Desizing agent for production process in pretreatment of printing and dyeing and preparation method thereof

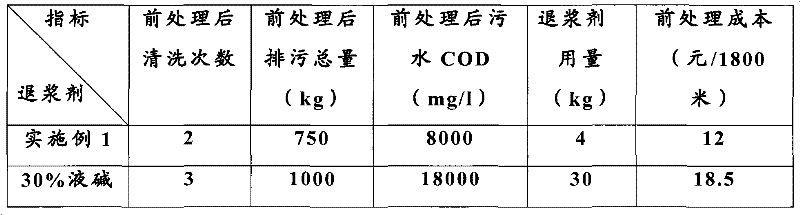

A production process and desizing agent technology, which is applied to dry cleaning fiber products, textiles and papermaking, etc., can solve the problems of large amount of waste water, pollution and difficult treatment, and achieve the effects of low waste water output, easy availability of raw materials and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with specific examples, but the present invention is not limited to the following examples.

[0026] A desizing agent, which is prepared through the following steps:

[0027] (1) Put a 1L beaker in a constant temperature water bath, set the constant temperature water bath at 40°C, add 290g of water, 25g of disodium hydrogen phosphate and 50g of sodium silicate (modulus 1.5 to 3.5) into the beaker, stir, Then gradually add 125g of sodium hydroxide and keep at 40°C for 90min;

[0028] (2) After mixing 3g OEP70, 3gOAS and 4g accelerator Q10 (BASF, Germany) evenly, add it to the solution obtained in step (1), raise the temperature to 65°C, keep stirring for 90min to obtain a light yellow liquid. Cool to obtain the desizing agent.

[0029] The desizing agent obtained by the above method is composed of 25% sodium hydroxide, 5% sodium dihydrogen phosphate, 10% sodium silicate, 2% alkali-resistant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com