Dyeing and finishing process for cotton and T400 interweaved elastic fabric

A fabric and elastic technology, applied in the direction of dyeing, textile and papermaking, dry cleaning fiber products, etc., can solve the problems of poor dyeing percentage and dyeing uniformity of cotton and T400 interwoven fabrics, and achieve good dyeing uniformity and deformation memory. Good properties, good for diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

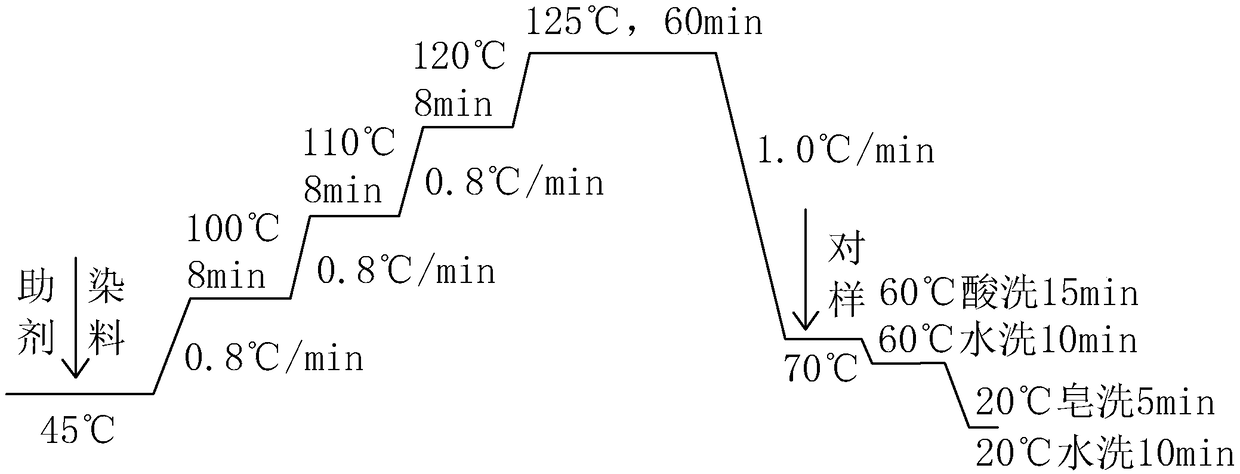

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1: a kind of dyeing and finishing process of cotton and T400 interweaving elastic fabric, it is characterized in that: comprise the following steps:

[0047] (1) Singeing: One burner is positive and the other is reversed, the flame temperature is 900°C, the singeing air pressure is 12mbar, and the vehicle speed is 110m / min;

[0048] (2) The first open-width desizing: transport the singeed fabric to the open-width desizing machine, the temperature of the open-width desizing is 80°C, the time is 30min, and the moving speed of the fabric is 60m / min; Steam at 100°C for 1 hour, then fully wash with hot water and cold water successively, then paddle with 5g / L sulfuric acid solution, then stack for about 1 hour, and then fully wash with water;

[0049] The open-width desizing liquid used is composed of the following components by weight: 4 parts of liquid caustic soda with a concentration of 32%, 3 parts of hydrogen peroxide with a concentration of 35%, 2 parts of f...

