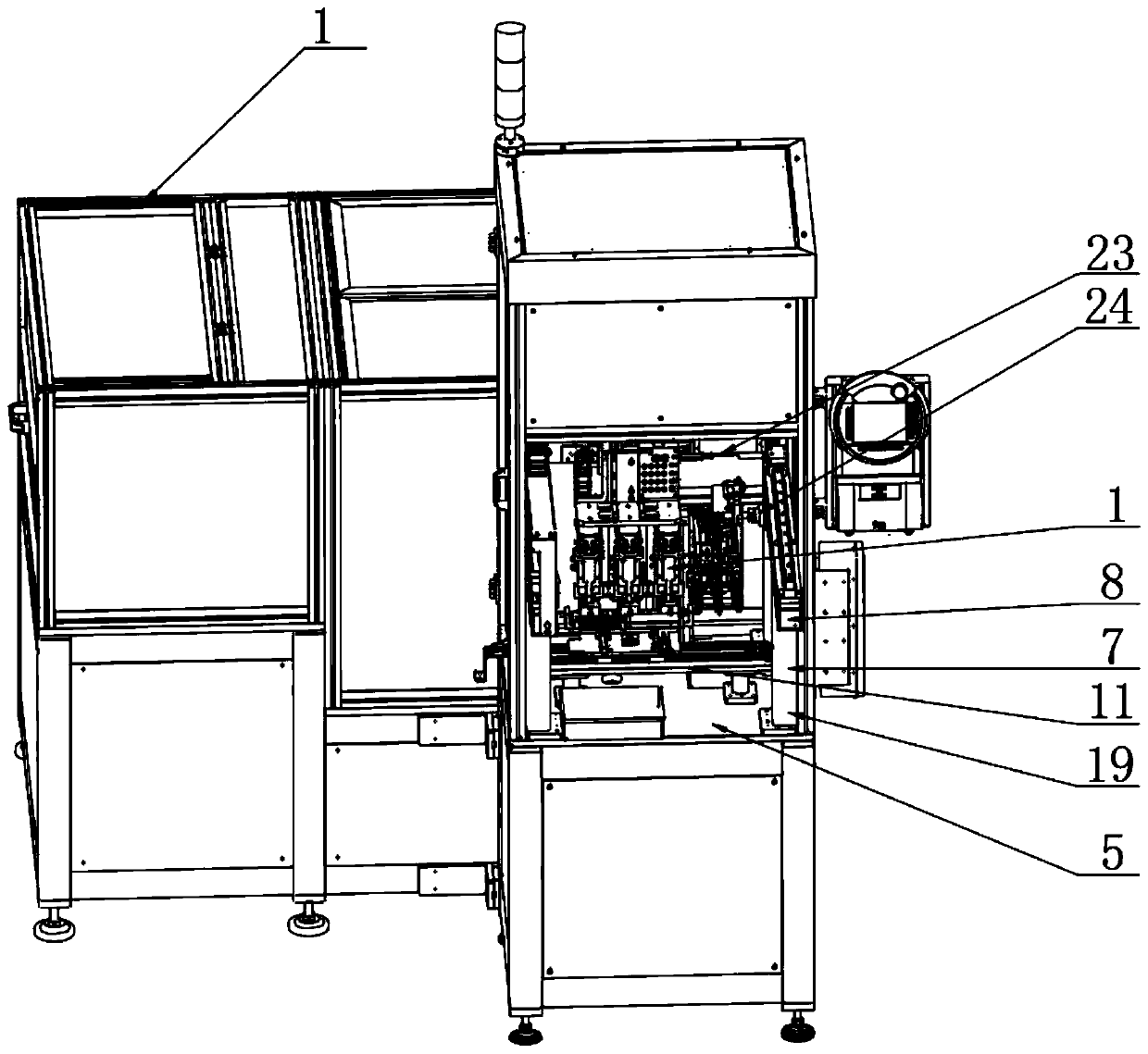

Automatic feeding mechanism

A technology of automatic feeding and blocking mechanism, which is applied in the direction of conveyor objects, conveyor control devices, transportation and packaging, etc. It can solve the problems of inconvenient packaging or production, low efficiency, and automation equipment cannot be fully automated. Achieve the effect of improving production efficiency, high degree of automation, and neat feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

