and dyeing costsDyeing processEngineeringDigital printing

Belonging to the technical field of preventing digital printing and dyeing ageing, the invention relates to a method for preventing color difference in digital printing and dyeing ageing, and aims tosolve the technical problems of strong dependency on various conditions and easy generation of color difference under the circumstance of slight deviation of technological parameters in the printing process of reactive dyes. According to a technical scheme adopted by the invention, the method for preventing color difference in digital printing and dyeing ageing improves the capillary effect of cloth in the process before printing and dyeing. The method provided by the invention can greatly reduce the dependency of reactive dyes on various conditions in the printing process and greatly increasethe success rate of printing and dyeing. The method can achieve the printing and dyeing effects of uniform coloring and bright color, and greatly lowers the printing and dyeing cost.

Owner:佛山市佑隆印染有限公司

Active black K-BR and nonpolluting production technology thereof

The invention discloses an active black K-BR and a nonpolluting production technology thereof, relating to the dye field, and having a general structure as showed in the right formula, wherein Me is equal to Cr plus Co, R is equal to para / meta position / ortho position SO3 Na and COONa. The solubility of a product is more than or equal to 100 g / L, the soaping fastness is 4 level, the rubbing fastness is ranged from 4 level to 5 level, the ironing is ranged from 4 level to 5 level, the quality index is high, and the color yield of the product is high, therefore, the product can be used for deep color printing and dry powder pulp conditioning, and lowers the cost for printing and dyeing.

Owner:无锡润新染料有限公司

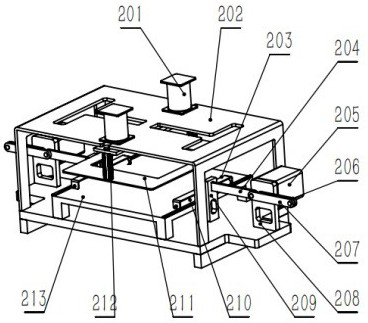

Automatic printing and dyeing equipment

ActiveCN112726060ANo labor requiredSave human effortTextile treatment machine arrangementsRotary pressesProcess engineeringIndustrial engineering

The invention discloses automatic printing and dyeing equipment. The automatic printing and dyeing equipment comprises an input guide device, a dyeing device, a printing device and an overall framework. The input guide device is connected with the dyeing device and is arranged in front of the dyeing device, cloth needing to be dyed is pressed and flattened, rollers in the dyeing device can be used for printing and dyeing the cloth in different colors and coloring the cloth, and the printing device is arranged above the integral framework and is used for directly printing the cloth after dyeing the cloth. The automatic printing and dyeing equipment can be fully automatic, so that manpower and material resources are saved, the printing and dyeing effect is better, and printing and dyeing are more uniform.

Owner:江苏旭宣纺织品有限公司

Establishment method of basic data database of yarn visible segments on warp and weft surface of fashion fabrics

ActiveCN108829733BMeet real needsReduce utilityData processing applicationsDigital data information retrievalTextile printerYarn

Owner:ZHONGYUAN ENGINEERING COLLEGE

A kind of hydrophobic stiffening agent and its preparation method and use method

ActiveCN106758236BWill not affect the waterproof effectPoor hydrophilicityLiquid repellent fibresMonomerRaw material

The invention relates to a hydrophobic stiffening agent and a preparation method and a use method thereof. The hydrophobic stiffening agent is prepared from the following raw materials and components in percentage by weight: 2 to 5% of dispersive stabilizer, 45 to 50% of comonomer, 0.05 to 0.3% of initiator, 0.4 to 1% of adjusting acid, 0.1 to 0.6% of neutralizing alkaline, and 43 to 53% of deionized water.

Owner:苏州联胜化学有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com