Preparation method and application of a reactive polyquaternium salt type formaldehyde-free color-fixing crosslinking agent

A quaternary ammonium salt-type, formaldehyde-free color-fixing technology, which is applied in the field of fine polymer material preparation, can solve the problems of poor color fastness and small influence of cellulose fiber fabrics, and improve color fastness and fastness , The effect of simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~12

[0028] The preparation method of reactive polyquaternium salt type formaldehyde-free color-fixing cross-linking agent is:

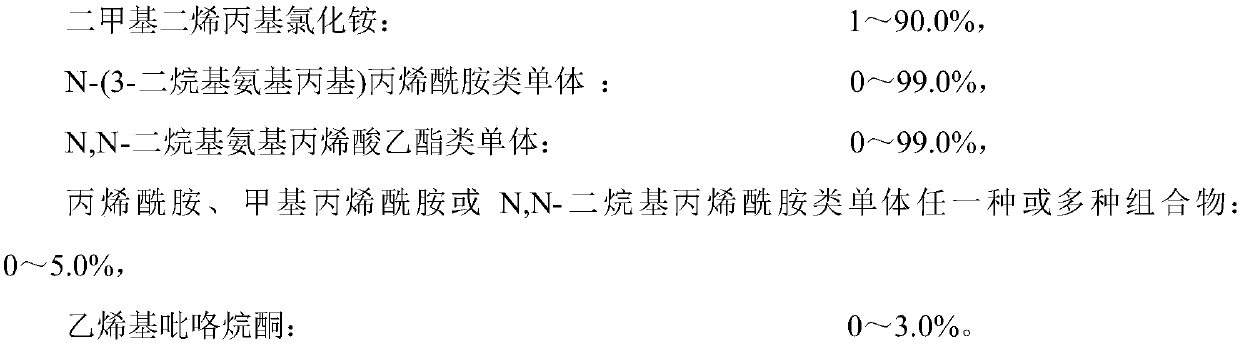

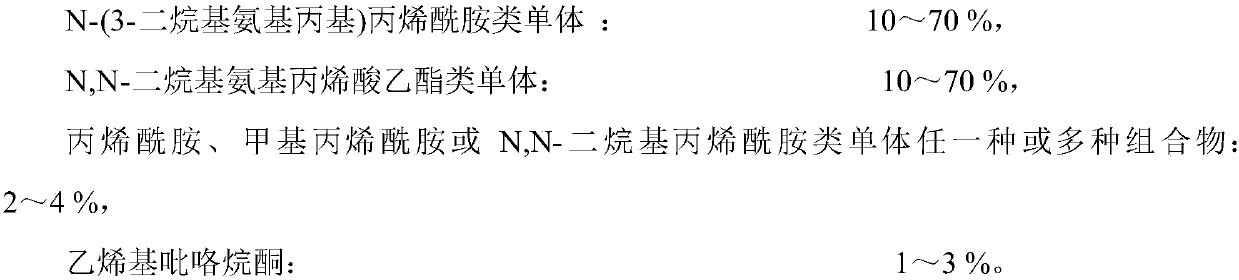

[0029] A. Dimethyl diallyl ammonium chloride, N-(3-dialkylaminopropyl)acrylamide monomer, N,N-dialkylaminoethyl acrylate monomer, acrylamide The monomer, vinylpyrrolidone and deionized water are added into the reaction kettle, and the stirring is started to completely dissolve the added monomer to form a mixed solution. Feed nitrogen into the mixed solution of the reactor to replace the oxygen in the reactor, after being warmed up to the reaction temperature listed in Tables 1 and 2, slowly add the aqueous solution of the initiator dropwise to the mixed solution, and control the dropping time as shown in Table 1 And the dropwise time listed in table 2, after dropwise is completed, carry out constant temperature reaction and make quaternary ammonium salt type cationic polymer after the time shown in table 1 and 2;

[0030] B. After cooling the quaternary ...

Embodiment 13

[0045] Add 90g of dimethyl diallylammonium chloride, 5g of acrylamide, 3g of vinylpyrrolidone and 148g of deionized water into the reactor, start stirring to completely dissolve the added monomers; Oxygen in the reaction kettle is heated up to 90°C; 2g of 10% aqueous potassium persulfate solution with a monomer mass fraction of 0.2% is slowly added dropwise, and the dropping time is controlled for 1.0h. Quaternary ammonium salt type cationic color fixing agent.

[0046] Application process of reactive polyquaternium salt-type formaldehyde-free color-fixing crosslinking agent and quaternary ammonium salt-type cationic color-fixing agent:

[0047] The pure cotton fabric dyed by 4% reactive red 3BSN (Zhejiang Longsheng Co., Ltd.) is fixed: the reactive polyquaternium type formaldehyde-free solid content of 40% to 50% of the solid content obtained in Examples 1 to 12 is Color crosslinking agent and the quaternary ammonium salt type cationic color-fixing agent of embodiment 13 gai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com