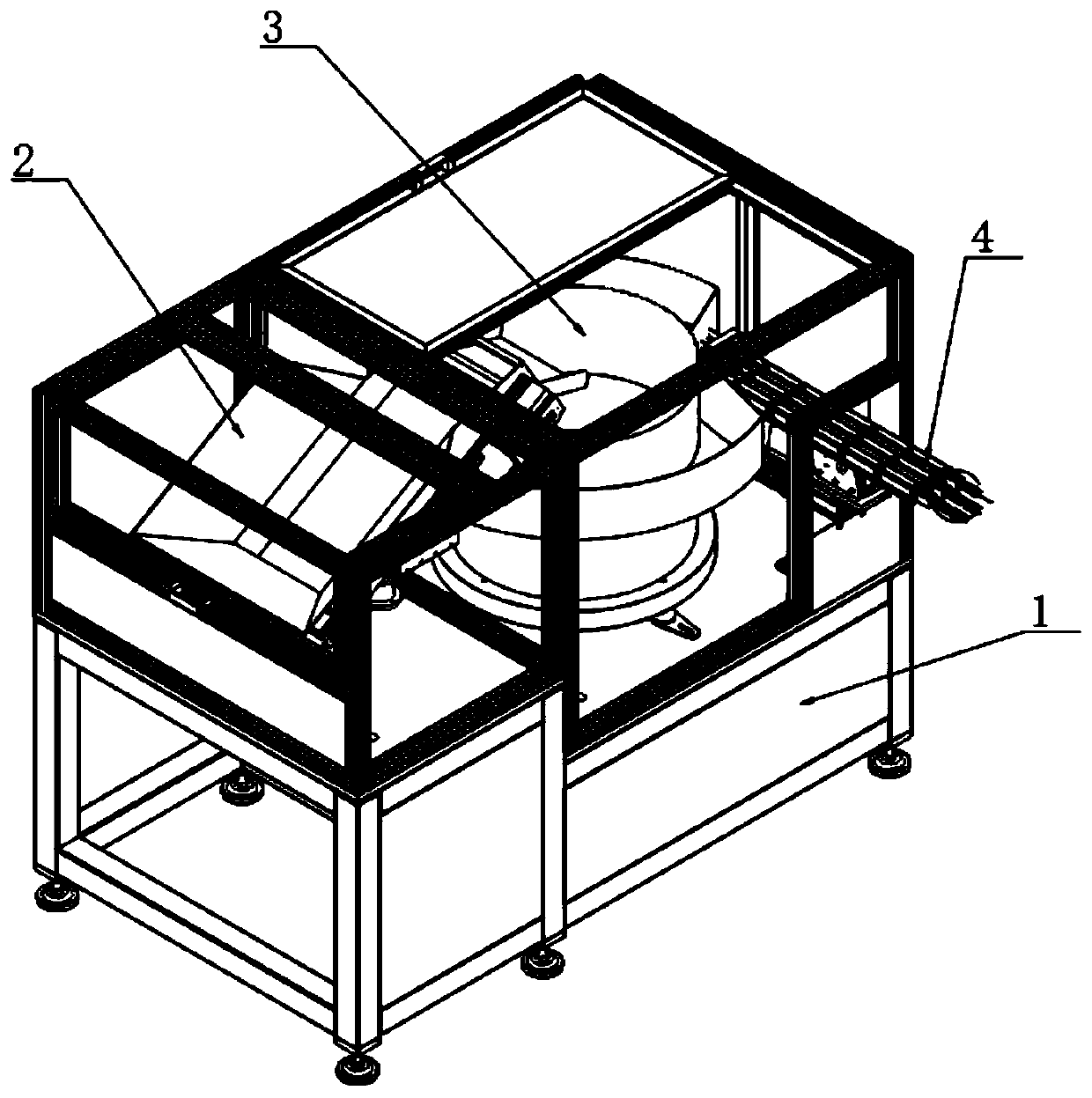

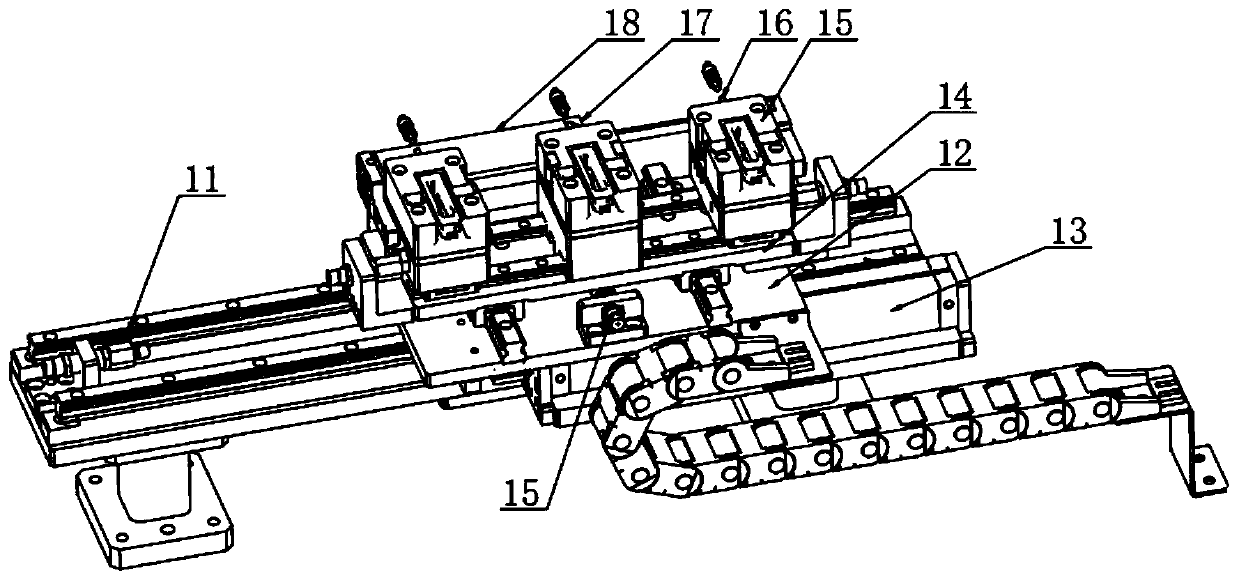

[0029] Embodiment: When in use, the product at the silo 2 enters the vibrating plate 3, and the vibrating plate 3 makes the products be transported through three groups of material channels 4 in an orderly manner (through the way of 1 out of 3), and the product is guided in the material channel 4 down into the tray 15, at this time, the driving cylinder 63 drives the receiving plate 64 to make the stoppers 65 enter the corresponding material channels 4 respectively, so that the product is blocked, and the in-position sensor 16 senses whether the product is on the tray 15. The material cylinder 17 drives the longitudinal sliding plate 14 to move forward, so that the tray 15 is separated from the material channel 4. When the tray 15 is separated from the material channel 4, the camera body 243 takes pictures, judges the front and back of the product and sends a PLC signal, and then the pallet separates the cylinder. 18. Separate the three groups of trays 15. After separation, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com