Printing and dyeing textile equipment for producing textile fabric and production method thereof

A technology for textile printing and dyeing and textile cloth is applied in the field of textile printing and dyeing equipment for producing textile cloth, which can solve the problems of long textile cloth length, increase production cost, and increase labor intensity of workers, so as to reduce labor intensity, avoid waste, and save printing and dyeing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

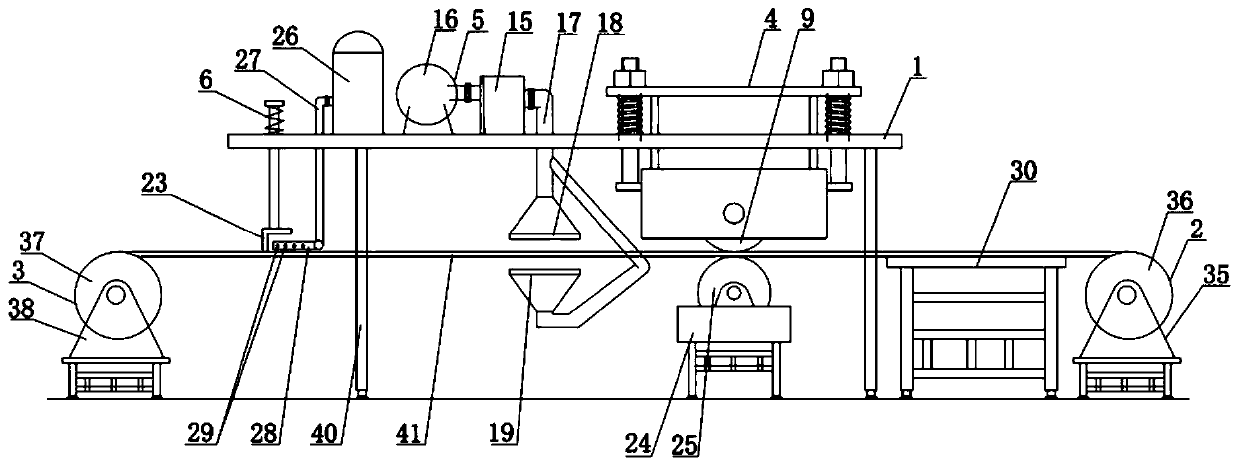

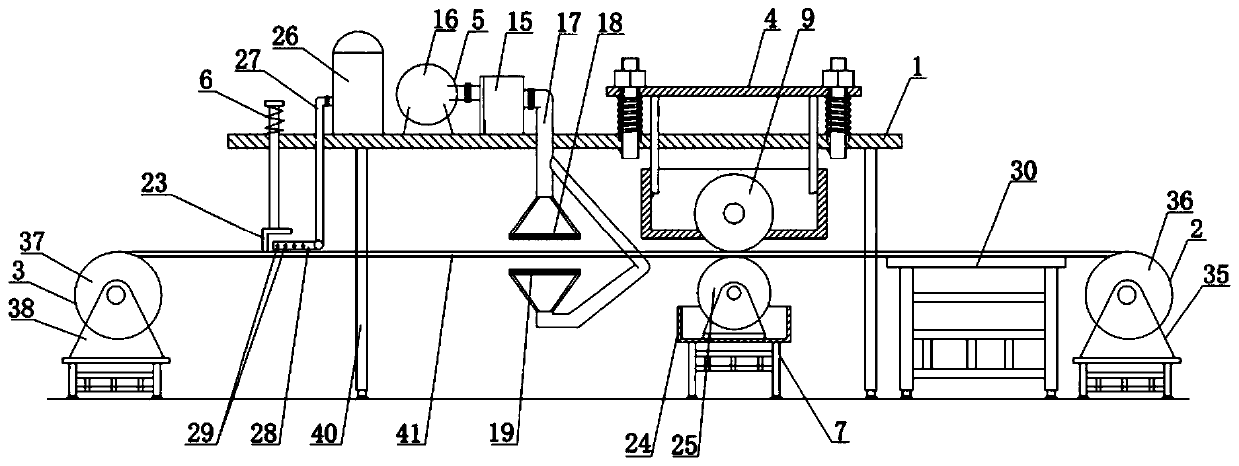

[0037] Embodiment one: if Figure 1-7 As shown, a textile printing and dyeing equipment for producing woven fabrics, which includes a workbench 1, a winding device 2 and an unwinding device 3 respectively arranged on the left and right sides of the workbench 1, and on the workbench 1 and sequentially arranged from right to left An upper printing and dyeing device 4, a textile fabric drying device 5 and a granular pigment scraping device 6, and a lower printing and dyeing device 7 located directly below the upper printing and dyeing device 4 is arranged under the workbench 1; the upper printing and dyeing device 4 includes an upper printing and dyeing box 8 And the upper printing and dyeing roller 9, the upper printing and dyeing box 8 is arranged under the workbench 1, the upper printing and dyeing roller 9 is longitudinally arranged in the upper printing and dyeing box 8, and the two ends of the upper printing and dyeing roller 9 are respectively rotatably mounted on the upper...

Embodiment 2

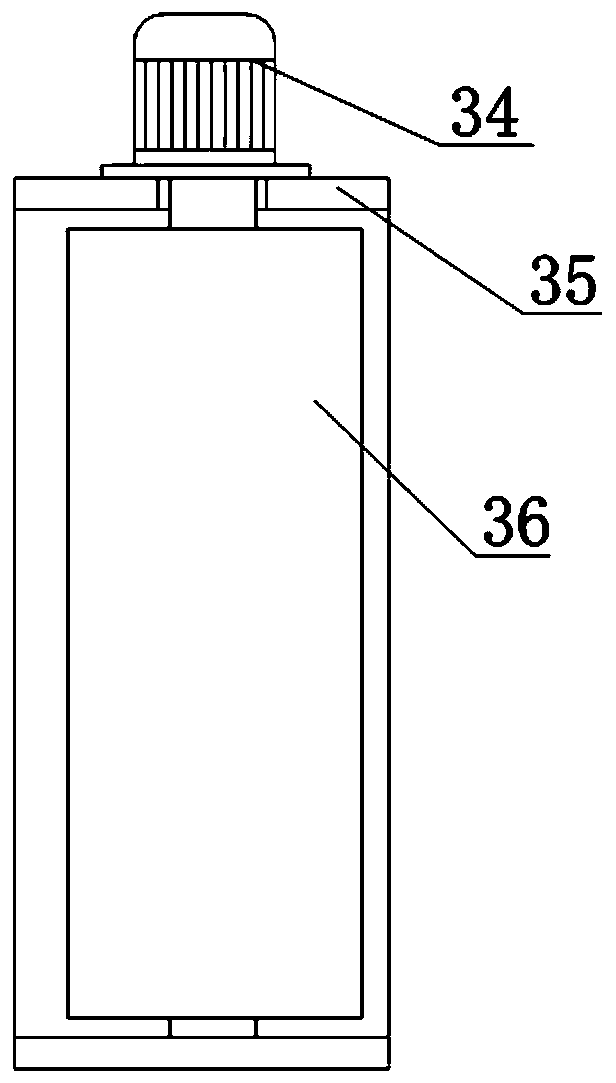

[0049] Embodiment two: if Figure 8As shown, a kind of textile printing and dyeing equipment for producing woven fabrics, it also includes a controller 39, the controller 40 is electrically connected with the motor 34, the induced draft fan 16 and the air compressor 26, and the controller 39 is arranged on the workbench 1 On the table, workers can control the start or stop of motor 34, induced draft fan 16 and air compressor 26 through controller 39, which has the characteristics of high degree of automation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com