A device for recycling condensed water of a textile printing and dyeing dryer and its application method

A technology for textile printing and dyeing and drying machine, which is applied in the direction of processing textile material equipment configuration, textile and papermaking, textile material processing, etc., can solve the problems of increasing printing and dyeing cost, low drying machine efficiency, low thermal efficiency, etc. cost, reduce resource consumption and improve drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

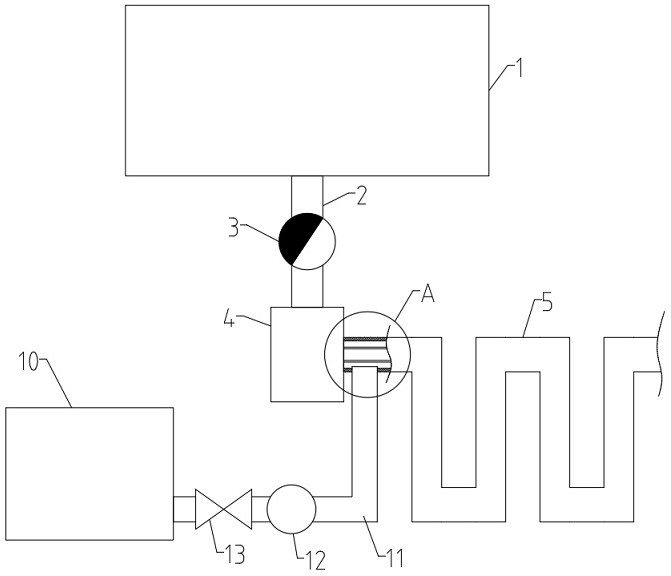

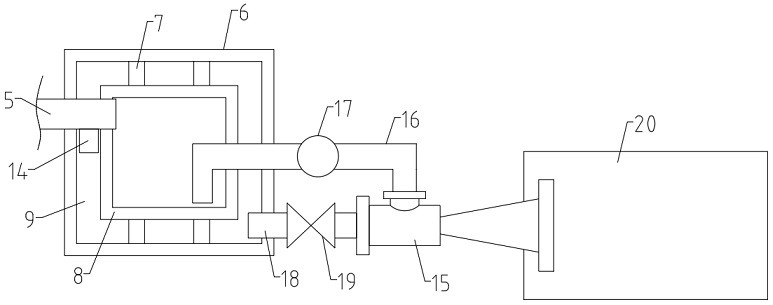

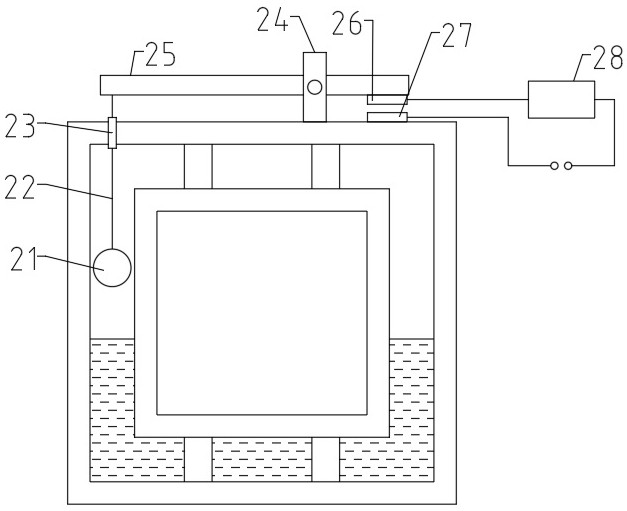

[0032] refer to Figure 1-5 , a textile printing and dyeing dryer condensed water recycling device and its use method, comprising a dryer 1, the inside of the dryer 1 is connected with a condensation inlet pipe 2, and the end of the condensation inlet pipe 2 away from the dryer 1 is connected with a Filter 4, steam trap 3 is installed on the condensate inlet pipe 2, the end of the filter 4 away from the condensate inlet pipe 2 is connected with an inner pipe 51, and the outer walls of both ends of the inner pipe 51 are sealed and connected with a sleeve 5, and the sleeve 5 is connected to the inner pipe 5. An interlayer 52 is formed between the tubes 51. A water storage tank 6 is provided on the side of the sleeve pipe 5 away from the filter 4. A condensation tank 8 is provided inside the storage tank 6. The upper and lower side walls of the condensation tank 8 are fixedly connected with multiple Connecting rod 7, one end of a plurality of connecting rods 7 away from condensat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com