Hydrophobic stiffening agent and preparation method and use method thereof

A stiffening agent and hydrophobic technology, applied in textiles and papermaking, fiber treatment, liquid-repellent fibers, etc., can solve problems affecting the waterproof effect of textiles, achieve the effects of improving printing and dyeing efficiency, avoiding environmental pollution, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

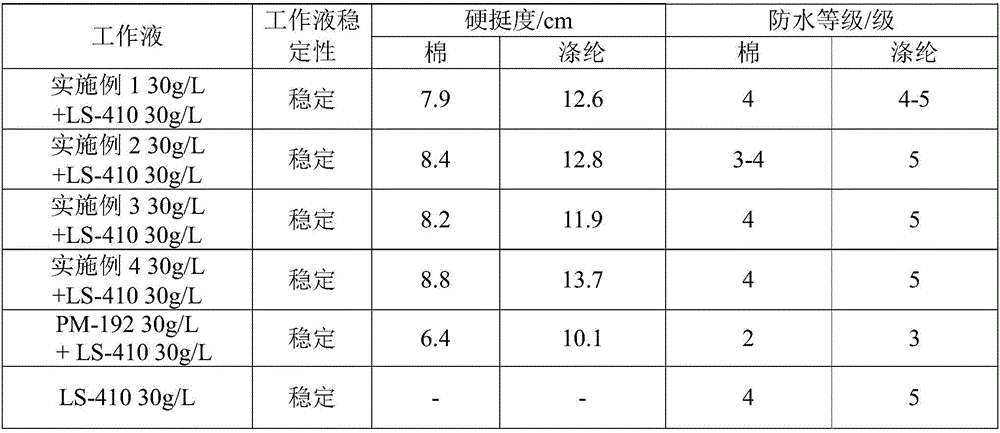

Examples

Embodiment 1

[0061] Step S101) Add 2 parts of dispersion stabilizer and 52.45 parts of deionized water into the reaction vessel; the dispersion stabilizer includes 1 part of polyvinyl alcohol 0599 and 1 part of modified polyvinyl alcohol RS-1717.

[0062] Step S102) heating up to 88° C., stirring at a speed of 180 rpm to 220 rpm for 30 minutes to form a mixed solution.

[0063] Step S103) After the dispersion stabilizer is completely dissolved in deionized water, the temperature is lowered to 70°C.

[0064] Step S104) Add 0.4 parts of the regulating acid to the reaction container, and continuously stir at a speed of 120 rpm to 150 rpm, and adjust the pH value of the mixed solution to 6; The regulating acid is formic acid.

[0065] Step S105) Adding 0.05 parts of an initiator into the reaction vessel; the initiator is ammonium persulfate.

[0066] Step S106) Keep the temperature at 70°C, add 45 parts of comonomer dropwise to the reaction vessel, and drop it in 3.5 hours; the 45 parts of c...

Embodiment 2

[0072] Step S201) Add 3 parts of dispersion stabilizer and 50.1 parts of deionized water into the reaction vessel; the dispersion stabilizer includes 1.5 parts of polyvinyl alcohol 1799 and 1.5 parts of modified polyvinyl alcohol RS-1717.

[0073] Step S202) heating up to 90° C., stirring at a speed of 180 rpm to 220 rpm for 40 minutes to form a mixed solution.

[0074] Step S203) After the dispersion stabilizer is completely dissolved in deionized water, the temperature is lowered to 75°C.

[0075] Step S204) Add 0.6 parts of the adjusting acid to the reaction container, and continuously stir at a speed of 120rpm-150rpm, and adjust the pH value of the mixed solution to 5; The regulating acid is acetic acid.

[0076] Step S205) adding 0.1 part of initiator into the reaction container; the initiator is sodium persulfate.

[0077] Step S206) Keep the temperature at 75°C, add 46 parts of comonomer dropwise to the reaction vessel, and drop it in 4 hours; the 46 parts of comonome...

Embodiment 3

[0083] Step S301) Add 4 parts of dispersion stabilizer and 46.6 parts of deionized water into the reaction vessel; the dispersion stabilizer includes 2 parts of polyvinyl alcohol 1799 and 2 parts of modified polyvinyl alcohol RS-1717.

[0084] Step S302) heating up to 92° C., stirring at a speed of 180 rpm to 220 rpm for 50 minutes to form a mixed solution.

[0085] Step S303) After the dispersion stabilizer is completely dissolved in deionized water, the temperature is lowered to 80°C.

[0086] Step S304) Add 0.8 parts of the regulating acid to the reaction container, and continuously stir at a speed of 120rpm-150rpm, and adjust the pH value of the mixed solution to 4; The regulating acid is citric acid.

[0087] Step S305) adding 0.2 part of initiator into the reaction container; the initiator is potassium persulfate.

[0088] Step S306) Keeping the temperature at 80° C., 48 parts of comonomers were added dropwise to the reaction vessel, and the drops were completed in 4.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com