Fabric dyeing method and apparatus therefor

A fabric and dye technology, applied in the field of fabric printing and dyeing and its equipment, can solve the problems of high production cost, high labor intensity of workers, low degree of automation, etc., and achieve low printing and dyeing costs, uniform and beautiful colors, and high printing and dyeing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

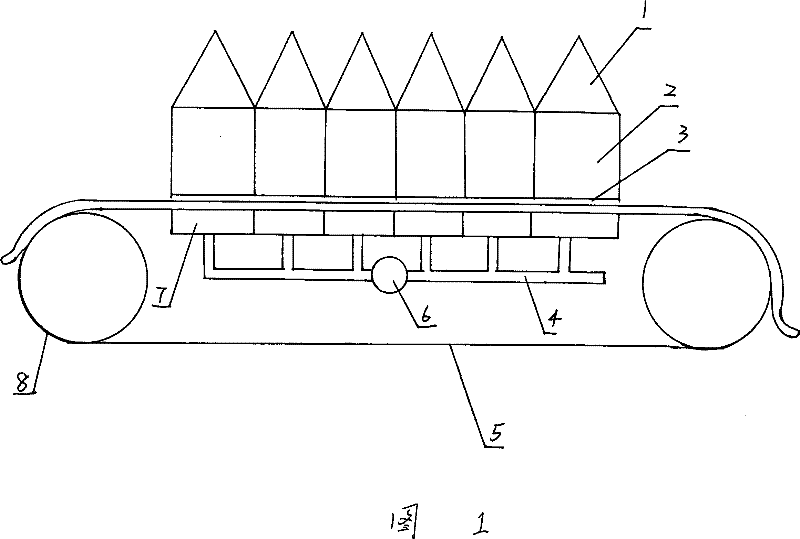

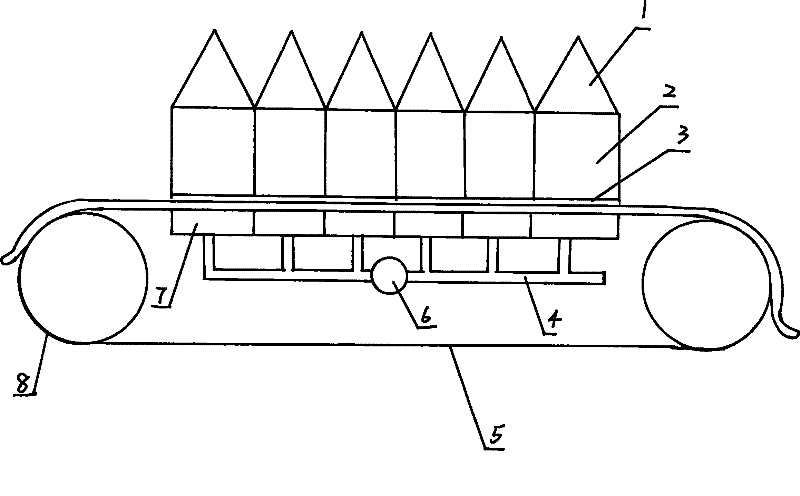

[0017] Example 1. A method for printing and dyeing fabrics, which uses vacuum negative pressure to absorb and dye atomized dyes on the fabric.

Embodiment 2

[0018] Example 2. A method for printing and dyeing fabrics, which uses vacuum negative pressure to absorb and dye atomized dyes on the fabric. The steps are as follows,

[0019] (1) Place the fabric to be printed and dyed on a stationary operating table, which is made of breathable material or has vent holes;

[0020] (2) Place the vacuum negative pressure generating system under the operating table, atomize the dye, and start the vacuum negative pressure generating system. Under the action of negative pressure, the atomized dye is absorbed from the top of the fabric through the pattern plate and the operating table. On the fabric, get it.

Embodiment 3

[0021] Example 3. A method for printing and dyeing fabrics, which uses vacuum negative pressure to absorb and dye atomized dyes on the fabric. The steps are as follows,

[0022] (1) Place the fabric to be printed and dyed on a moving conveyor belt, which is made of breathable material or has vent holes;

[0023] (2) Place the vacuum negative pressure generation system under the conveyor belt, atomize the dye, and start the vacuum negative pressure generation system. Under the action of negative pressure, the atomized dye is absorbed from the top of the fabric through the pattern plate and the conveyor belt. On the fabric, get it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com