Preparation of sodium carboxymethyl cellulose

A technology of sodium carboxymethylcellulose and cellulose, which is applied in the field of polymer chemistry, can solve the problems of high substitution degree and high viscosity, difficulties in meeting product quality requirements, and poor distribution of product substituents. Good market prospects, increase the proportion, and reduce the effect of printing and dyeing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

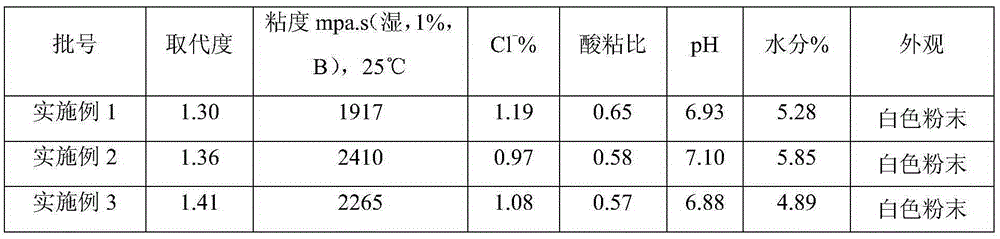

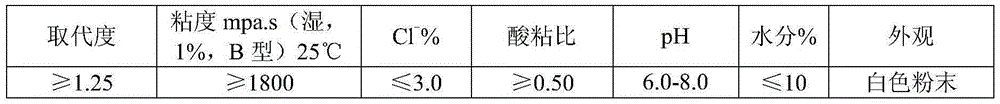

Examples

preparation example Construction

[0024] The invention provides a method for preparing sodium carboxymethyl cellulose, comprising the steps of:

[0025] A. Alkalinization of cellulose: Refined cotton according to the weight ratio: cellulose activator = 1: 10~15 Weigh the refined cotton and put it into a reaction kettle with cellulose activator, vacuumize, stir in an oxygen-free environment for alkali The alkalization temperature is 15°C-20°C, and the alkalization time is 60-120min to obtain alkalized cellulose;

[0026] The cellulose activator, according to the weight ratio of sodium hydroxide: water in the mixed solution of low molecular weight alcohol and water = 4 ~ 7: 3 ~ 6, takes sodium hydroxide and puts it into the mixed solution of low molecular weight alcohol and water. In the reaction kettle, the holding temperature is 70°C-80°C, the holding time is 40-50min, and it is obtained by stirring evenly;

[0027] The weight ratio of the mixed solution of the low molecular weight alcohol and water is: low m...

Embodiment 1

[0042] Mixed alcohol and water mixed solution: Mix 1.85kg of water and 23.15kg of pure isopropanol evenly to obtain 25kg of mixed solution.

[0043] Etherifying agent chloroacetic acid solution: Dissolve 2.75kg of chloroacetic acid in 2.25kg of pure isopropanol and mix well.

[0044] Add 25kg of mixed solvent into the 50L reaction kettle, then add 2.25kg of caustic soda, stir and heat up to 72°C, and keep it warm for 50min. Cool down to 20°C, add 2.5kg of cotton powder, vacuum 5 times, control the temperature at 20°C, and keep warm for 120min. Add 5kg of etherifying agent chloroacetic acid solution, heat up to 78°C in 30 minutes, and keep the reaction for 70 minutes. After the reaction is over, cool to 40°C and discharge. Adjust pH=7.3 with hydrochloric acid, wash 4 times with 65% ethanol, and centrifuge. The sample was dried at 60°C for 24 hours, and then crushed to obtain the product.

Embodiment 2

[0046] Mixed alcohol: Mix 14kg of ethanol and 14kg of isopropanol evenly to obtain 28kg of mixed alcohol.

[0047] Mixed alcohol and water mixed solution: Mix 1.5kg water and 28kg mixed alcohol evenly to obtain 29.5kg mixed solution.

[0048] Etherifying agent chloroacetic acid solution: Dissolve 3.5kg of chloroacetic acid in 1.5kg of pure tert-butanol solvent and mix well.

[0049]Add 29.5kg of mixed alcohol-water mixed solvent into the 50L reaction kettle, then add 3kg of caustic soda, stir and raise the temperature to 75°C, and keep it warm for 45min. Cool down to 20°C, add 2.5kg of cotton powder, vacuum 5 times, control the temperature at 20°C, and keep warm for 70min. Add 5 kg etherifying agent chloroacetic acid solution (concentration 70%), heat up to 76° C. in 25 minutes, and keep the temperature for 90 minutes. After the reaction is finished, cool to 30°C and discharge. Adjust pH=7.0 with hydrochloric acid, wash 4 times with 72% ethanol, and centrifuge. The sample ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com