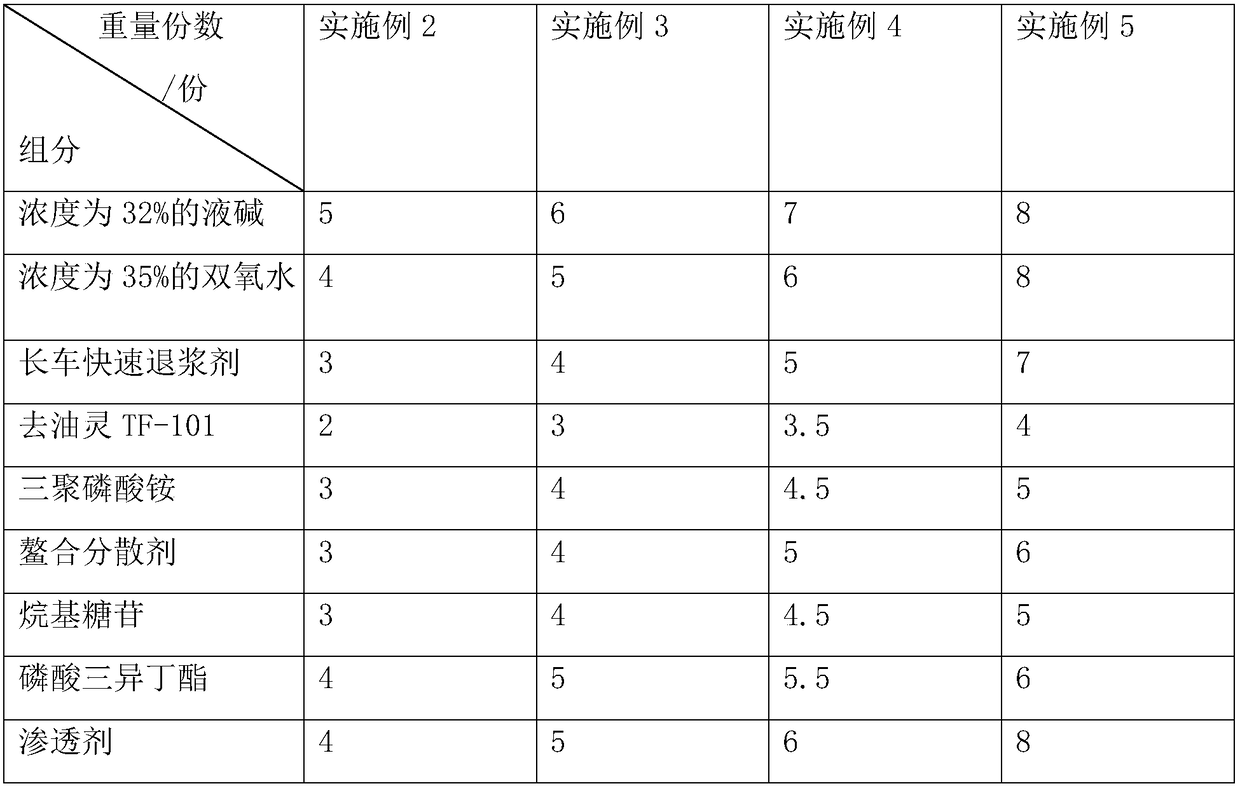

Embodiment 2-5

[0060] Example 2-5: A dyeing and finishing process of cotton and T400 interwoven elastic fabric. The difference from Example 1 is that the components of the open-width treatment solution and the corresponding parts by weight of each component are shown in Table 1.

[0061] The components of the open-width retreat slurry and the corresponding parts by weight of each component in Table 1 embodiment 2-5

[0062]

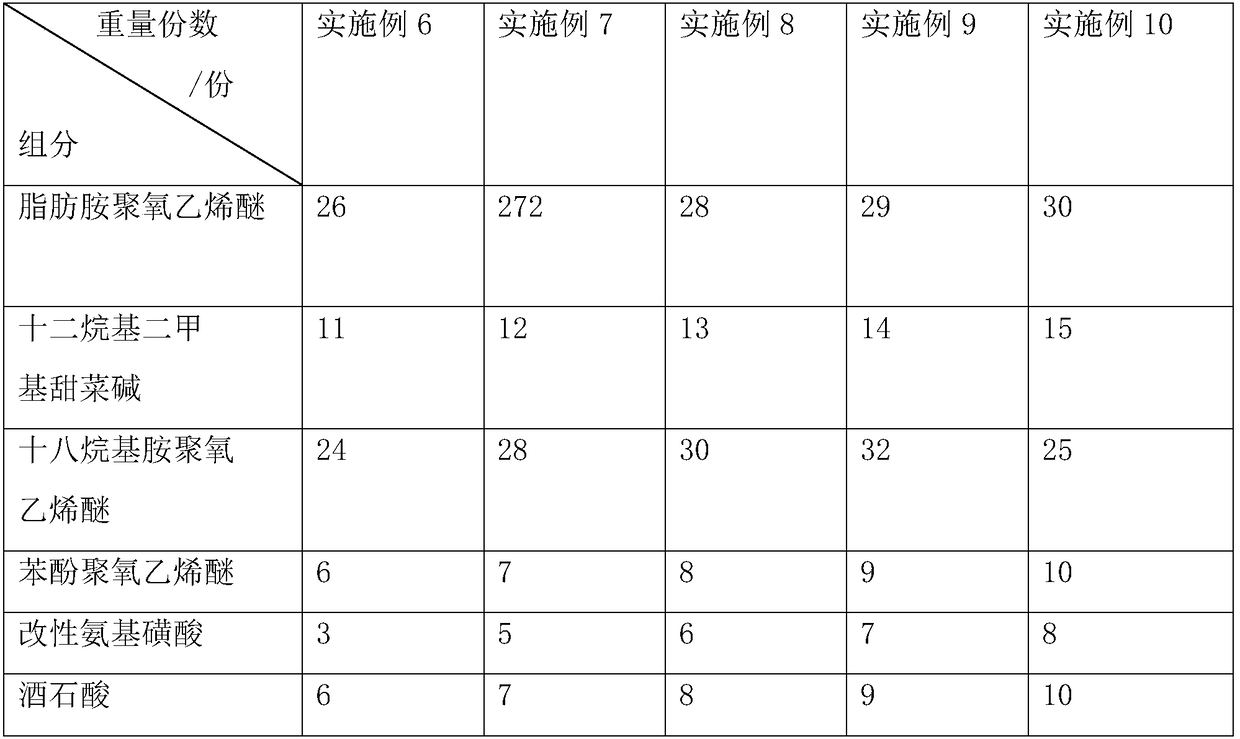

Embodiment 6-10

[0063] Embodiment 6-10: a dyeing and finishing process of cotton and T400 interwoven elastic fabric, the difference from Example 1 is that the components of the microfiber leveling agent and the corresponding parts by weight of each component are shown in Table 2 .

[0064] Components of superfine fiber leveling agent and the corresponding parts by weight of each component in table 2 embodiment 6-10

[0065]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com