Automatic printing and dyeing equipment

A kind of printing and dyeing equipment, automatic technology, applied in the direction of processing textile material equipment configuration, printing, printing machines, etc., can solve the time-consuming and labor-consuming problems of manual printing and dyeing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

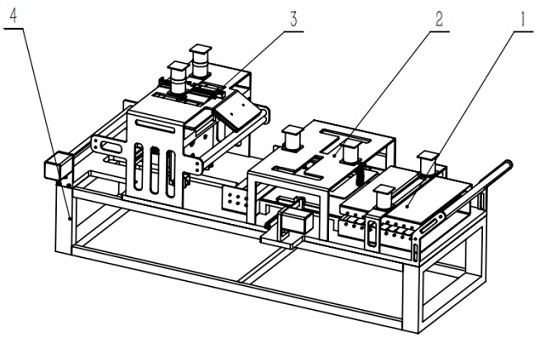

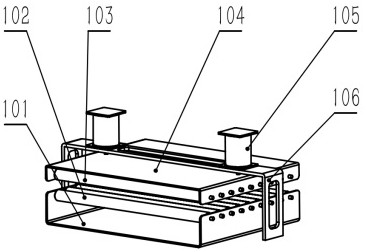

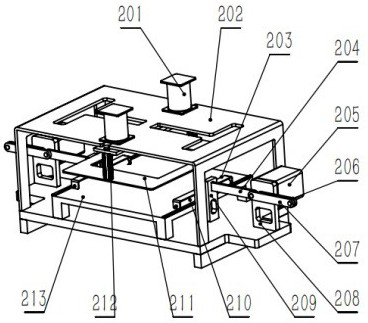

[0027] Embodiment, as shown in Fig. 1, Fig. 2, Fig. 3, Fig. 4 and Figure 5 As shown, an automatic printing and dyeing device includes: an input guide device 1, a dyeing device 2, a printing device 3, an overall framework 4 and a control device;

[0028] The input guiding device 1 is arranged on the front side of the dyeing device 2, and the input guiding device 1 is connected with the dyeing device 2, and the printing device 3 is fixed with the integral frame 4, and the integral frame 4, as an integral part of the complete machine, has the functions of fixing and connecting The functions of each device, the control device is installed on the side of the overall frame 4; the control device is provided with a touchable operation display screen, the inside of the control device is automatically controlled by a single-chip microcomputer, and the user inputs relevant instruction information through the touch operation display screen;

[0029] The input guiding device 1 includes: a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com