A kind of normal temperature and pressure dyeable negative ion polyester fiber and its preparation method and application

A technology of polyester fibers and negative ions, which is applied in the field of dyeable negative ion polyester fibers at normal temperature and pressure and its preparation, can solve the problem that it is difficult to obtain bright and strong hues, achieve less addition, less agglomeration, and easy production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Raw material ratio:

[0039] raw material

source

weight

(share)

Shanghai Compida

30

Normal temperature and pressure dyeable polyester chips

Zhejiang Chemical Fiber Union

Produced by Tuan Co., Ltd. (Jinghua

Card)

70

[0040] Preparation steps:

[0041] This test uses a vacuum oven to create good conditions for ensuring the drying effect of the resin. When selecting drying process parameters, it is necessary to ensure that the mass fraction of dry slice water is not greater than 60ppm

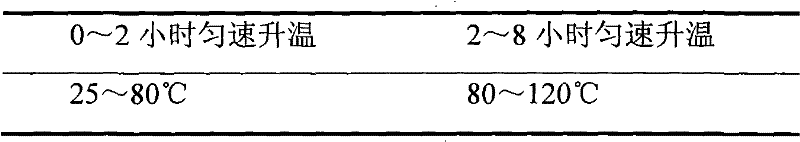

[0042] Chip drying process parameters

[0043]

[0044] The chip is cooled down to 90°C under vacuum condition, while the powder is heated up to 30°C. At this temperature, the anion powder and slices are blended and kneaded.

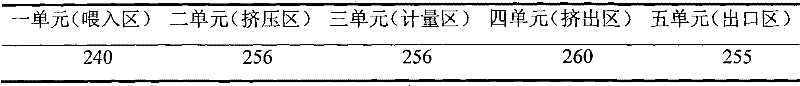

[0045] The SHL~35 twin-screw extruder and static mixer produced by Shanghai Chemical Machinery No. 4 Factory were used, the feed screw was...

Embodiment 2

[0049] Raw material ratio:

[0050] raw material

source

weight

(share)

Negative ion masterbatch

Example 1

2

Normal temperature and pressure dyeable polyester chips

Zhejiang Chemical Fiber United Group Co., Ltd.

Produced by the company (Jinghua brand)

98

[0051] Preparation steps:

[0052] Put 2 parts of negative ion masterbatch and 98 parts of dyeable polyester chips at normal temperature and pressure according to the weight ratio, put them in a vacuum oven, heat up to 80°C, keep warm for 2 hours, and pre-crystallize the chips. Continue to heat up to 100°C, keep warm for 5 hours, turn off the power, and cool naturally, with a moisture content of 0.08%. The spinning equipment is VC406 spinning machine produced by Changshu Textile Machinery Factory. The blended slices enter the screw extruder for heating, melting and compression. The blended melt extruded by the rotating screw enters the meteri...

Embodiment 3

[0055] Raw material ratio:

[0056] raw material

source

weight

(share)

Negative ion masterbatch

Example 1

10

Normal temperature and pressure dyeable polyester chips

Zhejiang Chemical Fiber United Group Co., Ltd.

Produced by the company (Jinghua brand)

90

[0057] Preparation steps:

[0058] According to the weight ratio, put 10 parts of negative ion masterbatch and 90 parts of normal temperature and pressure dyeable polyester chips into a vacuum oven, heat up to 80°C, keep warm for 2 hours, and pre-crystallize the chips. Continue to heat up to 100°C, keep warm for 3 hours, turn off the power, and cool naturally, with a moisture content of 0.08%. The spinning equipment is VC406 spinning machine produced by Changshu Textile Machinery Factory. The blended chips enter the screw extruder to be heated, melted and compressed. The blended melt extruded by the rotating screw enters the metering pump th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com