Ecological nano dye and use method thereof

An ecological and dye technology, applied in dyeing methods, organic dyes, textiles and papermaking, etc., can solve the problems of low color fixing rate, low dyeing rate, poor color fastness, etc. The effect of color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0008] Embodiment 1 Ecological nano dye red B (weight ratio)

[0009] IMPERONK Red K—BC 20 (produced by DyStar)

[0010] Liquid Ecoactive Dye Red BFS 80

[0011] Add IMPERONK Red K-BC into liquid reactive dye red BFS under low-speed stirring to become ecological nano dye red B.

Embodiment 2

[0012] Example 2 Ecological Nano Dye Blue B

[0013] IMPERONK Blue K—BC 20

[0014] Liquid active blue BPS 80

[0015] Add IMPERONK Blue K-BC into liquid reactive dye blue BFS under low-speed stirring to become ecological nano dye (active) blue B

Embodiment 3

[0016] Embodiment 3: the application of ecological nano dyes in exhaust dyeing

[0017] Material: Pure cotton bleached knitted fabric

[0018] Implement Step 1 Fabric Cationic Modification

[0019] Process prescription: (%)

[0020] Environmentally friendly paint darkening agent PNT 5%

[0021] Temperature 80 ℃ keep warm for 30 minutes

[0022] Bath ratio 1:20

[0023] Process flow: cationic modification→washing

[0024] 2. Dyeing with ecological nano-dye

[0025] Process prescription: (%)

[0026] Eco Nano Dye Red B 2

[0027] Yuanming powder (g / L) 25

[0028] Soda ash (g / L) 15

[0029] Bath ratio 1:20

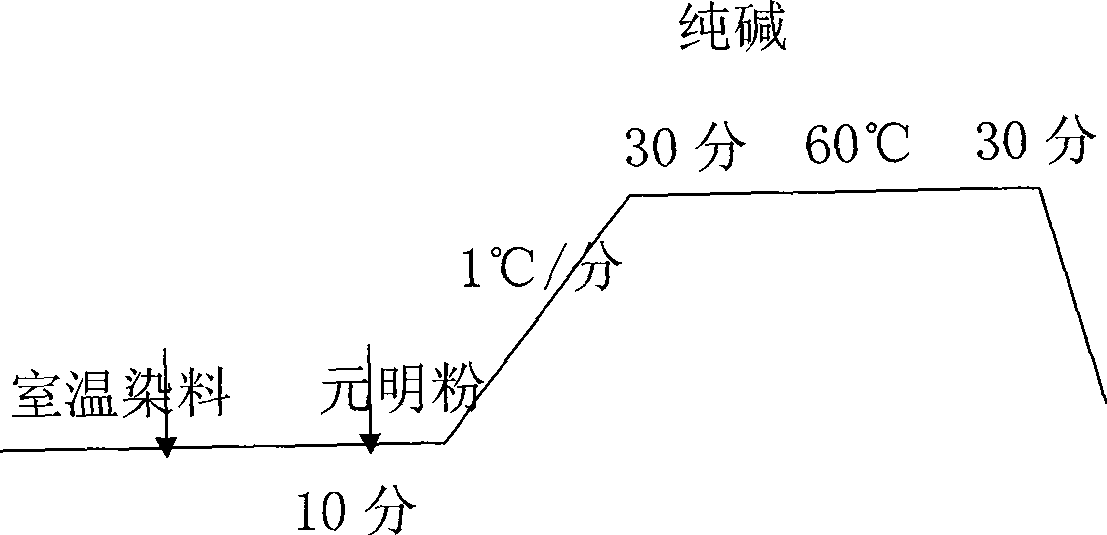

[0030] Process curve: the attached figure is the process curve

[0031] 3. Drying and shaping

[0032] Wet rubbing fastness improver PG(g / L) 40

[0033] Rolling wet rubbing fastness improver PW (40g / L) before the sizing machine

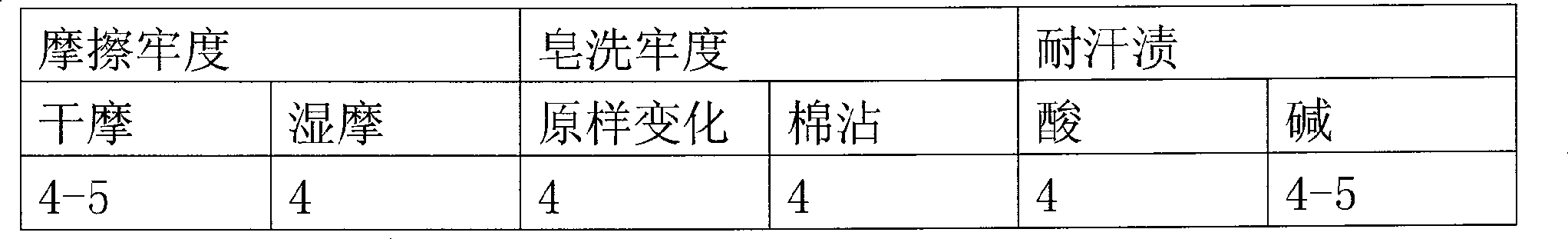

[0034] 4. Color fastness of finished products dyed with ecological nano dyes

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com